Safety in Design and Installaon of Heat Recovery Steam ... · Safety in Design and Installaon of...

-

Upload

vuongtuyen -

Category

Documents

-

view

225 -

download

3

Transcript of Safety in Design and Installaon of Heat Recovery Steam ... · Safety in Design and Installaon of...

SafetyinDesignandInstalla0onofHeatRecoverySteamGenerator

CEPSI2016byJohnnyKwong

24Oct2016

2

Content

● Introduc9on● HRSGsinLammaPowerSta9on● CommonRisksandFailuresofHRSG● SafetyforDesign● SafetyforInstalla9on● Conclusion

3

Introduc0on

Stage I L1-3 : 250 MW x 3 (1982-84) Stage II L4-6 : 350 MW x 3 (1987-92) Stage III L7-8 : 350 MW x 2 (1995-97)

8 Coal-Fired Units 2,500 MW

GT1 : 55 MW (1978) GT2,3,4,6 : 125 MW x 4 (1989-90)

5 Oil-Fired Open Cycle GT Units 555 MW

2 Gas/Oil Dual-Fired CCGT Units

GT57CC : 345 MW (2002) L9 : 335 MW (2006) 335 MW

345 MW

~3,737 MW (Incl. Renewable)

Total Installed Capacity :

800kW

1MW

● Lamma Power Station and Extension

4

Introduc0on

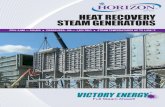

● Heat Recovery Steam Generators (HRSG) have been adopted widely due to growth in CCGT plants

● HRSG is essentially a Boiler but without firing; it captures residual heat of high temperature flue gas (typically 540-650oC) and generate steam for power generation and/or district heating;

● Heat present in flue gas falls typically within 40-70% of initial fuel energy of a F-class CCGT

5

HRSGsinLammaPowerSta0onCCGT Unit GT 5&7 L9 L10 (future)

Flue Gas Flow Vertical Vertical Horizontal

Pressure Stages HP, LP HP, IP, LP; With Reheat

HP, IP, LP; With Reheat

Drum Type ü ü ü SCR/CO Catalyst X X SCR catalyst

Supplementary Firing X X X

Casing design Cold/Hot casing Cold Cold

Steam Output 195.15 t/hr 512 oC

73.5 kg/cm2g

279.7 t/hr 539.9 oC

109.4 kg/cm2g

294.7 t/hr 582 oC

139.4 kg/cm2g

1 Preheater 2 LP evaporator 3 LP superheater 4 HP economizer 5 Catalyst 6 HP evaporator 7 NH3 injection 8 HP superheater

Typical Vertical Design HP drum

LP drum Feedwater tank

1 2 3 4 5 6 7 8

Typical Horizontal Design Feedwater tank LP drum HP drum

8 7 6 5 4 3 2 1

6

CommonRisksandFailuresofHRSG● Corrosion

Ø General Corrosion Ø Stress Corrosion Cracking Ø Flow Accelerated Corrosion

● Low Cycle Fatigue ● Water/Steam Cycle Chemistry

7

SafetyforDesignofHRSG

● General Corrosion – Rate of corrosion

Relative Corrosion Rate of Fe and Cu

8

SafetyforDesignofHRSG

● Prevention Measures Ø Materials Selection + Water Chemistry (pH, conductivity..)

SA 299

/Deaerator

9

Flow Mal-distribution

• Mechanical configuration

• Un-even heat absorption during transient/load change

• High duct firing • Poor venting/drainage

Off-design Water

Chemistry

• Poor control of water quality (global FAC effects)

Poor Materials Selection

for vulnerable

section

• Low grade CS vs Higher Cr alloy steel (e.g. Grade 11 or above)

SafetyforDesignofHRSG

● Flow Accelerated Corrosion

10

SafetyforDesignofHRSG

● Wear Rate of Carbon Steel and Various Alloy Steels

11

SafetyforDesignofHRSG

● Wear Rate of Carbon Steel and Various Alloy Steels

12

SafetyforDesignofHRSG

● Fatigue (Low Cycle Fatigue)

Two-shift Cycling

• Fast Start up/Shut down would increase thermal stress

Presence of condensate

• High difference in tube-to-tube temperature

• Inadequate drains/vents

Unresolved thermal

expansion at harps

• Configuration that inhibit expansion, thus induces stress

13

SafetyforDesignofHRSG● Fatigue (Low Cycle Fatigue)

14

SafetyforDesignofHRSG

● Stress Corrosion Cracking

Corrosive Environment

Tensile Stress

Susceptible

Material

SCC

15

SafetyforDesignofHRSG● Water Cycle Chemistry

Failure Mechanisms

Affected by Water Cycle Chemistry

CF

FAC SCC

Hydrogen Damage Pitting

Deposit Related – Overheating or

Caustic Gouging

Controlled parameters: Oxygen, pH, Conductivity Insoluble, Carryover, TDS

Independent of Cycle Chemistry

LCF/HCF, Weld Failure,

Thermal Fatigue, Creep,

Cold end tube corrosion

With established Action Plan, such as blow down, chemical dosing, etc. in case of deviation

16

SafetyforDesignofHRSG● All Volatile Treatment (Oxidizing) – AVT(O) ● Reddish color is the Hematite (Fe2O3) formed on the wall

while the black color is mainly the Magnetite (Fe3O4). AVT(R) AVT(O

)

17

SafetyforDesignofHRSG

● HRSG Dry Lay-up Arrangement (Preservation) Ø Dry Lay-up

Dehumidifier

FWP

18

SafetyforInstalla0onofHRSG

● WelderQualifica0onTest

19

SafetyforInstalla0onofHRSG

● Pre-WeldingInspec0on

20

SafetyforInstalla0onofHRSG● HRSGModuleMovingInandLiMing(HorizontalHRSG)

21

Conclusion

● Safety in design and installation is a must in securing the performance of HRSG within its design life (~30 years).

● Design-code compliance is the minimum requirement only;

More attention to be paid on the HRSG failure mechanisms and the prevention measures in design stage.

● Live monitoring of water chemistry & metal temperature with good maintenance /lay-up practice are required to ensure the operation is within design boundaries.

KopKhunKrap!ThankYou!