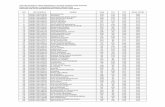

Roco Fittings: Product Catalogue 12125° 125° 175° 175° 90°90° 95° 95° 95° 95° 95° 95°...

Transcript of Roco Fittings: Product Catalogue 12125° 125° 175° 175° 90°90° 95° 95° 95° 95° 95° 95°...

Page 113• Spec i f i ca t ions and des ign sub jec t to change w i thout no t ice • A l l d imens ions in mi l l imet res (nomina l )• Spec i f i ca t ions and des ign sub jec t to change w i thout no t ice • A l l d imens ions in mi l l imet res (nomina l )

CONCEALED - HINGESCONCEALED - HINGES

CONCEALED HINGES

HINGES FGV

HINGES CABX

Page 114 • Spec i f i ca t ions and des ign sub jec t to change w i thout no t ice • A l l d imens ions in mi l l imet res (nomina l )

5

The Integra hinge is the latest solution for dampening

doors in the FGV range. A SlowMotion linear damper

hidden in the hinge arm offers effective and constant

performances under all conditions. A rapid installation

and 3D adjustments allow to nd easily the door’s

correct position. Integra is the right solution

to meet the customer’s needs keeping an eye on costs.

SlowMotion Inside

Integra

SlowMotion technology inside

Improved modern design

Strength and high performances

Easy click xing system

HINGES - FGVHINGES - FGV

CLIP ON HINGESCLICK HINGE INTEGRA WITHOUT DAMPER - FGV

FIXING TYPE TECHNICAL DRAWING OPENING ANGLE

R515SH50500C50000mm 110 Deg - Screw Fixing

166

HINGES

125° 125° 175° 175°

90° 90° 90° 90°

95° 95° 95° 95°95° 95°

90° 90°90° 90°

105° 105°105°105°110°110° 110° 110°

Angles

Cup hole distance

D

CUP HOLE DISTANCE 52x5.5mm

I

CUP HOLE DISTANCE 48x6mm

A

CUP HOLE DISTANCE 45x9.5mm

N

NYLON (GLASS)

KM

CUP HOLE DISTANCE 38x8mm

50

8

29K

38

66

7.5

43K

52

S

CUP HOLE DISTANCE 52x7.5mm

SELFTAPPING SCREW DOWEL

X-PANDO DOWEL EURO SCREW ZIP

VELOFIX DOWELCENTRA

Fixing System

Pictograms

11Values given in mm

105°105°

CRANK 0For lay-on doors

CRANK 8For partial lay-on doors

CRANK 15For inset doors

C A

H

K

T

C

H

C=A

H

K

37+

T37 37

K

T T

H=0

37

4

23.3

69

37

37+

T

H=0

27.6

69

H=0

36.3

69+

T

14 23

A

Table to determinate the minimum distance A so that a door with T thickness can open without protrusion from the cabinet and without interfering with adjacent doors.

T= 16 17 18 19 20 21 22 23 24 25 26

K=3 A= 0.9 1.1 1.5 1.8 2.3 2.8 3.6 4.3 5.2 6.0 6.9

K=4 A= 0.8 1.1 1.4 1.8 2.2 2.7 3.3 4.0 4.7 5.5 6.5

K=5 A= 0.8 1.0 1.3 1.7 2.1 2.5 3.1 3.7 4.4 5.1 5.9

K=6 A= 0.8 1.0 1.3 1.6 2.0 2.4 2.9 3.5 4.1 4.8 5.5

K=7 A= 0.7 1.0 1.3 1.6 1.9 2.3 2.7 3.3 3.8 4.5 5.2

3 4 5 6 7

21 0

20 0

19 0 2

18 0 2

17 0 2 4

16 2 4

15 2 4

14 4

13 4

Drilling distance (K)

Ove

rlay

(C

)

Mounting plates (H)

3 4 5 6 7

11 0

10 0

9 0 2

8 0 2

7 0 2 4

6 2 4

5 2 4

4 4

3 4

Drilling distance (K)

Ove

rlay

(C

)

Mounting plates (H)

3 4 5 6 7

4 2

3 2

2 0 2

1 0 2

0 0 2

Drilling distance (K)

Ove

rlay

(C

)

Mounting plates (H)

166

HINGES

125° 125° 175° 175°

90° 90° 90° 90°

95° 95° 95° 95°95° 95°

90° 90°90° 90°

105° 105°105°105°110°110° 110° 110°

Angles

Cup hole distance

D

CUP HOLE DISTANCE 52x5.5mm

I

CUP HOLE DISTANCE 48x6mm

A

CUP HOLE DISTANCE 45x9.5mm

N

NYLON (GLASS)

KM

CUP HOLE DISTANCE 38x8mm

50

8

29K

38

66

7.5

43K

52

S

CUP HOLE DISTANCE 52x7.5mm

SELFTAPPING SCREW DOWEL

X-PANDO DOWEL EURO SCREW ZIP

VELOFIX DOWELCENTRA

Fixing System

Pictograms

R515SH60500S50000mm 110 Deg - Dowel Fixing

166

HINGES

125° 125° 175° 175°

90° 90° 90° 90°

95° 95° 95° 95°95° 95°

90° 90°90° 90°

105° 105°105°105°110°110° 110° 110°

Angles

Cup hole distance

D

CUP HOLE DISTANCE 52x5.5mm

I

CUP HOLE DISTANCE 48x6mm

A

CUP HOLE DISTANCE 45x9.5mm

N

NYLON (GLASS)

KM

CUP HOLE DISTANCE 38x8mm

50

8

29K

38

66

7.5

43K

52

S

CUP HOLE DISTANCE 52x7.5mm

SELFTAPPING SCREW DOWEL

X-PANDO DOWEL EURO SCREW ZIP

VELOFIX DOWELCENTRA

Fixing System

Pictograms

R515SH50508C50008mm 110 Deg - Screw Fixing

166

HINGES

125° 125° 175° 175°

90° 90° 90° 90°

95° 95° 95° 95°95° 95°

90° 90°90° 90°

105° 105°105°105°110°110° 110° 110°

Angles

Cup hole distance

D

CUP HOLE DISTANCE 52x5.5mm

I

CUP HOLE DISTANCE 48x6mm

A

CUP HOLE DISTANCE 45x9.5mm

N

NYLON (GLASS)KM

CUP HOLE DISTANCE 38x8mm

50

8

29K

38

66

7.5

43K

52

S

CUP HOLE DISTANCE 52x7.5mm

SELFTAPPING SCREW DOWEL

X-PANDO DOWEL EURO SCREW ZIP

VELOFIX DOWELCENTRA

Fixing System

Pictograms

11Values given in mm

105°105°

CRANK 0For lay-on doors

CRANK 8For partial lay-on doors

CRANK 15For inset doors

C A

H

K

T

C

H

C=A

H

K

37+

T37 37

K

T T

H=0

37

4

23.3

69

37

37+

T

H=0

27.6

69

H=0

36.3

69+

T

14 23

A

Table to determinate the minimum distance A so that a door with T thickness can open without protrusion from the cabinet and without interfering with adjacent doors.

T= 16 17 18 19 20 21 22 23 24 25 26

K=3 A= 0.9 1.1 1.5 1.8 2.3 2.8 3.6 4.3 5.2 6.0 6.9

K=4 A= 0.8 1.1 1.4 1.8 2.2 2.7 3.3 4.0 4.7 5.5 6.5

K=5 A= 0.8 1.0 1.3 1.7 2.1 2.5 3.1 3.7 4.4 5.1 5.9

K=6 A= 0.8 1.0 1.3 1.6 2.0 2.4 2.9 3.5 4.1 4.8 5.5

K=7 A= 0.7 1.0 1.3 1.6 1.9 2.3 2.7 3.3 3.8 4.5 5.2

3 4 5 6 7

21 0

20 0

19 0 2

18 0 2

17 0 2 4

16 2 4

15 2 4

14 4

13 4

Drilling distance (K)

Ove

rlay

(C

)

Mounting plates (H)

3 4 5 6 7

11 0

10 0

9 0 2

8 0 2

7 0 2 4

6 2 4

5 2 4

4 4

3 4

Drilling distance (K)

Ove

rlay

(C

)

Mounting plates (H)

3 4 5 6 7

4 2

3 2

2 0 2

1 0 2

0 0 2

Drilling distance (K)

Ove

rlay

(C

)

Mounting plates (H)

166

HINGES

125° 125° 175° 175°

90° 90° 90° 90°

95° 95° 95° 95°95° 95°

90° 90°90° 90°

105° 105°105°105°110°110° 110° 110°

Angles

Cup hole distance

D

CUP HOLE DISTANCE 52x5.5mm

I

CUP HOLE DISTANCE 48x6mm

A

CUP HOLE DISTANCE 45x9.5mm

N

NYLON (GLASS)

KM

CUP HOLE DISTANCE 38x8mm

50

8

29K

38

66

7.5

43K

52

S

CUP HOLE DISTANCE 52x7.5mm

SELFTAPPING SCREW DOWEL

X-PANDO DOWEL EURO SCREW ZIP

VELOFIX DOWELCENTRA

Fixing System

Pictograms

R515SH60508S50008mm 110 Deg - Dowel Fixing

166

HINGES

125° 125° 175° 175°

90° 90° 90° 90°

95° 95° 95° 95°95° 95°

90° 90°90° 90°

105° 105°105°105°110°110° 110° 110°

Angles

Cup hole distance

D

CUP HOLE DISTANCE 52x5.5mm

I

CUP HOLE DISTANCE 48x6mm

A

CUP HOLE DISTANCE 45x9.5mm

N

NYLON (GLASS)

KM

CUP HOLE DISTANCE 38x8mm

50

8

29K

38

66

7.5

43K

52

S

CUP HOLE DISTANCE 52x7.5mm

SELFTAPPING SCREW DOWEL

X-PANDO DOWEL EURO SCREW ZIP

VELOFIX DOWELCENTRA

Fixing System

Pictograms

R515SH50515C500015mm 110 Deg - Screw Fixing

166

HINGES

125° 125° 175° 175°

90° 90° 90° 90°

95° 95° 95° 95°95° 95°

90° 90°90° 90°

105° 105°105°105°110°110° 110° 110°

Angles

Cup hole distance

D

CUP HOLE DISTANCE 52x5.5mm

I

CUP HOLE DISTANCE 48x6mm

A

CUP HOLE DISTANCE 45x9.5mm

N

NYLON (GLASS)

KM

CUP HOLE DISTANCE 38x8mm

50

8

29K

38

66

7.5

43K

52

S

CUP HOLE DISTANCE 52x7.5mm

SELFTAPPING SCREW DOWEL

X-PANDO DOWEL EURO SCREW ZIP

VELOFIX DOWELCENTRA

Fixing System

Pictograms

11Values given in mm

105°105°

CRANK 0For lay-on doors

CRANK 8For partial lay-on doors

CRANK 15For inset doors

C A

H

K

T

C

H

C=A

H

K

37+

T37 37

K

T T

H=0

37

4

23.3

69

37

37+

T

H=0

27.6

69

H=0

36.3

69+

T

14 23

A

Table to determinate the minimum distance A so that a door with T thickness can open without protrusion from the cabinet and without interfering with adjacent doors.

T= 16 17 18 19 20 21 22 23 24 25 26

K=3 A= 0.9 1.1 1.5 1.8 2.3 2.8 3.6 4.3 5.2 6.0 6.9

K=4 A= 0.8 1.1 1.4 1.8 2.2 2.7 3.3 4.0 4.7 5.5 6.5

K=5 A= 0.8 1.0 1.3 1.7 2.1 2.5 3.1 3.7 4.4 5.1 5.9

K=6 A= 0.8 1.0 1.3 1.6 2.0 2.4 2.9 3.5 4.1 4.8 5.5

K=7 A= 0.7 1.0 1.3 1.6 1.9 2.3 2.7 3.3 3.8 4.5 5.2

3 4 5 6 7

21 0

20 0

19 0 2

18 0 2

17 0 2 4

16 2 4

15 2 4

14 4

13 4

Drilling distance (K)

Ove

rlay

(C

)

Mounting plates (H)

3 4 5 6 7

11 0

10 0

9 0 2

8 0 2

7 0 2 4

6 2 4

5 2 4

4 4

3 4

Drilling distance (K)

Ove

rlay

(C

)

Mounting plates (H)

3 4 5 6 7

4 2

3 2

2 0 2

1 0 2

0 0 2

Drilling distance (K)

Ove

rlay

(C

)

Mounting plates (H)166

HINGES

125° 125° 175° 175°

90° 90° 90° 90°

95° 95° 95° 95°95° 95°

90° 90°90° 90°

105° 105°105°105°110°110° 110° 110°

Angles

Cup hole distance

D

CUP HOLE DISTANCE 52x5.5mm

I

CUP HOLE DISTANCE 48x6mm

A

CUP HOLE DISTANCE 45x9.5mm

N

NYLON (GLASS)

KM

CUP HOLE DISTANCE 38x8mm

50

8

29K

38

66

7.5

43K

52

S

CUP HOLE DISTANCE 52x7.5mm

SELFTAPPING SCREW DOWEL

X-PANDO DOWEL EURO SCREW ZIP

VELOFIX DOWELCENTRA

Fixing System

Pictograms

R515SH60515S500015mm 110 Deg - Dowel Fixing

166

HINGES

125° 125° 175° 175°

90° 90° 90° 90°

95° 95° 95° 95°95° 95°

90° 90°90° 90°

105° 105°105°105°110°110° 110° 110°

Angles

Cup hole distance

D

CUP HOLE DISTANCE 52x5.5mm

I

CUP HOLE DISTANCE 48x6mm

A

CUP HOLE DISTANCE 45x9.5mm

N

NYLON (GLASS)

KM

CUP HOLE DISTANCE 38x8mm

50

8

29K

38

66

7.5

43K

52

S

CUP HOLE DISTANCE 52x7.5mm

SELFTAPPING SCREW DOWEL

X-PANDO DOWEL EURO SCREW ZIP

VELOFIX DOWELCENTRA

Fixing System

Pictograms

R515H850545C500045 Deg - Screw Fixing

166

HINGES

125° 125° 175° 175°

90° 90° 90° 90°

95° 95° 95° 95°95° 95°

90° 90°90° 90°

105° 105°105°105°110°110° 110° 110°

Angles

Cup hole distance

D

CUP HOLE DISTANCE 52x5.5mm

I

CUP HOLE DISTANCE 48x6mm

A

CUP HOLE DISTANCE 45x9.5mm

N

NYLON (GLASS)

KM

CUP HOLE DISTANCE 38x8mm

50

8

29K

38

66

7.5

43K

52

S

CUP HOLE DISTANCE 52x7.5mm

SELFTAPPING SCREW DOWEL

X-PANDO DOWEL EURO SCREW ZIP

VELOFIX DOWELCENTRA

Fixing System

Pictograms

15Values given in mm

ANGLE 30° ANGLE 45° ANGLE 90°

105° 105°

K K

C

T30

°

H=0 H=0

37

C

45°

H=0

37

T

69 69

C

90°

K

T

23

55

Table to determinate the minimum distance A so that a door with T thickness can open without protrusion from the cabinet and without interfering with adjacent doors.

T= 16 17 18 19 20 21 22 23 24 25 26

K=3 A= 0.9 1.1 1.5 1.8 2.3 2.8 3.6 4.3 5.2 6.0 6.9

K=4 A= 0.8 1.1 1.4 1.8 2.2 2.7 3.3 4.0 4.7 5.5 6.5

K=5 A= 0.8 1.0 1.3 1.7 2.1 2.5 3.1 3.7 4.4 5.1 5.9

K=6 A= 0.8 1.0 1.3 1.6 2.0 2.4 2.9 3.5 4.1 4.8 5.5

K=7 A= 0.7 1.0 1.3 1.6 1.9 2.3 2.7 3.3 3.8 4.5 5.2

166

HINGES

125° 125° 175° 175°

90° 90° 90° 90°

95° 95° 95° 95°95° 95°

90° 90°90° 90°

105° 105°105°105°110°110° 110° 110°

Angles

Cup hole distance

D

CUP HOLE DISTANCE 52x5.5mm

I

CUP HOLE DISTANCE 48x6mm

A

CUP HOLE DISTANCE 45x9.5mm

N

NYLON (GLASS)

KM

CUP HOLE DISTANCE 38x8mm

50

8

29K

38

66

7.5

43K

52

S

CUP HOLE DISTANCE 52x7.5mm

SELFTAPPING SCREW DOWEL

X-PANDO DOWEL EURO SCREW ZIP

VELOFIX DOWELCENTRA

Fixing System

Pictograms

R51AH860545S500045 Deg - Dowel Fixing

166

HINGES

125° 125° 175° 175°

90° 90° 90° 90°

95° 95° 95° 95°95° 95°

90° 90°90° 90°

105° 105°105°105°110°110° 110° 110°

Angles

Cup hole distance

D

CUP HOLE DISTANCE 52x5.5mm

I

CUP HOLE DISTANCE 48x6mm

A

CUP HOLE DISTANCE 45x9.5mm

N

NYLON (GLASS)

KM

CUP HOLE DISTANCE 38x8mm

50

8

29K

38

66

7.5

43K

52

S

CUP HOLE DISTANCE 52x7.5mm

SELFTAPPING SCREW DOWEL

X-PANDO DOWEL EURO SCREW ZIP

VELOFIX DOWELCENTRA

Fixing System

Pictograms

R515WH50500C50000mm 175 Deg - Screw Fixing

166

HINGES

125° 125° 175° 175°

90° 90° 90° 90°

95° 95° 95° 95°95° 95°

90° 90°90° 90°

105° 105°105°105°110°110° 110° 110°

Angles

Cup hole distance

D

CUP HOLE DISTANCE 52x5.5mm

I

CUP HOLE DISTANCE 48x6mm

A

CUP HOLE DISTANCE 45x9.5mm

N

NYLON (GLASS)

KM

CUP HOLE DISTANCE 38x8mm

50

8

29K

38

66

7.5

43K

52

S

CUP HOLE DISTANCE 52x7.5mm

SELFTAPPING SCREW DOWEL

X-PANDO DOWEL EURO SCREW ZIP

VELOFIX DOWELCENTRA

Fixing System

Pictograms37

H=0

2.7

46

69

37

H=0

K

T

C A 37

60.1

37

12.7

H=0

56

69

H=0

C A

K

T

70.1

H=0

T

26.2

69

3720

°

37

H=0

36.2

69

T

20°

13Values given in mm

165° 165°

CRANK 0For lay-on doors

CRANK 8For partial lay-on doors

3 4 5 6 7

21 0

20 0

19 0 2

18 0 2

17 0 2

16 2

15 2

Drilling distance (K)

Ove

rlay

(C

)

Mounting plates (H)

3 4 5 6 7

11 0

10 0

9 0 2

8 0 2

7 0 2

6 2

5 2

Drilling distance (K)

Ove

rlay

(C

)

Mounting plates (H)

T= 16 17 18 19 20 21 22 23 24 25 26

K=3 A= 0.0 0.0 0.0 0.0 0.0 0.0 0.06 0.19 0.41 0.77 1.31

K=4 A= 0.0 0.0 0.0 0.0 0.0 0.0 0.06 0.21 0.46 0.88 1.57

K=5 A= 0.0 0.0 0.0 0.0 0.0 0.0 0.07 0.52 1.05 1.05 2.13

K=6 A= 0.0 0.0 0.0 0.0 0.0 0.0 0.08 0.62 2.33 2.33 3.33

K=7 A= 0.0 0.0 0.0 0.0 0.0 0.0 0.09 0.75 1.33 1.33 2.33

Table to determinate the minimum distance A so that a door with T thickness can open without protrusion from the cabinet and without interfering with adjacent doors.

166

HINGES

125° 125° 175° 175°

90° 90° 90° 90°

95° 95° 95° 95°95° 95°

90° 90°90° 90°

105° 105°105°105°110°110° 110° 110°

Angles

Cup hole distance

D

CUP HOLE DISTANCE 52x5.5mm

I

CUP HOLE DISTANCE 48x6mm

A

CUP HOLE DISTANCE 45x9.5mm

N

NYLON (GLASS)

KM

CUP HOLE DISTANCE 38x8mm

50

8

29K

38

66

7.5

43K

52

S

CUP HOLE DISTANCE 52x7.5mm

SELFTAPPING SCREW DOWEL

X-PANDO DOWEL EURO SCREW ZIP

VELOFIX DOWELCENTRA

Fixing System

Pictograms

R515WH60500S50000mm 175 Deg - Dowel Fixing

166

HINGES

125° 125° 175° 175°

90° 90° 90° 90°

95° 95° 95° 95°95° 95°

90° 90°90° 90°

105° 105°105°105°110°110° 110° 110°

Angles

Cup hole distance

D

CUP HOLE DISTANCE 52x5.5mm

I

CUP HOLE DISTANCE 48x6mm

A

CUP HOLE DISTANCE 45x9.5mm

N

NYLON (GLASS)

KM

CUP HOLE DISTANCE 38x8mm

50

8

29K

38

66

7.5

43K

52

S

CUP HOLE DISTANCE 52x7.5mm

SELFTAPPING SCREW DOWEL

X-PANDO DOWEL EURO SCREW ZIP

VELOFIX DOWELCENTRA

Fixing System

Pictograms

R515H850590C500090 Deg Blind Cnr - Screw Fixing

166

HINGES

125° 125° 175° 175°

90° 90° 90° 90°

95° 95° 95° 95°95° 95°

90° 90°90° 90°

105° 105°105°105°110°110° 110° 110°

Angles

Cup hole distance

D

CUP HOLE DISTANCE 52x5.5mm

I

CUP HOLE DISTANCE 48x6mm

A

CUP HOLE DISTANCE 45x9.5mm

N

NYLON (GLASS)

KM

CUP HOLE DISTANCE 38x8mm

50

8

29K

38

66

7.5

43K

52

S

CUP HOLE DISTANCE 52x7.5mm

SELFTAPPING SCREW DOWEL

X-PANDO DOWEL EURO SCREW ZIP

VELOFIX DOWELCENTRA

Fixing System

Pictograms

15Values given in mm

ANGLE 30° ANGLE 45° ANGLE 90°

105° 105°

K K

C

T30

°

H=0 H=0

37

C

45°

H=0

37

T

69 69

C

90°

K

T

23

55

Table to determinate the minimum distance A so that a door with T thickness can open without protrusion from the cabinet and without interfering with adjacent doors.

T= 16 17 18 19 20 21 22 23 24 25 26

K=3 A= 0.9 1.1 1.5 1.8 2.3 2.8 3.6 4.3 5.2 6.0 6.9

K=4 A= 0.8 1.1 1.4 1.8 2.2 2.7 3.3 4.0 4.7 5.5 6.5

K=5 A= 0.8 1.0 1.3 1.7 2.1 2.5 3.1 3.7 4.4 5.1 5.9

K=6 A= 0.8 1.0 1.3 1.6 2.0 2.4 2.9 3.5 4.1 4.8 5.5

K=7 A= 0.7 1.0 1.3 1.6 1.9 2.3 2.7 3.3 3.8 4.5 5.2166

HINGES

125° 125° 175° 175°

90° 90° 90° 90°

95° 95° 95° 95°95° 95°

90° 90°90° 90°

105° 105°105°105°110°110° 110° 110°

Angles

Cup hole distance

D

CUP HOLE DISTANCE 52x5.5mm

I

CUP HOLE DISTANCE 48x6mm

A

CUP HOLE DISTANCE 45x9.5mm

N

NYLON (GLASS)

KM

CUP HOLE DISTANCE 38x8mm

50

8

29K

38

66

7.5

43K

52

S

CUP HOLE DISTANCE 52x7.5mm

SELFTAPPING SCREW DOWEL

X-PANDO DOWEL EURO SCREW ZIP

VELOFIX DOWELCENTRA

Fixing System

Pictograms

R51AH860530S500030 Deg - Screw Fixing

166

HINGES

125° 125° 175° 175°

90° 90° 90° 90°

95° 95° 95° 95°95° 95°

90° 90°90° 90°

105° 105°105°105°110°110° 110° 110°

Angles

Cup hole distance

D

CUP HOLE DISTANCE 52x5.5mm

I

CUP HOLE DISTANCE 48x6mm

A

CUP HOLE DISTANCE 45x9.5mm

N

NYLON (GLASS)

KM

CUP HOLE DISTANCE 38x8mm

50

8

29K

38

66

7.5

43K

52

S

CUP HOLE DISTANCE 52x7.5mm

SELFTAPPING SCREW DOWEL

X-PANDO DOWEL EURO SCREW ZIP

VELOFIX DOWELCENTRA

Fixing System

Pictograms

15Values given in mm

ANGLE 30° ANGLE 45° ANGLE 90°

105° 105°

K K

C

T30

°

H=0 H=0

37

C

45°

H=0

37

T

69 69

C

90°

K

T

23

55

Table to determinate the minimum distance A so that a door with T thickness can open without protrusion from the cabinet and without interfering with adjacent doors.

T= 16 17 18 19 20 21 22 23 24 25 26

K=3 A= 0.9 1.1 1.5 1.8 2.3 2.8 3.6 4.3 5.2 6.0 6.9

K=4 A= 0.8 1.1 1.4 1.8 2.2 2.7 3.3 4.0 4.7 5.5 6.5

K=5 A= 0.8 1.0 1.3 1.7 2.1 2.5 3.1 3.7 4.4 5.1 5.9

K=6 A= 0.8 1.0 1.3 1.6 2.0 2.4 2.9 3.5 4.1 4.8 5.5

K=7 A= 0.7 1.0 1.3 1.6 1.9 2.3 2.7 3.3 3.8 4.5 5.2

166

HINGES

125° 125° 175° 175°

90° 90° 90° 90°

95° 95° 95° 95°95° 95°

90° 90°90° 90°

105° 105°105°105°110°110° 110° 110°

Angles

Cup hole distance

D

CUP HOLE DISTANCE 52x5.5mm

I

CUP HOLE DISTANCE 48x6mm

A

CUP HOLE DISTANCE 45x9.5mm

N

NYLON (GLASS)

KM

CUP HOLE DISTANCE 38x8mm

50

8

29K

38

66

7.5

43K

52

S

CUP HOLE DISTANCE 52x7.5mm

SELFTAPPING SCREW DOWEL

X-PANDO DOWEL EURO SCREW ZIP

VELOFIX DOWELCENTRA

Fixing System

Pictograms

HINGES - FGVA premium worldwide brand associated with Roco Fittings for the past 25 years. FGV is built on quality & reliability.

Page 115• Spec i f i ca t ions and des ign sub jec t to change w i thout no t ice • A l l d imens ions in mi l l imet res (nomina l )

167

LEV

A

MOUNTING PLATES

SELFTAPPING SCREW

EURO SCREW

DOWEL

X-PANDO DOWEL

Fixing System

37DRILLING DISTANCE 37mm

DRILLING DISTANCE 28mm

28

WALL HANGING BRACKETS

SELFTAPPING SCREW DOWEL X-PANDO DOWEL

Fixing System

STEEL NYLON ABS POLYSTYRENE

Material

TECHNOLOGIES

GENIOS

ONETOUCH SLOWMOTION ZITTO

SLOWMOTION ALFA SLOWMOTION DELTA

167

LEV

A

MOUNTING PLATES

SELFTAPPING SCREW

EURO SCREW

DOWEL

X-PANDO DOWEL

Fixing System

37DRILLING DISTANCE 37mm

DRILLING DISTANCE 28mm

28

WALL HANGING BRACKETS

SELFTAPPING SCREW DOWEL X-PANDO DOWEL

Fixing System

STEEL NYLON ABS POLYSTYRENE

Material

TECHNOLOGIES

GENIOS

ONETOUCH SLOWMOTION ZITTO

SLOWMOTION ALFA SLOWMOTION DELTA

167

LEV

AMOUNTING PLATES

SELFTAPPING SCREW

EURO SCREW

DOWEL

X-PANDO DOWEL

Fixing System

37DRILLING DISTANCE 37mm

DRILLING DISTANCE 28mm

28

WALL HANGING BRACKETS

SELFTAPPING SCREW DOWEL X-PANDO DOWEL

Fixing System

STEEL NYLON ABS POLYSTYRENE

Material

TECHNOLOGIES

GENIOS

ONETOUCH SLOWMOTION ZITTO

SLOWMOTION ALFA SLOWMOTION DELTA

SOFT CLOSING

HINGES - FGVHINGES - FGV

INTEGRA CLICK PLATE - SCREW FIXING

R525A01M50200000 2mm Screw Fixing

R525A01M50400000 4mm Screw Fixing

R525A33M500000 0mm V Shaped 4 Holes Screw Fixing ( Frame Hinge )

R52RA44L50205000 2mm With Cam Adjustment & Stp Screws

INTEGRA CLICK PLATE - X-PANDO DOWEL

R525AN5M50200000 2mm With X-Pando Dowels 5mm X 9.8mm

INTEGRA CLICK PLATE - EUROSCREW

R52RA47L502A5000 2mm With Cam Adjustment & 14mm Euroscrews

CLICK HINGE INTEGRA WITH DAMPER - FGVFIXING TYPE TECHNICAL DRAWING OPENING ANGLE

R51ASH50500C50000mm 110 Deg - Screw Fixing

166

HINGES

125° 125° 175° 175°

90° 90° 90° 90°

95° 95° 95° 95°95° 95°

90° 90°90° 90°

105° 105°105°105°110°110° 110° 110°

Angles

Cup hole distance

D

CUP HOLE DISTANCE 52x5.5mm

I

CUP HOLE DISTANCE 48x6mm

A

CUP HOLE DISTANCE 45x9.5mm

N

NYLON (GLASS)

KM

CUP HOLE DISTANCE 38x8mm

50

8

29K

38

66

7.5

43K

52

S

CUP HOLE DISTANCE 52x7.5mm

SELFTAPPING SCREW DOWEL

X-PANDO DOWEL EURO SCREW ZIP

VELOFIX DOWELCENTRA

Fixing System

Pictograms

11Values given in mm

105°105°

CRANK 0For lay-on doors

CRANK 8For partial lay-on doors

CRANK 15For inset doors

C A

H

K

T

C

H

C=A

H

K

37+

T37 37

K

T T

H=0

37

4

23.3

69

37

37+

T

H=0

27.6

69

H=0

36.3

69+

T

14 23

A

Table to determinate the minimum distance A so that a door with T thickness can open without protrusion from the cabinet and without interfering with adjacent doors.

T= 16 17 18 19 20 21 22 23 24 25 26

K=3 A= 0.9 1.1 1.5 1.8 2.3 2.8 3.6 4.3 5.2 6.0 6.9

K=4 A= 0.8 1.1 1.4 1.8 2.2 2.7 3.3 4.0 4.7 5.5 6.5

K=5 A= 0.8 1.0 1.3 1.7 2.1 2.5 3.1 3.7 4.4 5.1 5.9

K=6 A= 0.8 1.0 1.3 1.6 2.0 2.4 2.9 3.5 4.1 4.8 5.5

K=7 A= 0.7 1.0 1.3 1.6 1.9 2.3 2.7 3.3 3.8 4.5 5.2

3 4 5 6 7

21 0

20 0

19 0 2

18 0 2

17 0 2 4

16 2 4

15 2 4

14 4

13 4

Drilling distance (K)

Ove

rlay

(C

)

Mounting plates (H)

3 4 5 6 7

11 0

10 0

9 0 2

8 0 2

7 0 2 4

6 2 4

5 2 4

4 4

3 4

Drilling distance (K)

Ove

rlay

(C

)

Mounting plates (H)

3 4 5 6 7

4 2

3 2

2 0 2

1 0 2

0 0 2

Drilling distance (K)

Ove

rlay

(C

)

Mounting plates (H)166

HINGES

125° 125° 175° 175°

90° 90° 90° 90°

95° 95° 95° 95°95° 95°

90° 90°90° 90°

105° 105°105°105°110°110° 110° 110°

Angles

Cup hole distance

D

CUP HOLE DISTANCE 52x5.5mm

I

CUP HOLE DISTANCE 48x6mm

A

CUP HOLE DISTANCE 45x9.5mm

N

NYLON (GLASS)

KM

CUP HOLE DISTANCE 38x8mm

50

8

29K

38

66

7.5

43K

52

S

CUP HOLE DISTANCE 52x7.5mm

SELFTAPPING SCREW DOWEL

X-PANDO DOWEL EURO SCREW ZIP

VELOFIX DOWELCENTRA

Fixing System

Pictograms

R51ASH60500S50000mm 110 Deg - Dowel Fixing

166

HINGES

125° 125° 175° 175°

90° 90° 90° 90°

95° 95° 95° 95°95° 95°

90° 90°90° 90°

105° 105°105°105°110°110° 110° 110°

Angles

Cup hole distance

D

CUP HOLE DISTANCE 52x5.5mm

I

CUP HOLE DISTANCE 48x6mm

A

CUP HOLE DISTANCE 45x9.5mm

N

NYLON (GLASS)

KM

CUP HOLE DISTANCE 38x8mm

50

8

29K

38

66

7.5

43K

52

S

CUP HOLE DISTANCE 52x7.5mm

SELFTAPPING SCREW DOWEL

X-PANDO DOWEL EURO SCREW ZIP

VELOFIX DOWELCENTRA

Fixing System

Pictograms

R51ASH50508C50008mm 110 Deg - Screw Fixing

166

HINGES

125° 125° 175° 175°

90° 90° 90° 90°

95° 95° 95° 95°95° 95°

90° 90°90° 90°

105° 105°105°105°110°110° 110° 110°

Angles

Cup hole distance

D

CUP HOLE DISTANCE 52x5.5mm

I

CUP HOLE DISTANCE 48x6mm

A

CUP HOLE DISTANCE 45x9.5mm

N

NYLON (GLASS)

KM

CUP HOLE DISTANCE 38x8mm

50

8

29K

38

66

7.5

43K

52

S

CUP HOLE DISTANCE 52x7.5mm

SELFTAPPING SCREW DOWEL

X-PANDO DOWEL EURO SCREW ZIP

VELOFIX DOWELCENTRA

Fixing System

Pictograms

11Values given in mm

105°105°

CRANK 0For lay-on doors

CRANK 8For partial lay-on doors

CRANK 15For inset doors

C A

H

K

T

C

H

C=A

H

K

37+

T37 37

K

T T

H=0

37

4

23.3

69

37

37+

T

H=0

27.6

69

H=0

36.3

69+

T

14 23

A

Table to determinate the minimum distance A so that a door with T thickness can open without protrusion from the cabinet and without interfering with adjacent doors.

T= 16 17 18 19 20 21 22 23 24 25 26

K=3 A= 0.9 1.1 1.5 1.8 2.3 2.8 3.6 4.3 5.2 6.0 6.9

K=4 A= 0.8 1.1 1.4 1.8 2.2 2.7 3.3 4.0 4.7 5.5 6.5

K=5 A= 0.8 1.0 1.3 1.7 2.1 2.5 3.1 3.7 4.4 5.1 5.9

K=6 A= 0.8 1.0 1.3 1.6 2.0 2.4 2.9 3.5 4.1 4.8 5.5

K=7 A= 0.7 1.0 1.3 1.6 1.9 2.3 2.7 3.3 3.8 4.5 5.2

3 4 5 6 7

21 0

20 0

19 0 2

18 0 2

17 0 2 4

16 2 4

15 2 4

14 4

13 4

Drilling distance (K)

Ove

rlay

(C

)

Mounting plates (H)

3 4 5 6 7

11 0

10 0

9 0 2

8 0 2

7 0 2 4

6 2 4

5 2 4

4 4

3 4

Drilling distance (K)

Ove

rlay

(C

)

Mounting plates (H)

3 4 5 6 7

4 2

3 2

2 0 2

1 0 2

0 0 2

Drilling distance (K)

Ove

rlay

(C

)

Mounting plates (H)

166

HINGES

125° 125° 175° 175°

90° 90° 90° 90°

95° 95° 95° 95°95° 95°

90° 90°90° 90°

105° 105°105°105°110°110° 110° 110°

Angles

Cup hole distance

D

CUP HOLE DISTANCE 52x5.5mm

I

CUP HOLE DISTANCE 48x6mm

A

CUP HOLE DISTANCE 45x9.5mm

N

NYLON (GLASS)

KM

CUP HOLE DISTANCE 38x8mm

50

8

29K

38

66

7.5

43K

52

S

CUP HOLE DISTANCE 52x7.5mm

SELFTAPPING SCREW DOWEL

X-PANDO DOWEL EURO SCREW ZIP

VELOFIX DOWELCENTRA

Fixing System

Pictograms

R51ASH60508S50008mm 110 Deg - Dowel Fixing

166

HINGES

125° 125° 175° 175°

90° 90° 90° 90°

95° 95° 95° 95°95° 95°

90° 90°90° 90°

105° 105°105°105°110°110° 110° 110°

Angles

Cup hole distance

D

CUP HOLE DISTANCE 52x5.5mm

I

CUP HOLE DISTANCE 48x6mm

A

CUP HOLE DISTANCE 45x9.5mm

N

NYLON (GLASS)

KM

CUP HOLE DISTANCE 38x8mm

50

8

29K

38

66

7.5

43K

52

S

CUP HOLE DISTANCE 52x7.5mm

SELFTAPPING SCREW DOWEL

X-PANDO DOWEL EURO SCREW ZIP

VELOFIX DOWELCENTRA

Fixing System

Pictograms

R51ASH50515C500015mm 110 Deg - Screw Fixing

166

HINGES

125° 125° 175° 175°

90° 90° 90° 90°

95° 95° 95° 95°95° 95°

90° 90°90° 90°

105° 105°105°105°110°110° 110° 110°

Angles

Cup hole distance

D

CUP HOLE DISTANCE 52x5.5mm

I

CUP HOLE DISTANCE 48x6mm

A

CUP HOLE DISTANCE 45x9.5mm

N

NYLON (GLASS)

KM

CUP HOLE DISTANCE 38x8mm

50

8

29K

38

66

7.5

43K

52

S

CUP HOLE DISTANCE 52x7.5mm

SELFTAPPING SCREW DOWEL

X-PANDO DOWEL EURO SCREW ZIP

VELOFIX DOWELCENTRA

Fixing System

Pictograms

11Values given in mm

105°105°

CRANK 0For lay-on doors

CRANK 8For partial lay-on doors

CRANK 15For inset doors

C A

H

K

T

C

H

C=A

H

K

37+

T37 37K

T T

H=0

37

4

23.3

69

37

37+

T

H=0

27.6

69

H=0

36.3

69+

T

14 23

A

Table to determinate the minimum distance A so that a door with T thickness can open without protrusion from the cabinet and without interfering with adjacent doors.

T= 16 17 18 19 20 21 22 23 24 25 26

K=3 A= 0.9 1.1 1.5 1.8 2.3 2.8 3.6 4.3 5.2 6.0 6.9

K=4 A= 0.8 1.1 1.4 1.8 2.2 2.7 3.3 4.0 4.7 5.5 6.5

K=5 A= 0.8 1.0 1.3 1.7 2.1 2.5 3.1 3.7 4.4 5.1 5.9

K=6 A= 0.8 1.0 1.3 1.6 2.0 2.4 2.9 3.5 4.1 4.8 5.5

K=7 A= 0.7 1.0 1.3 1.6 1.9 2.3 2.7 3.3 3.8 4.5 5.2

3 4 5 6 7

21 0

20 0

19 0 2

18 0 2

17 0 2 4

16 2 4

15 2 4

14 4

13 4

Drilling distance (K)

Ove

rlay

(C

)

Mounting plates (H)

3 4 5 6 7

11 0

10 0

9 0 2

8 0 2

7 0 2 4

6 2 4

5 2 4

4 4

3 4

Drilling distance (K)

Ove

rlay

(C

)

Mounting plates (H)

3 4 5 6 7

4 2

3 2

2 0 2

1 0 2

0 0 2

Drilling distance (K)

Ove

rlay

(C

)

Mounting plates (H) 166

HINGES

125° 125° 175° 175°

90° 90° 90° 90°

95° 95° 95° 95°95° 95°

90° 90°90° 90°

105° 105°105°105°110°110° 110° 110°

Angles

Cup hole distance

D

CUP HOLE DISTANCE 52x5.5mm

I

CUP HOLE DISTANCE 48x6mm

A

CUP HOLE DISTANCE 45x9.5mm

N

NYLON (GLASS)

KM

CUP HOLE DISTANCE 38x8mm

50

8

29K

38

66

7.5

43K

52

S

CUP HOLE DISTANCE 52x7.5mm

SELFTAPPING SCREW DOWEL

X-PANDO DOWEL EURO SCREW ZIP

VELOFIX DOWELCENTRA

Fixing System

Pictograms

R51ASH60515S500015mm 110 Deg - Dowel Fixing

166

HINGES

125° 125° 175° 175°

90° 90° 90° 90°

95° 95° 95° 95°95° 95°

90° 90°90° 90°

105° 105°105°105°110°110° 110° 110°

Angles

Cup hole distance

D

CUP HOLE DISTANCE 52x5.5mm

I

CUP HOLE DISTANCE 48x6mm

A

CUP HOLE DISTANCE 45x9.5mm

N

NYLON (GLASS)

KM

CUP HOLE DISTANCE 38x8mm

50

8

29K

38

66

7.5

43K

52

S

CUP HOLE DISTANCE 52x7.5mm

SELFTAPPING SCREW DOWEL

X-PANDO DOWEL EURO SCREW ZIP

VELOFIX DOWELCENTRA

Fixing System

Pictograms

R51AH850545C500045 Deg - Screw Fixing

166

HINGES

125° 125° 175° 175°

90° 90° 90° 90°

95° 95° 95° 95°95° 95°

90° 90°90° 90°

105° 105°105°105°110°110° 110° 110°

Angles

Cup hole distance

D

CUP HOLE DISTANCE 52x5.5mm

I

CUP HOLE DISTANCE 48x6mm

A

CUP HOLE DISTANCE 45x9.5mm

N

NYLON (GLASS)

KM

CUP HOLE DISTANCE 38x8mm

50

8

29K

38

66

7.5

43K

52

S

CUP HOLE DISTANCE 52x7.5mm

SELFTAPPING SCREW DOWEL

X-PANDO DOWEL EURO SCREW ZIP

VELOFIX DOWELCENTRA

Fixing System

Pictograms

15Values given in mm

ANGLE 30° ANGLE 45° ANGLE 90°

105° 105°

K K

C

T30

°

H=0 H=0

37

C

45°

H=0

37

T

69 69

C

90°

K

T

23

55

Table to determinate the minimum distance A so that a door with T thickness can open without protrusion from the cabinet and without interfering with adjacent doors.

T= 16 17 18 19 20 21 22 23 24 25 26

K=3 A= 0.9 1.1 1.5 1.8 2.3 2.8 3.6 4.3 5.2 6.0 6.9

K=4 A= 0.8 1.1 1.4 1.8 2.2 2.7 3.3 4.0 4.7 5.5 6.5

K=5 A= 0.8 1.0 1.3 1.7 2.1 2.5 3.1 3.7 4.4 5.1 5.9

K=6 A= 0.8 1.0 1.3 1.6 2.0 2.4 2.9 3.5 4.1 4.8 5.5

K=7 A= 0.7 1.0 1.3 1.6 1.9 2.3 2.7 3.3 3.8 4.5 5.2

166

HINGES

125° 125° 175° 175°

90° 90° 90° 90°

95° 95° 95° 95°95° 95°

90° 90°90° 90°

105° 105°105°105°110°110° 110° 110°

Angles

Cup hole distance

D

CUP HOLE DISTANCE 52x5.5mm

I

CUP HOLE DISTANCE 48x6mm

A

CUP HOLE DISTANCE 45x9.5mm

N

NYLON (GLASS)

KM

CUP HOLE DISTANCE 38x8mm

50

8

29K

38

66

7.5

43K

52

S

CUP HOLE DISTANCE 52x7.5mm

SELFTAPPING SCREW DOWEL

X-PANDO DOWEL EURO SCREW ZIP

VELOFIX DOWELCENTRA

Fixing System

Pictograms

R51AWH50500C50000mm 175 Deg - Screw Fixing

166

HINGES

125° 125° 175° 175°

90° 90° 90° 90°

95° 95° 95° 95°95° 95°

90° 90°90° 90°

105° 105°105°105°110°110° 110° 110°

Angles

Cup hole distance

D

CUP HOLE DISTANCE 52x5.5mm

I

CUP HOLE DISTANCE 48x6mm

A

CUP HOLE DISTANCE 45x9.5mm

N

NYLON (GLASS)

KM

CUP HOLE DISTANCE 38x8mm

50

8

29K

38

66

7.5

43K

52

S

CUP HOLE DISTANCE 52x7.5mm

SELFTAPPING SCREW DOWEL

X-PANDO DOWEL EURO SCREW ZIP

VELOFIX DOWELCENTRA

Fixing System

Pictograms

37

H=0

2.7

46

69

37

H=0

K

T

C A 37

60.1

37

12.7

H=0

56

69

H=0

C A

K

T

70.1

H=0

T

26.2

69

3720

°

37

H=0

36.2

69

T

20°

13Values given in mm

165° 165°

CRANK 0For lay-on doors

CRANK 8For partial lay-on doors

3 4 5 6 7

21 0

20 0

19 0 2

18 0 2

17 0 2

16 2

15 2

Drilling distance (K)

Ove

rlay

(C

)

Mounting plates (H)

3 4 5 6 7

11 0

10 0

9 0 2

8 0 2

7 0 2

6 2

5 2

Drilling distance (K)

Ove

rlay

(C

)

Mounting plates (H)

T= 16 17 18 19 20 21 22 23 24 25 26

K=3 A= 0.0 0.0 0.0 0.0 0.0 0.0 0.06 0.19 0.41 0.77 1.31

K=4 A= 0.0 0.0 0.0 0.0 0.0 0.0 0.06 0.21 0.46 0.88 1.57

K=5 A= 0.0 0.0 0.0 0.0 0.0 0.0 0.07 0.52 1.05 1.05 2.13

K=6 A= 0.0 0.0 0.0 0.0 0.0 0.0 0.08 0.62 2.33 2.33 3.33

K=7 A= 0.0 0.0 0.0 0.0 0.0 0.0 0.09 0.75 1.33 1.33 2.33

Table to determinate the minimum distance A so that a door with T thickness can open without protrusion from the cabinet and without interfering with adjacent doors.

166

HINGES

125° 125° 175° 175°

90° 90° 90° 90°

95° 95° 95° 95°95° 95°

90° 90°90° 90°

105° 105°105°105°110°110° 110° 110°

Angles

Cup hole distance

D

CUP HOLE DISTANCE 52x5.5mm

I

CUP HOLE DISTANCE 48x6mm

A

CUP HOLE DISTANCE 45x9.5mm

N

NYLON (GLASS)

KM

CUP HOLE DISTANCE 38x8mm

50

8

29K

38

66

7.5

43K

52

S

CUP HOLE DISTANCE 52x7.5mm

SELFTAPPING SCREW DOWEL

X-PANDO DOWEL EURO SCREW ZIP

VELOFIX DOWELCENTRA

Fixing System

Pictograms

R51AWH60500S50000mm 175 Deg - Dowel Fixing

166

HINGES

125° 125° 175° 175°

90° 90° 90° 90°

95° 95° 95° 95°95° 95°

90° 90°90° 90°

105° 105°105°105°110°110° 110° 110°

Angles

Cup hole distance

D

CUP HOLE DISTANCE 52x5.5mm

I

CUP HOLE DISTANCE 48x6mm

A

CUP HOLE DISTANCE 45x9.5mm

N

NYLON (GLASS)

KM

CUP HOLE DISTANCE 38x8mm

50

8

29K

38

66

7.5

43K

52

S

CUP HOLE DISTANCE 52x7.5mm

SELFTAPPING SCREW DOWEL

X-PANDO DOWEL EURO SCREW ZIP

VELOFIX DOWELCENTRA

Fixing System

Pictograms

R51AH850590C500090 Deg Blind Cnr

166

HINGES

125° 125° 175° 175°

90° 90° 90° 90°

95° 95° 95° 95°95° 95°

90° 90°90° 90°

105° 105°105°105°110°110° 110° 110°

Angles

Cup hole distance

D

CUP HOLE DISTANCE 52x5.5mm

I

CUP HOLE DISTANCE 48x6mm

A

CUP HOLE DISTANCE 45x9.5mm

N

NYLON (GLASS)

KM

CUP HOLE DISTANCE 38x8mm

50

8

29K

38

66

7.5

43K

52

S

CUP HOLE DISTANCE 52x7.5mm

SELFTAPPING SCREW DOWEL

X-PANDO DOWEL EURO SCREW ZIP

VELOFIX DOWELCENTRA

Fixing System

Pictograms

15Values given in mm

ANGLE 30° ANGLE 45° ANGLE 90°

105° 105°

K K

C

T30

°

H=0 H=0

37

C

45°

H=0

37

T69 69

C

90°

K

T

23

55

Table to determinate the minimum distance A so that a door with T thickness can open without protrusion from the cabinet and without interfering with adjacent doors.

T= 16 17 18 19 20 21 22 23 24 25 26

K=3 A= 0.9 1.1 1.5 1.8 2.3 2.8 3.6 4.3 5.2 6.0 6.9

K=4 A= 0.8 1.1 1.4 1.8 2.2 2.7 3.3 4.0 4.7 5.5 6.5

K=5 A= 0.8 1.0 1.3 1.7 2.1 2.5 3.1 3.7 4.4 5.1 5.9

K=6 A= 0.8 1.0 1.3 1.6 2.0 2.4 2.9 3.5 4.1 4.8 5.5

K=7 A= 0.7 1.0 1.3 1.6 1.9 2.3 2.7 3.3 3.8 4.5 5.2166

HINGES

125° 125° 175° 175°

90° 90° 90° 90°

95° 95° 95° 95°95° 95°

90° 90°90° 90°

105° 105°105°105°110°110° 110° 110°

Angles

Cup hole distance

D

CUP HOLE DISTANCE 52x5.5mm

I

CUP HOLE DISTANCE 48x6mm

A

CUP HOLE DISTANCE 45x9.5mm

N

NYLON (GLASS)

KM

CUP HOLE DISTANCE 38x8mm

50

8

29K

38

667.

5

43K

52

S

CUP HOLE DISTANCE 52x7.5mm

SELFTAPPING SCREW DOWEL

X-PANDO DOWEL EURO SCREW ZIP

VELOFIX DOWELCENTRA

Fixing System

Pictograms

INTEGRA MOUNTING PLATES

Page 116 • Spec i f i ca t ions and des ign sub jec t to change w i thout no t ice • A l l d imens ions in mi l l imet res (nomina l )

175o S

trai

ght SCREW FIXING

R51MW150500C00

DOWEL FIXINGR51MW160500S00

175o 8

mm

Cra

nk SCREW FIXING R51MW150508C00

45o C

orne

r

SCREW FIXING R51MS850545C00

DOWEL FIXINGR51MS860545S00

Neg

ativ

e 25

o

SCREW FIXING R51MK850525C00

24o to

30o C

orne

r SCREW FIXING R51MS850530C00

Blin

d C

orne

r SCREW FIXING R51MS850590C00

110

o 8m

m C

rank SCREW FIXING

R51MS150508C00

DOWEL FIXINGR51MS160508S00

110

o 15m

m C

rank SCREW FIXING

R51MS150515C00

110

o Str

aigh

t

SCREW FIXING R51MS150500C00

DOWEL FIXINGR51MS160500S00

Cor

ner C

upbo

ard SCREW FIXING

R51MS830535C00

Stee

l Cru

cifo

rm

Bas

e Pl

ate

with

out s

crew

s HEIGHT CODE

H = 0 R520201M500100

H = 2 R520201M502100

H = 4 R520201M504100

Stee

l Cru

cifo

rm

Bas

e Pl

ate

with

5m

m

X-Pa

ndo

dow

els 9.2mm Dowel

HEIGHT CODE

H = 2 R5252N5M502100

H = 4 R5202N5M504100

Slid

e O

n Pl

ate

4 H

ole

HEIGHT CODE

H = 2 R525231M502100

H = 4 R525231M504100

HINGES - FGVHINGES - FGV

SLIDE-ON HINGES

Page 117• Spec i f i ca t ions and des ign sub jec t to change w i thout no t ice • A l l d imens ions in mi l l imet res (nomina l )

90o 8

mm

Cra

nk GLASS DOOR HINGER51MG112308000

26mm Cup

90o 1

5mm

Cra

nk GLASS DOOR HINGE R51MG112315000

26mm Cup

90 o S

trai

ght GLASS DOOR HINGE

R51MG112300000

26mm Cup

Stee

l Cru

cifo

rm

Bas

e Pl

ate

with

out s

crew

s HEIGHT CODE

H = 0 R520201M500100

H = 2 R520201M502100

H = 4 R520201M504100

Rou

nd F

ace

Plat

efo

r Gla

ss D

oor

Hin

ge

COLOUR CODE

CHROME R5101500501R00

BLACK R5101500801R00

MATT CHROME R5101500G01R00

0mm

Cra

nk

SCREW FIXING R51MZF5M512055

HINGES - FGVHINGES - FGV

GLASS DOOR HINGES

ANTI-SLAM DEVICE & BRACKET

SHORT ARM HINGE / FRAME HINGE

RFG595300

FGV ANTI-SLAM PISTON

RFG590337

FGV ANTI-SLAM & PUSH TO OPEN

MOUNTING BRACKET

Page 118 • Spec i f i ca t ions and des ign sub jec t to change w i thout no t ice • A l l d imens ions in mi l l imet res (nomina l )

Assembly:

100

100

Ideal assembly:

The OneTouch device for door without handles has to be mounted in the corresponding area of the handle.

Ø10

+3/-0

STNEMTSUJDAECIVED HCUOTENO

ETALP GNITNUOM RAENILmm73 ETALP GNITNUOM

Assembly:

100

100

Ideal assembly:

The OneTouch device for door without handles has to be mounted in the corresponding area of the handle.

Ø10

+3/-0

STNEMTSUJDAECIVED HCUOTENO

ETALP GNITNUOM RAENILmm73 ETALP GNITNUOM

Assembly:

100

100

Ideal assembly:

The OneTouch device for door without handles has to be mounted in the corresponding area of the handle.

Ø10

+3/-0

STNEMTSUJDAECIVED HCUOTENO

ETALP GNITNUOM RAENILmm73 ETALP GNITNUOM

Stee

l Cru

cifo

rm

Bas

e Pl

ate

with

out s

crew

s HEIGHT CODE

H = 0 R520201M500100

H = 2 R520201M502100

H = 4 R520201M504100

HINGES - FGVHINGES - FGV

PUSH TO OPEN HINGES & MECHANISMS

Installation without mounting bracket

IDEAL ASSEMBLY:The One Touch device for door without handles has to be mounted in the corresponding area of the handle.

RFG590337

FGV ANTI-SLAM & PUSH TOP OPEN

MOUNTING BRACKET

R594200P610F00

PUSH TO OPEN DEVICE WITH MAGNET + ADHESIVE PLATE

PUSH TO OPEN HINGES FIXING TYPE TECHNICAL DRAWING OPENING ANGLE

R51MS15P500000000mm 110 Deg - Screw Fixing

166

HINGES

125° 125° 175° 175°

90° 90° 90° 90°

95° 95° 95° 95°95° 95°

90° 90°90° 90°

105° 105°105°105°110°110° 110° 110°

Angles

Cup hole distance

D

CUP HOLE DISTANCE 52x5.5mm

I

CUP HOLE DISTANCE 48x6mm

A

CUP HOLE DISTANCE 45x9.5mm

N

NYLON (GLASS)

KM

CUP HOLE DISTANCE 38x8mm

50

8

29K

38

66

7.5

43K

52

S

CUP HOLE DISTANCE 52x7.5mm

SELFTAPPING SCREW DOWEL

X-PANDO DOWEL EURO SCREW ZIP

VELOFIX DOWELCENTRA

Fixing System

Pictograms

11Values given in mm

105°105°

CRANK 0For lay-on doors

CRANK 8For partial lay-on doors

CRANK 15For inset doors

C A

H

K

T

C

H

C=A

H

K

37+

T37 37

K

T TH=0

37

4

23.3

69

37

37+

T

H=0

27.6

69

H=0

36.3

69+

T

14 23

A

Table to determinate the minimum distance A so that a door with T thickness can open without protrusion from the cabinet and without interfering with adjacent doors.

T= 16 17 18 19 20 21 22 23 24 25 26

K=3 A= 0.9 1.1 1.5 1.8 2.3 2.8 3.6 4.3 5.2 6.0 6.9

K=4 A= 0.8 1.1 1.4 1.8 2.2 2.7 3.3 4.0 4.7 5.5 6.5

K=5 A= 0.8 1.0 1.3 1.7 2.1 2.5 3.1 3.7 4.4 5.1 5.9

K=6 A= 0.8 1.0 1.3 1.6 2.0 2.4 2.9 3.5 4.1 4.8 5.5

K=7 A= 0.7 1.0 1.3 1.6 1.9 2.3 2.7 3.3 3.8 4.5 5.2

3 4 5 6 7

21 0

20 0

19 0 2

18 0 2

17 0 2 4

16 2 4

15 2 4

14 4

13 4

Drilling distance (K)

Ove

rlay

(C

)

Mounting plates (H)

3 4 5 6 7

11 0

10 0

9 0 2

8 0 2

7 0 2 4

6 2 4

5 2 4

4 4

3 4

Drilling distance (K)

Ove

rlay

(C

)

Mounting plates (H)

3 4 5 6 7

4 2

3 2

2 0 2

1 0 2

0 0 2

Drilling distance (K)

Ove

rlay

(C

)

Mounting plates (H)

166

HINGES

125° 125° 175° 175°

90° 90° 90° 90°

95° 95° 95° 95°95° 95°

90° 90°90° 90°

105° 105°105°105°110°110° 110° 110°

Angles

Cup hole distance

D

CUP HOLE DISTANCE 52x5.5mm

I

CUP HOLE DISTANCE 48x6mm

A

CUP HOLE DISTANCE 45x9.5mm

N

NYLON (GLASS)

KM

CUP HOLE DISTANCE 38x8mm

50

8

29K

38

66

7.5

43K

52

S

CUP HOLE DISTANCE 52x7.5mm

SELFTAPPING SCREW DOWEL

X-PANDO DOWEL EURO SCREW ZIP

VELOFIX DOWELCENTRA

Fixing System

Pictograms

R51MS15P508000008mm 110 Deg - Screw Fixing

166

HINGES

125° 125° 175° 175°

90° 90° 90° 90°

95° 95° 95° 95°95° 95°

90° 90°90° 90°

105° 105°105°105°110°110° 110° 110°

Angles

Cup hole distance

D

CUP HOLE DISTANCE 52x5.5mm

I

CUP HOLE DISTANCE 48x6mm

A

CUP HOLE DISTANCE 45x9.5mm

N

NYLON (GLASS)

KM

CUP HOLE DISTANCE 38x8mm

50

8

29K

38

66

7.5

43K

52

S

CUP HOLE DISTANCE 52x7.5mm

SELFTAPPING SCREW DOWEL

X-PANDO DOWEL EURO SCREW ZIP

VELOFIX DOWELCENTRA

Fixing System

Pictograms

11Values given in mm

105°105°

CRANK 0For lay-on doors

CRANK 8For partial lay-on doors

CRANK 15For inset doors

C A

H

K

T

C

H

C=A

H

K

37+

T37 37

K

T T

H=0

37

4

23.3

69

37

37+

T

H=0

27.6

69

H=0

36.3

69+

T

14 23

A

Table to determinate the minimum distance A so that a door with T thickness can open without protrusion from the cabinet and without interfering with adjacent doors.

T= 16 17 18 19 20 21 22 23 24 25 26

K=3 A= 0.9 1.1 1.5 1.8 2.3 2.8 3.6 4.3 5.2 6.0 6.9

K=4 A= 0.8 1.1 1.4 1.8 2.2 2.7 3.3 4.0 4.7 5.5 6.5

K=5 A= 0.8 1.0 1.3 1.7 2.1 2.5 3.1 3.7 4.4 5.1 5.9

K=6 A= 0.8 1.0 1.3 1.6 2.0 2.4 2.9 3.5 4.1 4.8 5.5

K=7 A= 0.7 1.0 1.3 1.6 1.9 2.3 2.7 3.3 3.8 4.5 5.2

3 4 5 6 7

21 0

20 0

19 0 2

18 0 2

17 0 2 4

16 2 4

15 2 4

14 4

13 4

Drilling distance (K)

Ove

rlay

(C

)

Mounting plates (H)

3 4 5 6 7

11 0

10 0

9 0 2

8 0 2

7 0 2 4

6 2 4

5 2 4

4 4

3 4

Drilling distance (K)

Ove

rlay

(C

)

Mounting plates (H)

3 4 5 6 7

4 2

3 2

2 0 2

1 0 2

0 0 2

Drilling distance (K)

Ove

rlay

(C

)

Mounting plates (H)

166

HINGES

125° 125° 175° 175°

90° 90° 90° 90°

95° 95° 95° 95°95° 95°

90° 90°90° 90°

105° 105°105°105°110°110° 110° 110°

Angles

Cup hole distance

D

CUP HOLE DISTANCE 52x5.5mm

I

CUP HOLE DISTANCE 48x6mm

A

CUP HOLE DISTANCE 45x9.5mm

N

NYLON (GLASS)

KM

CUP HOLE DISTANCE 38x8mm

50

8

29K

38

66

7.5

43K

52

S

CUP HOLE DISTANCE 52x7.5mm

SELFTAPPING SCREW DOWEL

X-PANDO DOWEL EURO SCREW ZIP

VELOFIX DOWELCENTRA

Fixing System

Pictograms

Adjustment Installation with mounting bracket

Page 119• Spec i f i ca t ions and des ign sub jec t to change w i thout no t ice • A l l d imens ions in mi l l imet res (nomina l )

16

35

1432

1660

44

31

min. 15

+5 -18

+18-6

16

35

1432

1660

44

31

min. 15

+5 -18

+18-6

164

Wall hanging bracket plates & bars

Plate 027Wall hanging bracket plate of 50mm. 1.8mm of thickness. EN15939 Certi cation.

Plate 028Wall hanging bracket double plate of 130mm. 1.8mm of thickness. Precut for application with side cabinets. EN15939 Certi cation.

Bar 029Wall hanging bracket bar. Drilling and pre-cutting arrangement with 50mm pitch. UNI10768 Certi cation.Available different lengths.

1.8

41

50

25

6

26

6

Code Description Packing

22.0027.07.005CF 027 wall hanging bracket plate 500 pieces

Finish: zinc plated.

Code Description Packing

53.0700.70.13000 028 wall hanging bracket plate 500 piecesFinish: zinc plated.

27

130

10

25

4.5

48Ø6

27

4

1.8

7.5

7.527

Code Description Packing

53.0029.07.02000 029 wall hanging bracket bar 200mm 200 pieces

53.0029.07.10000 029 wall hanging bracket bar 1000mm 10 pieces

53.0029.07.15000 029 wall hanging bracket bar 1500mm 10 pieces

53.0029.07.20000 029 wall hanging bracket bar 2000mm 10 pieces

53.0029.07.30000 029 wall hanging bracket bar 3000mm 10 pieces

Finish: zinc plated.

1.2

47.5

200

2000-3000

6

24

4

50

10

Ø10

Ø13

HINGES - FGVHINGES - FGV

WALL HANGING BRACKET FOR LEVA - FGV

R535753A100000 LEVA WHITE

LEVA - WALL HANGING BRACKETSYMMETRICAL WALL HANGING BRACKET• Fixing with selftapping screws• Symmetrical hook• Front adjustment easy to access• Adjustment screws to avoid accidental dismounting• Flap for screws covering

WALL HANGING PLATE

R22002707005CF 41X50mm

Page 120 • Spec i f i ca t ions and des ign sub jec t to change w i thout no t ice • A l l d imens ions in mi l l imet res (nomina l )

AeroBus

174

Code Description Kit Door Height (mm) Door Weight (Kg) Packing

59.0VBS.A9.D20.0000 Kit AeroBus D20

180 2.2 - 5.5

10 kits per box250 1.6 - 4.0

300 1.3 - 3.5

400 1.0 - 2.5

59.0VBS.A9.D40.0000 Kit AeroBus D40

180 5.3 - 12.3

10 kits per box250 3.8 - 8.9

300 3.2 - 7.4

400 2.4 - 5.5

Packed in a kit, consists of:• 2 symmetrical and damped mechanisms• 2 covers, RH and LH • 2 click mounting plates• 6 selftapping screws Ø4x15 mm• 8 selftapping screws Ø4x35 mm• Assembly instructions

Technical speci cations:

• Upwards operation• Easy and rapid assembly with click-on door xing• No hinges required• No stabilization bar required• Door and weight adjustments• SlowMotion technology for controlled and silent closing

AeroBus Video

175Values given in mm

AER

O

Adjustments:

Application:

12.5

3278

-A

A

107°

28.5

min

. 150

Max

22

159

153.5

H (max 400 mm)

37 64

3774

107

137

32

55

98

127

Ø5

Weight adjustment

Door adjustment

Cabinet xing Door xing

+/-1.5 -2+4

+2-2

175Values given in mm

AER

O

Adjustments:

Application:

12.5

3278

-A

A

107°

28.5

min

. 150

Max

22

159

153.5

H (max 400 mm)

37 64

3774

107

137

32

55

98

127

Ø5

Weight adjustment

Door adjustment

Cabinet xing Door xing

+/-1.5 -2+4

+2-2

175Values given in mm

AER

O

Adjustments:

Application:

12.5

3278

-A

A

107°

28.5

min

. 150

Max

22

159

153.5

H (max 400 mm)

37 64

3774

107

137

32

55

98

127

Ø5

Weight adjustment

Door adjustment

Cabinet xing Door xing

+/-1.5 -2+4

+2-2

175Values given in mm

AER

O

Adjustments:

Application:

12.5

3278

-A

A

107°

28.5

min

. 150

Max

22

159

153.5

H (max 400 mm)

37 64

3774

107

137

32

55

98

127

Ø5

Weight adjustment

Door adjustment

Cabinet xing Door xing

+/-1.5 -2+4

+2-2

182

AeroWing

SINGLE KIT

Code Description Packing

59.0VW0.05.00.00000 Kit AeroWing hole distance 37mm 50 kits

59.0VW0.05.28.00000 Kit AeroWing hole distance 28mm 50 kits

Packed in a kit, consists of:• 1 joint AeroWing• 1 bracket for cabinet• 1 bracket for wooden door• 1 bracket for aluminium frame• 4 selftapping screws Ø4x15 mm • Assembly instructions

INDUSTRIAL PACKING

Code Description Packing

59.0VWR.05.0000000 Joint AeroWing 50 pcs per box

59.0WBL.05.0000000 Set of brackets for cabinet and brackets for wooden door hole distance 37mm 100 sets per box

59.0WBA.05.0000000 Set of brackets for cabinet and brackets for aluminium frame hole distance 37mm 100 sets per box

59.0WBL.05.2800000 Set of brackets for cabinet and brackets for wooden door hole distance 28mm 100 sets per box

59.0WBA.05.2800000 Set of brackets for cabinet and brackets for aluminium frame hole distance 28mm 100 sets per box

Technical speci cations:

• The three in one lifter solution: - self holding in all positions - self lifting and SlowMotion - ap with brake• 32mm standard cabinet drilling• Covers 75°, 90° and 105° angles• Combined with SlowMotion hinges, it confers a perfect movement

to the door

183Values given in mm

AER

O3215

0 +

A

32

12

28/37

23

3211

8 +

A

150

+ A

28/37

28/37

28/37

32

28/37

135

132

131

126

130

75°90°

90°

90°

105°

AAA

12

32

13290

92

110

==

141

28/37

9532

130

Magnet required. Not supplied. Magnet not required.

16

14

12

10

8

6

4

2

00502 3025 35 40 45

AeroWing x2 AeroWing x1

14

12

10

8

6

4

2

00502 3025 35 40 45

DO

OR

WEI

GH

T (k

g)

DO

OR

WEI

GH

T (k

g)

DOOR HEIGHT (cm) DOOR HEIGHT (cm)

Up solution application:

Down solution application:

Door xing

183Values given in mm

AER

O3215

0 +

A

32

12

28/37

23

3211

8 +

A

150

+ A

28/37

28/37

28/37

32

28/37

135

132

131

126

130

75°90°

90°

90°

105°

AAA

12

32

13290

92

110

==

141

28/37

9532

130

Magnet required. Not supplied. Magnet not required.

16

14

12

10

8

6

4

2

00502 3025 35 40 45

AeroWing x2 AeroWing x1

14

12

10

8

6

4

2

00502 3025 35 40 45

DO

OR

WEI

GH

T (k

g)

DO

OR

WEI

GH

T (k

g)

DOOR HEIGHT (cm) DOOR HEIGHT (cm)

Up solution application:

Down solution application:

Door xing

183Values given in mm

AER

O3215

0 +

A

32

12

28/37

23

3211

8 +

A

150

+ A

28/37

28/37

28/37

32

28/37

135

132

131

126

130

75°90°

90°

90°

105°

AAA

12

32

13290

92

110

==

141

28/37

9532

130

Magnet required. Not supplied. Magnet not required.

16

14

12

10

8

6

4

2

00502 3025 35 40 45

AeroWing x2 AeroWing x1

14

12

10

8

6

4

2

00502 3025 35 40 45

DO

OR

WEI

GH

T (k

g)

DO

OR

WEI

GH

T (k

g)

DOOR HEIGHT (cm) DOOR HEIGHT (cm)

Up solution application:

Down solution application:

Door xing

183Values given in mm

AER

O3215

0 +

A

32

12

28/37

23

3211

8 +

A

150

+ A

28/37

28/37

28/37

32

28/37

135

132

131

126

130

75°90°

90°

90°

105°

AAA

12

32

13290

92

110

==

141

28/37

9532

130

Magnet required. Not supplied. Magnet not required.

16

14

12

10

8

6

4

2

00502 3025 35 40 45

AeroWing x2 AeroWing x1

14

12

10

8

6

4

2

00502 3025 35 40 45

DO

OR

WEI

GH

T (k

g)

DO

OR

WEI

GH

T (k

g)

DOOR HEIGHT (cm) DOOR HEIGHT (cm)

Up solution application:

Down solution application:

Door xing

183Values given in mm

AER

O3215

0 +

A

32

12

28/37

23

3211

8 +

A

150

+ A

28/37

28/37

28/37

32

28/37

135

132

131

126

130

75°90°

90°

90°

105°

AAA

12

32

13290

92

110

==

141

28/37

9532

130

Magnet required. Not supplied. Magnet not required.

16

14

12

10

8

6

4

2

00502 3025 35 40 45

AeroWing x2 AeroWing x1

14

12

10

8

6

4

2

00502 3025 35 40 45

DO

OR

WEI

GH

T (k

g)

DO

OR

WEI

GH

T (k

g)

DOOR HEIGHT (cm) DOOR HEIGHT (cm)

Up solution application:

Down solution application:

Door xing

75º 90º

APPLICATION

105º

AEROBUS LIFT MECHANISM - FGV

R590VBSA9D400 D40 - 2.4-5.5KG DOOR

R590VW0050000

AERO WING LIFT STAY MECHANISM - FGV

37mm

TECHNICAL SPECIFICATIONS:

• Upwards operation• Easy and rapid assembly with click-on door fixing• No hinges required• No stabilization bar required• Door and weight adjustments• SlowMotion technology for controlled and silent closing

TECHNICAL SPECIFICATIONS:

• The three in one lifter solution:- self holding in all positions- self lifting and SlowMotion- flap with brake• 32mm standard cabinet drilling• Covers 75°, 90° and 105° angles• Can becombined with slowmotion hinges

UP SOLUTION APPLICATION

UP SOLUTION APPLICATION

DOWN SOLUTION APPLICATION

DOWN SOLUTION APPLICATION

AEROBUS & AERO WING LIFT MECHANISMS

Page 121• Spec i f i ca t ions and des ign sub jec t to change w i thout no t ice • A l l d imens ions in mi l l imet res (nomina l )

232

Domino W with hinged doorTechnical speci cations:

• Sliding system for folding hinged doors• Max door width of 1000mm (500+500), max door thickness of 25mm• Mechanism max load capacity of 50kg • Door weight applied to the upper bar • Application also without lower truck and lower bar

Code Description Packing

59.0DW0.03.0000000 Kit Domino W for folding hinged door 10 kits

Kit Domino W

Kit Domino W for folding door, consisting of:• 1 upper roller truck • 1 lower rail truck • 2 central folding hingesHinges for door side xing not included

232

Domino W with hinged doorTechnical speci cations:

• Sliding system for folding hinged doors• Max door width of 1000mm (500+500), max door thickness of 25mm• Mechanism max load capacity of 50kg • Door weight applied to the upper bar • Application also without lower truck and lower bar

Code Description Packing

59.0DW0.03.0000000 Kit Domino W for folding hinged door 10 kits

Kit Domino W

Kit Domino W for folding door, consisting of:• 1 upper roller truck • 1 lower rail truck • 2 central folding hingesHinges for door side xing not included

232

Domino W with hinged doorTechnical speci cations:

• Sliding system for folding hinged doors• Max door width of 1000mm (500+500), max door thickness of 25mm• Mechanism max load capacity of 50kg • Door weight applied to the upper bar • Application also without lower truck and lower bar

Code Description Packing

59.0DW0.03.0000000 Kit Domino W for folding hinged door 10 kits

Kit Domino W

Kit Domino W for folding door, consisting of:• 1 upper roller truck • 1 lower rail truck • 2 central folding hingesHinges for door side xing not included

234

Domino W bars and accessories

Folding hinges.Metal hinge with zinc nish.

50 32

9

15

Ø3.1

27

21

1.2

6.5

Code Fixing Packing

51.EL15.07.000.00 Screws 250 pieces

27

45.5

60

Code Finish Packing

59.0DWB.AA.SE.^^.000 Anodized 12 pieces

59.0DWB.0A.SE.^^.000 Raw 12 pieces

^^ length: 20 = 2000mm / 30 = 3000mm

Domino W upper bar, over the top panel xing.Aluminium upper bar, screw xing.

Code Finish Packing

59.0DWB.AA.SI.^^.000 Anodized 12 pieces

59.0DWB.0A.SI.^^.000 Raw 12 pieces

^^ length: 20 = 2000mm / 30 = 3000mm

28.6

25.5

Domino W upper bar, under the top panel xing.Aluminium upper bar, screw xing.

15

15

Code Finish Packing

59.0DWB.AA.I0.^^.000 Anodized 12 pieces

59.0DWB.0A.I0.^^.000 Raw 12 pieces

^^ length: 20 = 2000mm / 30 = 3000mm

Lower bar for Domino W.Aluminium lower bar, screw xing.

234

Domino W bars and accessories

Folding hinges.Metal hinge with zinc nish.

50 32

9

15

Ø3.1

27

21

1.2

6.5

Code Fixing Packing

51.EL15.07.000.00 Screws 250 pieces

27

45.5

60

Code Finish Packing

59.0DWB.AA.SE.^^.000 Anodized 12 pieces

59.0DWB.0A.SE.^^.000 Raw 12 pieces

^^ length: 20 = 2000mm / 30 = 3000mm

Domino W upper bar, over the top panel xing.Aluminium upper bar, screw xing.

Code Finish Packing

59.0DWB.AA.SI.^^.000 Anodized 12 pieces

59.0DWB.0A.SI.^^.000 Raw 12 pieces

^^ length: 20 = 2000mm / 30 = 3000mm

28.6

25.5

Domino W upper bar, under the top panel xing.Aluminium upper bar, screw xing.

15

15

Code Finish Packing

59.0DWB.AA.I0.^^.000 Anodized 12 pieces

59.0DWB.0A.I0.^^.000 Raw 12 pieces

^^ length: 20 = 2000mm / 30 = 3000mm

Lower bar for Domino W.Aluminium lower bar, screw xing.

233Values given in mm

*SYSTEM TO BE USED ALSO WITHOUT LOWER TRUCK AND LOWER BAR

43

2424

19

22.5

28.5

6

45.5

30.5

1743

60

Ø35

6.5

6.5

19

13 5

30.5

45.5

43

60

17

13 4

28.6

19.8

6.5

Ø35

25.5

4412

.5

28.5

28.6

22.56

ForoØ35

48

2424

25.5

4412

.5

Ø35

4.5

6.5

28.5

15

1515

28.5

15

15

15

ForoØ35

2424

48

6.5

6.5

ForoØ35

Application with upper bar over the top panel

Application with upper bar under the top panel

Application with lower bar*

DO

MIN

O

233Values given in mm

*SYSTEM TO BE USED ALSO WITHOUT LOWER TRUCK AND LOWER BAR

43

2424

19

22.5

28.5

6

45.5

30.5

1743

60

Ø35

6.5

6.5

19

13 5

30.5

45.5

43

60

17

13 4

28.6

19.8

6.5

Ø35

25.5

4412

.5

28.5

28.6

22.56

ForoØ35

48

2424

25.5

4412

.5

Ø35

4.5

6.5

28.5

15

1515

28.5

15

15

15

ForoØ35

2424

48

6.5

6.5

ForoØ35

Application with upper bar over the top panel

Application with upper bar under the top panel

Application with lower bar*

DO

MIN

O

233Values given in mm

*SYSTEM TO BE USED ALSO WITHOUT LOWER TRUCK AND LOWER BAR

43

2424

19

22.5

28.5

6

45.5

30.5

1743

60

Ø35

6.5

6.5

19

13 5

30.5

45.5

43

60

17

13 4

28.6

19.8

6.5

Ø35

25.5

4412

.528.5

28.6

22.56

ForoØ35

48

2424

25.5

4412

.5

Ø35

4.5

6.5

28.5

15

1515

28.5

15

15

15

ForoØ35

2424

48

6.5

6.5

ForoØ35

Application with upper bar over the top panel

Application with upper bar under the top panel

Application with lower bar*

DO

MIN

O

HINGES - FGVHINGES - FGV

TECHNICAL SPECIFICATIONS:

•Sliding system for folding hinged doors•Max door width of 1000mm (500+500), max door thickness of 25mm•Mechanism max load capacity of 50kg•Door weight applied to the upper bar•Application also without lower truck and lower bar

R590DWB0AI02000L

DOMINO W LOWER RAIL - FGV2m ALUMINIUM

R590DWB0ASI2000UDOMINO W UPPER RAIL - FGV2m ALUMINIUM

DOMINO W - FOLDING DOOR SYSTEM

R590DW0030000 DOMINO W FOLDING DOOR KIT - FGV HINGES EXCLUDING RAILS

ECONO

Page 122 • Spec i f i ca t ions and des ign sub jec t to change w i thout no t ice • A l l d imens ions in mi l l imet res (nomina l )

ECONOMICALLY SOURCED & PRICED RANGES OF HARDWARE FOR THE KITCHEN & FURNITURE INDUSTRIES

HINGES - CABX

CABX SLIDE ON HINGE WITH MOUNTING PLATE

SINGLE FORM SINGLE WITH DOWELS PREPACKED IN PAIRS

AFTS145W34 110° STRAIGHT ALL METAL HINGE WITHOUT DOWELSIncludes 4 Hole Mounting PlateTested To 50 000 Cycles

AFTS145WD110° STRAIGHT 0MM ALL METAL HINGEWITH DOWELSIncludes 4 Hole Mounting Plate

AFTS145W34P 110° STRAIGHT 0MM ALL METAL HINGEWITHOUT DOWELSIncludes 4 Hole Base Plate2 per pack

AFTS245WI 110° 9MM OFFSET ALL METAL HINGE WITHOUT DOWELS Includes 4 Hole Mounting PlateTested To 50 000 Cycles

AFTS245WD110° 9MM OFFSET ALL METAL HINGEWITH DOWELSIncludes 4 Hole Mounting Plate

AFTS245W34P 110° OFFSET 9MM ALL METAL HINGEWITHOUT DOWELSIncludes 4 Hole Mounting Plate2 per pack

AFTS345WI 110° INSET ALL METAL HINGE WITHOUT DOWELS INCLUDES MOUNTING PLATEIncludes 4 Hole Mounting PlateTested To 50 000 Cycles

AFTS345WD110° INSET ALL METAL HINGEWITH DOWELSIncludes 4 Hole Mounting Plate

AFQS145WI 45° HINGE ALL METALWITHOUT DOWELSIncludes 4 hole Mounting PlateTested To 50 000 Cycles

AFQS145WD45’ HINGE ALL METALWITH DOWELSIncludes 4 Hole Mounting Plate

AFMS148WI 165° STRAIGHT CORNER HINGE ALL METALWITHOUT DOWELSIncludes 4 hole Mounting PlateTested To 50 000 Cycles

AFTSPLATESLIDE ON BASE PLATE4 Hole

(Optional Extra)

Page 123• Spec i f i ca t ions and des ign sub jec t to change w i thout no t ice • A l l d imens ions in mi l l imet res (nomina l )

SOFT CLOSING SOFT CLOSING

SOFT CLOSING SOFT CLOSING

21Values given in mm

Pictograms

HINGES

165° 165° 105° 105°105°105° 105° 105°

Angles

SELFTAPPING SCREW DOWELEURO SCREW VELOFIX DOWEL

Fixing System

MOUNTING PLATES

EURO SCREW SELFTAPPING SCREW DOWEL

Fixing System

37DRILLING DISTANCE 37mm

Cup hole distance

D 5.5

5265.6

K

35

CUP HOLE DISTANCE 52x5.5mm

IK

9.5

4560

35

CUP HOLE DISTANCE 48x6mm

A

K6

4860

35

CUP HOLE DISTANCE 45x9.5mm

HINGES - CABXHINGES - CABX

WITH INTEGRATED SOFT CLOSING DAMPER AND MOUNTING PLATE

CABX SOFT CLOSING CLIP ON HINGE

SINGLE FORM

AFTS6190110° STRAIGHT OMM ALL METAL HINGE WITH INTEGRATED SOFT CLOSING DAMPERIncludes 4 Hole Mounting PlateTested To 50 000 Cycles

AFTS6199110° OFFSET ALL METAL HINGE WITH INTEGRATED SOFT CLOSING DAMPER 9MMIncludes 4 Hole Mounting PlateTested To 50 000 Cycles

SINGLE FORM

AFTS6195 165° CORNER HINGE ALL METALWITH INTEGRATED SOFTCLOSING DAMPERIncludes 4 hole Mounting PlateTested To 50 000 Cycles

AFTST4545° HINGE ALL METALWITH INTEGRATED SOFTCLOSING DAMPERIncludes 4 hole Mounting PlateTested To 50 000 Cycles

Page 124 • Spec i f i ca t ions and des ign sub jec t to change w i thout no t ice • A l l d imens ions in mi l l imet res (nomina l )

RSCWH

ASCH3AB

HINGES - OTHERHINGES - OTHER

FLUSH HINGES

BUTT HINGES

SELF CLOSING HINGES 5 KNUCKLE PER PAIR

RSCBB Bright Brass

RSCBMA Antique Copper

RSCGB Georgian Brass

RSCCP Chrome

RSCWH White

3 KNUCKLE PER PAIR

ASCH3AB Antique Brass

ASCH3NP Nickel Plated

PIANO HINGE

APHEB32COILS 32mm Electro Brass 30m Coils

ECONOMICALLY SOURCED & PRICED RANGE OF HINGES FOR THE KITCHEN & FURNITURE INDUSTRIES

HINGES - OTHER

FLUSH HINGES

AFH50EB 50mm Electro Brass

AFH50NP 50mm Nickel Plated

AFH50YP 50mm Yellow Passivated

AFH64EB 64mm Electro Brass

AFH64NP 64mm Nickel Plated

BUTT HINGE

ABH50BR 50mm Brass

ABH64BR 64mm Brass

RSCBMA

RSCGB

RSCBB

SUPPLIED IN PAIRS INCLUDING SCREWS