Role of Ergonomic Factors A Leather Garment-Based SMEs of ...

Transcript of Role of Ergonomic Factors A Leather Garment-Based SMEs of ...

symmetryS S

Article

Role of Ergonomic Factors Affecting Production ofLeather Garment-Based SMEs of India: Implicationsfor Social Sustainability

Koppiahraj Karuppiah 1 , Bathrinath Sankaranarayanan 1,* , Syed Mithun Ali 2

and Golam Kabir 3,*1 Department of Mechanical Engineering, Kalasalingam Academy of Research and Education,

Krishnankoil 626126, Tamil Nadu, India; [email protected] Department of Industrial and Production Engineering, Bangladesh University of Engineering and

Technology, Dhaka 1000, Bangladesh; [email protected] Industrial Systems Engineering, University of Regina, Regina, SK S4S 0A2, Canada* Correspondence: [email protected] (B.S.); [email protected] (G.K.)

Received: 29 July 2020; Accepted: 22 August 2020; Published: 25 August 2020�����������������

Abstract: This paper aims to identify, evaluate, and measure the ergonomic factorshampering the production of leather garment-based small and medium-sized enterprises (SMEs).Ergonomic problems faced by the workers largely impact the health of individuals and alsothe productivity of a firm. Based on experts’ opinions and a literature survey, three emergingcategories—namely, occupational disease, personal factors, and the industrial environment—witha total of twenty factors were identified to examine symmetrical impact in five leather garmentcompanies. In this research work, Cronbach’s α was evaluated to check the validity of the ergonomicfactors identified through the literature survey. Then, using the fuzzy analytic hierarchy process(FAHP), the identified ergonomic factors were evaluated. A sensitivity analysis was carried out tovalidate the robustness of the results obtained using the integrated approach. Outdated machinery,vibration, operational setup, fatigue, and poor ventilation and lighting are the top five factors inducingergonomic-related problems and hampering the production of the leather garment companies inIndia. These top ergonomic factors are the result of a failure in the provision of an ambient workingenvironment. Providing ergonomically designed working environments may lower the occurrence ofergonomic problems. The findings of this study will assist industrial managers to enhance productionrate and to progress towards social sustainability in Indian SMEs. The proposed symmetricalassessment in this study could also be considered as a benchmark for other companies in whichhuman–machine interaction is significant.

Keywords: ergonomic factors; fuzzy AHP; social sustainability; sensitivity analysis

1. Introduction

According to Workplace Safety and Health Guidelines, an Occupational Disease (OD) iscontracted as a result of exposure to risk factors in a working environment [1]. The incidenceof occupational disease is increasing among workers in production sectors [2]. This issue hasreceived much attention, but only after the United Nations, with their sustainable developmentgoals (SDG), defined sustainable industrialization as one of seventeen goals to alleviate poverty,improve workers’ health, and enhance social prosperity. In connection with the United NationsSDGs, many manufacturing companies in developed countries started providing a safe workingenvironment. However, manufacturing companies, especially small and medium-sized enterprises(SMEs), in developing countries, face challenges in following the ergonomics practice [3]. Providing an

Symmetry 2020, 12, 1414; doi:10.3390/sym12091414 www.mdpi.com/journal/symmetry

Symmetry 2020, 12, 1414 2 of 22

ergonomically designed working environment allows for the manufacturing company to producequality goods and to enhance the workers’ well-being, thus increasing employee productivity. The SMEsof developing countries, in recent years, have provided a considerable contribution to the economy ofmost developing nations [4]. India, a developing country, mainly relies on SMEs to combat problems,such as high unemployment, unstructured business organizations, and a lack of foresighted businesspolicy. Noticeably, these sectors hold a considerable share in a country’s Gross Domestic Product(GDP) and offer employment opportunities for economically weaker sections [5]. As a result, there aremore SMEs in India than large companies [6]. Although SMEs do provide employment and financialassistance for the economically marginalized and semi-skilled population, most of the SMEs are unawareof sustainable development goals [7]. As largely known, the sustainability concept covers three areas,including economic, environmental, and social areas. However, most industrial perspectives note theirprimary concern as economically sustainable success in financial markets [8]. Due to pressure fromthe customers for sustainable manufacturing practices and to meet the government’s environmentalnorms, the manufacturing sector has necessarily started to concentrate on matters of environmentaland social sustainability [9].

Social sustainability is related to the creation of a social system that enables the rise of workers’wealth and health, and that contributes to the nation’s development; environmental sustainabilityis related to the minimization of natural resource utilization [10]. Industrial factors affecting theworkers’ health may result in the frequent absenteeism of workers and in the loss of productionhours, which hampers the production rate. Hence, there is a need to understand the relationship andsynergy between the working environment and workers’ health. The problem in social sustainabilityoccurs mainly in four areas: internal human resources, external populations, stakeholder participation,and social performance issues [11]. In the four problematic areas, Indian SMEs primarily strugglewith the utilization of internal human resources and social performance [12]. The Bureau of IndianStandards (BIS) states that an industry’s workspace and work environment should be designed inaccordance with the anthropometric dimensions of the workforce and environmental firms. However,most of the SMEs do not adhere to these standards; many are unaware of the importance of theergonomic problems associated with their production [13]. The SMEs were of the mindset that theycan hire workers for a minimum wage who are ready to work in a poor working environment [14].Working under such environments may lead to painful disorders in the muscles, joints, nerves, tendons,and soft tissues of the body, which are collectively called “work-related musculoskeletal disorder(WMSD)” [15]. The majority of the workforce in the manufacturing sector suffers from WMSDs,knowingly or unknowingly, and it results in low productivity [16,17].

Recently, in the health and safety management area, the concept of “vision zero” is gainingsignificant importance [18]. The concept emphasizes three core aspects, health, safety and well-beingof the workers. “Vision Zero” was first introduced by the International Labour Organization (ILO)in Singapore in 2017. There is a perception that “vision zero” will assist in industrial progresstowards SDGs. Though the concept was conceived in a constructive manner, reluctance and pooradherence by the business organization puts a big question on the success of the concept [19].Additionally, the industrial sectors in developing countries are not even aware of the concept. As aresult, the prevalence of occupational accidents and injuries is high in developing countries suchas India. In India, there exists a void in understanding the significance of ergonomic issues and itsinfluence on the production capacity of the manufacturing sector [20].

From the above information, it is apparent that the majority of Indian SMEs are not awareof the synergy between ergonomic importance and productivity. Further, research work onergonomic problems in the context of developing countries is very scant. In a study carried outby [21] Bernard et al. (2020), it was reported that the number of occupation-related illness in the Brazilianindustrial sector has increased progressively in the last 6 years. Not only in Brazil, but the prevalenceof occupational illness is also increasing steeply in many developing countries where the knowledgeand significance of ergonomics are meagre. This finding was endorsed by [22] Olabode et al. (2017) in

Symmetry 2020, 12, 1414 3 of 22

a study which indicated the absence of strict legislation and reforms as the reason for this. Such anindication suggests the need for potential intervention in industries based on the nature of occupationalhazards [23]. Most of the industries in developing countries, such as India, are unaware of ergonomicsand are reluctant to improve the working environment [24]. The condition is similar in other developingcountries such as China and Bangladesh, where socio-economic conditions hamper the improvisedergonomic conditions [25,26].

From this perspective, this study intends to identify the critical ergonomic factors that hamperproductivity based on symmetry principles. For this, we selected the leather garment industry, which isone of the principal niches of the Indian economy. In connection with this, this research work carriesout multiple case studies among workers from five leather garment companies. The reason why a casestudy in the leather sector is particularly important is because leather exports are expected to be 9 billionby 2020; 2019 figures stand at 5.85 billion (http://www.makeinindia.com/sector/leather). The findingsof the study under Indian leather garments can be used as a benchmark for other developing countriessuch as China, Indonesia, and Bangladesh as the socio-economic conditions are similar. Additionally,the economies of these countries are significantly enhanced by leather garments. As a matter offact, it should be noticed that many countries located in Asia are players in the global leather trade.Besides this, we have selected the leather garment industry mainly for two reasons. Firstly, the foreigntrade of India largely depends on the leather garment industry. At the same time, this industry facesserious issues such as workers’ safety, health risks, and employee rights. Secondly, this sector iswell-established and needs best practices in the social sustainability context to reshape its negativesocial reputation.

Given the importance of the ergonomic problem in the Indian context, this study addresses thecritical gap in the literature. First, the study made a literature review to identify various ergonomicproblems faced by workers in a manufacturing background and in the context of developing countries.From the literature review, the study identified 20 critical ergonomic factors and categorized threeimportant categories—occupational disease, industrial environment and personal factors. From theresults, the study postulates practical implications, such as providing reasonable pay irrespectiveof the gender, conducting frequent motivational programs for the workers, and the provision ofcomfortable and aesthetic working environments, which will reduce ergonomic problems withinworking environments. Such steps by the industries will assist in the progress towards SDGs.

The justification behind the proposed study is to understand the significance of ergonomic factorsand its influence on the production capacity of the manufacturing sector. In this study, Indian leathergarments were chosen as a case industry as they contribute significantly to economic development.Additionally, at present, India is on the track of massive development and has one of the mostanticipated economies in the world.

From this perspective, this research explores some questions for analysis, as follows:

I. What are the critical ergonomic factors affecting production in the leather garment industryof India?

II. What are the vital sustainability-related social implications of ergonomic factors in Indian SMEs?

To reveal the answers to the above research questions, an SPSS statistical software-assisted fuzzyAHP-based symmetrical assessment approach was used. Here, SPSS statistical software was utilizedfor statistical analysis of the ergonomic factors identified through a literature survey. Then, fuzzy AHPwas used to evaluate and prioritize those ergonomic factors. Finally, some implications for attainingsocial sustainability were suggested.

The remainder of the paper is organized as follows: Section 2 details the literature review, Section 3describes the materials and methods, Section 4 presents the data evaluation, Section 5 presents theresults, Section 6 provides discussion. Finally, Section 7 concludes this paper.

Symmetry 2020, 12, 1414 4 of 22

2. Literature Review

2.1. Emerging Economy

Emerging economies denote the economic conditions of the developing nations, which concentratemore on the production sector [27]. These developing countries are striving hard to attain the status ofdeveloped countries by giving great impetus to manufacturing sectors. The industrial advancement ofdeveloping countries is important for developed countries as their economy depends on developingcountries [3]. Recently, the World Bank classified world economies into four categories—high,upper-middle, lower-middle, and low. According to this, countries whose income is less thanUSD 1025 are low-income economies, and countries with an income greater than USD 12,375 arehigh-income economies. Under this classification, India, with an income of USD 2020, is categorizedas a lower-middle income economy [28]. From the report, it is evident that India is an emergingnation with a higher rate of unemployment, an unorganized business sector and a lack of foresight foreconomic reforms. Hence, the effective functioning of the present manufacturing sector may help inmoving the country’s economy forward.

2.2. Ergonomics Problems

Although most of the industries in India are desperate to increase their production rate, they arereluctant to make technological changes [29,30]. On investigation, it was identified that most of themanufacturing units in India are small and medium industries (SMEs), which have inadequate financialsupport. Leather garment industries are one of the SMEs in India contributing immensely to theeconomic growth of the country. Leather garments play an important role in alleviating poverty byproviding job opportunities to uneducated and semi-skilled people. Hence, SMEs in India are showinginterest in hiring workforces at minimal wage rather than implementing advanced manufacturingtechniques. The Bureau of Indian Standards (BIS) has listed several norms for industries—providingsufficient space and designing tools and machines in accordance with the anthropometric data ofworkers. However, the majority of the industries, especially SMEs, are not adhering to the rules andregulations [31,32]. Any discomfort felt by the workforce within the working environment shows itsimpact on the production rate of a firm. Industrial factors, such as plant layout, workstation design,working capacity, and working schedule, were identified as the primary potential threats affectingthe physical and mental health of workers [33,34]. Any shortcomings in providing industrial hygienemay largely influence the mental and physical health of workers as they are constrained to work ina limited environment for hours [35,36]. Such discomforts felt by the workers, both physically andmentally within industrial environments, are collectively termed as ergonomic problems [37,38].

2.3. Ergonomics in Leather Garments

Persons working in garments have to work under some common constraints such as limitedspace for movement, sizes/weights of scissors, poor lighting, and having to connect thread and needlewith great difficulty [39,40]. Repetitive low-load tasks in an awkward position for a long duration,lifting heavy weights, and moving items manually have been reported as the potential contributorsfor WMSDs [41–44]. The risk of WMSDs is usually related to age, stature, gender, frequency ofwork, and travel distance. Any machine or instrument used in an industry must be designed inaccordance with the anthropometric data of the workforce. Human factors, such as anthropometrydata, age, and gender, should be considered while designing a workplace’s layout or when assigningtasks, as these detail the physical well-being of a worker. Instruments designed without consideringanthropometric data are not ergonomically designed and may impose discomfort for workers [45].Prolonged use of out dated machinery in manufacturing results in vibrations which induce Hand-ArmVibration Syndrome (HAVS) and hearing problems among workers [46]. Leather garments rely onoutdated second-hand machines because they are cheap rather, than buying the latest machines which

Symmetry 2020, 12, 1414 5 of 22

are expensive. Attention must be given to anthropometric data as these have a huge impact on leathergarment production, where monotonous and repetitive activity is prevalent [47–49].

2.4. Factors of Ergonomics Problems

Ergonomics is a scientific approach concerned with the understanding of human interactionwith the machine and applies theories and principles for the optimization of human well-being [50].Ergonomics is a broad concept that covers wide areas—namely, physical (health, motion, perception),cognitive (attention, communication, knowledge, memory, and reasoning), physiological (emotions,relationships, self-management), and anthropometric data of humans—and their influence on theworking environment. Addressing the ergonomics problems is important for industries, as anergonomically designed working environment ensures an aesthetic working atmosphere. Aestheticworking environment enhances the working enthusiasm among workers, resulting in increasedproduction rates [51]. The nature of work is related to the kind of task the worker is performing and itdetermines the rate at which an individual is exposed to stress and pain [52]. Repeatedly carrying outa particular task over a long period may induce pain or soreness in a particular part of the body [53].

Human aspects are related to an individual’s physical capacity, upon which variation in therate of fatigue exposure varies among workers. Variation in the level of exposure to fatigue, loss ofstrength, age, and gender to a great extent influence the production rate of a manufacturing firm [54].Industrial hygiene is a crucial aspect in ensuring the safety and health of the workers. From providingproper ventilation and lightening to ensuring the safety of workers, industrial hygiene plays a criticalrole [55]. The factors of ergonomic problems are listed in Table 1.

Table 1. List of identified ergonomic factors affecting production.

Factors Sub-Factors Description Supporting Literature

Occupational disease (E1)

Spinal cord problem (E11) Prevalent among workers working in astatic position for a long duration [48]

Shoulder pain (E12) Occurs in persons working withinappropriate height tables [34,44,48,53]

Low Back Pain (E13) Common among workers engaged inlifting heavy weights [34,44,48,56]

Knee joint pain (E14)Predominant among workers involved in

movement of raw materials within theworkplace

[44]

Sore feet (E15) Seen among workers working in astanding position for a long duration [57,58]

Neck pain (E16) Repeated to-and-fro movement of theneck induces neck pain [34,44,48,56]

Wrist pain (E17) Use of heavy scissors cause wrist pain [34,44]

Personal factors (E2)

Fatigue (E21) Repeated, monotonous work withoutsufficient break intervals causes fatigue [59]

Job satisfaction (E22) Appraisal, rewards and salary hike for thework executed [60]

Self-motivation (E23) Internal force motivating the worker tomove towards the goal [61]

Conscientiousness (E24) Being hardworking, dutiful, and reliable [33]

Extraversion (E25) Ability to be cheerful, spread positiveenergy and spirited [62]

Competence (E26) Capacity of a person in carrying out thetask [33,62]

Role perception (E27) Central concept through which theindividual and workers interact Proposed in this article

Industrial environment (E3)

Vibration (E31) Old and repaired machine often causevibration [51,63]

Outdated machinery (E32) Old, traditional machines which are notergonomically designed [42,44]

Operational setup (E33)Adequate spacing must be provided

between machines and machines must bearranged on the basis of work sequence

[37,54]

Poor ventilation and lighting (E34) Adequate light and air circulation mustbe ensured [40,62,64]

Shock (E35) Proper insulation must be provided forelectric wires Proposed in this article

Industrial hygiene (E36) Pest and microbe free workingenvironment must be provided [65]

Symmetry 2020, 12, 1414 6 of 22

2.5. Ergonomics Based Research Gap in Indian Context

The knowledge of the ergonomics problem and its impact on production rate is very scant amongIndian industries, in particular, SMEs. Most leather garment producers (case industry considered inthis study) are trying to increase their production rate but most of them fail in addressing ergonomicproblems. The literature on ergonomic problems in the Indian context is not well established.Research on the ergonomics problems may help SMEs in enhancing their production rate. This researchwork intends to identify the common ergonomics problem faced by leather garment workers andsuggests some practical implications in overcoming ergonomics problems that may help industrialistsin increasing the production rate.

3. Materials and Methods

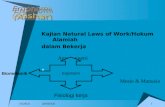

The research layout of this work is given in Figure 1. To identify the common ergonomic factorsaffecting the production rate of leather garment workplaces, we first reviewed relevant papers onvarious ergonomic factors and their roles/importance in leather garments of different countries; we thencollected those common factors (Table 1).

The data collected need to be reliable and valid for further analyses and future studies.Reliability refers to the degree of consistency. Validity refers to the degree to which the factorsconsidered measure the intended purpose. The reliability of the data was evaluated by calculatingCronbach’s α using SPSS tool. For this, 100 participants (50 males and 50 females), working for not lessthan 8 years from the five leather garment companies were asked to express their opinions about theimportance of the selected ergonomic factors via a five-point Likert’s scale (5–strongly agree, 4—agree,3—neutral, 2—disagree, and 1—strongly disagree) [55]. After consolidating the workers’ responses,Cronbach’s α was calculated for the identified ergonomic factors using SPSS statistical software [66].The value of cronbach’s α should lie between 0 and 1. In most general cases, a minimum α valueof 0.70 is considered as a criterion for establishing internal consistency. Sampling adequacy for anormal distribution was measured by Barlett’s test of sphericity and Kaiser–Mayer–Olkin (KMO) test.In some case—i.e., non-normal distribution—Levene’s test is used instead of Barlett’s test of sphericity.Using Barlett’s test of sphericity, the null hypothesis was eliminated—i.e., the variances are equal forall samples. Statically, the null hypothesis is given as H0 : σ1

2 = σ22 = . . . = σk

2. The Breusch–Pagantest is conducted to reject the null hypothesis of heteroskedasticity. The KMO value lies between 0and 1. KMO values between 0.8 and 1 indicate the sampling adequacy [67]. When the collected datasatisfied the validity and reliability test (Table 2), the ergonomic factors hindering production rateof leather garments were evaluated using FAHP. The factors and sub-factors of ergonomic causingproduction loss were also evaluated using FAHP.

The statistical results after the deletion of the factors are summarized in Table 3. The Cronbach’sα value, including all the factors, was 0.877, indicating that the data used for the study were reliable.Additionally, Cronbach’s α value of factors should be noted if the item deleted is less than 0.877.Hence, all factors under study are reliable. As far as the inter-item correlation matrix is considered,it should be noted that all the factor values are greater than 0.3. This indicates that the factors are likelyto have common factors.

Table 2. Reliability statistics.

Cronbach’s α Cronbach’s α Based on Standardized Items No. of Items

0.873 0.877 20

A combined fuzzy set based AHP using a linguistic scale [68] is widely used to solveactual-time problems that include human factors as it helps to clear up imprecise information.Generally, there are two types of fuzzy numbers—namely triangular and trapezoidal fuzzy numbers.In this study, trapezoidal fuzzy numbers were preferred over triangular fuzzy numbers as they are more

Symmetry 2020, 12, 1414 7 of 22

representative of linguistic estimations in ergonomic evaluation. In comparison with triangular fuzzynumbers, the trapezoidal fuzzy numbers offer more choice of expressions. In FAHP, the consistencyratio (CR) was calculated and it must agree with the CR value.Symmetry 2020, 12, x FOR PEER REVIEW 7 of 23

Figure 1. Proposed methodology to explore ergonomic factors affecting production.

Table 2. Reliability statistics.

Cronbach’s α Cronbach’s α Based on Standardized Items No. of Items

0.873 0.877 20

The statistical results after the deletion of the factors are summarized in Table 3. The Cronbach’s

α value, including all the factors, was 0.877, indicating that the data used for the study were reliable.

Additionally, Cronbach’s α value of factors should be noted if the item deleted is less than 0.877.

Hence, all factors under study are reliable. As far as the inter-item correlation matrix is considered, it

should be noted that all the factor values are greater than 0.3. This indicates that the factors are likely

to have common factors.

Figure 1. Proposed methodology to explore ergonomic factors affecting production.

Table 4 shows two tests that measure the data adequacy. The KMO measure of sampling adequacyvalue in this study was 0.802. High values (close to 1.0) indicate that the factor under study is suitablefor further analysis. However, when the value is less than 0.5, the data are not useful for analysis.In our case, the KMO value is 0.802, which is close to 1.0 and, hence, the data are suitable for analysis.Next, the significance level in the Barlett’s test was 0.00 in our case. Small values (less than 0.05) of thesignificance level indicate that the factor is useful.

Symmetry 2020, 12, 1414 8 of 22

Table 3. Cronbach’s α (if item deleted).

Scale Mean IfItem Deleted

Scale VarianceIf ItemDeleted

CorrectedItem—TotalCorrelation

SquaredMultiple

Correlation

Cronbach’s α

If ItemDeleted

Spinal cord problem (E11) 92.5510 15.377 0.346 . 0.871Shoulder pain (E12) 92.6020 14.733 0.478 . 0.867Low Back Pain (E13) 92.5867 14.326 0.569 . 0.863Knee joint pain (E14) 92.6684 13.423 0.661 . 0.859

Sore feet (E15) 92.6684 14.879 0.304 . 0.873Neck pain (E16) 92.6684 14.295 0.438 . 0.868Wrist pain (E17) 92.6888 14.349 0.416 . 0.869

Fatigue (E21) 92.6939 14.111 0.457 . 0.868Job satisfaction (E22) 92.6122 14.690 0.448 . 0.868Self-motivation (E23) 92.6531 14.279 0.535 . 0.864

Conscientiousness (E24) 92.6378 14.109 0.554 . 0.864Extraversion (E25) 92.6684 14.079 0.583 . 0.862Competence (E26) 92.6276 14.532 0.459 . 0.867

Role perception (E27) 92.6378 14.489 0.532 . 0.865Vibration (E31) 92.5969 14.765 0.512 . 0.866

Outdated machinery (E32) 92.6684 14.797 0.318 . 0.873Operational setup (E33) 92.6939 14.285 0.462 . 0.867

Poor ventilation and Lighting (E34) 92.6020 14.641 0.555 . 0.865Shock (E35) 92.6071 14.558 0.543 . 0.865

Industrial hygiene (E36) 92.5612 15.181 0.421 . 0.869

Table 4. KMO and Barlett’s test.

KMO and Barlett’s Test

Kaiser–Meyer–Olkin measure of sampling adequacy 0.802Barlett’s Test of SphericityApprox. χ2 1379.913df 190Sig. 0.000

Trapezoidal fuzzy numbers are given in Table 5 [65]. The scale of significance, given in Table 5,is used to represent the significance level of each ergonomic factor. In this study, a five-point significancescale, representing the level of each ergonomic factor, is used. Initially, evaluation is made using thesignificance scale. Later, the significance scale value is converted in the trapezoidal number, given inTable 5, and evaluated.

Table 5. Scale of significance used in the pair-wise comparison of fuzzy AHP.

Linguistic Variables Scale of Significance Trapezoidal Fuzzy Numbers Trapezoidal Fuzzy Reciprocal Numbers

Equally significant (E) 1 (1,1,1,1) (1,1,1,1)Weakly significant (W) 3 (2, 5/2, 7/2, 4) (1/4, 2/7, 2/5, 1/2)Really significant (R) 5 (4, 9/2, 11/2, 6) (1/6, 2/11, 2/9, 1/4)

Very strongly significant (VS) 7 (6, 13/2, 15/2, 8) (1/8, 2/15, 2/13, 1/6)Absolutely significant (A) 9 (8, 17/2, 9, 9) (1/9, 1/9, 2/17, 1/8)

Before calculating the weight of the ergonomic factors, the consistency ratio (CR) value has tobe calculated (Table 6). Based on the number of factors, the recommended CR value varies. For thecorresponding number of factors, the CI was defined. Only when the calculated CR value was satisfiedwere the factors subjected to weight calculation.

Table 6. Random Index and recommended consistency ratio (CR) values.

Size (n) 3 4 5 6 7 8 9 10

CI 0.58 0.90 1.12 1.24 1.32 1.41 1.45 1.49Recommended

CR value <0.05 <0.08 <0.10 <0.10 <0.10 <0.10 <0.10 <0.10

The steps involved in fuzzy extent in AHP are given below [67].

Symmetry 2020, 12, 1414 9 of 22

A trapezoidal fuzzy number, denoted as E = (l, m, n, u), has the following membership function:

µE(x) =

x−lm−l l ≤ x ≤ m

1 m ≤ x ≤ ns−xs−n n ≤ x ≤ s

(1)

where (m, n) are called the mode interval of E, and parameters l and u are the lower and upper boundof E, which limits the field of possible calculation. Let us consider two trapezoidal numbers, E1 andE2, E1 = (l1, m1, n1, u1) and E2 = (l2, m2, n2, u2). The main operational laws for these two trapezoidalnumbers, E1 and E2, are listed below:

E1 ⊕ E2 = (l1 + l2, m1 + m2, n1 + n2, u + u2) (2)

E1 ⊗ E2 = (l1l2, m1m2, n1n2, u1u2) f orli ≥ 0, mi ≥ 0, ni ≥ 0, ui ≥ 0, i = 1, 2 (3)

λ⊗ E = (λl1,λm1,λn1,λu1), f orλ > 0,λ ∈ R, l1 > 0, m1 > 0, n1 > 0, u1 > 0 (4)

E =

(1u1

,1n1

,1

m1,

1l1

), f orl1 > 0, m1 > 0, n1 > 0, u1 > 0 (5)

Weight Calculations

In this study, trapezoidal fuzzy numbers are used to represent a pair-wise comparison. Here, a9-point scale is used to represent trapezoidal fuzzy numbers in the pair-wise comparison.

Step 1: Pair-wise comparison matrix establishment

As per the pair-wise comparison, a matrix E is constructed.

E =

ˆE11 . . . ˆE1n... . . .

...ˆEn1 . . . Enn

(6)

where Ei j is the scale of Ti compared with Tj. Similarly, the scale is Ei j =(Ei j

)−1when Tj is compared

to Ti.Ei j = (li j, mi j, ni j, ui j) (7)

E ji = (Ei j)−1

= (u−1i j , n−1

i j , m−1i j , l−1

i j ) (8)

Step 2: Consistency checking

It is necessary to check the consistency of a pair-wise comparison matrix before calculating theweights of sub-factors. To verify the consistency of the pair-wise comparison matrix, fuzzy numbersare improved to crisp numbers. The result of the defuzzified crisp matrix is:

E =

E11 . . . E1n

... . . ....

En1 . . . Enn

(9)

To calculate the consistency index (CI), λmax has to be calculated. To calculate λmax, W′ has tobe calculated.

W =

W1

W2

.Wn

andWi =

n∑i−1αi j

n(10)

Symmetry 2020, 12, 1414 10 of 22

W′ = EW =

W′1W′2

.W′n

(11)

λmax =1n

(W′1W1

+W′2W2

+ . . . . . .+W′nn

)(12)

Using Equation (13), the consistency index of the comparison matrix can be calculated.

Consistency Index(CI)=λmax − n

n− 1(13)

where λmax is the largest Eigenvalue of the comparison matrix and n is the dimension of the matrix.

Consistency Ratio (CR) =CI

Random Index (RI)(14)

Step 3: Calculate the weights

Let E =(ei j

)nn

be the fuzzy pair-wise comparison matrix, where ei j = (li j, mi j, ni j, ui j). The weightcan be calculated as follows:

α j =

n∏j=1

li j

1/n

(15)

β j =

n∏j=1

mi j

1/n

(16)

χ j =

n∏j=1

ni j

1/n

(17)

δ j =

n∏j=1

ui j

1/n

(18)

Thus:

α =n∑

j=1

α j (19)

β =n∑

j=1

β j (20)

χ =n∑

j=1

χ j (21)

δ =n∑

j=1

δ j (22)

Fuzzy weights can be computed as:

ω j =(α jδ−1, β jχ

−1,χ jβ−1, δ jα

−1), f or j = 1, . . . . . . n (23)

Symmetry 2020, 12, 1414 11 of 22

Fuzzy weight vector ω can be obtained.

W = (w1, w2, . . . . . . , wn) (24)

After calculating the individual weights of all the sub-factors within the main factors, the globalweight of the factors is calculated. Equation (25) is used to calculate the global weight of the factors.

GSi j =∑

(CWi jXGWci j) (25)

where

GSij—global score of sub-factors;CWij—local weight of sub-factors with respect to the main factor;CWc

ij —global weight of the main factor.

4. Data Evaluation

After accessing the validity and reliability of the factors, an expert panel comprising of ten members(Appendix A Table A1) was asked to rate the level of influence of the factors in the production capabilityof the industries. For this, the experts were provided with a questionnaire containing the ergonomicfactors along with the fuzzy scale (Table 5). Based on the experts’ responses, the ergonomic factorswere analyzed using FAHP. In evaluating the factors influencing the leather garments production,the significance of each factor must be considered. Hence a pair-wise comparison of each factor wascarried out. The established pair-wise comparison matrix is shown in Table 7. All the trapezoidal fuzzynumbers were normalized to crisp numbers. The largest eigenvalue and eigenvector were calculatedusing Equations (11) and (12), as shown in Table 8.

Table 7. Factor to Factor (F–F) Pair-wise comparison matrix.

Main Factors E1 E2 E3

E1 (1,1,1,1) (1/4, 2/7, 2/5, 1/2) (1/9,1/9,2/17,1/8)E2 (2,5/2,7/2,4) (1,1,1,1) (1/4,2/7,2/5,1/2)E3 (8,17/2,9,9) (2,5/2,7/2,4) (1,1,1,1)

Table 8. Largest Eigenvalue and Eigenvector.

Main Factors W W’ λmax CR Value

Occupational disease (E1) 0.08 3.063.0517

CI = (3.0517 − 3)/2 = 0.02585Personal factors (E2) 0.24 3.02 CR = 0.02585/0.58 = 0.044

Industrial environment (E3) 0.68 3.07

Then, the Consistency Index (CI) and Consistency Ratio (CR) were calculated using Equations(13) and (14). The calculated consistency ratio was 0.044, which was in accordance with therecommended consistency ratio, given in Table 6. The ranking of the main factors is presentedin Table 9. Similarly, the pair-wise comparison matrix of sub-factors, with respect to E1, E2, and E3,was carried out. However, in this paper, the pair-wise comparison of main factors alone is displayed.The consistency ratio for all sub-factors within the main factors was calculated and found to satisfy therequired condition. Once the individual weight of the sub-factors in each main factor was calculated,the global priority weight of the sub-factors was calculated. The global weights of the sub-factors werecalculated using Equation (25) and their priority rank is shown in Table 10.

Symmetry 2020, 12, 1414 12 of 22

Table 9. Ranking of main factors influencing leather garment production.

Main Factors Preference Weight Ranking

Occupational disease (E1) 0.08 3Personal factors (E2) 0.24 2

Industrial environment (E3) 0.68 1

Table 10. Local and global weights of main and sub-factors of the leather garment industry.

Factors Weight Rank Sub-Factors Local Weight Rank Global Weight Rank

E1 0.08 3

E11 0.3153 1 0.025224 10E12 0.1259 5 0.010072 16E13 0.1400 3 0.0112 14E14 0.2013 2 0.016104 13E15 0.0458 6 0.003664 19E16 0.1399 4 0.011192 15E17 0.0318 7 0.002544 20

E2 0.24 2

E21 0.3702 1 0.088848 4E22 0.2129 2 0.051096 6E23 0.1707 3 0.040968 7E24 0.1036 4 0.024864 11E25 0.0913 5 0.021912 12E26 0.0267 6 0.006408 17E27 0.0246 7 0.005904 18

E3 0.68 1

E31 0.2270 2 0.15436 2E32 0.3884 1 0.264112 1E33 0.1612 3 0.109616 3E34 0.1293 4 0.087924 5E35 0.0513 5 0.034884 8E36 0.0428 6 0.029104 9

5. Results

5.1. Reliability and Validity Analysis

The calculated Cronbach’s α value is shown in Tables 2 and 3. In our case, the Cronbach’sα is 0.873, which is acceptable. The Cronbach’s α value, if item deleted for all factors, is above0.8. Hence, from this it could be inferred that all 20 factors considered in this study are reliable andcan be used for future study. In this case, the KMO value is 0.802 (Table 4), which indicates thesampling is adequate. Thus, we finalized the ergonomic factors hindering the production rate ofleather garment-based SMEs. After finalization using FAHP, the factors and sub-factors of ergonomicscausing production loss were evaluated.

5.2. Weight of Ergonomic Factors

After accessing the validity and reliability, the factors were evaluated by the experts using fuzzyAHP. Before calculating the weights of the factors, the consistencies of the factors were checked.The consistency ratio (CR) calculated is shown in Table 8. Here, the CR value is 0.044 which is accepted,as per the standard given in Table 6. After this, the preference weight of the main factors was calculatedand is given in Table 9. Likewise, the local weight of sub-factors was also calculated, as shown inTable 10. Then, the local weight of sub-factors was multiplied with the preference weight of the mainfactor to get global weight. The calculated global weight of the sub-factors is given in Table 10.

5.3. Sensitivity Analysis

Normally, responses received through questionnaires are based on human judgments, and hencethey are prone to imprecision and vagueness. A small variation in relative weights will largely

Symmetry 2020, 12, 1414 13 of 22

influence the final ranking of variables [69]. The final rank check is mandatory as the inputs usedin fuzzy AHP are based on human linguistic judgments. In this work, a sensitivity analysis wascarried out to monitor the priority ranking of ergonomic factors in leather garments production.To illustrate the effect of the sensitivity analysis in this work, the dimensions of the most influencingfactor “Industrial environment (E3)” is increased from 0.1 to 0.9 with an increment of 0.1. As weightsof main factors change, the ranking of sub-factors also changes. Table 11 shows corresponding globalweight change in sub-factors. The rank of the sub-factors based on the sensitivity analysis is shown inFigure 2.

Table 11. Global weights for sub-factors by sensitivity analysis.

0.1 0.2 0.3 0.4 0.5 0.6 0.68 (Normal) 0.7 0.8 0.9

E11 0.0709 0.0630 0.0551 0.0473 0.0394 0.0315 0.0252 0.0236 0.0157 0.0078E12 0.0283 0.0251 0.0220 0.0188 0.0157 0.0125 0.0100 0.0094 0.0062 0.0031E13 0.0314 0.0279 0.0244 0.0209 0.0174 0.0139 0.0112 0.0104 0.0069 0.0034E14 0.0452 0.0402 0.0352 0.0301 0.0251 0.0201 0.0161 0.0150 0.0100 0.0050E15 0.0103 0.0091 0.0080 0.0068 0.0057 0.0045 0.0036 0.0034 0.0022 0.0011E16 0.0314 0.0279 0.0244 0.0209 0.0174 0.0139 0.0111 0.0104 0.0069 0.0034E17 0.0071 0.0063 0.0055 0.0047 0.0039 0.0031 0.0025 0.0023 0.0015 0.0007E21 0.2499 0.2221 0.1943 0.1666 0.1388 0.1110 0.0888 0.0833 0.0555 0.0277E22 0.1436 0.1277 0.1117 0.0957 0.0798 0.0638 0.0510 0.0478 0.0319 0.0159E23 0.1152 0.1024 0.0896 0.0768 0.0640 0.0512 0.0409 0.0384 0.0256 0.0128E24 0.0699 0.0621 0.0543 0.0466 0.0388 0.0310 0.0248 0.0233 0.0155 0.0077E25 0.0616 0.0547 0.0479 0.0410 0.0342 0.0273 0.0219 0.0205 0.0136 0.0068E26 0.0180 0.0160 0.0140 0.0120 0.0100 0.0080 0.0064 0.0060 0.0040 0.0020E27 0.0166 0.0147 0.0129 0.0110 0.0092 0.0073 0.0059 0.0055 0.0036 0.0018E31 0.0227 0.0454 0.0681 0.0908 0.1135 0.1362 0.1543 0.1589 0.1816 0.2043E32 0.0388 0.0776 0.1165 0.1553 0.1942 0.2330 0.2641 0.2719 0.3107 0.3495E33 0.0161 0.0322 0.0483 0.0644 0.0805 0.0967 0.1096 0.1128 0.1289 0.1450E34 0.0129 0.0258 0.0387 0.0517 0.0646 0.0775 0.0879 0.0904 0.1034 0.1163E35 0.0051 0.0102 0.0153 0.0205 0.0256 0.0307 0.0348 0.0359 0.0410 0.0461E36 0.0042 0.0085 0.0128 0.0171 0.0213 0.0256 0.0291 0.0299 0.0342 0.0385

Symmetry 2020, 12, x FOR PEER REVIEW 15 of 23

Figure 2. Sensitivity analysis of sub-factors (rank).

6. Discussion

From Table 9, the rank of the main factors is obtained as follows: E3 > E2 > E1. “Industrial

environment (E3)” receives the highest weight in the priority ranking. This indicates that the impact

of the industrial environment on workers’ health is more pressing when compared to the other

categories of factors. The effective utilization of manpower in companies is often jeopardized by

poor machine design, plant layout, and poor infrastructure [70]. Persons working with

inappropriate table height over a short or long period are exposed to MSDs; such tables force the

workers to work in awkward positions. A study carried by Bontrup et al. [71] insisted that poor

industrial working environment may limit the quality of workers’ health and may lead to frequent

absenteeism. The abovementioned research works confirm that industrial environments definitely

influence workers’ health. Next, “Personal factors (E2)” occupies the second position in the priority

ranking, another important ergonomic factor. Personal factors include fatigue, job satisfaction,

endurance, and self-motivation; these factors determine the working capacity of workers. In a study

carried out by Vulović et al. [72] in a call center, the rate of exposure of workers to low back pain is

directly linked with an individual’s health aspects. Based on the duration of the employees having to

sit, the severity of low back pain may be acute or chronic.

The study also confirmed that sitting behavior and low back pain are inherently linked. Those

reviewed research works confirm that personal factors play a pivotal role in enhancing the

production rate and it is also an important factor of ergonomic problems. “Occupational disease

(E1)” occupies the third rank in the priority ranking. However, occupational disease remains a

significant influence on workers’ health and their production rate. The occurrence of

ergonomic-related problems differs from workplace to workplace and depends upon the actual

work being done. Persons working in sectors such as construction work or being a driver or porter

are exposed to different types of ergonomic problems. Employees who spend hours in front of

computers develop the possibility of quick exposure to MSDs. Generally, people who spend more

time on computers experience neck pain, wrist pain, and back pain [73]. These findings confirm that

occupational disease induces different types of pain among workers.

6.1. Sub-Factors Ranking Using FAHP

6.1.1. Occupational Disease

Occupational disease results from the kind of work performed by a worker. While the factor

“occupational disease” holds the third position in the priority ranking, it still needs due

consideration in preventing the occurrence of ergonomic problems. The ranking of sub-factors

placed under occupational disease are as follows: E11 > E14 > E13 > E16 > E12 > E15 > E17 (Table 10).

“Spinal cord problem” occupies the first position in the ergonomic problem arising among workers.

Figure 2. Sensitivity analysis of sub-factors (rank).

6. Discussion

From Table 9, the rank of the main factors is obtained as follows: E3 > E2 > E1. “Industrialenvironment (E3)” receives the highest weight in the priority ranking. This indicates that the impact ofthe industrial environment on workers’ health is more pressing when compared to the other categories offactors. The effective utilization of manpower in companies is often jeopardized by poor machine design,plant layout, and poor infrastructure [70]. Persons working with inappropriate table height over a short or

Symmetry 2020, 12, 1414 14 of 22

long period are exposed to MSDs; such tables force the workers to work in awkward positions. A studycarried by Bontrup et al. [71] insisted that poor industrial working environment may limit the quality ofworkers’ health and may lead to frequent absenteeism. The abovementioned research works confirmthat industrial environments definitely influence workers’ health. Next, “Personal factors (E2)” occupiesthe second position in the priority ranking, another important ergonomic factor. Personal factors includefatigue, job satisfaction, endurance, and self-motivation; these factors determine the working capacity ofworkers. In a study carried out by Vulovic et al. [72] in a call center, the rate of exposure of workers to lowback pain is directly linked with an individual’s health aspects. Based on the duration of the employeeshaving to sit, the severity of low back pain may be acute or chronic.

The study also confirmed that sitting behavior and low back pain are inherently linked.Those reviewed research works confirm that personal factors play a pivotal role in enhancing theproduction rate and it is also an important factor of ergonomic problems. “Occupational disease (E1)”occupies the third rank in the priority ranking. However, occupational disease remains a significantinfluence on workers’ health and their production rate. The occurrence of ergonomic-related problemsdiffers from workplace to workplace and depends upon the actual work being done. Persons workingin sectors such as construction work or being a driver or porter are exposed to different types ofergonomic problems. Employees who spend hours in front of computers develop the possibility ofquick exposure to MSDs. Generally, people who spend more time on computers experience neck pain,wrist pain, and back pain [73]. These findings confirm that occupational disease induces differenttypes of pain among workers.

6.1. Sub-Factors Ranking Using FAHP

6.1.1. Occupational Disease

Occupational disease results from the kind of work performed by a worker. While the factor“occupational disease” holds the third position in the priority ranking, it still needs due considerationin preventing the occurrence of ergonomic problems. The ranking of sub-factors placed underoccupational disease are as follows: E11 > E14 > E13 > E16 > E12 > E15 > E17 (Table 10). “Spinal cordproblem” occupies the first position in the ergonomic problem arising among workers. The findingaligns with the results of [74]. These authors report that the majority of workers in the leather garmentsindustry are prone to spinal cord injuries because they work in awkward positions for long durations.“Knee joint pain”, ranked second, is the most common ergonomic problem among workers in garmentsectors. Prolonged standing within a restricted space aggregates the possibility of knee joint pain.Sitting in a constrained space and working in a leaning forward position monotonously induces“low back pain” and it secures the third rank. Additionally, the provision of improper height tablesmay trigger the occurrence of low back pain.

6.1.2. Personal Factors

Personal factors include self-motivation, job satisfaction, and fatigue, and play a significant role inexecuting an assigned work task. The ranking of sub-factors under personal factors are: E21 > E22 >

E23 > E24 > E25 > E26 > E27 (Table 10). “Fatigue” is ranked first in personal factors. Only low-qualityproducts are manufactured by workers when they suffer fatigue [75]. The sub-factor “job satisfaction”comes next in the priority ranking. Extended working hours may develop fatigue and hatred onthe job. Lack of respect, no sense of appreciation, and few rewards are the main reasons that createjob dissatisfaction. The sub-factor “self-motivation” holds third place in the priority ranking amongpersonal factors. Unless the workers are self-motivated, they will not be able to perform the assignedwork in the stipulated time in a precise manner. Lack of self-motivation will result in delayed workcompletion, poorly done or incomplete work, and work with more flaws.

Symmetry 2020, 12, 1414 15 of 22

6.1.3. Industrial Environment

Industrial environment includes aspects such as providing basic infrastructure and an ambientworking atmosphere. Providing an aesthetic pleasing working environment for workers is vitalin nurturing both the physical and mental health of workers. The ranking of sub-factors underthe industrial environment are as follows: E32 > E31 > E33 > E34 > E35 > E36 (Table 10).“Outdated machinery” holds the top position in the industrial environment. The usage of outdatedmachinery triggers other ergonomic factors, such as low back pain, neck pain, and vibrations,which hinder the production rate of leather garments [12]. “Operational setup” comes next in thepriority ranking of sub-factors. For carrying the assigned works without much repetition or duplicationof efforts, a well-designed industrial layout is needed. The layout should be designed depending onthe sequence of operations to be carried out. “Industrial hygiene” is very important in leather garmentsbecause the possibility of contracting fungal and bacterial infection is high. Hence, providing ahygienic working environment is imperative [36]. Companies must ensure they provide a hygienicworking environment.

6.2. Sensitivity Analysis

The result obtained in this study is completely based on the opinions of experts and hence theyare subjective to bias. Therefore, there is a need to check the reliability and robustness of the result.For this, sensitivity analysis is performed. Usually, sensitivity analysis is performed either by changingthe preference weight of the experts or by changing the weight of factors with the highest weight.In this case, the weight of the factor receiving the highest weight is changed with an increment of0.1 from 0.1 to 0.9. Similar kinds of work have been performed in earlier studies [76,77]. In our case,the factor “industrial environment” has the highest weight and the weight is changed from 0.1 to0.9. The change in the weight of sub-factors with respect to change in the weight of the main factorsis given in Table 11. From Table 11 and Figure 2, it could be inferred that sub-factor “fatigue (E21)”occupies the highest rank with values 0.1 to 0.4, while sub-factor E36, “industrial hygiene”, occupies thelowest rank with a value 0.1. From values 0.2 to 0.9, sub-factor “wrist pain (E17)”, occupies the lowestrank. Sub-factor “outdated machinery (E32)” secures the highest rank with values from 0.5 to 0.9.From this, it is understood that usage of “outdated machinery” has been the prime reason for theoccurrence of allied ergonomic problems. Further, poor working environment and work scheduleimposes “fatigue” among the workers. Poor working environment is a big threat for the hygiene of theworkers. Such environment brings in health issues, such as breathing problem and skin allergies.

6.3. Managerial Implications

Leather garment companies in India immensely contribute to the nation’s economic development.However, workers at these industries suffer an enormous amount of pain while the garments industryitself struggles to attain social sustainability. This research may help industrial managers in identifyingergonomic factors and in providing an ergonomically designed working environment. This researchoffers the following managerial implications for social sustainability.

Enhancing the workers’ welfare in attaining social sustainability: In our study, it has beenrevealed that the use of “outdated machinery” in leather garments is the prominent factor affecting thehealth of workers. Such an undesired impact on the workers poses a question regarding the socialresponsibility of industrial management. As a step towards social sustainability, the management mustnurture the workers’ welfare. For this, industrial management has to replace the existing outdatedmachines with new ergonomically designed machines. Next, by providing reasonable pay for theworkers, it is possible to alleviate the poverty of the workers [64]. Reasonable pay for all employeeswill aid in overcoming gender inequality regarding income. Frequent motivational programs forworkers will encourage them to carry out their assigned work tasks in a whole-hearted manner [78].Further, management must establish an ambient working atmosphere where workers can perform

Symmetry 2020, 12, 1414 16 of 22

the assigned task with ease. By providing an ample working environment, management may ensurethe workers’ health and safety. Waste from leather companies remains a major concern for the localcommunity. Hence, proper waste management practices, such as 6R (recycle, redesign, reuse, repair,reduce, rethink), and effluent treatment plants, must be used. By practicing skillful waste management,the leather garment industry may establish a good reputation in society and develop a reputation forcaring about the community [79].

Emphasizing personal factors during workers selection: Being the major player in decidingproduction capacity, workers’ physical and mental aspects must be considered as important factors.Fatigue has also been identified as a major ergonomic factor. Performing routine work withoutsufficient intervals may quickly expose workers to fatigue. Fatigue affects cognitive skill and interestin work. Hence, it is important to address the fatigue problem of workers. Frequent motivational andmeditation programs must be conducted to nurture mental health. Mutual respect and trust betweentop-level management and the worker will improve the job satisfaction factor [80]. A stress-free friendlyenvironment reduces worker fatigue and increases endurance level. A proper blend of younger andmore experienced employees should be considered since, in some situations, experience would bewelcomed, whereas in other situations a younger worker might be better equipped to carry moreweight. Reasonable wages based on the mode of work should be paid regardless of gender. Job rotationmust be implemented to minimize fatigue among workers and to enhance mental sharpness.

Establishing ergonomically designed working environment: An ergonomically designed workplacewill ensure increased productivity. An industrial environment with adequate space and lighting willprevent the workers from ergonomic exposure. Hence, it becomes mandatory for industrial managementto provide a worker-friendly environment. By replacing old machines with newer ergonomicallydesigned machines that offer inclined arm rests and back support, workers’ exposure to MSDs can beminimized [81]. Maintaining a hygienic environment within companies is vital as it directly influencesthe health of workers who directly determine the production capacity. Sufficient space must be providedbetween each section and sections should be designed sequentially, depending on the operational sequence.Further, proper ventilation and shock arresters must be provided to ensure a better workplace. Cushion matflooring will mitigate heel pain when workers stand for a long duration. Height-adjustable chairs lowerneck and back pain. Ensuring the adequate presence of carriages, automated guide vehicles (AGVs),and wagons for transporting raw materials and finished products from one place to another, will reducethe movement of workers. With industries becoming digitalized, industrial management need to integratedigitized technology [82,83]. Worksite physical activities between work tasks will reduce suffering.

7. Conclusions

Ergonomic issues faced by the workers within the working environment to a large extent reducethe working efficiency. In some cases, ergonomic issues may bring in severe complexities, such asmusculoskeletal disorders (MSDs), breathing difficulties and skin problems. Such complexitiesmay increase the frequency of absenteeism of workers, resulting in decreased production andloss of working hours. Realizing the influence of ergonomic issues in industrial performance,developed countries have started paying significant attention in providing ergonomic free workingenvironments. However, due to a lack of awareness about ergonomic issues and the availabilityof a cheap workforce, developing countries are not considering ergonomic issues as a serious.Hence, this study intends to identify the ergonomic problems faced by workers in leather garmentindustries in Southern India. For identifying the ergonomic factors, the extant literature was reviewed,and industrial experts’ opinions were sought. Then, using the SPSS tool, the twenty most influentialidentified ergonomic factors were validated. The twenty identified factors were classified underthree categories. To evaluate the identified ergonomic factors, a multiple case study was carried outin five leather garment companies. The fuzzy AHP method was used to prioritize the identifiedergonomic factors. The rankings of the main ergonomic factors using fuzzy AHP were obtained asfollows: Industrial environment, Personal factors, and Occupational disease. The factor “industrial

Symmetry 2020, 12, 1414 17 of 22

environment” secured the highest rank and it needs immediate attention from management inenhancing production rate and also in attaining social sustainability. The sub-factors of ergonomicproblems were also prioritized in this study. In this work, the sub-factor of outdated machinery(found within the industrial environment category) secures the first rank in the priority ranking.So, the management of the garment must replace existing outdated machinery with new ergonomicallydesigned machines. A sensitivity analysis was carried out to ensure the priority ranking of sub-factorsobtained through fuzzy AHP.

This study has some significant contributions. Firstly, this work imparts knowledge and awarenessabout the importance of addressing ergonomic issues from the context of the developing nation.Such types of work in developing nation contexts are scant. Secondly, in this work, the validity ofthe data was assessed using SPSS software by calculating the Cronbach’s and Barlett’s test. In earlierstudies, Cronbach’s alone is calculated. Finally, this work has considered and evaluated the role ofpersonal factors in ergonomic issues, a factor not considered in earlier studies.

To overcome the identified ergonomic issues, some possible managerial implications are suggested.Firstly, the industries must replace existing outdated machinery with the latest machines. Machines withadjustable height must be provided as it greatly reduces the occurrence of back pain of the workers.Next, industrial management must pay attention to the provision of hygienic working environments.Providing a hygienic working environment may reduce the workers’ exposure to health hazards.Finally, work schedules with adequate intervals must be provided. Additionally, frequent motivationalprograms must be conducted to reduce the fatigue of the workers. The findings of this study shouldnot be limited only to the leather garment industry; the findings are applicable to other SMEs, such ashandloom weaving companies, spinning mills, or packaging companies in which human and machineinteraction is imperative.

Though this study contributes significantly to the literature on ergonomic issues, it also hasseveral limitations. For instance, the ergonomic factors considered and evaluated in this study werecollected from the Indian context. So, caution must be exercised while carrying an ergonomic studiesconsidering these factors in other developing countries. Next, this study only evaluates the weight ofergonomic factors.

As a future direction of the study, a study using DEMATEL and ISM may reveal theinter-relationship among these factors, both in an Indian context and in the contexts of other countries.Some of the factors considered in this study may become insignificant in a future study. For instance,the factor “outdated machinery” may become insignificant in future, as India is on a path of development.At present, a lot of manual work is exerted from the workers by industrial management and hence,the study evaluated the factors related to physical health. However, in future, with technologicaladvancement, the study on the ergonomic problem may be more focused on psychological andcognitive factors. Further, with the concept of corporate social responsibility (CSR) gaining attention,the future study of ergonomics may be merged with the CSR concept.

Author Contributions: Conceptualization, K.K. and B.S.; methodology, K.K.; software, K.K.; validation, B.S.,S.M.A., and G.K.; formal analysis, B.S.; investigation, B.S.; resources, B.S., and S.M.A.; data curation, K.K.;writing—original draft preparation, B.S. and K.K.; writing—review and editing, S.M.A. and G.K.; visualization,B.S.; supervision, S.M.A.; project administration, G.K.; funding acquisition, G.K. All authors have read and agreedto the published version of the manuscript.

Funding: This research received no external funding.

Acknowledgments: This research did not receive any specific grant from funding agencies in the public,commercial, or not-for-profit sectors.

Conflicts of Interest: The authors declare no conflict of interest.

Symmetry 2020, 12, 1414 18 of 22

Appendix A

Table A1. Profile of the experts.

Characteristics Classifications Experts Percentage (%)

GenderMale 6 6.00

Female 4 4.00

AgeUp to 30 years 2 2.00

31–45 4 4.0046–60 4 4.00

Experience1–10 3 3.00

11–20 4 4.0021–30 3 3.00

EducationGraduate 3 3.00

Postgraduate 4 4.00Doctorates 3 3.00

References

1. Workplace Safety and Health Council. Workplace safety and health guidelines. J. Chem. Inf. Model. 2013, 53,1689–1699. [CrossRef]

2. Rastogi, A.; Pati, S.P.; Dixit, J.K.; Kumar, P. Work disengagement among SME workers: Evidence from India.Benchmark. Int. J. 2018, 25, 968–980. [CrossRef]

3. Aastveit, K.A.; Bjørnland, H.C.; Thorsrud, L.A. What Drives Oil Prices? Emerging versus DevelopedEconomies. SSRN Electron. J. 2013. [CrossRef]

4. Prashar, A. Towards sustainable development in industrial small and Medium-sized Enterprises: An energysustainability approach. J. Clean. Prod. 2019, 235, 977–996. [CrossRef]

5. Baker, H.K.; Kumar, S.; Singh, H.P. Working capital management: Evidence from Indian SMEs.Small Enterp. Res. 2019, 26, 143–163. [CrossRef]

6. Narasimhan, R.; Kumar, M.R.; Sridhar, M.K. Organizational Transformation of Internationalizing Hi-TechSMEs in India: A Case-Based Analysis. In Transnational Entrepreneurship; Springer: Singapore, 2019;pp. 379–400.

7. Xu, W.; Furie, D.; Mahabhaleshwar, M.; Suresh, B.; Chouhan, H. Applications of an interaction, process,integration and intelligence (IPII) design approach for ergonomics solutions. Ergonomics 2019, 62, 954–980.[CrossRef] [PubMed]

8. Lin, C.J.; Belis, T.T.; Kuo, T.C. Ergonomics-based factors or criteria for the evaluation of sustainable productmanufacturing. Sustainability 2019, 11, 4955. [CrossRef]

9. Thakur, V.; Mangla, S.K. Change management for sustainability: Evaluating the role of human, operationaland technological factors in leading Indian firms in home appliances sector. J. Clean. Prod. 2019, 213, 847–862.[CrossRef]

10. Munguía Vega, N.E.; Flores Borboa, V.S.; Zepeda Quintana, D.S.; Velazquez Contreras, L.E. Assessing theeffectiveness of integrating ergonomics and sustainability: A case study of a Mexican maquiladora. Int. J.Occup. Saf. Ergon. 2019, 25, 587–596. [CrossRef]

11. Shirazi, M.R.; Keivani, R. Social sustainability discourse: A critical revisit. In Urban Social Sustainability;Routledge: Abingdon-on-Thames, UK, 2019; pp. 1–26.

12. Moktadir, A.; Rahman, T.; Jabbour, C.J.C.; Mithun Ali, S.; Kabir, G. Prioritization of drivers of corporate socialresponsibility in the footwear industry in an emerging economy: A fuzzy AHP approach. J. Clean. Prod.2018, 201, 369–381. [CrossRef]

13. Kong, F. Development of metric method and framework model of integrated complexity evaluations ofproduction process for ergonomics workstations. Int. J. Prod. Res. 2019, 57, 2429–2445. [CrossRef]

Symmetry 2020, 12, 1414 19 of 22

14. Mukhopadhyay, P. Investigation of Ergonomic Risk Factors in Snacks Manufacturing in Central India:Ergonomics in Unorganized Sector. In Handbook of Research on Human Factory in Contemporary WorkforceDevelopment; IGI Glob: Hershey, PA, USA, 2017; pp. 425–449.

15. Arrogi, A.; Schotte, A.; Bogaerts, A.; Boen, F.; Seghers, J. Short- and long-term effectiveness of a three-monthindividualized need-supportive physical activity counseling intervention at the workplace. BMC Public Health2017, 17, 1–20. [CrossRef] [PubMed]

16. Hellig, T.; Mertens, A.; Brandl, C. The interaction effect of working postures on muscle activity and subjectivediscomfort during static working postures and its correlation with OWAS. Int. J. Ind. Ergon. 2018, 68, 25–33.[CrossRef]

17. Ncube, F.; Kanda, A.; Chirengendure, Y. An evaluation of ergonomic risks associated with tailoring tasksusing the rapid entire body assessment method. Int. J. Hum. Factors Ergon. 2019, 6, 124–142. [CrossRef]

18. Felekoglu, B.; Tasan, S.O. Interactive ergonomic risk mapping: A practical approach for visual managementof workplace ergonomics. Int. J. Occup. Saf. Ergon. 2020, 0, 1–41. [CrossRef] [PubMed]

19. Zwetsloot, G.; Leka, S.; Kines, P.; Jain, A. Vision zero: Developing proactive leading indicators for safety,health and wellbeing at work. Saf. Sci. 2020, 130, 104890. [CrossRef]

20. Nagaraj, T.S.; Jeyapaul, R.; Vimal, K.E.K. The Management of Operations Integration of human factorsand ergonomics into lean implementation: Ergonomic-value stream map approach in the textile industry.Prod. Plan. Control. 2019, 0, 1–18. [CrossRef]

21. Bernardes, J.M.; Ruiz-Frutos, C.; Moro, A.R.P.; Dias, A. A low-cost and efficient participatory ergonomicintervention to reduce the burden of work-related musculoskeletal disorders in an industrially developingcountry: An experience report. Int. J. Occup. Saf. Ergon. 2020, 1–8. [CrossRef]

22. Olabode, S.O.; Adesanya, A.R.; Bakare, A.A. Ergonomics Awareness and Employee Performance:An Exploratory Study. Econ. Environ. Stud. 2017, 17, 813–829. [CrossRef]

23. Emmatty, F.J.; Panicker, V.V. Ergonomic interventions among waste collection workers: A systematic review.Int. J. Ind. Ergon. 2019, 72, 158–172. [CrossRef]

24. Sirajudeen, M.S.; Siddik, S.S.M. Knowledge of Computer Ergonomics among Computer Science Engineeringand Information Technology Students in Karnataka, India. Asian J. Pharm. Res. Health Care 2017, 9, 64.[CrossRef] [PubMed]

25. Feng, Q.; Liu, S.; Yang, L.; Xie, M.; Zhang, Q. The Prevalence of and Risk Factors Associated withMusculoskeletal Disorders among Sonographers in Central China: A Cross-Sectional Study. PLoS ONE2016, 11, e0163903. [CrossRef] [PubMed]

26. Kibria, M.G.; Rafiquzzaman, M. Ergonomic computer workstation design for University Teachers inBangladesh. Jordan J. Mech. Ind. Eng. 2019, 13, 91–103.

27. Balakrishnan, R.; Danninger, S.; Elekdag, S.; Tytell, I. The Transmission of Financial Stress from Advanced toEmerging Economies. J. Emerg. Mark. Financ. Trade 2011, 47, 40–68. [CrossRef]

28. The World Bank. World Development Report 2019: The Changing Nature of Work; The World Bank: Washington,DC, USA, 2019; ISBN 9781464813283.

29. Mishra, R.; Mishra, R.; Management, M.T. Conceptualizing sources, key concerns and critical factors formanufacturing flexibility adoption: An exploratory study in Indian manufacturing firms. J. Manuf. Technol. Manag.2016, 27, 379–407. [CrossRef]

30. Dangayach, G.S.; Deshmukh, S.G. Advanced manufacturing technology implementation. J. Manuf. Technol. Manag.2005, 16, 483–496. [CrossRef]

31. Kucuk Yilmaz, A.; Flouris, T.G. Values, Ergonomics and Risk Management in Aviation Business Strategy; Springer:Berlin, Germany, 2019; ISBN 9789811510052. [CrossRef]

32. Shukla, A.; Yadav, S.; Das, S.; Babu, N.; Kumar, N.; Sharma, S.M. Ergonomics in industry A review. Ind. Eng. J.2017, 10, 6–13. [CrossRef]

33. Barkhordari, A.; Malmir, B.; Malakoutikhah, M. An Analysis of Individual and Social Factors AffectingOccupational Accidents. Saf. Health Work 2019, 10, 205–212. [CrossRef]

34. Li, X.; Gül, M.; Al-Hussein, M. An improved physical demand analysis framework based on ergonomic riskassessment tools for the manufacturing industry. Int. J. Ind. Ergon. 2019, 70, 58–69. [CrossRef]

35. Biswas, S.; Rahman, T. The Effect of Working Place on Worker’s Health in a Tannery in Bangladesh.Adv. Anthropol. 2013, 3, 46–53. [CrossRef]

Symmetry 2020, 12, 1414 20 of 22

36. Longo, F.; Nicoletti, L.; Padovano, A. Modeling workers’ behavior: A human factors taxonomy and a fuzzyanalysis in the case of industrial accidents. Int. J. Ind. Ergon. 2019, 69, 29–47. [CrossRef]

37. Dalju, I.; Dessie, A.; Bogale, L.; Mekonnen, T.H. Occupational risk factors associated with respiratorysymptoms among tannery workers in Mojo town, Southeast Ethiopia 2018: A comparative cross-sectionalstudy. Multidiscip. Respir. Med. 2019, 14, 1–10. [CrossRef]

38. Suri, S.; Das, R. Occupational health profile of workers employed in the manufacturing sector of India.Natl. Med. J. India 2016, 29, 277–281. [PubMed]

39. Delleman, N.J.; Dul, J. Sewing machine operation: Workstation adjustment, working posture, and workers’perceptions. Int. J. Ind. Ergon. 2002, 30, 341–353. [CrossRef]

40. Sealetsa, O.J.; Thatcher, A. Ergonomics issues among sewing machine operators in the textile manufacturingindustry in Botswana. Work 2011, 38, 279–289. [CrossRef] [PubMed]

41. Ciriello, V.M.; Dempsey, P.G.; Maikala, R.V.; Brien, N.V.O. Revisited: Comparison of two techniques toestablish maximum acceptable forces of dynamic pushing for male industrial workers. Int. J. Ind. Ergon.2007, 37, 877–882. [CrossRef]

42. Santos, J.; Baptista, J.S.; Monteiro, P.R.R.; Miguel, A.S.; Santos, R.; Vaz, M.A.P. The influence of task design on upperlimb muscles fatigue during low-load repetitive work: A systematic review. Int. J. Ind. Ergon. 2014, 52, 78–91.[CrossRef]

43. Bhattacharya, A. International Journal of Industrial Ergonomics Costs of occupational musculoskeletaldisorders (MSDs) in the United. Int. J. Ind. Ergon. 2014, 44, 448–454. [CrossRef]

44. Occhipinti, E.; Colombini, D. A toolkit for the analysis of biomechanical overload and prevention of WMSDs:Criteria, procedures and tool selection in a step-by-step approach. Int. J. Ind. Ergon. 2016, 52, 18–28. [CrossRef]

45. Fan, H.; Yu, S.; Chu, J.; Wang, M.; Chen, D.; Zhang, S.; Wang, W.; Wu, T.; Wang, N. Anthropometric characteristicsand product categorization of Chinese auricles for ergonomic design. Int. J. Ind. Ergon. 2019, 69, 118–141.[CrossRef]

46. Vihlborg, P.; Bryngelsson, I.L.; Lindgren, B.; Gunnarsson, L.G.; Graff, P. Association between vibration exposureand hand-arm vibration symptoms in a Swedish mechanical industry. Int. J. Ind. Ergon. 2017, 62, 77–81. [CrossRef]

47. Nicolay, C.W.; Walker, A.L. Grip strength and endurance: Influences of anthropometric variation, handdominance, and gender. Int. J. Ind. Ergon. 2005, 35, 605–618. [CrossRef]

48. Eksioglu, M. Musculoskeletal and visual symptoms among undergraduate students: Individual andcomputer-use-related risk factors and interference with academic performance. Int. J. Ind. Ergon. 2017, 60, 26–34.[CrossRef]

49. Hokari, K.; Pramudita, J.A.; Ito, M.; Noda, S.; Tanabe, Y. International Journal of Industrial Ergonomics therelationships of gripping comfort to contact pressure and hand posture during gripping. Int. J. Ind. Ergon.2019, 70, 84–91. [CrossRef]

50. Dul, J.; Weerdmeester, B. Ergonomics for Beginners: A Quick Reference Guide; CRC Press: Boca Raton, FL, USA, 2008.51. Suhardi, B.; Juwita, E.; Astuti, R.D. Facility layout improvement in sewing department with Systematic

Layout planning and ergonomics approach. Cogent Eng. 2019, 6. [CrossRef]52. Rothmore, P.; Aylward, P.; Karnon, J. The implementation of ergonomics advice and the stage of change

approach. Appl. Ergon. 2015, 51, 370–376. [CrossRef]53. Charles, L.E.; Ma, C.C.; Burchfiel, C.M.; Dong, R.G. Vibration and Ergonomic Exposures Associated with

Musculoskeletal Disorders of the Shoulder and Neck. Saf. Health Work 2018, 9, 125–132. [CrossRef]54. Kolus, A.; Wells, R.; Neumann, P. Production quality and human factors engineering: A systematic review

and theoretical framework. Appl. Ergon. 2018, 73, 55–89. [CrossRef]55. Properties, I.; Semg, O.F.L.; Systems, A. Overview of Contemporary Low-cost sEMG Hardware for

Appli-cations in Human Factors and Ergonomics. SAJE 2016, 60, 408–412.56. Silva, C.; Barros, C.; Cunha, L.; Carnide, F.; Santos, M. Prevalence of back pain problems in relation to

occupational group. Int. J. Ind. Ergon. 2016, 52, 52–58. [CrossRef]57. Gani, Z.; Abdullah, S.; Mustafa, N.A.N.N. Determination of Ergonomic Hazards at a Semiconductor

Manufacturing Company: An Initial Study. J. Asian Vocat. Educ. Train. 2015, 8, 25–35.58. Rehman, N. Ergonomics Risk Factors Prevailing in Kota Doria Loom Weavers of India; Springer International

Publishing: New York, NY, USA, 2019; Volume 820, ISBN 9783319960821.

Symmetry 2020, 12, 1414 21 of 22

59. Zhang, Z.; Way, K.; Zhang, W.; Ma, L.; Chen, Z. International Journal of Industrial Ergonomics Muscular fatigueand maximum endurance time assessment for male and female industrial workers. Int. J. Ind. Ergon. 2012, 6–11.[CrossRef]

60. Abubakar, M.I.; Wang, Q. Key human factors and their effects on human centered assembly performance.Int. J. Ind. Ergon. 2019, 69, 48–57. [CrossRef]

61. Sangwan, K.S.; Bhamu, J.; Mehta, D. Development of lean manufacturing implementation drivers for Indianceramic industry. Int. J. Product. Perform. Manag. 2014, 63, 569–587. [CrossRef]

62. Gandhi, N.S.; Thanki, S.J.; Thakkar, J.J. Ranking of Drivers for Integrated Lean-Green Manufacturing forIndian Manufacturing SMEs; Elsevier, B.V., Ed.; Elsevier: Amsterdam, The Netherlands, 2018; Volume 171,ISBN 9190335082.

63. Alasim, H.N.; Nimbarte, A.D.; Jaridi, M. Impact of pulling direction and magnitude of force exertion on theactivation of shoulder muscles. Int. J. Ind. Ergon. 2019, 69, 14–22. [CrossRef]

64. Thatcher, A.; Nayak, R.; Waterson, P. Human factors and ergonomics systems-based tools for understandingand addressing global problems of the twenty-first century. Ergonomics 2020, 63, 367–387. [CrossRef]

65. Tosi, F.; Pistolesi, M. Ergonomics Evaluation of Workstations for Mechanical Engineering Companies withParticular Attention to Older Workers. In Proceedings of the Congress of the International ErgonomicsAssociation, Florence, Italy, 26–30 August 2018; Springer: Cham, Switzerland, 2018; pp. 410–420.

66. Ahmad, N.; Rabbany, M.G.; Ali, S.M. Organizational and human factors related challenges to ISO 20000.Int. J. Manpow. 2019. [CrossRef]

67. Chang, D.Y. Applications of the extent analysis method on fuzzy AHP. Eur. J. Oper. Res. 1996, 95, 649–655.[CrossRef]

68. Vukadinovic, S.; Macuzic, I.; Djapan, M.; Milosevic, M. Early management of human factors in lean industrialsystems. Saf. Sci. 2019, 119, 392–398. [CrossRef]

69. Govindan, K.; Diabat, A.; Madan Shankar, K. Analyzing the drivers of green manufacturing with fuzzyapproach. J. Clean. Prod. 2015, 96, 182–193. [CrossRef]

70. Di Valentin, C.; Emrich, A.; Werth, D.; Loos, P. User-centric workflow ergonomics in industrial environments:Concept and architecture of an assistance system. In Proceedings of the 2015 International Conference onComputational Science and Computational Intelligence (CSCI’15), Las Vegas, NV, USA, 7–9 December 2015;IEEE: Piscataway, NJ, USA; pp. 754–759. [CrossRef]

71. Bontrup, C.; Taylor, W.R.; Fliesser, M.; Visscher, R.; Green, T.; Wippert, P.M.; Zemp, R. Low back pain andits relationship with sitting behaviour among sedentary office workers. Appl. Ergon. 2019, 81, 102894.[CrossRef] [PubMed]

72. Vulovic, R.; Papic, Ž.M.; Stankovic, N.; Papic, M. Ergonomics and Health issues caused by working withcomputer. Metal. Int. 2012, 17, 155.

73. Talapatra, S.; Rahman, M.H. Safety Awareness and Worker’s Health Hazards in the Garments Sector ofBangladesh. Eur. J. Adv. Eng. Technol. 2016, 3, 44–49.

74. Yung, M.; Kolus, A.; Wells, R.; Neumann, W.P. Examining the fatigue-quality relationship in manufacturing.Appl. Ergon. 2020, 82, 102919. [CrossRef] [PubMed]

75. Chang, C.W.; Wu, C.R.; Lin, C.T.; Chen, H.C. An application of AHP and sensitivity analysis for selecting thebest slicing machine. Comput. Ind. Eng. 2007, 52, 296–307. [CrossRef]

76. Banda, W. An integrated framework comprising of AHP, expert questionnaire survey and sensitivity analysisfor risk assessment in mining projects. Int. J. Manag. Sci. Eng. Manag. 2019, 14, 180–192. [CrossRef]

77. Goepel, K.D. Implementation of an Online Software Tool for the Analytic Hierarchy Process (AHP-OS). Int. J.Anal. Hierarchy Process. 2018, 10. [CrossRef]

78. Kadir, B.A.; Broberg, O.; Conceição, C.S. Current research and future perspectives on human factors andergonomics in Industry 4.0. Comput. Ind. Eng. 2019, 137, 106004. [CrossRef]

79. Baric, A. Corporate social responsibility and stakeholders: Review of the last decade (2006–2015). Bus. Syst.Res. J. 2017, 8, 133–146. [CrossRef]

80. Hendiani, S.; Bagherpour, M. Developing an integrated index to assess social sustainability in constructionindustry using fuzzy logic. J. Clean. Prod. 2019, 230, 647–662. [CrossRef]

81. Karthikeyan, K.; Aaron, K.P.; Krishnaraj, K.; Chandrasekaran, B.; Krishna, K.M.J. Study and Evaluation ofWork related Musculoskeletal Disorder risk in Leather Garments Manufacturing Industry. Int. J. Theor. Appl.Res. Mech. Eng. 2014, 3, 2319–3182.

Symmetry 2020, 12, 1414 22 of 22

82. Furjan, M.T.; Tomicic-Pupek, K.; Pihir, I. Understanding Digital Transformation Initiatives: Case StudiesAnalysis. Bus. Syst. Res. J. 2020, 11, 125–141. [CrossRef]

83. Pejic Bach, M.; Spremic, M.; Susa Vugec, D. Integrating Digital Transformation Strategies into Firms: Values, Routes andBest Practice Examples; Novo, M.P., Machado, C., Eds.; Taylor & Francis Group/CRC Press: Boca Raton, FL, USA,2018; ISBN 978-1-4987-8760-4.