Roller Mills

-

Upload

sarah-frazier -

Category

Documents

-

view

6 -

download

0

description

Transcript of Roller Mills

-

COAL PULVERISER

-

PULVERISER IS USED IN POWER PLANT.CRUSHING THE COAL.EFFICIENT COMBUSTION OF COAL.

FUNDAMENTAL REQUIREMENT OF PULVERISERINTRODUCTIONFEED SYSTEM.AIR SYSTEM.GRINDING,CLASSIFYING & CIRCULATINGCOAL ANALYSISMOISTURE, HGI, GCVPERFOMANCE.LOAD. Tons/HrFINNESS.>70% through 200 mesh> 99 % through 50 mesh

-

RAW COAL FEEDING SYSTEMSUPPLIES UNINTERRUPTED FLOW OF RAW COAL FROM COAL BUNKER TO PULVERISERREGULATE THE FLOW OF COAL CORRESPONDING TO BOILER LOAD,CALORIFIC VALVE etc.,TYPES OF COAL FEEDERS VOLUMETRIC FEEDER.SCRAPPER/DRAG CHAIN FEEDER.ROTARY VOLUMETRIC FEEDER.GRAVIMETRIC FEEDER.MECHANICAL WEGHTING.ELECTRONIC STRAIN GUAGE.

-

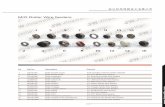

ROTARY VOLUMETRIC FEEDER

GATE(HINGED LEVELING)FROM COAL BUNKERSPIDER WHEELTO PULVERISERGATE(HINGED LEVELING)PIV MotorCLUTCH Assemble

(VOLUMETRIC FEEDER)

-

LOAD CELL.COALSPAN FLOW MILLI-VOLT OUT PUT.SPEED FREQUENCY-OPTICAL ENCODERDEAD WEIGHT SCRAPPER DELIVERY POINT.CONVEYOR CLEANING.

ELECTRONIC STRAIN GAUAGE

(GRAVIMETRIC FEEDER)

-

AIR SYSTEM (COAL DRYING & TRANSPORTING) COLD PRIMARY AIR SYSTEM HOT PRIMARY AIR SYSTEM TEMPERING AIR SEAL AIR PURGE AIR

-

MILLING SYSTEM(GRINDING,CLASSIFING & CIRCULATING)TYPES OF PULVERISERSSPEED OF ROTATION OF MILL (RPM)

Slow Speed (15 25 rpm) - Ball / Tube Mill.

Medium Speed (30 100 rpm) - Bowl Mill, Ball & Race Mills.

High Speed (600 1000 rpm) - Beater Mill / Hammer Mills.SHAFT ORIENTATION

Horizontal Shaft Mills - Generally slow speed & High Speed Mills. Vertical Shaft Mills -Generally Medium Speed Mills.

-

BALL / TUBE MILL25% to 30% of cylinder volume is filled with wear resistant balls of 30 60mm dia.The cylinder is rotated at a speed of about 20 rpm.Suitable for hard coals.Highly reliable & requires low maintenance.

-

HOT PRIMARY AIRCOAL / HOT AIR MIXING BOXCLASSIFIERSFROM COAL FEEDERCOAL FEEDERTO BURNERS / WIND BOXOversize returnHOT PRIMARY AIRBALL / TUBE MILL

-

BALL / TUBE MILLCLASSIFYING & CIRCULATINGTAILINGMIXING BOXBY-PASS AIRclassifierPulverised coalCLASSIFING VANESCLASSIFING CONE

-

BALL / TUBE MILLGRINDING MECHANISM

Pulverization due to Impact.

Pulverization due to Attrition.

Pulverization due to Crushing.

-

PULVERIZATION DUE TO IMPACTCoal FeedingArmour PlateOuter ShellSteel Ball (40-60mm)

-

PULVERIZATION DUE TO ATTRITIONRubbing CoalArmour PlateOuter ShellSteel Ball (40-60mm)Friction/Centrifugal force

-

PULVERIZATION DUE TO CRUSHINGcrushingArmour PlateOuter ShellSteel Ball (40-60mm)Friction/Centrifugal force(Reverse direction)

-

BOWL MILLThe most widely used mill for grinding coal.

The raw coal is fed into the center of the mill.

This is an intermediate speed pulverizer.

The vertical shaft rotates at a speed 30 50 rpm.

-

CLASSIFIERGRINDING CHAMBERROLLERBOWLMILL BASEGEAR & DRIVE UNITCLASSIFIER VANESHOT AIR78BOWL MILL

-

SUCTION MILL / NON-PRESSURISED

-

Mill Is Operating At Negative Pressure

Suction Is Created By An Exhauster Fan Placed After Mill & Handle High Temperature Pulverized Coal & Air Mixture.

Each Mill Is Having Its Own Exhauster Fan.

The Mill & Exhauster Fan Is Operated By The Common Motor.

Tempering/ Cold Air Is Sucked From Atmosphere & Controlled By Regulating Damper.SUCTION MILL / NON-PRESSURISED

-

CLASSIFYING & CIRCULATINGGRNDING CHAMBER ROLLERCLASSIFIERPULVERISED COAL WITH COARSER PARTICLES

COARSER PARTICLES

CLASSIFING CONECLASSIFING VANESBOWL MILL

-

GRINDING MECHANISMPulverization due to Crushing:- Crushed Coal In Between Roller & Bowl.

Pulverization due to Attrition:- Rubbing The Coal With Bowl Or In Roller.

BOWL MILL

-

The primary airflow measurement by round cross-sectional area venturis - flow nozzles provided to measure and control primary airflow to improve mill performanceBOWL MILL

-

Similar to radial fan.Beater wheel harden blades.Pulverization is more effective high speed of blades & excellent drying facility.FD fan air is used for drying & transporting.HAMMER/BEATER MILL

-

INLET SIDE DOORGRINDING CHAMBERCLASSIFIERBEATER WHEELBEARINGDRIVE6HAMMER/BEATER MILL

-

CIRCULATING & CLASSYIFINGCLSSIFIERPULVERISED COAL WITH COARSER PARTICLESBEATER WHEELCOARSER PARTICLESFOR FURTHER GRINDINGFINEED COAL TO BURNERCLASSIFING VANESCLASSIFING CONEHAMMER/BEATER MILL

-

HAMMER/BEATER MILLGRINDING MECHANISM

Pulverization due to Impact.

Pulverization due to Attrition.

Pulverization due to Crushing.

-

COAL TO BEATER WHEELREJECTS OUT LETHAMMER/BEATER MILLPULVERIZATION DUE TO IMPACTOUTER CASINGBEATER WHEEL

-

COAL TO BEATER WHEELREJECTS OUT LETOUTER CASINGBEATER WHEELHAMMER/BEATER MILLPULVERIZATION DUE TO ATTRITION

-

CRUSHED COAL TO CLASSIFIERREJECTS OUT LETOUTER CASINGBEATER WHEELHAMMER/BEATER MILLPULVERIZATION DUE TO CRUSHINGCRUSHED COAL

-

FACTORS AFFECTING FINNESS

FUEL- Grindability Of Coal.- Moisture Content.- Calorific Value.- Size Of Coal.

MILL- Mill Wear.- Air Thro Mill.- Gap Between Roller & Bull Ring Segment.- Spring Tension Of Roller.- Condition Of Roller & Bull Ring Segment.

- Ball Loading for ball mill.- Armour plate condition for ball mill

MILL

-

OPERATIONAIRFLOW CONTROL.AIR TEMPERATURE CONTROL.FINNESS.ARMOUR PLATE CONDITION.BALL LOADINGMAINTENANCE BALL LOADING.ARMOUR PLATE CONDITION & REPLACEMENT.CHECK THE MILL LEVEL & CONTROL NOISE..CLASSIFIER & CLASSIFIER VANES CHECKING.CONDITION OF BEARING.

OPERATION & MAINTANACEBALL & TUBE MILL

-

OPERATIONAIRFLOW CONTROL.AIR TEMPERATURE CONTROL.LOAD & FINNESS.ROLLER SPRING TENSION.CLASSIFIER VANES SETTING.MILL REJECTS.MAINTENANCEBULL RING SEGMENT REPAIR & REPLACEMENT.ROLLER REPAIR & ROLLER REPLACEMENT.CLASSIFIER & CLASSIFIER VANES CHECKING.CONDITION OF BEARING.

BOWL MILL

OPERATION & MAINTANACE

-

BEATER MILL / HAMMER MILLMAINTENANCEBLADE CONDITIONCLASSIFIER SETTINGCONDITION OF BEARING

OPERATION & MAINTANACE

-

DAILY CHECK

LUBE OIL SYSTEM.BEARING TEMPERATURE.REGULAR MAINTENANCE FOR ALL MILL

-

****************