SC1B-SXXX MANUALE ENG-ITA...18 dewaterer 19 hopper 24 25 English 1 CE indentification label 2...

Transcript of SC1B-SXXX MANUALE ENG-ITA...18 dewaterer 19 hopper 24 25 English 1 CE indentification label 2...

20 21

English

The Green Machine Food Waste ProcessorService manual ISE-B200

22 23

Index

Chapter 1 General data 23

Chapter 2 Description and technical data 24

Chapter 3 Transport and movement 27

Chapter 4 Use of the machine 31

Chapter 5 Maintenance 33

Chapter 6 Disposal 34

Chapter 7 Spare parts 35

Attachment A Declaration of conformity 39

2 0 2 1

This manual is an essential part of the machine TGMi and it must always be together with it.

All rights reserved. The manufacturer reserves the right to add to this manual minor modifi cations or upgrades without previous notice.

All actions described in this manual, except for those included in chapter 4, must be executed by the maintenance

company only.

DefinitionsEuropean DistributorThe Green Machine Ind.

M ach ineThe Green Machine Food Waste Processor CWS-1

UserPhysical or legal subj ect at whom the machine is used.

Operatorualified or not qualified person who operates

the machine and eeps it clean together with its installation place e she is specifically trained to operate the machine but isn’t authorized for settings nor for maintenance.

Mantenance companyPhysical or legal subj ect authorized by the manufacturer for settings and maintenance of the machine e she is qualified for mechanical and electrical actions, even on live parts, and was specifically trained by the manufacturer

Personal protective equipment

(PPE)

I n some paragraphs are shown symbols of the PPE the personnel is compelled to wear

Head protection

Protection gloves

Protection clothes

Safety shoes

Warranty

The manufacturer guarantees the machine against material and wor defects for months from the invoice’s date on. D amages or defects due to not respecting this manual or to improper use, as defi ned in chapter , are not covered by warranty. D amaged parts are replaced for free by the manufacturer if they are originally defective. The manufacturer reserves the right to upgrade any part of the machine without notice, or to suspend or discontinue the machine. The manufacturer is not responsible for electrical and hydraulic connections to respective systems, nor for any ind of damage due to the connections themselves.The useful life of the product if properly used and maintained is 10 years.

Service

To as for technical support please contact the manufacturer reporting the machine’s serial number

The Green Machine IndP.O. Box 1083600 AC MaarssenThe NetherlandsTel.: +31 06 53 192 [email protected]

Chapter 1General data

Protection gloves

Safety shoes

English

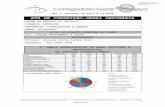

400V 50Hz - 3,1 kW

8 cm

100 cm70 cm90 cm

195 kg

79 dB(A) operator’s workstation

three-phase + earth 16 A

400V - 50 Hz - 4,1 kW

1 command panel

2 emergency button

3 trash bin

4 bin level sensor

5 tap

6 spray hose

7 handle with block system

8 outlet presence sensor

24 25

Technical data

Description

The machine is intended to grind edible food waste only.

Chapter 2Description and technical data

Dimensions WidthDept

Height

Weight

Loudness

Socket

Power source

English

9 magnets

10 disposer

11 bin sensor

12 lid sensor

13 hot water inlet

14 recycled water inlet

15 cold water inlet

16 electrical panel

17 pump

18 dewaterer

19 hopper

24 25

English

1 CE indentification label 2 warnings

26 27

REF

SN

REF

SN

manufacturer

code

serial number

year of production

power source

Identifi cation plate

Do not clean or oil moving machinery

Keep guards in place

Moving machinery

Warnings

English

26 27

31

2

Transport and movement

Before installation, the machine has to be transported and moved by mechanical tools only and with the original packaging: wrapped up in plastic fi lm, in vertical position on wooden pallet.The machine must be stored at a temperature ranging from 0° to 45° and a humidity ranging from 10% to 95%.

Positioning

The machine must be used at temperatures ranging from 5° to 35° and a humidity ranging from 20% to 80% non-condensing.

Chapter 3 Transport and handling

English

1

2

3

4

5

Electrical connection

1. Open the consol and make sure thedisconnector is on O;

2. insert the power cord through the cable glands;

3. wire the power cord to terminals L1 L2 L3;

4. switch the disconnector to 1 and close theconsole;

5. plug the power cord into the socket and switchon.

All actions described in this manual, except for those included in chapter 4, must be executed by the maintenance

company only

28 29

English

3/4”

3 BAR 3 BAR3 BAR

3/4” 3/4”

30,5 cm

21 c

m

15 c

m

Hydraulic connections

The machine needs the following connections to the hydraulic system:

• cold water - pipe 3/4” - 3 bar - tap upstreamthe inlet

• hot water - pipe 3/4” - 3 bar - tap upstream theinlet

• if available, recycled water - pipe 3/4” - 3 bar

Connections under the bottom:

• drain (Ø 50 mm)

• hopper overfl ow (Ø 25 mm)

The drain pipe to be installed must slope downwards by 1% minimum.

The machine must always be connectedto the cold and hot water net, even if a recycled water net is available

> 1°

1 overflow

2 drain

For all models the cold water inlet is next to the power cord

28 29

English

Parameters

Function Description Parameter Default

CYCLE working cycle duration T 10’INJECT. cycle: duration of water injection into the hopper TH 5”

cycle: pause of water injection into the hopper TL 3”INJCT.CLN cleaning: duration of water injection into the hopper TH 5”

cleaning: pause of water injection into the hopper TL 3”FOTOCEL number of remote photocell inputs for cycle start ON 30

BIN.LEV enabling / disabling bin level sensor switch on

*if aviable

30 31

A B

Date and time setup

After installing the machine, date and time must be set in the administrator area:

1. press anf then ESC;

2. go to LOGO! SETTINGS → SETUP → SWITCHTO ADMIN and press ENTER;

3. insert the Password printed in this manual onthe inside back cover;

4. go to LOGO! SETTINGS → SETUP → CLOCK→ SET CLOCK and press ENTER;

5. set data and time using the arrows;

6. go to LOGO! SETTINGS → SETUP → SWITCHTO OP and press ENTER to exit the administratorarea.

A display

B controls

Parameters setup

Right after the machine’s installation, start one or more cycles adjusting the parameters in the table below. Any other parameter can not be modified except by the manufacturer.

To set the parameters proceed as follows:

1. turn on the machine;

2. go to PROGRAM → SET PARAMETER andpress ENTER;

3. the list of adjustable functions is visualized. Move to the desired one with the arrows and

and press ENTER;

4. go to the desired parameter with arrowsand and press ENTER, the cursor lights;

5. modify the values with the arrows and ,then press ENTER.

Repeat these steps for all the functions to be modified, then press ESC repeatedly until the date / time screen. Now press to the home screen.

English

30 31

Chapter 4Use of the machine

Proper and improper use of the

machine

The machine is intended to process food waste only. Process always a mixture of materials and not just one type, especially if it is a dry material. Dry material must be dropped slowly in order to avoid clogging.

Are considered improper uses:

• Inserting in the hopper material other thanfood waste

• Washing the machine by pressure jet

• Installing and use the machine in area withhigh dust concentration or oily substancessuspended in the air

• Installing and use the machine in open air

• Installing and use the machine in potentiallyexplosive atmosphere or in area with openflames

• Tampering the machine in any way

• Operating the emergency button in absenceof a real danger

• Removing the identification label

• Pouring any kind of soap or detergent into thehopper

• Washing the lid in the washing machine

• Leaving the spray hose’s tap open even whenit is not being used

• Using the machine wearing dresses withlarge sleeves, scarves, ties, bracelets andnecklaces

• Siting on the machine or lay heavy objects onit

Operator position

Do not put heavy objects on the machine. Do not sit on the machine.

Correct position

English

Use

1. Make sure no alarm is on;

2. press and hold the green button: the automaticcycle starts. If provided, the cycle can be startedautomatically by a remote photocell;

3. drop the materials into the hopper.

The cycle automatically stops in an adjustable time, or it can be stopped manually by pressing the red button.

The machine stops automatically when thetrash bin is full.To open the lid pull up the knob besides the handle and move the central knob.

Cleaning

At least once a day it is mandatory making sure no leftovers are present. Please perform the following steps:

1. remove and clean the lid with cold water;

2. clean the hopper with the spray hose;

3. press and hold the blue button to startcleaning; do not drop anything in the hopperduring cleaning;

4. clean the exterior with a soft rag.

Do not pour any kind of soap or detergent into the hopper

32 33

EmergencyThe emergency button must be operated in case of real danger only. Remove the dangerous situation and its causes, then reactivate the button with the special key. Run a cleaning cycle even if not needed.

English

Signals and solutions

In case of failure the display blinks red and reports the problem detected.

Message Cause / SolutionREADY standby WORKING active cycle EMERGENCY STOP ACTIVE It has been pressed the emergency

buttonEMERGENCY – PLEASE CHECK LID OR BIN

trash or cover absent

PUMP THERMAL PROTECTION – PLEASE CONTACT SERVICE

Pump motor has overheated, unlock the rotor if necessary and wait few minutes for the overload to reset

DISPOSER THERMAL PROTECTION – PLEASE CONTACT SERVICE

Disposer motor has overheated, unlock the rotor if necessary and wait few minutes for the overload to reset

DEWATERER THERMAL PROTECTION – PLEASE CONTACT SERVICE

Dewaterer motor has overheated, unlock the rotor if necessary and wait few minutes for the overload to reset

PHASES ERROR – PLEASE CONTACT SERVICE

One phase is missing or phases rotation is wrong. Make sure all phases are active, if needed reverse the wiring of two phases

BIN IS FULL bin is full, empty the binCOLD WATER MISSING – PLEASE CHECK THE TAPS OR CONTACT SERVICE

Check internal and external taps

WARM WATER MISSING – PLEASE CHECK TAPS OR CONTACT SERVICE

Check internal and external taps

CLEANING – LOADING FORBIDDEN

active cleaning

STOPPING – LOADING FORBIDDEN

end of the cycle

DISP.HOURS XX disposer’s working hoursDEW. HOURS XX dewaterer’s warking hours PUMP HOURS XX pump’s working hoursTHERM.DISP XX number of interventions of the

thermal heat sink protection from the beginning of life

THERM.DEW. XX number of thermal protection interventions of the dewaterer since the beginning of life

THERM.PUMP XX number of thermal protection interventions of the pump since the beginning of life

EMERG.BUTTN XX number of pressures of the emergency button from the beginning of life

32 33

Routine maintenance

The only routine maintenance in charge of the user is the cleaning described in chapter 4.

Emergency maintenance

Before any intervention on the electrical components, turn off the machine and unplug the power cable from the socket.

All actions described in this manual, except for those included in chapter 4, must be executed by the maintenance

company only.

Possible failures are signaled on the screen

Clogging

If improper objects fall into the hopper:

1. switch the machine off and unplug the powercable;

2. remove the object that caused the clogging;

3. switch the machine on and start a cycle,making sure that everything is ok

Temporary stop

If it is not possible to restore completely the correct functioning after a maintenance intervention:

1. clean the machine;

2. unplug the power cord;

3. apply on the machine a sign with the message“out of order”.

English

Chapter 5Maintenance

34 35

Setting the machine out of

order

If the machine has to be put out of order for a long time, proceed as follows:

1. clean the machine;

2. unplug the electrical power cord;

3. apply on the machine a sign with the message“out of order”.

Disposal

As from European Directive 2012/19/EU, the machine to be demolished must be disposed separately from other waste.

Proceed as follows:

1. make unusable both the identifi cation plateand the manual;

2. deliver the machine to a special collection cen-ter for electric and electronic waste.

Illegal disposal of the machine implies fi nancial sanctions as stated by the laws in force.

Chapter 6Disposal

English

1. EC060086 Blu lamp2. EC060085 Blue lamp head3. EC060077 Yellow lamp4. EC060076 Yellow lamp head5. EC060094 Red lamp6. EC060093 Red lamp head7. EC060078 Green lamp8. EC060075 Green lamp head9. EC060069 Emergency button w/ key10. EC060088 Sensor Telemecanique XX518A3PAL2 11. EC060089 Sensor Telemecanique XCKP2145P1612. EC060046 Sensor pair Pizzato SR BD40AN2-B02F (2 NC)13. EC060092 Display Logo Siemens TDE 6ED1055-4MH00-0BA1

14. EC070034 Solenoid valve ACL E107DB12///30B15. EC070062 Flow switch Valco FCM 1 - 4.15.GO

16. EC050905 Closed cover 317400117. EC050908 Closed cover w/ thermal sensor 34206114 ST18. EC050903 O-ring 118519. EC050901+EC050902 Impeller + seal 317400920. EC050906 Open cover 317400821. EC050907 Seeger SB 50 int.22. EC050899 Spacer 317402223. EC050898 Seeger 7435 est. 317402324. EC000607 Pump body Minor with two reduction bushes

Available depending on the version25. EC000056 Right cylinder26. EC000056-1 Left cylinder27. EC090500 Belt HTD 776-8M-2028. EC090508 Belt HTD 800-8M-20

29. EC050017 Motor30. EC030036 Grinding ring31. EC030037 Turntable32. EC030041 Low cone33. EC090295 Speedi-sleeve Skf 9919334. EC090512 O-ring 3900 – NBR35. EC090122 Seals pair GBP 50x68x8 FKM

34 35

Chapter 7Spare parts

How to order spare partsFor ordering spare parts, you always must inform the manufacturer of the machine’s serial numbe r.Please contact:

The Green Machine IndustrialP.O. Box 1083600 AC Maarssen, The NetherlandsTel.: +31 (0) [email protected]

List of available spare parts

English

36. EC070113 Spry hose37. EC070116 triangular support for spry hose38. EC070135 Spiral pipe39. EC090632 Splash guard40. EC040025 Bin 21 liters

36 37

English

36 37

English

38 39

English

36 TM

Attachment ADeclaration of conformity

•

Declaration of conformityAccording to Directive 2006/42/EC, annex II point 1.A

The Manufacturer: Ecofast Italia S.r.l. Name of the person autorized to manage the technical file: Ing. Piero Rusconi Clerici CEO Hereby declares that the following machine:

complies with the following directives:

2006/42/EC – Machines Directive• 2004/108/EC – EMC Directive

Main technical standards applied:• UNI EN ISO 12100:2010• UNI EN ISO 13857:2008• CEI EN 60204-1:2006• UNI EN 953:2009

English

Europe Distributor The Green Machine Food Waste Processors

The Green Machine IndustrialP.O. Box 1083600 AC Maarssen, The NetherlandsT +31 0 [email protected]