scandinavia zine

-

Upload

oscar-langley -

Category

Documents

-

view

251 -

download

0

description

Transcript of scandinavia zine

sam

leu

ngos

car

lang

ley

jam

es lac

hian

na

ScandinavianWood BendingDesign Technology 4:Grap 1052

Square Mobius StripThe Square mobius strip was done in order to test the degree and limit of bending the veneer. The mould was created to give a 90 degree + bend in the veneer. Three veneers were then steamed and placed in the mould. Once removed, the three veneer strips were glued and left to dry. The end result is a square mobius strip that has seamless join and the only separation of the veneers is at the tight bends.

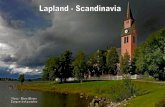

Scandinavia

“Developing the understanding and relationship between technology and design”

In this unit of learning for the wood portion of technology, we explore the Scandinavian method of woodwork. Unlike the previous unit in which we experienced Japanese wood

joinery.The Scandinavian wood principle is based around laminated wood bending.

We explore the Scandinavian craftsmanship by experimenting with their techniques. These methods include Steam bending, Kerf-cut bending, Laminated wood bending and

microwave bending.

Ply-Wood 11mm 10mm Spacing

Red Gum 19mm

Ply-Wood 9mm 20mm Spacing

Pine 20mm 5mm spacing

Ply-Wood 9mm 7mm Spacing6.5mm Cut

Ply-Wood 10mm 7mm Cut6mm Spacing

Red Gum 19mm 3mm Spacing17mm Cut

Kerf Cut Bending Creating Sweep Curves

Experimental Variables included:- Types of wood- Wood thickness- Lamination

Mould BendingUsing an MDF mould which had a curve cut, then extra material removed to create a smooth edge, compensate for the veneers thickness and prevent the veneers from splitting. Three veneers were then steamed and placed between the two moulds parts to dry. Once they dried the veneers were then glued together and place back into the mould to dry. The finished curve bend was almost identical to the curve cut in the MDF wicth only small flex, as the glue has aided to givethe veneer a new memory.

Mobius StripThis was our initial mobius stripwe did it using a mould that comprised of two cylinders mounted onto a board, the cylinders were able to shift up and down to vary the length of twist.The strip was laminated in 3 ply and suc-cessfully retained its shape although we were unable to achieve a seamless finish.The layers also split at the bends