Roll 555 - Tecnau · 3 Rewinder 555 *Length will vary by printer model. 21' 8" / 6600 mm * 22' 8" /...

Transcript of Roll 555 - Tecnau · 3 Rewinder 555 *Length will vary by printer model. 21' 8" / 6600 mm * 22' 8" /...

E m p o w e r i n g D i g i t a l P r i n t

Ro

ll

T

o

Ro

ll

S

ol

ut

io

ns

Roll 555Roll out productivity

9 Speed up to 500 fpm

9 Reliable feeding

9 Maximum printer productivity

9 Unattended printing

The Roll 555 solution includes

the Unwinder 550 and the Rewinder 555.

With hours of production between loading and unloading, there is no more efficient solution for handling digital printer output than the Roll 555.

Global service and around-the-clock support help ensure our reputation as the industry’s reliability leader. Our products increase productivity, cut labor and paper costs, and even make new applications possible - Tecnau solutions truly empower digital print to help you do more with less.

Experience the efficiency of rewinding printed rolls for post-processing in any application, including direct mail, billing and statements, and even print on demand. The Roll 555 solution operates with today’s fastest web-fed digital printers, and prepares you for the future with UP3i compliance.

Center-shaft driven, this solution rewinds rolls at speeds up to 500 feet per minute, and is ideal for special applications such as labels. With proven reliability, operators can count on extended run times as well as minimal intervention.

SPECIALPromo

-28

Promo

Promo

VISION &CONTROLPROCESSORSCONTINUOUS

CUT & STACKCONTINUOUS

FANFOLDREADY

SOLUTIONSBOOK ONDEMAND SHEETFEEDERSROLL TO ROLL SPECIALS BOOKSSOLUTIONS PRODUCTS

FLAGS

APPLICATIONS

Promo

GRAPHIC ARTS

Promo

Promo

Promo

TRANSPROMO ON SITE SUPPORT SPARE PARTS SERVICE TEAM REMOTE ASSISTANCE

BUFFER

©2015 Tecnau. All rights reserved. The Tecnau name and logo and Web Vision are trademarks of Tecnau. Tecnau reserves the right to make any technical amendments without prior notification.16112015

w w w . t e c n a u . c o m

Europe Italy +39 0125 631678 [email protected] +46 372 256 00 [email protected]

Americas USA +1 978 608 0500 [email protected] Pacific China +86 159 00710147 [email protected]

Singapore +65 6793 9478 [email protected]

Configuration Example

hours without the need for operator atten-tion to loading and unloading.

Optional CapabilitiesCenter SlitterSlit web in center and rewind two rolls to-gether.

Automatic Tension ControlSwitch easily and reliably between multiple applications and paper weights.

WebVision™Capture large, high-resolution images of the entire web with no operator adjustments. WebVision verifies bar codes for readability, detects small image artifacts, and more.

Roll cartsEasily move, store and load paper rolls.

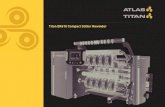

Roll 555Roll out productivity

Rewinder 555 Easy transport

Technical Specifications

Performance / Media

Speed max 500 ft/min 150 m/min

Print Simplex, Duplex

Feeding Pinfed or Pinless

Paper weight 10.5# bond - 140# index, 40 - 250 gsm(above 200 gsm with heavy paper kit and subject to application review)

Roll diameter 4” - 52” 100 mm - 1320 mm

Roll weight max 1389 lbs 630 kg

Core size 3, 5, 6” 70, 120, 150, 200 mm

Web tension Loose

Web width 8” - 21.25” 200 mm - 540 mm

Electrical

Power208 VAC, 1 Phase, 15A, or200-240 VAC 50/60 Hz, 10A

Center-shaft drive

3 2

1 Unwinder 5502 Duplex Printer3 Rewinder 555

*Length will vary by printer model.

21' 8" / 6600 mm *

22' 8" / 6900 mm

*

2

1

The Roll 555 solution features the Unwinder 550 and Rewinder 555 which work in con-junction with a Loop Control to produce high quality, tightly wound rolls for prob-lem-free feeding of inserters or other finish-ing equipment.

The center-shaft driven Unwinder 550 feeds a roll of paper up to 21.25” wide and 52” in diameter into the printer for continuous printing. Once the paper is printed, the Loop Control acts as a buffer between the printer and Rewinder 555.

The Rewinder 555 then rewinds up to a 52” roll of paper at speeds up to 500 feet per

minute. Standard features of the Re-winder 555 include UP3i compliance, an interactive touch screen display and compatibility with multiple core sizes. Options are also available for auto-mated web guides, a center-s l i t t ing device and auto-matic tension control for increased com-patibility with a wide variety of applications and paper weights. Once printed forms are rewound, they can then be transported to another Unwinder 550 to feed an inserter or offline cutter. Optional roll carts make roll handling, loading and unloading easy.

All components are compact, and are de-signed to dramatically improve work-flow. The Roll 555 solution feeds your printer for