Section 10155 Toilet Compartments Part 1

-

Upload

jacksondcpl -

Category

Documents

-

view

680 -

download

0

description

Transcript of Section 10155 Toilet Compartments Part 1

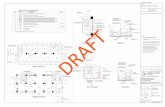

Mt. Pleasant Library 10155-1 100% Printing: 20 March 2009 CORE Group, P.C. TOILET COMPARTMENTS

SECTION 10155

PART 1 - GENERAL

TOILET COMPARTMENTS

1.1 RELATED DOCUMENTS

A. Drawings and general provisions of the Contract, including General and Supplementary Conditions and Division 1 Specification Sections, apply to this Section.

1.2 SUMMARY

A. Section Includes:

1. Ceiling-hung stainless steel toilet compartments.

1.3 SUBMITTALS

A. Product Data: For each type of product indicated.

B. LEED Submittals:

1. Product Data for Credit MR 4.1 and Credit MR 4.2: For products having recycled content, documentation indicating percentages by weight of postconsumer and preconsumer recycled content. Include statement indicating costs for each product having recycled content.

2. Product Data for Credit EQ 4.4: For particleboard, documentation indicating that product contains no urea formaldehyde.

C. Shop Drawings: For toilet compartments. Include plans, elevations, sections, details, and attachments to other work.

D. Samples for each exposed product and for each color and texture specified.

E. Product certificates.

F. Maintenance data.

1.4 QUALITY ASSURANCE

A. Surface-Burning Characteristics: As determined by testing identical products according to ASTM E 84, or another standard acceptable to authorities having jurisdiction, by a qualified testing agency. Identify products with appropriate markings of applicable testing agency.

1. Flame-Spread Index: 25 or less.

Mt. Pleasant Library 10155-2 100% Printing: 20 March 2009 CORE Group, P.C. TOILET COMPARTMENTS

2. Smoke-Developed Index: 450 or less.

B. Regulatory Requirements: Comply with applicable provisions in the U.S. Architectural & Transportation Barriers Compliance Board's "Americans with Disabilities Act (ADA) and Architectural Barriers Act (ABA) Accessibility Guidelines for Buildings and Facilities" and ICC/ANSI A117.1 for toilet compartments designated as accessible.

PART 2 - PRODUCTS

2.1 MATERIALS

A. Steel Sheet: ASTM A 240/A 240M, Type 304 stretcher-level quality steel sheet for exposed applications; mill phosphatized and selected for smoothness.

B. Zamac: ASTM B 86, commercial zinc-alloy die castings.

2.2 STEEL UNITS

A. Basis-of-Design Product: Subject to compliance with DCPL standards requirements, provide toilet compartments manufactured by Global Partitions (Global Steel Products Corp.) or approved equal product as determined by Architect from one of the following:

1. Accurate Partitions Corporation. 2. All American Metal Corp. 3. American Sanitary Partition Corporation. 4. Ampco, Inc. 5. Bradley Corporation; Mills Partitions. 6. Flush Metal Partition Corp. 7. General Partitions Mfg. Corp. 8. Hadrian Manufacturing Inc. 9. Knickerbocker Partition Corporation. 10. Metpar Corp. 11. Rockville Partitions Incorporated. 12. Sanymetal; a Crane Plumbing company. 13. Shanahan's Limited.

B. Toilet-Enclosure Style: Ceiling-hung.

C. Door and Panel Construction: Seamless, one-inch- (25.4-mm-) thick, 22-gauge (0.0299-inch; 0.7595-mm) metal facing sheets pressure bonded with non-toxic adhesive to core material; with continuous, interlocking molding strip or lapped-and-formed edge closures; corners secured by welding or clips and exposed welds ground smooth. Exposed surfaces shall be free of pitting, seam marks, roller marks, stains, discolorations, telegraphing of core material, or other imperfections.

1. Core Material: Manufacturer's standard sound-deadening, full-face honeycomb of resin-impregnated kraft paper in thickness required to provide finished thickness of 1 inch (25 mm).

Mt. Pleasant Library 10155-3 100% Printing: 20 March 2009 CORE Group, P.C. TOILET COMPARTMENTS

2. Grab-Bar Reinforcement: Provide concealed internal reinforcement for grab bars mounted on units.

3. Tapping Reinforcement: Provide concealed reinforcement for tapping (threading) at locations where machine screws are used for attaching items to units.

D. Pilaster Construction: Seamless, 1-1/4-inch- (32-mm-) thick, 18-gauge (0.0478-inch; 1.2141-mm) metal facing sheets pressure bonded with non-toxic adhesive to core material; with continuous, interlocking molding strip or lapped-and-formed edge closures; corners secured by welding or clips and exposed welds ground smooth. Exposed surfaces shall be free of pitting, seam marks, roller marks, stains, discolorations, telegraphing of core material, or other imperfections.

1. Core Material: Manufacturer's standard sound-deadening, full-face honeycomb of resin-impregnated kraft paper in thickness required to provide finished thickness of 1-1/4 inches (32 mm)

2. Bottom of each pilaster shall be sealed with a 22-gauge (0.0299-inch; 0.7595-mm) stainless steel interlocking molding.

.

3. An 11-gauge (0.1196-inch; 3.0378-mm) slotted stirrup bracket shall be integrally welded in to top of each pilaster.

4. Two 3/8-inch- (9.5-mm-) diameter by 6-inch (152-mm) long cadmium-plated studs shall anchor the mounting bracket to overhead structure.

5. A show shall conceal each ceiling mounting, having an internal cross-section conforming to the pilaster and formed of Type 304 stainless steel, directional satin finish.

2.3 ACCESSORIES

A. Hardware and Accessories: Manufacturer's standard design, heavy-duty operating hardware and accessories.

1. Material for All Exposed Door Hardware: Chromium-plated die cast Zamac. 2. Hinges: Manufacturer's standard continuous, spring-loaded type.

a. Upper door hinge shall be recessed and interlocked in door with a nylon pin within the plane of the door.

b. Lower door hinge shall be recessed in door with mating box and pintle nylon cams. 1) Cams shall be adjustable to allow door to rest at any position within a 270-

degree range. 3. Latch and Keeper: Manufacturer's standard concealed latch unit designed for emergency

access and with combination rubber-faced door strike and keeper. Provide units that comply with regulatory requirements for accessibility at compartments designated as accessible.

4. Coat Hook: Manufacturer's standard combination hook and rubber-tipped bumper, sized to prevent in-swinging door from hitting compartment-mounted accessories.

5. Door Bumper: Manufacturer's standard rubber-tipped bumper at out-swinging doors. 6. Door Pull: Manufacturer's standard unit at out-swinging doors that complies with

regulatory requirements for accessibility. Provide units on both sides of doors at compartments designated as accessible.

Mt. Pleasant Library 10155-4 100% Printing: 20 March 2009 CORE Group, P.C. TOILET COMPARTMENTS

B. Anchorages and Fasteners: Manufacturer's standard exposed fasteners of chrome-plated steel, finished to match the items they are securing, with theft-resistant-type heads. Provide sex-type bolts for through-bolt applications. For concealed anchors, use stainless steel.

2.4 FABRICATION

A. Door Size and Swings: Unless otherwise indicated, provide 24-inch- (610-mm-) wide, in-swinging doors for standard toilet compartments and 36-inch- (914-mm-) wide, out-swinging doors with a minimum 32-inch- (813-mm-)

PART 3 - EXECUTION

wide, clear opening for compartments designated as accessible.

3.1 INSTALLATION

A. General: Comply with manufacturer's written installation instructions. Install units rigid, straight, level, and plumb. Secure units in position with manufacturer's recommended anchoring devices.

B. Clearances: Maximum 1/2 inch (13 mm) between pilasters and panels; 1 inch (25 mm)

C. Stirrup Brackets: Secure panels to walls and to pilasters with no fewer than three brackets attached at midpoint and near top and bottom of panel. Locate wall brackets so holes for wall anchors occur in masonry or tile joints. Align brackets at pilasters with brackets at walls.

between panels and walls.

3.2 ADJUSTING

A. Hardware Adjustment: Adjust and lubricate hardware according to hardware manufacturer's written instructions for proper operation. Set hinges on in-swinging doors to hold doors open approximately 30 degrees from closed position when unlatched. Set hinges on out-swinging doors to return doors to fully closed position.

END OF SECTION 10155

Mt. Pleasant Library 10200-1 16 January 2009 CORE Group, P.C. LOUVERS

SECTION 10200

PART 1 - GENERAL

LOUVERS

1.1 RELATED DOCUMENTS

A. Drawings and general provisions of the Contract, including General and Supplementary Conditions and Division 1 Specification Sections, apply to this Section.

1.2 SUMMARY

A. Section Includes:

1. Fixed, extruded-aluminum louvers.

B. See Division 8 Section "Steel Doors and Frames" for louvers in hollow-metal doors.

C. See Division 8 Section "Stile and Rail Wood Doors" for louvers in flush wood doors.

D. See Division 15 Sections for louvers that are a part of mechanical equipment.

1.3 PERFORMANCE REQUIREMENTS

A. Delegated Design: Design louvers, including comprehensive engineering analysis by a qualified professional engineer, using structural performance requirements and design criteria indicated.

B. Structural Performance: Louvers shall withstand the effects of gravity loads and the following loads and stresses within limits and under conditions indicated without permanent deformation of louver components, noise or metal fatigue caused by louver blade rattle or flutter, or permanent damage to fasteners and anchors.

1. Wind Loads: Determine loads based on pressures as indicated on Drawings.

C. Louver Performance Ratings: Provide louvers complying with requirements specified, as demonstrated by testing manufacturer's stock units identical to those provided, except for length and width according to AMCA 500-L.

1.4 SUBMITTALS

A. Product Data: For each type of product indicated.

1. For louvers specified to bear AMCA seal, include printed catalog pages showing specified models with appropriate AMCA Certified Ratings Seals.

Mt. Pleasant Library 10200-2 16 January 2009 CORE Group, P.C. LOUVERS

B. Shop Drawings: For louvers and accessories. Include plans, elevations, sections, details, and attachments to other work. Show frame profiles and blade profiles, angles, and spacing.

C. Samples: For each type of metal finish required.

D. Product Test Reports: Based on tests performed according to AMCA 500-L.

PART 2 - PRODUCTS

2.1 MATERIALS

A. Aluminum Extrusions: ASTM B 221 (ASTM B 221M)

B. Aluminum Sheet:

, Alloy 6063-T5, T-52, or T6.

ASTM B 209 (ASTM B 209M)

C. Fasteners: Use types and sizes to suit unit installation conditions.

, Alloy 3003 or 5005 with temper as required for forming, or as otherwise recommended by metal producer for required finish.

1. For fastening aluminum, use aluminum or 300 series stainless-steel fasteners. 2. For color-finished louvers, use fasteners with heads that match color of louvers.

D. Bituminous Paint: Cold-applied asphalt emulsion complying with ASTM D 1187.

2.2 FABRICATION, GENERAL

A. Fabricate frames, including integral sills, to fit in openings of sizes indicated, with allowances made for fabrication and installation tolerances, adjoining material tolerances, and perimeter sealant joints.

B. Join frame members to each other and to fixed louver blades with fillet welds concealed from view unless otherwise indicated or size of louver assembly makes bolted connections between frame members necessary.

2.3 FIXED, EXTRUDED-ALUMINUM LOUVERS

A. Horizontal Storm-Resistant Louver: 1. Manufacturers: Subject to compliance with requirements, provide products by one of the

following:

a. Air Balance Inc.; a Mestek company. b. Air Flow Company, Inc. c. Airolite Company, LLC (The). d. All-Lite Architectural Products. e. American Warming and Ventilating, Inc.; a Mestek company. f. Arrow United Industries; a division of Mestek, Inc. g. Construction Specialties, Inc. h. Greenheck Fan Corporation.

Mt. Pleasant Library 10200-3 16 January 2009 CORE Group, P.C. LOUVERS

i. Industrial Louvers, Inc. j. NCA Manufacturing, Inc. k. Nystrom Building Products. l. Reliable Products, Inc. m. Ruskin Company; Tomkins PLC. n. United Enertech Corp.

2. Louver Depth: 5 inches3. Frame and Blade Nominal Thickness: Not less than

(125 mm) unless otherwise indicated. 0.060 inch (1.52 mm) for blades and

0.080 inch (2.03 mm)4. Louver Performance Ratings:

for frames.

a. Free Area: Not less than 6.0 sq. ft. (0.56 sq. m) for 48-inch- (1220-mm-) wide by 48-inch- (1220-mm-)

b. Air Performance: Not more than high louver.

0.10-inch wg (25-Pa) static pressure drop at 700-fpm (3.6-m/s)

c. Wind-Driven Rain Performance: Not less than 95 percent effectiveness when subjected to a rainfall rate of

free-area exhaust velocity.

3 inches (75 mm) per hour and a wind speed of 29 mph (13 m/s) at a core-area intake velocity of 400 fpm (2.0 m/s)

5. AMCA Seal: Mark units with AMCA Certified Ratings Seal.

.

B. Horizontal, Drainable-Blade Louver: 1. Manufacturers: Subject to compliance with requirements, provide products by one of the

following:

a. Air Balance Inc.; a Mestek company. b. Air Flow Company, Inc. c. Airolite Company, LLC (The). d. All-Lite Architectural Products. e. American Warming and Ventilating, Inc.; a Mestek company. f. Arrow United Industries; a division of Mestek, Inc. g. Carnes Company, Inc. h. Cesco Products; a division of Mestek, Inc. i. Construction Specialties, Inc. j. Dowco Products Group; Safe-Air of Illinois, Inc. k. Greenheck Fan Corporation. l. Industrial Louvers, Inc. m. Louvers & Dampers, Inc.; a division of Mestek, Inc. n. Metal Form Manufacturing Inc. o. NCA Manufacturing, Inc. p. Nystrom Building Products. q. Reliable Products, Inc. r. Ruskin Company; Tomkins PLC. s. United Enertech Corp. t. Vent Products Company, Inc.

2. Louver Depth: 4 inches3. Frame and Blade Nominal Thickness: Not less than

(100 mm) unless otherwise indicated. 0.060 inch (1.52 mm) for blades and

0.080 inch (2.03 mm) for frames.

Mt. Pleasant Library 10200-4 16 January 2009 CORE Group, P.C. LOUVERS

4. Louver Performance Ratings:

a. Free Area: Not less than 7.5 sq. ft. (0.70 sq. m) for 48-inch- (1220-mm-) wide by 48-inch- (1220-mm-)

b. Point of Beginning Water Penetration: Not less than high louver.

1000 fpm (5.1 m/s)c. Air Performance: Not more than

. 0.10-inch wg (25-Pa) static pressure drop at 750-

fpm (3.8-m/s)

5. AMCA Seal: Mark units with AMCA Certified Ratings Seal.

free-area exhaust velocity.

C. Horizontal, Nondrainable-Blade Louver: 1. Manufacturers: Subject to compliance with requirements, provide products by one of the

following:

a. Air Balance Inc.; a Mestek company. b. Air Flow Company, Inc. c. Airolite Company, LLC (The). d. All-Lite Architectural Products. e. American Warming and Ventilating, Inc.; a Mestek company. f. Arrow United Industries; a division of Mestek, Inc. g. Carnes Company, Inc. h. Cesco Products; a division of Mestek, Inc. i. Construction Specialties, Inc. j. Dowco Products Group; Safe-Air of Illinois, Inc. k. Greenheck Fan Corporation. l. Louvers & Dampers, Inc.; a division of Mestek, Inc. m. Metal Form Manufacturing Inc. n. NCA Manufacturing, Inc. o. Nystrom Building Products. p. Reliable Products, Inc. q. Ruskin Company; Tomkins PLC. r. United Enertech Corp. s. Vent Products Company, Inc.

2. Louver Depth: 4 inches3. Blade Profile: Plain blade without center baffle.

(100 mm) unless otherwise indicated.

4. Frame and Blade Nominal Thickness: Not less than 0.080 inch (2.03 mm)5. Louver Performance Ratings:

.

a. Free Area: Not less than 8.0 sq. ft. (0.74 sq. m) for 48-inch- (1220-mm-) wide by 48-inch- (1220-mm-)

b. Point of Beginning Water Penetration: Not less than high louver.

800 fpm (4.1 m/s)c. Air Performance: Not more than

. 0.10-inch wg (25-Pa) static pressure drop at 700-

fpm (3.6-m/s)

2.4 LOUVER SCREENS

free-area exhaust velocity.

A. General: Provide screen at each exterior louver.

Mt. Pleasant Library 10200-5 16 January 2009 CORE Group, P.C. LOUVERS

B. Louver Screen Frames: Same kind and form of metal as indicated for louver to which screens are attached.

C. Louver Screening:

1. Bird Screening: Aluminum, 1/2-inch- (13-mm-) square mesh, 0.063-inch (1.60-mm)

2.5 ALUMINUM FINISHES

wire.

A. Clear Anodic Finish: AAMA 611, AA-M12C22A41, Class I, 0.018 mm or thicker.

PART 3 - EXECUTION

3.1 INSTALLATION

A. Locate and place louvers and vents level, plumb, and at indicated alignment with adjacent work.

B. Use concealed anchorages where possible. Provide brass or lead washers fitted to screws where required to protect metal surfaces and to make a weathertight connection.

C. Provide perimeter reveals and openings of uniform width for sealants and joint fillers, as indicated.

D. Repair damaged finishes so no evidence remains of corrective work. Return items that cannot be refinished in the field to the factory and refinish entire unit or provide new units.

E. Protect galvanized and nonferrous-metal surfaces that will be in contact with concrete, masonry, or dissimilar metals from corrosion and galvanic action by applying a heavy coating of bituminous paint.

END OF SECTION 10200

Mt. Pleasant Library 10265-1 16 January 2009 CORE Group, P.C. IMPACT-RESISTANT WALL PROTECTION

SECTION 10265

PART 1 - GENERAL

IMPACT-RESISTANT WALL PROTECTION

1.1 RELATED DOCUMENTS

A. Drawings and general provisions of the Contract, including General and Supplementary Conditions and Division 1 Specification Sections, apply to this Section.

1.2 SUMMARY

A. Section Includes: 1. Corner guards.

1.3 SUBMITTALS

A. Product Data: For each type of product indicated.

B. LEED Submittals:

1. Product Data for Credit EQ 4.1: For adhesives, including printed statement of VOC content.

C. Shop Drawings: For each impact-resistant wall protection unit. Include sections, details, and attachments to other work.

1. For installed products indicated to comply with design loads, include structural analysis data signed and sealed by the qualified professional engineer responsible for their preparation.

D. Samples: For each exposed product and for each color and texture specified, 12 inches (300 mm)

E. Material certificates.

long.

F. Material test reports.

G. Maintenance data.

H. Warranty: Sample of special warranty.

Mt. Pleasant Library 10265-2 16 January 2009 CORE Group, P.C. IMPACT-RESISTANT WALL PROTECTION

1.4 QUALITY ASSURANCE

A. Installer Qualifications: An employer of workers trained and approved by manufacturer.

B. Surface-Burning Characteristics: As determined by testing identical products per ASTM E 84, NFPA 255, or UL 723 by UL or another qualified testing agency.

C. Regulatory Requirements: Comply with applicable provisions in the U.S. Architectural & Transportation Barriers Compliance Board's ADA-ABA Accessibility Guidelines and ICC/ANSI A117.1.

D. Preinstallation Conference: Conduct conference at Project site.

1.5 WARRANTY

A. Special Warranty: Manufacturer's standard form in which manufacturer agrees to repair or replace components of impact-resistant wall protection units that fail in materials or workmanship within specified warranty period.

1. Failures include, but are not limited to, the following:

a. Structural failures.

2. Warranty Period: Five years from date of Substantial Completion.

PART 2 - PRODUCTS

2.1 MATERIALS

A. Stainless Steel Sheet: ASTM A 240/A 240M.

2.2 CORNER GUARDS

A. Surface-Mounted, Metal Corner Guards: Fabricated from one-piece, formed or extruded metal with formed edges; with 90- or 135-degree turn to match wall condition. 1. Basis-of-Design Product: Subject to compliance with requirements, provide corner guard

Model B-633 manufactured by Bobrick Washroom Equipment, Inc. or approved equal product as determined by architect from one of the following:

a. American Floor Products Co., Inc. b. Arden Architectural Specialties, Inc. c. Balco, Inc. d. Boston Retail Products. e. Construction Specialties, Inc. f. IPC Door and Wall Protection Systems; Division of InPro Corporation. g. Korogard Wall Protection Systems; a division of RJF International Corporation. h. Pawling Corporation.

Mt. Pleasant Library 10265-3 16 January 2009 CORE Group, P.C. IMPACT-RESISTANT WALL PROTECTION

i. Tepromark International, Inc. j. WallGuard.com.

2. Material: Stainless steel, Type 304; 18-8 S.

a. Thickness: 18-gauge (1.2 mm). b. Finish: Directional satin, No. 4. c. Exposed Edges and Corners: Rounded.

3. Corner Radius: 1/8 inch4. Mounting: Pressure-sensitive adhesive furnished by manufacturer.

(3 mm).

PART 3 - EXECUTION

3.1 INSTALLATION

A. General: Install impact-resistant wall protection units level, plumb, and true to line without distortions. Do not use materials with chips, cracks, voids, stains, or other defects that might be visible in the finished Work.

1. Install corner guards in locations and at mounting heights indicated on Drawings.

B. Remove excess adhesive using methods and materials recommended in writing by manufacturer.

END OF SECTION 10265

Mt. Pleasant Library 10801-1 100% Printing: 20 March 2009 CORE Group, P.C. TOILET AND BATH ACCESSORIES

SECTION 10801

PART 1 - GENERAL

TOILET AND BATH ACCESSORIES

1.1 RELATED DOCUMENTS

A. Drawings and general provisions of the Contract, including General and Supplementary Conditions and Division 1 Specification Sections, apply to this Section.

1.2 SUMMARY

A. Section Includes:

1. Public-use washroom accessories. 2. Warm-air dryers. 3. Custodial accessories.

1.3 SUBMITTALS

A. Product Data: For each type of product indicated.

B. Product Schedule: Indicating types, quantities, sizes, and installation locations by room of each accessory required.

1. Identify locations using room designations indicated. 2. Identify products using designations indicated.

C. Maintenance data.

D. Warranty: Sample of special warranty.

1.4 QUALITY ASSURANCE

A. Electrical Components, Devices, and Accessories: Listed and labeled as defined in NFPA 70, by a qualified testing agency, and marked for intended location and application.

1.5 WARRANTY

A. Special Mirror Warranty: Manufacturer's standard form in which manufacturer agrees to replace mirrors that develop visible silver spoilage defects and that fail in materials or workmanship within specified warranty period.

1. Warranty Period: 15 years from date of Substantial Completion.

Mt. Pleasant Library 10801-2 100% Printing: 20 March 2009 CORE Group, P.C. TOILET AND BATH ACCESSORIES

PART 2 - PRODUCTS

2.1 PUBLIC-USE WASHROOM ACCESSORIES

A. Manufacturers: Subject to compliance with requirements, provide Basis-of-Design products indicated or approved equal products as determined by Architect from one of the following:

1. A & J Washroom Accessories, Inc. 2. American Specialties, Inc. 3. Bobrick Washroom Equipment, Inc. (Bobrick). 4. Bradley Corporation. 5. GAMCO Specialty Accessories; a division of Bobrick Washroom Equipment, Inc. 6. Tubular Specialties Manufacturing, Inc.

B. Liquid-Soap Dispenser: 1. Basis-of-Design Product: Subject to compliance with requirements, provide soap

dispenser with soap vessel Model No. B-306 manufactured by Bobrick. 2. Description: Designed for dispensing soap in liquid or lotion form. 3. Materials:

a. Mounting Box and Door: 18-8 S, Type 304, 18-gauge (0.0478-inch; 1.2141-mm) stainless steel with directional satin finish of all-welded construction.

b. Soap Vessel: Molded plastic, large opening. c. Soap Valve: Valve mechanism with O-ring seals.

1) Spout and Inner Spring: Stainless steel. 2) Chrome-plated brass housing.

d. Body and Shank: ABS. e. Container: Polyethylene.

4. Mounting: Recessed mounting box. 5. Capacity: 45 fl. oz. (1.3 L)6. Lockset: Tumbler type.

.

7. Refill Indicator: Window type.

C. Baby Changing Station: 1. Basis-of-Design Product: Subject to compliance with DCPL’s standard requirements,

provide baby changing station Model No. 962 manufactured by Bradley Corporation. 2. Materials: Polyethylene body with Type 304 stainless steel exterior. 3. Mounting: Recessed. 4. Molded Dual Liner Dispenser: 50 liners per dispenser.

D. Grab Bar: 1. Basis-of-Design Product: Subject to compliance with DCPL’s standard requirements,

provide grab bar with snap flange Model No. B-5806 manufactured by Bobrick. 2. Materials:

a. Grab Bar: 18-8 S, Type 304, 18-gauge (0.0478-inch; 1.2141-mm) stainless steel with directional satin finish.

b. Concealed Mounting Flanges: 18-8 S, Type 304, 1/8-inch- (3-mm-) thick stainless steel plate.

Mt. Pleasant Library 10801-3 100% Printing: 20 March 2009 CORE Group, P.C. TOILET AND BATH ACCESSORIES

1) End Flanges: 2 inch by 3-1/8 inch (50 mm by 80 mm). 2) Intermediate Flanges: 2-5/8 inch by 3-1/8 inch (65 mm by 80 mm) wide by

3-1/8-inch (80-mm) diameter. c. Snap Flange Covers: 18-8 S, Type 304, 22-gauge (0.0299-inch; 0.7595-mm)

stainless steel with directional satin finish. 1) 3-1/4-inch (85-mm) diameter by 5/8-inch (16-mm) depth.

3. Outside Diameter: 1-1/4 inches4. Clearance Between Grab Bar and Wall: 1-1/2 inches (38 mm).

(32 mm).

5. Configuration and Length: As indicated on Drawings.

E. Seat-Cover Dispenser: 1. Basis-of-Design Product: Subject to compliance with requirements, provide seat-cover

dispenser Model No. B-221 manufactured by Bobrick. 2. Materials: 18-8 S, Type 304, 22-gauge (0.0299-inch; 0.7595-mm) stainless steel with

directional satin finish. 3. Construction: All welded with beveled opening. 4. Mounting: Surface mounted. 5. Minimum Capacity: 250 seat covers, filled through concealed opening in bottom.

F. Toilet Tissue (Roll) Dispenser: 1. Basis-of-Design Product: Subject to compliance with requirements, provide twin jumbo-

roll toilet tissue dispenser Model No. B-2892 manufactured by Bobrick. 2. Materials:

a. Cabinet: 18-8 S, Type 304, 20-gauge (0.0359-inch; 0.9119-mm) stainless steel with directional satin finish. 1) Lockset: Tumbler type.

b. Door: 18-8 S, Type 304, 18-gauge (0.0478-inch; 1.2141-mm) stainless steel with directional satin finish of drawn, one-piece, seamless construction.

c. Dispensing Mechanism: High-impact ABS. 3. Mounting: Surface mounted. 4. Operation: Sliding access panel exposing one roll at a time. 5. Capacity: Two rolls up to 10-inch- (254-mm-) diameter with 3-inch- (75-mm-) diameter

core.

G. Sanitary Napkin Disposal: 1. Basis-of-Design Product: Subject to compliance with requirements, provide sanitary

napkin disposal Model No. B-254 manufactured by Bobrick. 2. Materials:

a. Cabinet: All-welded 18-8 S, Type 304, heavy-gauge stainless steel with directional satin finish.

b. Door: 18-8 S, Type 304, 22-gauge (0.0299-inch; 0.7595-mm) stainless steel with directional satin finish. 1) Secured to cabinet with full-length stainless steel piano hinge. 2) Lockset: Tumbler type.

c. Disposal Panel: 18-8 S, Type 304, 22-gauge (0.0299-inch; 0.7595-mm) stainless steel with directional satin finish. 1) Bottom edge hemmed.

Mt. Pleasant Library 10801-4 100% Printing: 20 March 2009 CORE Group, P.C. TOILET AND BATH ACCESSORIES

2) Secured to door with spring-loaded full-length stainless steel piano hinge. d. Waste Receptacle: Leakproof, rigid-molded polyethylene.

1) Capacity: 1.2 gallons (4.6 L). 3. Mounting: Surface mounted. 4. Operation: Self-closing panel covers disposal opening.

H. Paper Towel (Roll) Dispenser: 1. Basis-of-Design Product: Subject to compliance with requirements, provide paper towel

dispenser Model No. 2490 manufactured by Bradley Corporation. 2. Materials:

a. Body: Heavy-gauge steel, baked enamel finish. b. Cover: Navy translucent high-impact plastic.

3. Mounting: Surface mounted. 4. Operation: Sensor-operated towels dispensing mechanism.

a. Power: Four D-size alkaline batteries. b. Automatic transfer system with 2-3/4-inch- (70-mm-) diameter stub roll capacity

5. Lockset: Key-activated spring lock.

I. Waste Receptacle: 1. Basis-of-Design Product: Subject to compliance with requirements, provide waste

receptacle Model No. B-364 manufactured by Bobrick. 2. Materials:

a. Cabinet: All-welded 18-8 S, Type 304, heavy-gauge stainless steel with directional satin finish.

b. Flange: 18-8 S, Type 304, 22-gauge (0.0299-inch; 0.7595-mm) stainless steel with directional satin finish. 1) Construction: Drawn and beveled, one-piece, seamless.

c. Waste Receptacle: 18-8 S, Type 304, 22-gauge (0.0299-inch; 0.7595-mm) stainless steel with directional satin finish. 1) Front and side edges of bottom and all top edges hemmed.

3. Mounting: Recessed 4. Minimum Capacity: 12 gallons (45.4 L)5. Lockset: Tumbler type.

.

J. Utility Shelf: 1. Materials:

a. Shelf: 18-8 S, Type 304, 18-gauge (0.0478-inch; 1.2141-mm) stainless steel with directional satin finish.

b. Brackets: 18-8 S, Type 304, 16-gauge (0.0598-inch; 1.5189-mm) stainless steel with directional satin finish.

2. Construction: Shelf shall be hollow pan with one-inch (25-mm) on front and sides and raised back splash fabricated from one piece and fully de-burred.

3. Size: As indicated on Drawings.

K. Folding Utility Shelf: 1. Basis-of-Design Product: Subject to compliance with requirements, provide folding

utility shelf Model No. B-287 manufactured by Bobrick.

Mt. Pleasant Library 10801-5 100% Printing: 20 March 2009 CORE Group, P.C. TOILET AND BATH ACCESSORIES

2. Materials: a. Shelf and Bracket: 18-8 S, Type 304, 18-gauge (0.0478-inch; 1.2141-mm)

stainless steel with directional satin finish of all welded construction. 3. Equipped with heavy-duty internal spring.

L. Mirror Unit: 1. Basis-of-Design Product: Subject to compliance with requirements, provide Inter-Lock

framed mirror Model No. 0600 manufactured by American Specialties, Inc. 2. Materials:

a. Frame: 18-8 S, Type 304, 18-gauge (0.0478-inch; 1.2141-mm) stainless steel with directional satin finish. 1) Unitized, all-welded. 2) Corners mitered, welded and polished. 3) Edges and corners fully de-burred.

b. Back: Full-size, one-piece 20 gauge (0.0359-inch; 0.9119-mm) corrosion protected steel.

c. Glass: No. 1 Quality, 1/4-inch- (6-mm-) thick plate/float glass, silver coated and hermetically sealed with a uniform coating of electrolytic copper plating.

d. Filler: Expanded polyethylene microcell foam sheet, shock absorbing, abrasion- and water-resistant. 1) Thickness: 1/8 inch (3 mm) total layer thickness.

e. Hanger Bracket: 18 gauge (0.0478-inch; 1.2141-mm) corrosion protected steel “H” bracket.

3. Size: As indicated on Drawings.

2.2 WARM-AIR DRYERS

A. Basis-of-Design Product: Subject to compliance with requirements, provide electronic hand dryer Model No. EHD-500 Series manufactured by Sloan Valve Company or approved equal product as determined by Architect from one of the following:

1. A & J Washroom Accessories, Inc. 2. American Dryer, Inc. 3. American Specialties, Inc. 4. Bobrick Washroom Equipment, Inc. 5. Bradley Corporation. 6. Excel Dryer Corporation. 7. GAMCO Specialty Accessories; a division of Bobrick Washroom Equipment, Inc. 8. Tubular Specialties Manufacturing, Inc. 9. World Dryer Corporation.

B. Description: XLerator Model Ultra-Fast, Sensor Activated.

C. Material: One-piece, heavy duty, rib-reinforced, die cast zinc alloy.

D. Finish: Bright chrome plate or electrostatically applied white epoxy.

Mt. Pleasant Library 10801-6 100% Printing: 20 March 2009 CORE Group, P.C. TOILET AND BATH ACCESSORIES

E. Operation: 1. Series commutated, through-flow discharge, vacuum-type motor/blower combination. 2. Infrared optical sensor with 35-second lockout. 3. Air Velocity: 16,000 linear feet (4,877 m) per minute.

2.3 CUSTODIAL ACCESSORIES

A. Manufacturers: Subject to compliance with requirements, provide products by one of the following:

1. A & J Washroom Accessories, Inc. 2. American Specialties, Inc. 3. Bobrick Washroom Equipment, Inc. 4. Bradley Corporation. 5. GAMCO Specialty Accessories; a division of Bobrick Washroom Equipment, Inc. 6. Tubular Specialties Manufacturing, Inc.

B. Utility Shelf: 1. Description: With exposed edges turned down not less than 1/2 inch (13 mm)

2. Size:

and supported by two triangular brackets welded to shelf underside.

16 inches (406 mm) long by 6 inches (152 mm)3. Material and Finish: Not less than nominal

deep. 0.05-inch- (1.3-mm-)

C. Mop and Broom Holder

thick stainless steel, No. 4 finish (satin).

1. Description: Unit with shelf, hooks, holders, and rod suspended beneath shelf. 2. Length: 36 inches3. Hooks: Three.

(914 mm).

4. Mop/Broom Holders: Four, spring-loaded, rubber hat, cam type. 5. Material and Finish: Stainless steel, No. 4 finish (satin).

a. Shelf: Not less than nominal 0.05-inch- (1.3-mm-)b. Rod: Approximately

thick stainless steel. 1/4-inch- (6-mm-)

D. Paper Towel (Folded) Dispenser:

diameter stainless steel.

1. Mounting: Surface mounted. 2. Minimum Capacity: 400 C-fold or 525 multifold towels. 3. Material and Finish: Stainless steel, No. 4 finish (satin). 4. Lockset: Tumbler type. 5. Refill Indicators: Pierced slots at sides or front.

E. Liquid-Soap Dispenser: 1. Description: Designed for dispensing soap in liquid or lotion form. 2. Mounting: Deck mounted on lavatory. 3. Capacity: 20 fl. oz. (600 mL).

Mt. Pleasant Library 10801-7 100% Printing: 20 March 2009 CORE Group, P.C. TOILET AND BATH ACCESSORIES

4. Materials: a. Spout, Cover and Escutcheon: Bright-polished, 4-inch (100-mm). b. Body and Shank: ABS. c. Container: Polyethylene.

5. Lockset: Tumbler type. 6. Refill Indicator: Window type.

2.4 FABRICATION

A. Keys: Provide universal keys for internal access to accessories for servicing and resupplying. Provide minimum of six keys to Owner's representative.

PART 3 - EXECUTION

3.1 INSTALLATION

A. Install accessories according to manufacturers' written instructions, using fasteners appropriate to substrate indicated and recommended by unit manufacturer. Install units level, plumb, and firmly anchored in locations and at heights indicated.

B. Grab Bars: Install to withstand a downward load of at least 250 lbf (1112 N)

END OF SECTION 10801

, when tested according to ASTM F 446.