SAEL s.r.l. Garda Papermills Garda 2016 ENGL.pdf · by 1Mbit CAN BUS high speed MULTIMASTER net,...

Transcript of SAEL s.r.l. Garda Papermills Garda 2016 ENGL.pdf · by 1Mbit CAN BUS high speed MULTIMASTER net,...

Engaged by LECTA group, SAEL madethe BIELOMATIK sheeter – P1089/DD-S - revamping at Riva del GardaPlant. The main Lecta objective wasto solve the production stops causedby the old automation system as wellas the unavailability of the spareparts. Beside this goal, together withMILLTEX, Sael implemented thelongitudinal cut format numbers. TheSael/Milltex partnership ensured theon time delivery as well as thewarranties required by Lecta.The whole supply involved:

- Old DC main motors electricalcabinet substitution with a newone by Sael having: end line; ACdistribution and link with theexisting cabinets; DC-Bus andnew AC motors Inverter

- Original wirings modification insidethe cabinets (controls placed

TTTTTececececechnolohnolohnolohnolohnologggggyyyyy

by: PPPPPaolo aolo aolo aolo aolo Andrighetti SAEL sAndrighetti SAEL sAndrighetti SAEL sAndrighetti SAEL sAndrighetti SAEL s.r.r.r.r.r.l..l..l..l..l.

above the machine) – re-used –and the logic PLC S5 N.1replacement vs. a new PLC S7(supplied and properly wired withinterface options – plates pre-wired; ET200S remote stations;

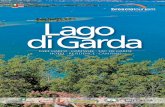

BielomaBielomaBielomaBielomaBielomatik P1089/DD-S Sheeter – end partik P1089/DD-S Sheeter – end partik P1089/DD-S Sheeter – end partik P1089/DD-S Sheeter – end partik P1089/DD-S Sheeter – end part.t.t.t.t. R R R R Reeeeebbbbbuilding auilding auilding auilding auilding at Gart Gart Gart Gart Gardadadadada

SAEL s.r.l. Garda Papermills

INTO THE PAPER ELECTRONIC AUTOMATIONEVER, SAEL REBUILT A BIELOMATIKSHEETER IN 15 DAYS AT CARTIERE DELGARDA. THE OLD CABINETS HAVE BEENRENEWED ALLOWING A THREE SHIFT/DAYPRODUCTION. THIS PROJECT WAS ANELECTRO-MECHANICAL UPGRADE – MADEIN COMINATION BETWEEN THE PAPER MILLTECHS AND THE SAEL AS WELL – FOCUSEDON BETTER EFFICIENCY, CUTTING QUALITYAND HIGHER SPEED: AAAAACTUCTUCTUCTUCTUALLALLALLALLALLYYYYY,,,,, THETHETHETHETHESPEED HASPEED HASPEED HASPEED HASPEED HAVE BEEN INCREASED BY 10%.VE BEEN INCREASED BY 10%.VE BEEN INCREASED BY 10%.VE BEEN INCREASED BY 10%.VE BEEN INCREASED BY 10%.

THANKS TO THE SOFTWARE IMPLEMENTAITON THE MANAGEMENT LINE GOT A GREAT BENEFIT INTERM OF CONFIGURATIONS AND VERASILITY.

interfacing relays and terminalbox.

- Internal components and wiringsmodification inside the existingcabinets (controls placed underthe machine) – re-used – and

TTTTTececececechnolohnolohnolohnolohnologggggyyyyy

Complete view of the sheeter rebuilt at Cartiera del Garda, LECTA Group.

the logic PLC S5 N.2 replacementvs. a new PLC S7 (supplied andproperly wired with interfaceoptions – plates pre-wired;ET200S remote stations;interfacing relays and terminalbox.

- Complete wirings dismantling insidethe existing cabinets (controlsplaced above the machine) – re-used as suppor t, and SMPmicrocontroller unit substitutionvs. the new PLC S7 supplied andproperly wired with interfaceoptions – plates pre-wired;ET200S remote stations;interfacing relays and terminalbox for a “pin-to-pin” to theoriginal SMP unit.

- Complete wirings dismantling insidethe existing cabinets (controlsplaced above the machine) – re-used as support, and “HXE” unitsubstitution vs. the new PLC S7supplied and properly wired withinterface options – plates pre-wired; ET200S remote stations;interfacing relays and terminalbox for a “pin-to-pin” to theoriginal HXE unit.

- Main Drive control unit par tialmodification (+P10) – a newpre-wired plate with a 15" LCDtouchscreen panel, will replacethe original controls. Actually thispc panel will have a PROFINETinterface for CPU master and thenew PLC S7 installed.

ONE Drive

- Main Drive control unit partial modification (+P11) – anew pre-wired plate with a 15" LCD touchscreen panel,will replace the original controls. Actually this pc panelwill have a PROFINET interface for CPU master andthe new PLC S7 installed.

- New Knives positioner system – STEP Drives for the STEPmotors control – mounted on two pre assembledplates. The two plates will be installed into the existingSMP (+H10) cabinet.

- Main pull drive by AC motors, as well as knives and belts– mechanical engineering, installation and supervisionincluded -.

- New longitudinal knives Dines TOP to TOP drive and cabinetsupply. This drive is used for the changing size – byadding a fifth knife with all the mechanical options -.Also in this case the engineering, the mounting andthe supervision are included.

- Q.ty 12 new programmable multiturn slip ring transducers,used for the open/closing tail stock position.

- Q.ty 6 new load cell amplifiers – PROFIBUS interface –used for the real unwinding paper pull measurementat each unwinding station. This system implementedthe paper pull management of every single unwindervia PLC S7 automation control – by a dedicated mainscreen option for the pull setting -.

Up view: Electrical wirings, Knives by Dines + SMP-HXE electronic and the old Bielomatik DC motors aborted

· Old main drive DC motorsreplacement by AC motors andgear motors whenever required.First belts motor displacement –sized according to the machineneeds – in emulation of theexisting DC motors. Beside thenew AC motors, the SAEL supplyalso included the options as wellas the engineering and themounting; the mechanical andelectrical supervision; the newfixing baseframes.

- Turnkey team supply for all themechanical and electricaloperations like:

o Existing transducers replacementand positioning.

o Diameter reading transducerreplacement.

o Machine main display replacement.o New engineering station composed

by: PC; 22" LCD monitor ;keyboard and trackball;ETHERNET double interface – forIntranet and LAN/WAN remoteassistance –paired to the newdrive for:

o DRIVES/Mastercan ONE SAELProgramming/Diagnostic (SAELsAZ Runner licence included).

production recipes and pre-setautomatic recall. Below the main datato be entered:· Unwinding coils/material type.· Production sizes.· Line speed.· Unwinding material pull· Rectifiers positioning.· Unwinding groups automatic

positioning.· Over lap trolley automatic

positioning.· Longitudinal knives and wing

automatic positioning.· Reams sizes.· Working pressures / loads.

PrPrPrPrProduction roduction roduction roduction roduction reeeeeporporporporpor tststststs

A SQL database will manage and

o PLC S7 and PROFIBUS/PROFINETnets Programming/Diagnostic.Temporary operator panelemulation in case ofmaintenance and documentationmanagement (PDF diagrams;hand books; S/ Manager licence,and so on).

o IWSA Remote assistance (LAN/Router INTERNET connectionupon the customer)

o New 32" LCD Wide screen monitor(OPT. 3) Programming/Diagnostic with future possiblecustomizations upon demand(Programming licence included).

Recipe management integrationRecipe management integrationRecipe management integrationRecipe management integrationRecipe management integration

Made via the main operator panel, by

SX: new AC motors vs. old DC motors, before the rebuildingTOP: Operations during the Cabinets Drive wirings. Old cabinets re-used.

compute several data from the PLC. The computing willprovide data in a similar way to the original versionbenchmarked by the customer.Below some data form our SQL database, to be read bythe customer SW system. The merge of the two system willprovide:

· Stops repor t (root-causes, quantity, times,percentage).· Daily production report (times, quantities, scrapcauses, production data).· Monthly production report (times, quantities, scrapcauses, production data).· Shift production report (times, quantities, scrapcauses, production data).· Single Order production report (times, quantities,scrap causes, production data).

IWSA – InterIWSA – InterIWSA – InterIWSA – InterIWSA – Internet net net net net WWWWWororororor ldldldldldwide Sael wide Sael wide Sael wide Sael wide Sael Assistance –Assistance –Assistance –Assistance –Assistance –REMOREMOREMOREMOREMOTE TE TE TE TE ASSISTASSISTASSISTASSISTASSISTANCEANCEANCEANCEANCE

The system includes the IWSA (Internet worldwide SaelAssistance). Via internet, in a real time, it is possible tosupport any kind of software trouble or simply install newsoftware, updates, modifications up to the PLC. Supervisorand SAELs Drives. IWSA has been used for thecommissioning as well: thanks to its architecture we linkedthe supervisor system to a plant Host, or other devices, viaEthernet net.

.............THE JOB .............THE JOB .............THE JOB .............THE JOB .............THE JOB AAAAAT T T T T THE PLANTTHE PLANTTHE PLANTTHE PLANTTHE PLANT............................................................

The supply is a “turn e key” who encloses the placing ofthe new electrical cabinets, modifications of the existingcabinets and the rebuilding of the electrical connections;the mechanical mountings – made in partnership with INDEXA ITALIA 2 -. Since the first tests during the star up, the customer got a quality implementation in terms of cut,machine speed: numbers who can easily drive to a short term Return Of Investment!The daily making went through many aspects normally discussed between the mechanical engineer/supplier and theElectronic engineer/supplier. Standing in front of a running machine, Sael – with 30 years of experience – made adeep investigation of the Bielomatik management system. This recognition allowed to re-study some actions that theoperator has to do avoiding production scraps. All the motor settings, the algorithms and the sequences have beenintegrated and offered by a new Siemens PLC S7 – with a Siemens MP277 video-keyboard – gave a better interfacebetween the operator and the machine. The automation is managed by a 314C CPU – with a profibus net – is on linewith the Drives and the remote I/O. The “INTELLIGENT DRIVE” Drives communication is also made via CANBUS, with arobust and fast transmission of the data to the Pull, Knife, Belts and Rolls. Through this net is managed a synchronizationbetween the Pull motor and the Knife motor too – with the best accuracy and short time during the change -.

UP: PLC S7 300 used vs. the old115U

SX: all the sensors and transducershave been replaced with standardproducts (Profibus based).

The original DC motorization havebeen replaced by AC laminatedmotors driven by SAELs VD inverters.Our drives use the samecommunication independently to theapplication – AC and DC – and thiswas a main strength for this job. As

reliable and engineered for the papermill industry – by a custom bridgeboard based on CAN-buscommunication. Without extra costsour inverters and dc converters canwork with any PLC available on themarket by exchanging reading andwriting words.Every SAELs product is engineeredand made to meet the customersneeds, using less componentspossible. Every application realizedwith our drives requires a simple PLConly. Each drive – AC or DC – isequipped by the same main board: itmeans less spare parts on stock (justone regulation board, IGBT orThyristor and that’s it). Our AC or DCdrives are up to 1MW. To be on linewith our customers need, as well asthe technology evolution, we have acommitted Team working on R&D andSoftware developments. By anobjective benchmark vs ourcompetitor s, there are maindifferences on Paper Mill main drive,Calander, Winder or whatever else:The performances got with a specific,fully dedicated drive as the SAEL“Intelligent Drive” are fare abovecompared anything else available onthe stand alone market. Beside theown drives, the international majors,use closed systems: in other words,it wont be possible for any systemintegrator to parallel his offer to ABB®, or SIEMENS® using stand aloneproducts. That’s why, at SAEL, wedecided to develop our own completepackage, and trying to make it betterand better! This is the key to competeagainst the international brands.Based on the “digital sectioning drive”our system is the first without thecascade MASTER process: actuallythe intelligence is inside the AC or DC

soon as the drive joins the PLCsProfibus net, it receives and sendsspeed and alarms information aboutthe conver ter/motor. More over itexpands the PLCs I/O becoming an I/O likely. Each DRIVE board, which has4 analogical input, 4 analogicaloutput, 8 digital I/O and 2 encoderinput up to 200khz, sends all thosedata to the PLC, getting the systembetter, richer for any regulation andless expansive in terms of lessperiphery needs. Another importantfeature of this rich architecture is thealgorithm computing inside the drivewithout overloads of the PLCs CPU.Positioning, servo diameter, signalfiltering using 3rd degree algorithms,computing, electrical trees, cam, loadcell regulation, speed adaptations,are possible. All the results are sentto the PLC: This allows the regulationof many other motors or externaldevices.Many realizations were made usingSiemens PLC S7 and SAEL ownproducts (“Intelligent Drive” invertersand dc converters), easy to use,

itself. Our solution is highlyappreciated by the customers, theoperators and the technicians of thepaper industry, because it perfectlyfits to their applications. Supportedby 1Mbit CAN BUS high speedMULTIMASTER net, the regulation ismade inside the AC or DC Drive. Theclassical PROFIBUS MASTER/SLAVEsystems are fare behind our solution,

because too many nodes in thenetwork slow down thecommunication speed, tremendously!The cascade offered by our systemoffers 6Msec speed per 60 AC or DCmotors. More over, beside that, SAELoffers its “REBORN” device: the bestsolution to re-use your old drive andsaving 50% off at least! We havebeen pushed to this incredible solution

because all drives get older, and wedo care about customers and theirsavings! REBORN is highly efficient,great quality, tough and rough. Wereplace the ole regulation board withour ONE “intelligent drive”, re-usingthe existing old components possible(eg: SCR bridge, Fuses, Reactance,etc)

The new monitor 40” to show the production data of the sheeter, Cartiera del Garda.