schwing stetter. 2003

-

Upload

anoop-koshy -

Category

Documents

-

view

221 -

download

13

Transcript of schwing stetter. 2003

A report on the Organization and the Industry based on the study conducted at Schwing Stetter India Pvt. Ltd., Chennai.

Prepared by, Anoop T koshy Manu R (Students: DC school of Management& Technology)

CHAPTER 1 INTRODUCTION

Indian Mining (earthmoving) and Construction Equipment Industry (ECE), is at a watershed in

its evolution and set to experience strong growth, spurred by the nation’s rapid economic

development. The industry spans a range of equipment for almost all construction/infrastructure

needs. It was sized about US$ 2.4- 2.6 billion for the year 2007 and has a growth of over 30%.

The exports growing at 30% is expected to be US$ 100-200 million by the end of 2010. The

sector is highly fragmented- top 6 of about 200 domestic manufacturers contributes 60% of

output. 71% of the sector comprises of public limited companies including PSU’s and 29%

private limited, or joint ventures including closely held private limited companies

.

With a wide production capacity base, India is perhaps the only developing country, which is

totally self- reliant in such highly sophisticated equipments. India has only a few, mainly

medium and large companies in the organized sector who manufacture these. The technology

barriers are high, especially with respect to mining equipment and therefore the role of SME’s is

restricted to manufacture of components and some sub-assemblies.

The key players in construction equipment industry in India are JCB India, Caterpillar, L&TK

with Komatsu, Telcon with Hitachi, Schwing Stetter, Action Construction Equipment Ltd.

(ACE), Escorts Construction Equipment Ltd.(ECEL), Bharat Earth Movers Ltd.(BEML) etc.

The ECE industry has a critical role to play in making India one of the world’s top five

economies by 2025. Construction equipment players have a unique opportunity to help realize

the potential of this sector and, in doing so, garner their share of the US$12-13 billion revenue

potential.

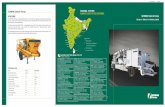

Schwing Stetter India Pvt. Ltd is a 100% subsidiary of M/s Schwing GmbH and belongs to

Schwing group of companies, market leaders in manufacturing equipments relating to

construction industry, more specifically for preparation, placement, and transportation of

concrete. It is a trend setter and a leader in supply of concrete construction equipment in India.

The group manufactures Concrete mixing equipments (batching plant),truck mixers, concrete

pumps, shotcreting machines used for concreting tunnels and recycling plants for conversion of

waste concretes. They are the only group in the world with the whole range of equipments

pertaining to the process of concrete making. The group has its operations in 12 countries and

has global presence in more than 145 countries.

OBJECTIVES OF STUDY

PRIMARY OBJECTIVE

The main objective of the study is to get an idea about the whole organization as such and to

understand the nature of the industry.

SECONDARY OBJECTIVES

To understand organization structure of the company and to get an idea about the various

departments and its functioning.

To know how the key business processes are being carried out in a manufacturing

industry.

To know about various policies and programs of the company.

Why Schwing Stetter?

SSIPL has been an important player in the Indian Construction Equipment Industry in

India with its major focus on the concrete manufacturing equipments. It has been a trend setter

ensuring best of their products and services to their customers- at all times. The company has

dedicated itself to a common quality policy wherein one of the focus points is building

confidence and value systems. Over the years, SSIPL has undergone many transformations in its

capacity, technology etc. under the leadership of Sri. A Sundaresan, with the stinted support of

qualified and dedicated staff.

SSI bagged the “BEST EUROPEAN COMPANY IN INDIA AWARD” in the SME Segment,

titled “IMPRESSA AWARD” conferred by the European Chamber of Commerce in the year

2004. Further, in the year 2006, the company bagged the ISO 9001-2000 Certificate .in the

recognition of the Quality Management Systems they follow in various spheres of activities of

the company. It has been able to achieve substantial growth over these years.

CHAPTERISATION

The report is prepared in five different chapters. The details of each chapter are as follows:

CHAPTER 1:- It gives an overall introduction about the study conducted. It includes a brief

account of the industry profile, company profile and the objectives of the study.

CHAPTER 2:- This chapter includes the industry profile. It is divided into two segments. The

first one deals with the global industry scenario and Indian industry picture in the second

segment. The major players in the industry are also discussed.

CHAPTER 3:- It covers the details about the company, the products and services offered

organization chart, operations and the departments.

CHAPTER 4:- This chapter gives the SWOT analysis of the company.

CHAPTER 5:- It is the conclusion part. It gives some details about the study, methodology,

findings and suggestions.

CHAPTER 2 INDUSTRY PROFILE

GLOBAL SCENARIO

Construction equipment is one of the key segments of any manufacturing sector. Construction

and mining equipment cover a variety of machinery such as hydraulic excavators, wheel loaders,

backhoe loaders, bull dozers, tippers, concrete mixers, wet mix plants, breakers, vibratory

compactors, scrapers, rope shovels etc. They perform a variety of functions like preparation of

ground, excavation, haulage of material, material handling, road construction etc. These

equipments are required for both construction and mining activity.

Global demand for construction machinery is projected to increase 5.3 percent annually through

2013. The developing Asia market, including India, China, Indonesia and South Korea, will see

the most rapid growth. Mixers, pavers and related equipments will be the fastest growing product

segment. In 2009 the world construction equipment demand was expected to reach $106 billion.

The growth will be supported by the expected continued expansion of emerging markets, with

high points including Eastern Europe, India and china. Within the triad (i.e., North America,

Japan, and Western Europe), North America is expected to maintain its lead in terms of both the

overall size of demand and growth potential, as the growth prospects for Japan and Western

Europe will be hampered by a combination of negative demographic and structural trends,

including aging populations and high level of regulation and taxation.

Future prospects remain very favorable in china, despite the recent weakening of the construction

equipment market due to tightening credit policies. Construction equipment demand will

continue to benefit from china’s aggressive industrialization efforts. While strong equipment

demand is usually foreshadowed by a combination of elements including favorable

demographics and burgeoning GDP performance. Eastern Europe is a somewhat different story,

as the region’s population is forecast to decline. However, based on the economic turnarounds

experienced by other countries joining the EU, expected infrastructure and economic

improvements should help to strongly increase construction equipment demand in the region.

Within the Triad, 2004 was a year of recovery and growth for North America, where expansion

in heavy construction equipment demand was driven by the explosive US real estate market.

Most competitors saw sales and operating profits improve after years of stagnation. Future

growth is expected to remain healthy in the region. Demand for construction equipment in Japan

will benefit from an improvement in fixed investment activity, but is expected to continue to be

undercut by soft public sector investment. Most West European markets are expected to post

only moderate construction equipment growth, with even strong-performing Spain experiencing

a tapering-off of demand. The strong euro-combined with an aging population, political turmoil

over the European Union itself, and other constraints- foreshadows moderate growth at best for

the region.

USA is the largest mining and construction equipment market in the world followed by China

(around 0.3 million units) and Europe (around 0.2 million units). The global Mining and

Construction Equipment (MCE) Industry has been on an upswing since 2003-04 and has grown

by over 15% annually until Q3, 2008-09. The growth was more pronounced in and was mainly

driven by the fast growing BRIC nations of China and India. The size of the MCE market in

emerging economies has also expanded significantly and now accounts for 50% of the global

market as against just 35% in 2004. The Indian market grew by over 30% annually during this

period but on a significantly lower base than in other major countries. The key growth drivers

were strong economic development, government and private investments in infrastructure, large

government projects like road building, high commodity prices (supporting mining activity), the

booming real estate industry and growing levels of mechanization.

The global MCE industry experienced a contraction in Q3 2008-09 as a result of reduced

construction activity, especially in the real estate segment; slowdown in mining activity and a

virtual standstill in equipment financing in the aftermath of the economic meltdown towards the

end of Q2, 2008-09. In 2008-09, the global MCE industry is estimated to have fallen by over

20%, mainly on account of a 38% fall in global demand for construction equipment while the

demand for mining equipment improved in little geographies. The fall in demand was led by

sharp declines in the key markets of Europe, Japan and North America. Barring certain markets

like china, the global CE industry continued to fall in the first nine months of 2009-10 as well,

although the magnitude of global decline slowed down to around 4% in Q3, 2009-10. The

mining industry on the other hand has shown stronger signs of recovery in Q3, 2009-10,

as commodity prices started inching upwards. In addition to china, where there has been a full

scale recovery of demand supported by fiscal stimulus and advancement in large-scale

infrastructure development, markets like Australia, Brazil, India, Indonesia, and Thailand have

shown signs of a more gradual recovery. Among the developed countries, the Japanese market

witnessed full usage of rental equipment in Q3, 2009-10. However, a lack of consumer

confidence in the prospects resulted in a weak demand for new equipment. Normally, full

usage of rental equipment is a precursor for fresh demand.

WORLD CONSTRUCTION EQUIPMENT DEMAND

(Billion dollars) Item 1999 2004 2009 World heavy construction

Equipment 70.7 81.4 105.9

North America 23.5 28.1 35.8

Western Europe 17.4 17.6 20.3

Asia /pacific 20.8 24.9 35.6

Other regions 9.0 10.8 14.2

(Source: study by The Freedonia Group, Inc.)

INDIAN SCENARIO

INTRODUCTION

The upswing in the Indian Economy has enhanced the demand for the construction and material

handling equipments. The demand for construction and material handling equipments is

correlated with the growth of other segments like Infrastructure Construction, Ports, Pipelines,

Roads, Steel, Power Projects, Mining, Building construction etc. Increase in foreign investment

(FDI/FII) and technology has led to a tremendous growth in requirement of mobile cranes and

construction equipments. The size of Indian Construction Industry is over US$25 billion and it

accounts for over 6.5% of GDP. With the GDP growth likely to increase going forward, the

demand for construction equipment will continue to grow with core sectors like construction,

cement, steel, chemicals, petroleum, mining etc.

India’s Construction Equipment Industry- Highlights

The industry spans a range of equipments for almost all construction/ infrastructure needs. It

sizes about US$ 25 billion, with a growth of over 30%. The exports are growing at 30%,

expected to be US$ 100-200 million by 2010. The sector is highly fragmented- top 6 of about

200 domestic manufacturers contributes 60% of output. Products and spare parts constitute the

bulk of the industry. Service segment is still nascent and presents good opportunity for growth.

Around 71 percent of the sector comprises of public limited companies including PSU’s and 29

percent private limited, or joint ventures including closely held private limited companies. The

unorganized sector contributes about 15% by value, though the majority of players belong here.

The key segments that constitute the construction equipment industry in India are:

Earth Moving Equipments

Material Handling Equipments

Construction Vehicles

Concrete equipment

Material Preparation

Tunneling & Drilling Equipment

Road Construction Equipment

And there are a range of products in each segment.

The industry has a wide product range:

EARTH MOVING EQUIPMENTS

CONCRETE EQUIPMENT

Backhoe Loaders Concrete BreakersExcavators Paver FinisherLoaders Concrete Batching PlantBulldozers Concrete PumpsWheeled loading Concrete MixersShovels Hot mix plantsWheel loadersMotor gradersMotor ScrappersDump trucksWheel dozersDraglines

MATERIAL HANDLING EQUIPMENT

MATERIAL PREPARATION

ROAD CONSTRUCTION EQUIPMENT

Telescopic Handlers Crushing Plant Compaction EquipCrawler Cranes Jaw Crushers Vibratory RollersMobile Cranes PaversTruck CranesForkliftsPick & Carry CranesSlew CranesTower CranesConveyors

CONSTRUCTION VEHICLES

TUNNELLING & DRILLING

Dumpers Rotary/DTH Drilling

Articulated Haulers Hammer Track Drill

Boring Equipment

Demolition Equipment

However, a few segments dominate the industry in size and volumes.

Construction Equipment Industry Structure

Birth of Indian Construction Equipment Industry

The Evolution of Indian Construction Equipment (CE) Industry can be broken up in a time frame

of five decade on bases of Industry trends, markets and products.

Year 1960- 70’s

Industry trend- domestic production began with setting up of BEML.

Market- government being the main producer and buyer

Products - dozers, dumpers, graders, scrapers, graders etc.

Year 1980’s

Industry trend- private sector entering the sector with likes of L&T, Telecom

Market- growth of market due to increase in mining/infrastructure activities

Products - hydraulic excavators, mining equipment etc.

Year 1990’s

Industry trend- joint venture with global player

Market- liberalization of economy with increase in construction activities

Products- pavers, loaders, backhoe etc

Year 2000’s

Industry trend- demand moving northward leading to capacity doubling

Market- infrastructure development gains momentum with investments pouring

Products- equipments of latest technology with increase load handling capacity

Current scenario & future

Industry trend- sectorial reforms and boost to infrastructure development

Market- increase in budgetary allocation, increase in international finance institution

funding for infrastructure.

Products- emerging as a manufacturing hub for designing and developing products for

global markets

Prior to the 1960’s domestic requirements of mining and construction equipment were entirely

met by imports.

Domestic production began in 1964 with the setting up of Bharat Earthmovers Ltd.(BEML), a

public sector unit of the Ministry of Defense, at Kolar in South India to manufacture dozers,

dumpers, graders, scrapers, etc. for defense requirements under license from Le Torneau

Westinghouse, USA and Komatsu, Japan. In the private sector, the Hindustan Motors’

Earthmoving Equipment Division was established in1969 at Tiruvallur, near Chennai with

technical collaboration from Terex, UK for manufacture of wheel loaders, dozers & dumpers.

This factory has since been taken over by Caterpillar for their Indian operations. The machines

manufactured by

Caterpillar in the Tiruvallur factory are marketed by TIL and GMMCO.

In 1974, L&T started manufacturing hydraulic excavators under license from Poclain, France. In

1980 and 1981, two more units, Telcon and Escorts JCB commenced manufacture of hydraulic

excavators (under license from Hitachi, Japan) and backhoe

Loaders (under license from JCB, UK) respectively. Escorts JCB has been taken over by JC

Bamford Excavators Ltd. U.K. in 2003 and is now called JCB India Ltd.

Most of the technology leaders like Case, Caterpillar, Hitachi, Ingersoll-Rand, JCB, John Deere,

Joy Mining Machinery, Komatsu, Lieberr, Poclain, Terex, Volvo are present in India as joint

venture companies, or have set up their manufacturing

facilities, or marketing companies.

The industry has made substantial investments in the recent past for setting up manufacturing

bases, despite small volumes and uneconomic scales of production compared to global standards.

Structure of the sector

71% of the sector comprises of public limited companies including PSU’s and 29% private

limited, or joint ventures including closely held private limited companies.

75% of the companies manufacturing in India were involved in the entire range of activities like

design and engineering, manufacturing, erection, servicing, and commissioning. There are only a

few companies who act as selling agents for international players. There are others who

manufacture and also import complete equipment or in SKD condition from their principals

abroad and market them.

Since each piece of the equipment in this product category has substantial value, a number of

companies have a turnover of over 100 crores and the larger ones have a turnover above Rs.1000

crores. The technology barriers have made the industry less fragmented in the mining machinery

sector whereas it is fragmented in the road construction equipment and the material-handling

segments. The international trend in the earthmoving and mining segment is one of

consolidation. This trend is also beginning to be seen in India. Some international companies are

looking at the prospects of enhancing their market presence based on higher investment in

mining and infrastructure and also using their Indian operations to meet demand in South and

South East Asia

Technology

The technology leaders in the construction equipment sector are: Komatsu, Caterpillar, Hitachi,

Terex, Volvo, Case, Ingersoll-Rand, HAMM, Bomag, John Deere, JCB, Poclain, Bitelli,

Kobelco, Hyundai and Daewoo. Except for the last 3, all the other companies are present in India

either as joint ventures, or have set up their own manufacturing facilities, or marketing

companies.

Exports

Exports currently constitute 2-3% of India’s construction equipment industry. Many factors

contributed to the low level of exports, including a lack of complete product range, the need to

avoid competition with JV partners and relatively low levels of technology & quality. But now,

exports are expected to grow rapidly. Increased outsourcing of manufacturing to low-cost

countries and improvements in technology and product range are expected to boost Infrastructure

Equipment (IE) exports from India.

New MNC entrants setting up base in India:

With MCE industry volumes of around 40,000-45,000 units per annum and an estimated

turnover of US$2.6-3.1 billion, the Indian market is relatively small as compared to the global

market that is estimated at over $75 billion. Nevertheless, many international OEMs have

indicated plans of setting up manufacturing facilities in India owing to its good growth prospects

and slack demand in the traditional developed markets. Some of the new entrants in the past 3-4

years were Japan’s excavator major Kobelco and ME company Komatsu; CE and farming

equipment major, John Deere (USA) in JV with Ashok Leyland Limited; excavator & CE

company Sany & Liugong (China) and MCE majors Hyundai and Doosan (Korea). Further,

existing participants like Caterpillar and excavator manufacturer Telco construction Equipment

Company Limited (Telcon) are either adding to their domestic capacities or increasing their

product portfolio. With the incremental capacities and new entrants, the industry is expected to

become more competitive and fragmented. However, growing mechanization and large

infrastructural projects proposed in the country indicate the potential to absorb these new

capacities. The entry of global MCE manufacturers has also facilitated product upgrades in the

growing Indian market.

Limited investments in Research & Development by MCE manufactures in India:

MCE companies with MNC parentage typically have depended on parental support for product

development and have made minimal investments on Research and Development (R&D) -

largely limited to homologation of the global products for Indian conditions. Further, the need

for technology investments specific to the Indian market is relatively low, as the requirements for

emission/noise control in Indian off-highway vehicles continues to be basic as compared to the

developed markets. The Indian MCE industry is currently BSII compliant, with the next

transition expected in April 2011. Developed nations like Japan and even emerging markets like

China have already moved to cutting edge technology of hybrids and EV (electric vehicles) to

increase productivity and comply with stringent emission/ noise control norms. With the

increasing presence of international companies/products in India, Indian market participants have

started to invest into R&D to match the international quality standards. Deeper understanding of

the market and the requirement for application/topography specific products has further raised

the need for increased R&D by participants in the Indian market.

Growth drivers for the industry

India has demonstrated strong growth across all sectors, with Indian economy moving in top gear

we are set to achieve exponential growth in coming years. The Indian Infrastructure development

has been on a high agenda for the Indian government over past few years as it is a key driver for

the overall economy development.

Infrastructure thrust

Attractive investment options emerge in the following areas

Earthmoving Equipment, Road Construction Equipment and Material Handling

Equipment appear the most attractive product segment, in terms of size and future growth

potential.

However, the Indian CE market also presents other areas that are nascent, but which have

high growth potential

Engineering Design Services

Equipment Rentals

Repair & Refurbishing of used equipment

Used and rental equipment markets are still in their nascent stages:

While there is good potential for used equipment in India, the market size of which is estimated

at about three times the primary market, India does not have an established common platform for

trading in used equipment.

Again, the current rental penetration in India at around 7-8% remains low as compared to the

global standards of 50-80%. An average of 30% of the equipments sold in Europe and over 60%

in the United Kingdom are to rental operators. A robust rental market enables reduction in

investments in projects by outsourcing the equipment requirement (including spares and

services) and improving capacity utilization of equipment. The key equipment in the rental fleet

in India currently is backhoe loaders, pick-and-carry (PNC) cranes, excavators, motor graders

and vibratory compactors.

While a number of organized equipment banks like Quippo Infrastructure Equipment Limited,

Sanghvi Movers Limited (for cranes), ABG Infralogistics Limited, GMMCO Limited & TIL

Limited (TIL-for Caterpillar equipment) have entered the fray with large fleets (of over 100

equipments), the market continues to be serviced mainly by small fleet owners with less than 10

equipment each. However, there are various structural/ operational concerns that need to be

resolved for the Indian equipment rental markets to evolve. Concerns include lack of

synchronization of interstate tax policies (on movement of equipment between states) and

logistics of the equipment. Further, the dominance of unorganized market participants that

operate on cash transactions (on rentals, thereby avoiding taxes and enjoying an unfair advantage

to the larger rental operators) prevents the evolution of a more organized system.

With the large infrastructure investment proposed over the next few years, demand for rental

equipment is expected to see a large growth over the medium term. Globally, a number of OEMs

like Caterpillar Inc, JC Bamford, UK and Volvo are actively involved in the equipment rental

business, an area that has not caught on in India as yet.

Industry players would need to address the following key success factors:

Outlook- A strong positive

The industry has been on an upturn supported by increased financing availability; step-up in

infrastructural investments and pick-up in demand for commodities globally. Large proposed

investment over the next several years in infrastructure (ports, airports, roads) has the potential to

sustain the growing demand for CE. The Eleventh Plan commission (2007-12) envisages the

need for an infrastructure investment of over US$ 155 billion for development of roads, bridges,

railways, ports and airports and over US$ 2 billion in mining. According to the Economic Survey

of 2009-10, the Ministry of Road Transport & Highways has set a target of completion of 20 km

of National highways per day, translating to over 35,000 km during the period from 2008-09 to

2013-14. The NHAI has formulated closely monitored work plans for awarding 12,000 km of

projects each during the years 2009-10 and 2010-11. The Special Accelerated Road

Development Programme in the North-eastern Region (SARDP-NE) envisages two / four-laning

of about 5,184 km of National Highways and two-laning / improvement of about 4,756 km of

State roads. These are, but a few of the large infrastructure initiatives that are currently under

way in the country.

India’s booming infrastructure sector is fuelling demand for all kinds of construction

equipments. With the infrastructure and construction sector undergoing dramatic changes- sky

scrapers being built in cities, kilometers of expressways- builders and contractors are acquiring

sophisticated equipments to execute multi-million-dollar projects. For CE industry, this is indeed

good news, as it paves way for an exciting future.

CHAPTER-3

COMPANY PROFILE

Schwing Stetter India Pvt. Ltd. (SSIPL) is a wholly-owned subsidiary of Schwing Gmbh,

Germany. The operations of SSIPL consist of manufacture and supply of equipment and spare

parts relating to handling of ready mix concrete (RMC), namely, concrete mixers, concrete

pumps, batching plants and recycling plants. SSIPL has three manufacturing plants in Chennai

and 12 branches across India. Schwing Group is one of the world’s leading manufacturers of

RMC equipment such as batching plants, truck mixers, concrete pumps, shotcreting machines

and recycling plants. The group has operations in 12 countries and has presence in more than 100

countries. The Company was incorporated as a Private Limited Company in the month of June,

1998 and the necessary permission was obtained from the Secretariat for Industrial Assistance,

Ministry of Industries, and Government of India for 100% foreign holding.

The entire product ranges of Schwing group are being sold for the last 24years in India either

through direct imports by the customers or through their erstwhile distributors. The group is

known for its quality products and has been recognized as one of the best manufacturers of these

equipments. Looking at the Design and Software potential in India, the group Management has

decided to off-load the group’s Design and development

Work and software development work to the Indian company and accordingly SSI has set up a

Software Technology Park (STP) unit.

SSI has branch offices and stocking centers at various strategic locations allover India to cater to

the requirements of customers. The company has also diversified its activities to undertake

turnkey projects under which the entire setting up of concrete plants as per requirements of the

customer is undertaken. SSI has Resident Engineers stationed at Surat, Jamnagar, Baroda,

Mandi,Kota, Panipat, Jaipur, Lucknow, Coimbatore, Vizag, Anantpur, Subansri &Guwahati. SSI

is organized into plants / branch offices, and from an administrative standpoint the company’s

Marketing & Sales function is organized into sales offices.

SSI is headed by Mr. Gerhard Schwing, the Chairman based in Germany. The day-to-day

operations of the company are in the able hands of Mr. A.Sundaresan, Managing Director,

assisted by a team of experienced professionals.

SSI completed construction of the new factory at Irungatukottai and commenced its production

in Nov ‘01. The investment in the Project is approx. Rs.14 crore. Just after 4 years of its

launching commercial production, in 2004, the Company embarked on an expansion project and

doubled the capacity, with an additional investment of Rs.18 crore.

SSI bagged the “BEST EUROPEAN COMPANY IN INDIA AWARD” in the SME Segment,

titled “IMPRESSA AWARD” conferred by the European Chamber of Commerce in the year

2004.

In 2005, SSI received a prestigious award for “Outstanding contribution towards Indo-German

economic relations” awarded by Indo German Chamber of Commerce & IMEA award for “Best

practices on Customer training for service” awarded by M/s Frost & Sullivan.

In 2006, SSI launched another big expansion programme, by starting a new factory in SIPCOT,

dedicated for the manufacture of concrete Batching &Mixing plants of various capacity levels,

incurring an investment of more thanRs.27 Crores. The facility is being utilized to its fullest

capacity, and unpublished statistics reckon that SSIPL is the largest producer of batching plants

in the world.

Further, in the year 2006, the company bagged the ISO 9001 – 2000Certificate, in recognition of

the Quality Management Systems we follow in various spheres of activities of the company. The

company has entered the Export market as well and export of various equipments is being made

to SCHWING group companies as well as other direct customers abroad. The quality of the

equipments has been well appreciated.

The market appears good for the Infrastructure Industry and considering the thrust on mammoth

Infrastructure development in India, SSI is confident of achieving substantial growth in the years

to come with better demand for quality equipments. The history of the Company’s turnover

growth is given below:

Year Turnover

(in Rs crore) (incl. excise duty)

2000 27

2001 47

2002 94

2003 118

2004 180

2005 290

2006 539

2007 803

Schwing stetter India Pvt. Ltd received six sigma compliance certification in 2006 for all its key

business processes from M/s.Nathan and Nathan consultants Pvt. Ltd. Six Sigma is a quality

improvement methodology structured to reduce product or service failure rates to a negligible

level. The Six Sigma process encompasses all aspects of a business, including management,

service delivery, design, production and customer satisfaction

The visionary of SSI

On March 17, 1934, master mechanic Friedrich Wilhelm Schwing, then 25 years

old, founded his handcraft enterprise, whose products quickly found buyers in the mining

industry, in road construction and in the building industry.

As early as in the 1930s, the Schwing Company began to devote itself to the

development of concrete construction machinery.

When post – war reconstruction began in 1945, this was also the greatest challenge ever

to the construction industry and to all manufacturers of construction machinery.

Friedrich Wilhelm Schwing was fascinated by the technical challenge of designing

construction winches, free-standing hoists or cranes. Many Schwing developments and patents

were pioneering achievements, some of which continue to define the state of the art to this day.

At the beginning of the 1950s, concrete began to conquer the world’s jobsites. The

negative aspects of concreting with cranes and buckets quickly brought about the demand for

continuous concrete transport. In 1957, Schwing commissioned the first oil-hydraulic twin

cylinder concrete pump ready for series production. The first mobile truck-mounted concrete

pump followed in 1965, with a placing boom being added to the pump only three years later. The

quick pace of development in the following years is demonstrated by the fact that already in

1973 SCHWING built truck-mounted concrete pumps with a 45-metre placing boom.

In 1980 the founder Friedrich Wilhelm Schwing entrusted his two sons with the management of

the company. Soon afterwards, Schwing took over Stetter GMBH. With this takeover Schwing

had found an ideal supplement to its own range of products and become a complete system

supplier .Since 1982, Schwing Stetter have been supplying the whole spectrum of concrete and

are today the leading systems manufacturer for concrete construction machine worldwide. With

their high excellent resale value, these products are a guarantee of success for customers.

With the foundation of branches and production facilities worldwide, the company came

in with a market- and customer oriented strategy while never losing its sense of proportion .The

company has production facilities in Germany, Austria, Brazil, USA, Russia, China and India

and branches in 12 locations throughout India and 15 locations in the rest of the world. The

company also has more than 100 sales and service centers across the world. No one else feels so

close to its customers as SCHWING STETTER, worldwide.

After 70 years, the foresight of a one-stop supplier has long become reality. Since 2001,

the family-owned company has been run by Gerhard Schwing alone. Under his leadership, the

company is now tackling new visions with concrete strategies. Today’s success is the proof that

SCHWING has the right solutions for the entrepreneurial challenges of the future.

Schwing Subsidiaries

1971 – SCHWING GmbH, St. Stefan, Austria

1974 – SCHWING Hyharulik Elektronik GmbH, Herne, Germany

1974 – SCHWING America, Inc., White Bear Lake, Minnesota, USA

1976 – SCHWING Equipamentos Industriais Ltda., Sao Paulo, Brazil

1982 – Take-over of Stetter GmbH, Memmingen, Germany

1982 – SCHWING-Stetter S.A., Souffelweyersheim, France

1982 – SCHWING-Stetter B.V., Raamsdonksveer, Netherlands

1982 – SCHWING-Stetter Baumaschinenwerk, St. Petersburg, Russia

1993 – SCHWING-Stetter Ostrava s.r.o., Ostrava, Czech Republic

1994 – SCHWING Shanghai Machinery Company Ltd., Shanghai, China

1997 – SCHWING GmbH Korea, Seoul, Korea

1998 – M/S SCHWING-Stetter India Pvt. Ltd., Chennai, India

1999 – SCHWING-Stetter Skandinavien AB, Molndal, Sweden

(Gmbh- Gesellschaft mit beschrankter Haftung, basically means a company with

limited liability or limited company)

Business and competitive position

Strong parent support by virtue of being a subsidiary of Schwing Gmbh, which is a leading

company in the global construction equipment industry

SSIPL is a wholly-owned subsidiary of Schwing Gmbh, Germany, which is a leading company

in the global construction equipment industry. Schwing Gmbh has 14 subsidiaries across the

world out of which 8 including SSIPL have manufacturing facilities. SSIPL is one of the key

subsidiaries for the group, as it caters to the growing market in India. SSIPL contributes to

around 14%-15% of the turnover of the group.

Being a subsidiary of Schwing Gmbh, SSIPL enjoys several key advantages such as:

Technology development: All the innovations, patents, designs and developments are

carried out by Schwing Gmbh and SSIPL makes modifications in product designs in order to

cater to the requirements of local customers. Consequently, the customers get products that

adhere to the global quality standards while also fulfilling the local requirements. Further, some

of the designs and technologies specific to Indian requirements are developed jointly by Schwing

Gmbh and SSIPL.

Training support: Schwing Gmbh also provides training to the engineers of SSIPL and helps

them in product development to cater to local market requirements. Training support from the

parent has enabled SSIPL to provide superior after-sales services to its customers.

Brand image: Schwing Group has developed a well-recognized brand in the construction

equipment industry across the globe by maintaining consistent quality standards and providing

efficient after-sales service. The strong brand image of the parent provides a competitive edge to

SSIPL in the Indian market.

The importance of SSIPL in Schwing group is also established from the fact that it has plans to

make SSIPL as its manufacturing hub for 17 m boom pumps that are used for the construction of

low-rise buildings. SSIPL will also manufacture truck mixer components for the US market.

(Source: ICRA Credit Perspective, SSIPL, June 2009)

Good brand recognition has enabled the company to establish a strong market position

SSIPL has developed a strong brand image and garnered a significant market share in the RMC

handling equipment segment. The leadership position of SSIPL is supported by its superior

product quality; branding support from the parent and an extensive distribution and service

network. The market position of the company is also evident from a significant share of revenues

coming from repeat client orders.

Focus on a single-product domain enables SSIPL to stay ahead of competition

SSIPL faces competition from different companies in different product categories. However, it

has been able to garner a significant market share primarily because of its focused approach on

concrete equipment. Being a provider of all the construction equipment related to concrete,

SSIPL enjoys a better position than its competitors. Further, the company enjoys a high level of

brand loyalty and has well-established relationships with its customers.

Diversified and reputed client base

SSIPL has developed a well-reputed customer base over the years. The company largely services

construction companies, RMC suppliers and equipment leasing companies. Of the three

categories, construction companies contribute to 65% of revenues. The major customers of

SSIPL include Gammon India Limited, Soma Enterprises Ltd, Larsen & Toubro Limited and

M/s. Lafarge Aggregates & Concretes India Pvt. Ltd. A significant portion of its business comes

from repeated client orders, thereby reflecting the brand loyalty enjoyed by the company.

Well-established distribution network and service centres enhance the marketability of the

products

SSIPL has opened several branch offices/service centres across India to provide easy access to its

customers. This well-established network of service centres ensures timely service to the

customers and timely availability of spares, thereby enhancing the value of its products to its

customers. Further, SSIPL provides the services of trained operators to its customers so as to

reduce the risks of poor handling/maintenance of equipment.

The network of service centres could help obtain annual maintenance contracts that offer high

margins and ensure a steady flow of revenues. The company plans to open more service centres

to widen its reach to its customers.

Vulnerability to fluctuations in raw material prices

The key raw material components used by the company include drum, hydraulic components,

engines, screw conveyor and BHS mixers. Some components like hydraulic components and

specialized steel components are imported from the parent company/vendors of the parent

company. The remaining raw materials are sourced locally.

As per the procurement policy of the company, imported raw material is bought in bulk

quantities to meet the requirements of the production schedule of the next few months. However,

local purchases are made in small quantities at regular intervals in line with the flow of

production.

Financial profile

Operating income buoyed by booming real estate and infrastructure sector

The operating income of the company has witnessed a significant uptrend during the last few

years, given the boom in real estate and infrastructure industry in India. The company also scaled

up its production facilities in order to meet the increasing demand for its products. In CY 2008,

the growth in turnover slowed down because of slowdown faced by the real estate and

construction sector. The operating income in CY 2008 grew to Rs. 7575 million from Rs. 7082

million in CY 2007.

Operating income

(INR million, approx)

CY 2005 2600

CY2006 4900

CY 2007 7000

CY 2008 7600

Increasing economies of scale boosted the profitability of the company

The profitability of the company has improved significantly over past few years. The operating

margins improved to 14.7% in CY 2007 from 10.6% in CY 2005 primarily on account of

increased economies of scale. In CY 2008, the company witnessed a marginal decline in

operating margins to 14.1% on account of increase in raw material prices and pressure on

realizations.

High inventory holding period results in high working capital intensity

The working capital intensity of SSIPL as measured by net working capital/operating income is

high at 36.3% in CY 2008 mainly on account of a high inventory holding period and low

turnover. The increase in working capital intensity also resulted in negative cash flows from

operations over the past few years. ICRA expects the working capital intensity to improve on the

back of the steps initiated by the management to improve inventory management.

Equity infusion and high internal accruals maintained the gearing at moderate levels

The gearing of the company was high at 2.75 times as on December 31, 2005 because of debt-

funded capex. Nevertheless, the gearing came down to 1.13 times in CY 2008 with further equity

infusion, internal accruals and repayment of the term loan. However, the debt repayment risks

are partially mitigated by the fact that the debt is mainly to fund working capital.

Profile of competitors:

Competitor Profile

Greaves cotton limited Greaves cotton limited is present in several product

domains such as power generators, engines, pump sets and construction equipments. It competes with SSIPL mainly in the concrete pumps segment.

Sany Heavy Industries India Private Limited

SHIIPL is mainly engaged in R&D, manufacture and distribution of engineering machinery, with the products covering 25 categories and above 120 types such as construction, road construction, and hoisting machinery. The leading products include the concrete pump, truck mounted concrete pump, concrete batching plant, asphalt batching plant, roller, asphalt paver, motor grader, truck crane and crawler crane.

Revathi Equipment Limited Revathi equipment limited is primarily a drilling equipment manufacturer. The company is also expanding its presence in the concrete equipment segment. The company has a low market share in the concrete equipment segment.

Aquaries engineers Private Limited

It is a manufacture and exporter of concrete pumps and batching plant. Aquaries also represents Gomaco, USA for its complete range of slip form pavers and carbing machines. It competes with SSIPL in the separate placing boom pumps segment.

Putzmeister Concrete Machinery Pvt. Ltd.

It is a subsidiary of Putzmeister Holding GmbH, Germany. The company is present in the entire concrete equipment segment.

ORGANIZATION CHARTS

Managerial

Managing Director

CF

CFO- CHIEF FINANCE OFFICER

COO- CHIEF OPERATING OFFICER

VP- VICE PRESIDENT GM- GENERAL MANAGER

Administration & personnel, HRD, Stores, Logistics and HR committee

1 Secretary

CFO&CS COO

VPMFG& ENGG

GMPURCHASE

2 3 4 5

1

Finance & Accounts

HR Committee

HRD

Admin & Personnel

Stores Logistics

Personnel Canteen Security Transport SHE

2

Sales & Marketing, Service, Commercial and Training

Secretary

F&A IT

Corporate Banking

SAP HW

Audit

Design

Cash & Bank

Excise

Direct Taxation

Accounts & Finance

Payables & Assets

Inventory & Production

3

Production, QC, Design, Projects and Maintenance

Training

Service Marketing Spares Commercial

Regional Heads

Service

Sales OfficesRegional Admin & Accts

Strategic Purchase

4

Production Mfg & Engg

QC Design Maintenance Projects

Concrete mixers Batching Plant

Concrete pumps

PRODUCTS & SERVICES OFFERED

5

Secretary

Ongoing PurchaseStrategic Purchase Vendor development

Over the years, SCHWING Stetter India has been responding to the changing needs of

customers with a wide range of Construction Equipment Machineries, which are

contemporaneous in design.

The various products and services offered are:

Equipments-

Batching plants

Concrete transit mixtures

Concrete pumps

Spares

Services-

Mounting the transit mixture on the truck chassis

Minor repairs of sub-assemblies

Warranty as well as post warranty service

Major repairs

Second-hand sales of an old equipment or part

Training: A separate department for training runs training Center in Chennai. The training is

meant for

Customer representatives

Newly recruited staff

Retraining of existing staff

Outsiders

The various products manufactured at SSI are:

Concrete Batching plants

Transit Mixers

Concrete Pumps

Shotcreting machines used for concreting tunnels

Recycling plants for conversion of waste concretes.

Transit Mixer Concrete Pumps

Batching plant Recycling plants

SSI has revolutionized the construction methods with its superior technology, highest quality

standards and excellent after sales service and spares backup provided at all nook and corners of

India. The presence of Schwing group in India is one of the sweetest things that could happen in

the Indian construction industry. SSI now offers total concrete solutions to all its customers with

its wide range of equipments and highly skilled technical team.

About the products:

Batching plants

A plant containing the equipment to measure, by weight or volume, the quantities of

different materials required to make a correct mix of concrete.

Our batching plants are fully computerized and state-of-the art. These plants were

originally designed in Germany and have further been modified at SSI for adaptations to Indian

conditions. The technology has been tried and tested with over 30 plants in operation in the

country. The product has been well received in the construction market.

The different models available are: CP 30, CP18, M1, M2, M2.25, H1, H1.25, H2, H2.25, H3,

H4, and H6. The high end product costs around 1.5 crores.

Concrete pumps A concrete pump is a tool for transferring liquid concrete by pumping. These machines

pump concrete easily and efficiently to heights of up to almost half a kilometre, or over distances

up to nearly 3 kilometres.

70 years of SCHWING experience in the field has led to concentration into each and every

machine that leaves the factory, and the results clearly speak for themselves - in terms of,

Low wear & tear

Low running costs and,

Superb overall service lines.

From one pump customers to the largest fleets in the world, Schwing truly brings

Solutions, Value and Success to the industry.

Transit Mixer

A transit mixer is a truck mounted drum with a capacity to carry certain quantity of

concrete at a time. The Stetter GmbH, Germany is a pioneer in the field of transit mixers. The

first Stetter transit mixer was introduced in the year 1958. Stetter GmbH belongs to the Schwing

group of companies.

There are several advantages of SCHWING Stetter transit mixers –

Fast filling

Fast and smooth discharging

Best mixing results

Development according to ecological and economical requests

Worldwide service network

Quality and Safety, Health and Environment policy.

Quality policy

Ensure utmost customer satisfaction by manufacturing and supplying equipments of international

quality standards and to provide excellent customer support.

Achieve and maintain market leadership and be a trendsetter by strictly adhering to best

engineering practices.

Provide congenial working atmosphere, clean and green work environment.

Upgrade human skills, build confidence and value system.

Improve continually in quality, service and timely deliveries to exceed customer expectation

Safety, health and environment policy

Schwing Stetter India is committed to providing a safe and healthy workplace and protecting

and conserving the environment. These core values are present in our operations, products and

services and demonstrate our commitment to being a responsible corporate citizen.

Achieving excellence in Safety, Health and environment matters is a plant wide responsibility

and it covers all the activities in each plant either directly or indirectly involved with the

manufacture of Construction equipments like Concrete pumps, Transit mixers, Batching plants,

Recycling units and activities at Chennai Service Center.

Responsible and effective standards and work practices that prevent risk to human health and

the environment add significant value. This value is created by reducing risks, liabilities and

costs, protecting our employees, exceeding expectations from our customers and committed to

comply with legal and other requirements concerning safety, health and environmental matters

that involve our manufacturing facilities and service center.

SSI implements a Safety, Health and Environment Management System (SHEMS) that is

consistent with the OHSAS 18001 Health and Safety Management System and the ISO 14001

International standard. SHEMS is designed to identify, evaluate and control significant

environmental aspects and health and safety risks. SHEMS is the foundation for continual

improvement for all plants. This improvement shall be measured by objectives and targets that

include:

1. Providing a safe workplace for all employees with zero tolerance for unsafe acts or

unsafe conditions

2. Providing employees and the contractors with training and information to enable them to

fulfill their responsibilities and duties in a safe, efficient, health, hygiene and

environmental friendly manner.

3. Achieving excellence through systematic safe, health and environment processes in the

areas of product design, development and manufacturing.

4. Developing and implementing procedures to deal promptly and effectively with fire,

security, environmental, emergencies

5. Reducing, reusing and/or recycling wastes and packaging materials

6. Monitor the disposed wastes till the end point and ensure no adverse impact on the

environment.

7. Improving the efficiency and conservation of energy and natural resources

8. The SHE policy is documented, displayed and communicated to all employees and

others.

Esteemed customers :

Aban Constructions Pvt Ltd

Afcons Infrastructure Ltd (H.O.)

APARNA Enterprises Limited

Ashok Leyland Limited

Automotive Manufacturers

B.G.Shirke Constn.Techn. Pvt Ltd

B.L.Kashyap & Sons Ltd

Coastal Projects Pvt Ltd

Consolidated Const Consortium Ltd

D.S.Constructions Ltd

DLF-Laing O Rourke (India) Pvt Ltd / DLF

EMAS Engineers & Contractors Pvt Ltd

ERA Infra Engineering Limited

Gammon India Limited

Gannon Dunkereley & Co Ltd

Gemini Equipment & Rentals Pvt Ltd

Grasim Industries Limited Ultra / Ready Mix Concrete (P) ltd.

Hindustan Construction Co Ltd

Indu Projects Ltd

ITD Cementation India Ltd

IVRCL Infrastructures & Projects Ltd

J.K.Lakshmi Cement Ltd

Jaiprakash Associates Ltd

JMC Projects (India) Ltd

L&T-AM JV – Tapovan

Lanco Infratech Limited

Madhucon Projects Limited

Maytas Infra Private Ltd

Motive Manufacturers

Nagarjuna Construction Co. Ltd

Navayuga Engineering Co Ltd

Orix Auto Infrastructures Services

Patel Engineering Limited

Raghu Constructions

Ray Mix Concrete

RDC Concrete (India) Limited

RMC Readymix (India) Pvt Ltd

SCHWING GmbH

SEW Constructions Limited / Prasad

Shapoorji Pallonji & Co Ltd

Simplex Infrastructures Limited

Soma Enterprises Limited / China Ghezbhou Soma

Srinivasa Constructions Limited

STETTER GmbH

TATA Motors Limited

The Associated Cement Companies Ltd

DEPARTMENTS AND FUNCTIONS

HRD, ADMINISTRATION & PERSONNEL, STORES, LOGISTICS AND HR COMMITTEE

All these departments function under the leadership of the company secretary.

Personnel and HR policy

To recruit without discrimination in terms of caste, color, creed, religion, sex, who are truly productive.

Improve their efficiency by broadening their skill

Protect people’s health and lives by providing them a clean and safe environment as free as practicable from the health hazards.

Providing adequate and timely information in all matters pertaining to their work, person –related matters.

Compensate them very fairly according to their contribution with their frame work of existing approved practices.

Develop and maintain human relations that inspire respect for confidence and trust in the company

Human Resource Department

It is headed by senior HR manger. The department has managers and a wing of executives to see that the functions are carried out properly.

The core functions include:

Recruitment and selection

Induction

Training and development

Performance Appraisal

Recruitment and selection

The department where there is a vacancy will send a Staff Requisition to the HR Department containing the job requirements. Based on the requirement the HR department will recruit from reliable sources and the final selection will be done after the interview.

Induction

This will help the new employee to get familiarized with the working environment. The department sees to it that the new employee is guided throughout his work during the initial period and proper support and motivation is also provided.

Training and Development

While numerous factors drive business successes, the purpose of Human resource & development in the work situation is to nourish the abilities of the individual and satisfy the current and future human resources needs of the organization. Rapid technological innovations impacting the workplace have made it necessary for people to consistently update their knowledge and skills

Training employees creates a more positive corporate culture by adding value to its key resources.

Training in SSI

SSI believes in Optimum Utilization of Human Resources through Training and Development which helps the employee to achieve their individual goals as well as the organizational goals.

Training for Workmen:

Workmen are encouraged with

“Attitude Engineering (Phase I & II)”

“Industrial Safety (Phase I & II)”

Training for staff and above:Frequent need based Training Programs are organized as a part of normal learning culture.

Taking the concept of customer orientation – “creating a customer centric culture” in the organization by making it a companywide activity – through one of the world leaders in “Taking sales & service to greater levels.”

Developing internal capability by identifying senior officials of SSI to impart training on customer orientation to our employees.

Continuous tie up with a leading training institution for our training options – for programs like team building, time management, presentation skills and communication skills.

Nomination of our senior officials to premier educational institutions like IIM’s for short term and long term programs based on needs.

Nominations to programs being conducted by professional bodies like CII, EFSI etc.

Program for new employees

WHERE ARE WE

SSI’s EYE for HANDHOLDING …………

In order to get something from everything; we must get to know People – “who-is-who” & so as to know the mode of help / support to seek for.

WHERE ARE WE - “Overview exposure & interactive session”

Program is exclusively meant for the new employee focusing at creating openness, trust & transparency in working together, in a learning organization along with hand-holding to some extent.

It mainly focuses on to develop relevant skills, knowledge and behavior of the employees through developing individual goals, which are linked to the departmental and organizational goals. These goals should be –

S – SPECIFIC M – MEASURABLE A – ACHIEVABLE SMART - GOALS R – REALISTIC T – TIME BOUND

The new entrant will give feedback on his induction to the HR Manager, Functional and Departmental Head after completion of the same.

BUDDY SYSTEM

“The most important single ingredient in the formula of success is knowing how to get along with people."

– Theodore Roosevelt

SSI’s belief in integrity is- “building relationship along with trust”To make this statement true, SSI came with a new intervention with efforts aimed at new Employee Delight and a mutually beneficial & long association.

“Buddy system”

New employees will learn their jobs and their roles within the organization better if they have a “ Buddy”- a seasoned employee assigned to them to help answer their questions and share with them an understanding of organizational practices.

Buddy system is a great way to accelerate the new employee’s ability to deal with only early disconcerting issues involves a transfer agent (buddy) and provides the new entrant with implicit knowledge of:

What is expected of them

What they in turn can expect from their organization

Features of Buddy System:

1. Friendship – Initiate / establish interpersonal bond to foster mutual trust

2. Sympathy 'vs.' Empathy- Understanding them by putting yourself in their shoes!

3. Counseling - 'To help a person to help himself‘4. Listening- Responding ; 5. Real concern for feelings; 6. Confidentiality

“Assist the New entrant to be capable of thinking/ acting independently.”

Performance Appraisal The HRD conducts performance appraisal of the employees. It is monthly or yearly basis.

Personnel and Administration departmentThe department is headed by Deputy General Manger, followed by Manager, Assistant Managers and office workers. The functions include:

Welfare measures Muster roll( attendance) Wages, salary of employees Canteen Security Transport

Safety health and Environment policy

Welfare measures:

Group Mediclaim Floater PolicyThe employee and his family members are covered under this policy from the date of joining time till exit from the company. The scheme provides coverage to self, father, mother, wife/husband, son/daughter (to a maximum of 2).Coverage includes:

All ailments including the pre-existing Maternity Child from day one till 90 days All surgeries 30 days Pre-hospitalization & 60 days Post-

hospitalization

Pre conditions for claims:-The claimant must be: Admitted in a hospital. Hospital must have a minimum of 15 bed capacity.The hospital must be run by a certified medical practitioner.

Claim intimation:-

The concerned employee must intimate the P&A Dept., within two days regarding the hospitalization by furnishing the following details:-

Name of the employee Employee number Name of the claimant Date of admission in the hospital Name and address of the hospital The ailment

Submission of claim:- The employee should submit the duly filled claim form along with the claim summary sheet (available at P&A Department) along with the following documents to the P & A department. Bill, receipt and the discharge certificate / card from the hospital – in original.Cash memos from the hospital / Chemist(s) supported by the proper prescription – in original.Receipt and Photostat copies of pathological test reports from a pathologist supported by the note from the attending medical practitioner surgeon demanding such pathological test.Surgeons certificate stating nature of the operation performed and the surgeon’s bill and receipt – in original.Attending doctor’s consultants /specialists / anesthetist’s bill and receipt and certificate regarding diagnosis – in original.In case of domiciliary hospitalization, receipt from qualified nurse who attended the patient at his/her residence duly supported by a certificate from attending medical practitioner.Certificate from the medical practitioner giving reasons for treatment under domiciliary hospitalization clause of policy.

Certificate from the medical practitioner / surgeon that the patient is fully cured.

Financial assistance: If estimated cost of medical expenses is beyond Rs. 40,000/-, the employee may make a request in the advance request format (available at P&A dept.) for financial assistance from the company. The advance payment will be released by means of a cheque favoring the hospital authorities.

Settlements The insurance company will settle your claim within 2 weeks from the receipt of all claim related documents. The settlement amount will be credited to your personal bank account.

Group Personal AccidentThe employees are covered under Group Personal Accident Policy from the date of joining till date of exit, 24hrs a day. The salient features of GPA policy are as follows:

Amount covered The employee has coverage of 60 months of your salary consisting of your BASIC, PA, HRA and Conveyance. Claims: Employee or his legal heir can make the following claims under this policy:

Permanent partial disablement

Permanent total disablement Temporary disablement Accidental death

Claim procedure

Employee or his family members have to intimate the P&A Dept in case of any accident that requires hospitalization or that requires employee to absent from duty.In case of hospitalization, employees are required to submit the discharge summary, fitness certificate and Police FIR (if any) to P&A Dept. Along with the claim form (available at P&A dept.).In case of death, the following documents have to be submitted to the P&A Dept:

Death certificate from the hospital / Concerned authorities Post mortem report F I R copy from the Police Legal heir certificate Bank account details of the legal heir

Group Term InsuranceEmployees including trainees are covered under a Group Term Insurance Policy against death

Employee State Insurance Scheme

The Employee State Insurance Scheme is a social welfare legislation enacted primarily with the object of providing

certain benefits to employees in case of sickness, maternity and employment injury and also to make provision for certain others matters incidental thereto.

All regular employees are covered as per ESI scheme. Employee’s contribution of 1.75% on actual gross earned per month and employer’s contribution of 4.75% is deposited in ESI account for the eligible employees.

Mobile Hardware Re-imbursement Scheme

Mobile Hardware Reimbursement is one such thing, where employees can get reimbursed the cost, according to their eligibility.The decision whether there is a need to provide a mobile phone will be the sole discretion of the management.The replacement cost of hardware can be claimed only once in three years. The cost can be drawn over a period of three years (the current block commences from 1-1-07 and will end on 31-12-2009). Any unutilized amount within this block will not be carried forward to the next block commencing from 1-1-2010 or 1-1-2011 as the case may be.The reimbursement charges will be claimed based on the bill to be submitted to the company and the expenses beyond the ceiling will be borne by the employee.Similarly the telephone charges for the residential phone shall be paid by the employee at the first instance and shall be claimed from the company by producing the original bill, subject to the ceiling.

Professional pursuit

Employees with one year of experience in SSI are eligible for this scheme Profession fees up to an amount of Rs. 3000/- per annum is reimbursed to the employees pursuing higher studies in their respective field / profession on presentation of valid current year receipt.

Best Employee Scheme

There will be five “Best Employee Awards” given away during the “Vijayadasami” day, as per the following classification –

For workers: Mixer division Plant division Pump division

For staff and above: Line functions Staff functions

Assessment procedure for workers category: A team of supervisors and engineers associated with the respective divisions will assess all the eligible workers within that division and short list the top 5 best performing workers.

The head of production along with head HR and administration will review the assessment and select the best 2 of the 5 workers in each division and put up the same to the Top Management Team (TMT) members.

The TMT will select the better of the 2 under each category and the awards shall be given to them.

Assessment procedure for staff and above category:The eligible employees team will be circulated with two assessment forms (one for line function and one for staff function). Each employee member will select one best performing employee from each set of functions, fill up the relevant assessment sheet and drop them in a ballot box.One cannot select his own name for this purpose.The results of the poll will be enumerated in a two way table, to find out who has got the maximum votes.These selected members will again be appraised by the HOD’s and forwarded to the relevant TMT member.The same will be further reviewed by the TMT members and they will decide on the two awards, one for the line function and one for the staff function respectively.

Bike scheme In order to facilitate ease in mobility of the employees, who are supposed to be on the move predominantly to either visit various customers' sites and / or on official business SSI has a motorcycle scheme to each of those employees, who as per the

assessment of the Management deserves such a facility. The assessment of the nature of the job of employees will be the sole discretion of the Management. However, it is mandatory to Sales and Service Engineers in all levels to come under this scheme or the car lease scheme, as may be applicable to his level.

Car scheme

The scheme has been designed to ensure safe, dependable and comfortable commuting mode for employees between the work place and home and other business visits, within the City and its neighborhood. This is also seen as a measure to ensure punctuality.Eligibility:-

The car scheme shall be applicable for those employees in the levels of Deputy Manager and above.

The relevant employee should have completed one year of service on the date on which his application for entering into the scheme is received by the Company (hereinafter referred to as “SSI”) and that he must be a confirmed employee as on that date.

The employee should have a residual service of 5 years on the above date, before he attains superannuation, even in case of renewal / replacement of the car.

Ayudha Pooja Every year on the eve of ayudha pooja, MD addresses an all employee congregation (at Chennai ) with a message for the year, after taking stock of last year’s performance. The program ends with high tea and a packet of sweets to take home to the family members.

Annual Day Annual day is celebrated on June 18th of every year with all fun and frolic where all employees (from Chennai) are invited to be a part of various cultural and sports events planned, along with their family members and dine in style with a 5 star dinner! Pick – up and drop of family members from their respective residences is customary!

Children Education Scheme SSI welfare measure extends to Children Education as a token of encouragement. Where Employees drawing a basic salary of less than Rs. 10,000/- per month are reimbursed with cost of books, school fees, uniform etc. of their children up to a maximum amount of Rs.3,000/-

Muster rollThe P&A department keep the record of the attendance of the factory workers through registers.

Remuneration of employeesThe workers in the manufacturing unit are hired from labour suppliers and are paid on the basis of their attendance per month and work experience in SSI and outside. The salary includes:

Basic payProvident fund

Provident Fund is a defined benefit scheme, where benefits are paid in lump-sum on exit. It is mandatory for all organization having more than 19 employees. Employer and Employees both contribute 12% of the wage bill to the fund. The accumulated amount with interest is returned to Employee on the retirement. After the introduction of EPS-95 part of the contribution to PF is diverted to State Pension Scheme, which provides salary linked benefits on Superannuation

Gratuity

As per The Payment of Gratuity Act, 1972, Any person employed on wages / salary is eligible for gratuity –At the time of retirement or resignation or on superannuation, if the employee has rendered a continuous service of not less than five years. In case of death or disablement, the gratuity is payable, even if he has not completed 5 years of service. The quantum of gratuity is computed at 15 days wages, based on rate of wages last drawn by the employee

concerned for every completed year of service or a part thereof exceeding 6 months.

The total amount of gratuity payable shall not exceed Rs.3, 50,000/-.i.e. Gratuity = (Monthly Salary / 26) * 15 days * no of yrs of service (Salary = Basic + DA.) However at SSI, the employee is eligible for gratuity even if he/she has completed 6months of Service, unlike the Acts requirement of 5 years of service. This is applicable for employees who are on regular rolls for Schwing Stetter India Pvt. Ltd.

Super annuation scheme

SSI has a unique Superannuation Scheme for the Assistant Managers and above category. 15% of the Basic pay is earmarked for this, which one can take as a part of his monthly salary, wherein the amount becomes taxable. The other option is – one can decide for the scheme where the amount is managed by reputed mutual fund organizations with possibility of reasonable return on investment in the future. However, this amount can be got back only at the time of superannuation and the money with the accrued interest in not taxable. Whereas in the case of resignation the amount that is given to the employee with accrued interest becomes taxable.

Employee Pension Scheme

Life pension to family of the individual demised while in Employment.

Pension at SSI is provided as per the Employee Pension Scheme, 1995,The amount of the pension benefit is based on the employee's average salary during the final year of employment and the total number of years of employment. Under the EPS, members must have completed a minimum of ten years of service and must be at least 58 years old. However, if an employee has completed twenty years of service, he/she may obtain an early pension from age 50. Under this provision, the amount of pension benefit is reduced by 3 per cent for every year falling short of 58.

CanteenThe canteen provides lunch to all the employees at a subsidized rate. It is on contract basis.

SecurityG4S, a labour supply firm provides the security staff to SSI, Chennai. They keep a watch at the entrances and maintain order. They also take care of the registers marking attendance of workers.

TransportTransportation facilities are arranged for all the employees according to working hours and shifts.

Safety, health, and environmentThere is a separate SHE department to see that safety is ensured at all levels. First aid facility is also arranged with the service of a doctor and assisting nurses. The workers in the factory are given proper safety gadgets in order to avoid risk to life. Fire extinguishers and alarms are also placed at different locations and they are checked at regular intervals. The safety department conducts mock drill for the employees. The environment is also kept clean, 30% of the factory surroundings are maintained as lawns and gardens. The department is headed by a manager.

Stores departmentThe department is headed by store managers, then store staffs and there are workers to assist in the storing function.

Stores department works with a norm of 1 month for raw material stocks. Stores inwards the materials after verifying the P.O no., part no., description & quantity with the vendor invoice and the delivery challan. In case of excess or shortage in goods, Discrepancy Note (DN) is issued by the Stores. Stores prepare the Goods Receipt Note (GRN) with the above details and forward it to Quality Department All excisable materials are sent to Excise Department for taking input credit on material purchased. Excise duty (paid) document will be handed over to the Excise Officer after making entry in the inward register. Quality issues the Goods Inspection Note (GIN) after checking and certifying the quality, and makes. In case of green channel

vendors (i.e. list of approved vendors available) the materials are not offered to Quality for inspection. Both the GRN and GIN are prepared by Stores themselves.

Storage Stores assign separate storage locations for the materials received from supplier. Storage locations are assigned to materials for indicating physical presence of the materials on that particular location at the time of unloading. Unloading point shows the direction of storage, say North Bay, SouthBay, West Bay, East Bay etc. on the premises. Both scrap generated from in-house production and received from the subcontractor (job work) are segregated according to the type of material as wooden, steel, tins and miscellaneous etc. and stored in respective location. Stores are ultimately responsible for proper storage of both domestic and imported materials.

Issue to productionStores receive monthly production work orders from Planning Department by 25th of every month for next month’s production. Pick List is issued by Planning to Stores for material to be picked and delivered to Production. Stores take a copy of Bill of Material from SAP and tick the quantity of materials to be issued to Production Department. Stores make ‘311’ movement in SAP for materials issued to Production through pick list and gets acknowledgement in the list from the concerned supervisor. This is based on material availability as per the SAP ledger. In case of shortage of materials (materials not available or available in lower quantity) as per the ledger, Stores informs

Planning and Purchase. If a material is not physically available though it was ticked and ‘311’movement was made, Stores reverses it by passing 312 movement.

Logistics departmentThe department is headed by General Manager, Logistics. Logistics is the management of the flow of goods, information and other resources between the point of origin and the point of consumption in order to meet the requirements of the consumers. The department plays a key role in the organization. It sees that the manufactured products are transported safely to the destination point within a fixed span of time so that the customer is delivered without any delay.

.

Finance & Accounts, Corporate Banking