RL LINER DECK - eboss.co.nz · PDF filespacings are in excess of 2.60mm ... for the user to...

Transcript of RL LINER DECK - eboss.co.nz · PDF filespacings are in excess of 2.60mm ... for the user to...

RL Liner Deck TDS, v.2, 10/15

1 0 0 5

1 8 2 910 (Effective Cover)

This Side to Framework

RL Liner Deck has been designed and engineered to provide a steel liner for the subsequent installation of the RoofLogic UltraTherm MSR roofing system. When installed in accordance with RoofLogic specifications it will provide a profiled steel liner that will support the system components and resist the point loads to which the liner is exposed during system installation.

DESCRIPTION

RL Liner Deck is a zinc aluminium coated trapezoidal profile liner used as the base for the RoofLogic UltraTherm MSR system. RL Liner Deck is manufactured in either 0.55mm or 0.75mm BMT. BMT is dependent on specified purlin centres.

MATERIAL AND FINISH

The standard finish for RL Liner Deck is a plain zinc aluminium coating. Where the RL Liner Deck is to the left exposed the designer has the option of selecting a colour coating to enhance the internal aesthetic. Popular colour options include off-white and black.

BENEFITS

The RL liner deck can be efficiently installed directly to purlin. This provides:

Programme Advantages. The RL Liner Deck, in combination with the RL Vapour Retarder, provides rapid close-in and weather-tightness. This allows internal fit-out works to proceed without delays caused by weather. The remainder of the roofing components can then be installed without affecting the critical path of the construction programme.

Health and Safety. The RL Liner Deck provides a safe working platform for the roofer and reduces the risk of fall from height. A continuous liner also protects tradesmen working within the building from the risk of falling objects.

Internal finish can be pre-coloured and left exposed, providing an improved aesthetic compared with the netting/roofing paper that is left exposed with traditional roofing.

INSTALLATION

The RL Liner Deck can be installed over timber or steel purlins. The deck is to be secured at every purlin and through each pan of the base deck profile. The following fixings are to be used when fixing RL Base Deck to purlins:-

Wood Purlins Steel Purlins up to 1.5mm Steel Purlins 1.5mm – 4.5mm Steel purlins 4.5mm-12mm

12- 11x40 Class 4 Type 17 Woodteks with neos

12- 14x20 Class 4 steelteks with neos

12- 14x20 steelteks With neos

12- 24x32 Class 4 steelteks, Series 500 with neos

It is important to establish compatibility of the Liner with the purlin material or other structural elements that the Liner may be installed over. For example, if CCA treated timber is utilised a separation strip (eg RL Vapour Retarder Strip) must be installed between the timber and the Liner sheet. Please contact RoofLogic if it is necessary to confirm material compatibility.

Where intermediate purlin spacings do not exceed 2.60mm RL Liner Deck at 0.55mm BMT is installed. Where intermediate purlin spacings are in excess of 2.60mm (to a maximum of 3.40mm) RL Liner Deck at 0.75mm BMT is installed.

Note that the metal top skin is connected directly to the structured purlin and therefore acts independently of the Liner sheet. For this reason purlin spacing will be determined by the performance of the metal top skin in respect to wind load, snow load and trafficability.

RL LINER DECK for UltraTherm MSR Roof System

TECHNICAL DATA SHEET

NZ and Australian Distributor: ROOFLOGIC Ltd, PO Box 1848, Wellington, ph 04 4757663, [email protected]

NZ and

RL Vapour Retarder TDS, v.2, 10/15

DESCRIPTION

RL Vapour Retarder is a self-adhesive SBS modified underlay for use in all RoofLogic roofing systems, including the UltraTherm Xtreme, UltraTherm MSR and UltraTherm Recover roofing systems. It is manufactured to the highest quality according to DIN EN 13707 with all technical values in exceedance of minimum standards.

BENEFITS

Efficient application due to cold self-adhesion. Substrate can be completely overlaid with RL Vapour Retarder without the use of a gas flame. Extremely secure joint connection by removable side lap foil ensures improved weather-tightness and vapour control. Vapour Barrier Class 3 according to DIN EN 1931.

APPLICATION

RL Vapour Retarder can be directly installed over steel base deck, plywood/timber substrates and pre-cast and in-situ concrete. RL Vapour Retarder can be used in both new and renovation projects. Please consult RoofLogic for application of RL Vapour Retarder to other substrates.

RL Vapour Retarder must be applied with 80mm overlaps by removing the foil of the side lap on the top and the foil on the bottom. T-joints must be cut in an angle of 45 degrees.

STORAGE

RL Vapour Retarder should be stored vertically and protected from moisture, UV light and heat. In the cold season the rolls should be brought on site from the frost-protected intermediate store directly before use.

TECHNICAL DATA

Notes: * tested with the system

The numerical values are nominal values, which are subject to statistical fluctuations. The right is reserved to make technical alterations. It is a matter for the user to assess the suitability of the product to the property concerned and to ensure, that he has access to the current version of the data sheet.

Topside Special foil and detachable foil on the side lap

Coating TOP - elastomeric bitumen, self-adhesive on the bottom

Carrier KTG composite carrier 120 g/m2

Underside Self-adhesive elastomeric bitumen and detachable foil

Characteristics EN 13707 Test Method / Classification Units Performance

Visible defects DIN EN 1850-1 - No defects

Length DIN EN 1848-1 m > 15,0

Width DIN EN 1848-1 m > 1,0

Straightness DIN EN 1848-1 mm / 10 m < 20 fulfilled

Thickness DIN EN 1849-1 mm > 2,0

Water tightness DIN EN 1928 Method B kPa > 200 (24 hours)

External fire performance DIN V EN 1928 1187 / EN 13501-5 - BROOF (t1) *

Reaction to fire EN ISO 11925-2 / EN 13501-1 - Class E

Water vapour properties DIN EN 1931 - µ = 20.000

Tensile properties: maximum tensile force l/t DIN EN 12311-1 N / 50 mm > 1100 / 1000

Tensile properties: elongation l/t DIN EN 12311-1 % > 5 / 5

Flexibility at low temperature DIN EN 1109 °C < - 30

Flow resistance at elevated temperature DIN EN 1110 °C > + 100

RL VAPOUR RETARDER TECHNICAL DATA SHEET

NZ and Australian Distributor: ROOFLOGIC Ltd, PO Box 1848, Wellington, ph 04 4757663, [email protected]

NZ and

RL Energy 3 PIR, TDS, V.2, 10/15

DESCRIPTION

RL Energy 3 PIR boards are Polyisocyanurate (PIR) rigid foam panels faced on both sides with a multi-layered aluminium complex. Alternatively RL Energy PIR can be supplied with a coated glass facer (CGF) for direct bonded applications. RL Energy PIR provides excellent thermal and fire performance and has exceptional compressive strength for a rigid thermoset insulation board.

APPLICATION

Rigid insulation layer providing high thermal performance in all RoofLogic UltraTherm Xtreme and UltraTherm MSR roofing systems.

ADVANTAGES

Light panels with excellent rigidity and dimensional stability

Excellent fire performance

Practically no water absorption due to its structure of closed cell foam and to the aluminium paper

Lower thickness insulation due to the low thermal conductivity coefficient of PIR foam and the aluminium complex

Easy to manipulate and cut during installation

High compressive strength

CFC/HCFC free with zero ozone depletion potential (ODP)

Range of facer options dependent on specific system and application

Does not allow water uptake by capillary action

Rot proof

PROPERTIES

CLASS acc. EN 13165

STANDARD UNIT SPECIFIED VALUES

Thermal conductivity coefficient λi, (7d, 10°C) EN 12667 W/m·K 0.0215

Declared thermal conductivity coefficient λD, 10°C EN 12667 W/m·K 0.023

Compressive strength* CS(10/Y)200 EN 826 kPa 225±50

Dimensional stability 48h, 70ºC, 90 %HR DS(70,90)3 EN 1604 % long, anch. <2

esp. <6

Water absorption WL(T)1 EN 12087 % <1

Thickness T2 EN 823 mm

e < 50 ±2 50 < e < 75 ±3

e >75 +5 -2

Reaction to fire of the product - EN 13501-1 - Euroclass E

Reaction to fire of the product in end use (insulation deck-type roofs)

- EN 15715 - B-s2, d0

* Thickness below 45 mm, compressive strength class is CS(10/Y)175

THERMAL PROPERTIES

Thickness (mm) 40 50 60 80 100 120 140

Thermal resistance (m2·K/W) 2.06 2.32 2.60 3.45 4.35 5.20 6.10

RL ENERGY 3 PIR TECHNICAL DATA SHEET

NZ and Australian Distributor: ROOFLOGIC Ltd, PO Box 1848, Wellington, ph 04 4757663, [email protected]

NZ and Australian Distributor: ROOFLOGIC Ltd, PO Box 1848, Wellington, ph 04 4757663, [email protected]

NZ and

RL Securock Fiber Roof Board TDS, v.1, 10/15

1

DESCRIPTION

RL Securock Roof Board is a high-performance roof board. Its unique fiber-reinforced, homogenous composition gives the panel strength and water resistance through to the core. Securock Fiber Roof Board provides exceptional bond and low absorption in adhered systems and, with its homogenous composition, achieves high wind-uplift ratings with no risk of facer delamination. Made from 97% recycled material, Securock Fiber Roof Board combines superior performance with sustainable design for all types of roofing systems, including FiberTite single ply, modified bitumen and metal skin (MSR) roofing.

ADVANTAGES

Exceptional Strength: Engineered to provide superior wind-uplift performance for a wide variety of roof assemblies. RL Securock Fiber Roof Board has uniform composition providing enhanced bond strength of membrane systems with no risk of facer delamination.

Fire Performance: Provides excellent fire performance and demonstrates exceptional surface burning characteristics (ASTM E84 (CAN/ULC-S102) Flame Spread 5, Smoke Developed 0).

Moisture and Mold: Uniform water-resistant core ensures excellent moisture and mold resistance. Scored a maximum "10" for mold resistance on ASTM D3273.

Versatile: Can be used as a component in single-ply, metal and modified bitumen roofing.

Sustainability: Made from 97% recycled materials and has earned independent certification from Scientific Certification Systems for this achievement.

LIMITATIONS

Securock Fiber Roof Board is engineered to perform within a properly designed roof system. Consult RoofLogic for specific instructions on the application of Securock Fiber Roof Board within their engineered roof systems. Weather conditions, dew, application temperature, installation techniques and moisture drive can have adverse effects on the performance of the roof system. In all applications refer to RoofLogic Project Specifications. Keep Securock Fiber Roof Board panels dry before, during and after installation. Securock Fiber Roof

Board should not be installed during rain, and any other conditions that deposit moisture on the surface of the board. Apply only as much Securock Fiber Roof Board that can be covered by the specified top skin in the same day.

For re-roof or re-cover applications, existing roofing system must be dry throughout prior to application of Securock Fiber Roof Board. Plastic or poly packaging applied at the plant to protect board during transit should be removed upon receipt to prevent condensation or trapping of moisture, which may cause application problems. Securock Fiber Roof Board should be stored flat and off the ground with protection from the weather. If stored outdoors, a breathable waterproof covering should be used. When applying solvent-based adhesives or primers, allow sufficient time for the solvent to evaporate to avoid damage to roofing components. Modified bitumen can be torched directly to the surface. Consult with RoofLogic for recommendations on this application.

TECHNICAL DATA SHEET

RL SECUROCK ROOF BOARD

RL Securock Fiber Roof Board TDS, v.1, 10/15

2

INSTALLATION

Refer to RoofLogic Specifications for proper installation techniques. Use fasteners specified in accordance with the Specifcation. Install approved fasteners with plates into the Securock

Fiber Roof Board, flush with the surface. Fasteners should be installed in strict compliance with RoofLogic's installation recommendations and standard fixing set-out design. Proper fastener spacing is essential to achieve wind-uplift performance.

Locate edge joints on, and parallel to, deck ribs. Stagger end joints of adjacent lengths of Securock Fiber Roof Board. Butt board edges and ends loosely in typical installations. Long, un-interrupted runs (greater than 60 metres) of Securock Fiber Roof Board will require slight gapping due to thermal expansion.

See product data table below for maximum flute span when panels are applied directly over RL Base Deck.

FIRE PERFORMANCE

UL Classified as to Surface Burning Characteristics and Noncombustibility in accordance with ASTM E84 (CAN/ULC-S102). - Flame Spread 5 and Smoke Developed 0.

6.5mm, 4.5mm, 12.7mm and 16mm thickness - Class A in accordance with UL790 (CAN/ULC-S107). See the UL Building Materials Directory for more information.

16mm thickness - Meets requirements of Type X per ASTM C1278 and may be used in P series designs as a thermal barrier.

SYSTEM PERFORMANCE

FM Approved - Complies with requirements of FM 4450 and FM 4470 - Meets FM Class 1

STANDARDS COMPLIANCE

Securock Fiber Roof Board is manufactured to conform to ASTM C1278, “Standard Specification for Fiber-Reinforced Panel.”

PHYSICAL PROPERTIES

Board Thickness 6.6mm 9.5mm 12.7mm 15.9mm

Width, standard 1220 mm 1220mm 1220mm 1220 mm

Length, standard 1220 mm and

2400 mm 1220 mm and

2400 mm 1220 mm and

2400 mm 1220 mm and

2400 mm

Pieces per unit for 1220x2440 sheets 50 40 30 24

Weight, nominal kg/m2 7.65 9.55 13.45 15.6

Compressive Strength psi nominal 12.4 Mpa 12.4 Mpa 12.4 Mpa 12.4 Mpa

Flute spanability per ASTM E661 65mm 125mm 200mm 250mm

Permeance.perms, per ASTM E96 30 26 26 24

Water Absorption, %max, nominal grams, per ASTM C473

10 10 10 10

Surface Water Absorption, nominal grams, per ASTM C473

1.6 1.6 1.6 1.6

Mold Resistance per ASTM D3273 10 10 10 10

NZ and Australian Distributor: ROOFLOGIC Ltd, PO Box 1848, Wellington, ph 04 4757663, [email protected]

NZ and

RL Trufast Fasteners #12 Purlin, TDS, v.2, 10/15

PART LENGTH (See chart) THREAD LENGTH (See chart)

4.5mm Major Diameter 5.25mm 4.7mm #4 DRILL POINT

2 m m

1 1 m m

# 3 S Q D R I V E

DESCRIPTION

The Trufast #12 Purlin Fastener is a self-drilling fastener engineered to secure concealed clip systems and single ply roofing membranes to structural steel purlins up to 4.5mm thick without pre-drilling. The specially designed 20mm long pilot point prevents the Base Deck from ‘jacking’ up the threads during the drilling operation, thereby reducing point burnout and breakage.

APPROPRIATE ACCESSORIES

Use with Trufast MP-2000, MPB-2000, MPB 2400 Seam Plates and RL Concealed Clips when installing Topdeck (C).

PRODUCT FEATURES

Special flat-formed double fluted drill point speeds drilling penetration.

Black e-coat coating provides superior corrosion resistance and is compatible with all coated steel, uncoated steel and aluminium roofing.

PRODUCT SPECIFICATION

PERFORMANCE DATA

INSTALLATION GUIDELINES

Using the #3 square drive bit provided and a 0-1800 rpm screw gun, install the fastener into the steel purlin. The fastener must penetrate the deck a minimum of 25mm, as measured from the underside of the purlin to the fastener tip. Care should be taken to orient the fastener perpendicular to the deck and not to over drive the fastener to prevent damage to the roof assembly

Disclaimer The performance specifications published in this data sheet are based on controlled laboratory tests & are intended as a guideline only. They are not guaranteed in any way by Altenloh, Brinck & Co US Inc. (the manufacturer) or RoofLogic Ltd (the distributor), since building design, engineering, & construction, including workmanship & materials, are beyond the control of the manufacturer & distributor. RoofLogic recommends that pull-out tests be conducted to verify the substrate provides adequate pull-out values

.

Part Number Part Length Thread Length

PF-1375 34.9 mm 19.1 mm (full)

PF-2750 69.9 mm 50.8 mm (full)

PF-3750 95.3 mm 85.7 mm

PF-4750 120.7 mm 85.7 mm

PF-5750 146.0 mm 85.7 mm

PF-6750 171.5 mm 85.7 mm

PF-7750 196.9 mm 85.7 mm

PF-8750 222.3 mm 85.7 mm

Property Standard Average Ultimate Value

Tensile Strength ASTM F606-10 15.6kN

Shear Strength NASM 1312-20 10.2kN

Corrosion Resistance FM 4470,ASTM D6294, DIN 50018 < 15% Red Rust after 30 kesternick cycles

Average Pull Ultimate Steel

out Values in Corrugated Deck Substrates Deck Substrates

Thickness 0.71mm

Yield Strength 250MPa 550MPa 700MPa

Pullout 2.06kN 3.09kN 3.58kN

TECHNICAL DATA SHEET

RL TRUFAST FASTENERS # 12 Purlin

NZ and Australian Distributor: ROOFLOGIC Ltd, PO Box 1848, Wellington, ph 04 4757663, [email protected]

NZ and

Low profile #3 square drive pancake head. Provides exceptional pull out resistance in steel purlins. FM approved. CE European Technical Approval ETA09/0375

Manufactured in U.S.A

RL Trufast Fasteners #15 Purlin, TDS, v.2, 10/15

DESCRIPTION

DESCRIPTION

The Trufast #15 EHD (Extra Heavy Duty) Fastener is engineered to provide optimal wind uplift performance in a wide range of RoofLogic roof assemblies, including UltraTherm Xtreme, UltraTherm Xtreme Recover and UltraTherm MSR (C).

PRODUCT FEATURES

Double flute drill point provides ease of penetration in to RL Base Deck,

Light weight steel purlins (up to 1.2mm) and timber decking/purlins.

Exclusive tapered entry thread wedges fastener tightly in to deck or

purlin for superior back-our resistance.

Black e-coat coating provides superior corrosion resistance and is compatible

with all coated steel, uncoated steel and aluminium roofing.

PRODUCT SPECIFICATION

PERFORMANCE DATA

INSTALLATION GUIDELINES

For RL Base Deck and plywood substrates: Using the #3 Phillips drive bit provided and a screw gun set to maximum 2500rpm install the fastener through the specified assembly in to the deck. For RL Base Deck and light weight steel purlins the #15 EHD fastener must penetrate through the deck or purlin a minimum of 20mm. For timber substrates and timber purlins the #15 EHD fastener must penetrate in to the substrate 30mm. With plywood attachment this will result in penetration through the plywood of approximately 12mm. Disclaimer The performance specifications published in this data sheet are based on controlled laboratory tests & are intended as a guideline only. They are not guaranteed in any way by Altenloh, Brinck & Co US Inc. (the manufacturer) or RoofLogic Ltd (the distributor), since building design, engineering, & construction, including workmanship & materials, are beyond the control of the manufacturer & distributor. RoofLogic recommends that pull-out tests be conducted to verify the substrate provides adequate pull-out values

.

Part No. Part Length Thread Length

EHD-1250 38.1 mm 38.1 mm (full)

EHD-2000 50.8mm 50.8 mm (full)

EHD-3000 76.2 mm 76.2 mm (full)

EHD-4000 101.6 mm 76.2 mm

EHD-5000 127.0 mm 101.6 mm

EHD-6000 152.4 mm 101.6 mm

EHD-7000 177.8 mm 101.6 mm

EHD-8000 203.2 mm 101.6 mm

EHD-9000 228.6 mm 101.6 mm

Part No. Part Length Thread Length

EHD-10000 254.0 mm 101.6 mm

EHD-11000 279.4 mm 101.6 mm

EHD-12000 304.8 mm 101.6 mm

EHD-14000 355.6 mm 101.6 mm

EHD-16000 406.4 mm 101.6 mm

EHD-18000 457.2 mm 101.6 mm

EHD-20000 508.0 mm 101.6 mm

EHD-22000 558.8 mm 101.6 mm

EHD-24000 609.6 mm 101.6 mm

Property Standard Average Ultimate Value

Tensile Strength ASTM F606-10 15.6kN

Shear Strength NASM 1312-20 10.6kN (thread zone)

Corrosion Resistance

FM 4470, DIN 50018 < 15% Red Rust after 30 kesternick cycles

Thickness .55mm .71mm .89mm

Yield Strength 550MP 230MPa 550MPa 700MPa 230MPa 550MP 700MPa

Pullout 2.5kN 2.06kN 3.09kN 3.58kN 2.7kN 3.8kN 4.3kN

TECHNICAL DATA SHEET

RL TRUFAST FASTENERS # 15 Purlin

Low profile Phillips truss head

FM approved.

CE European Technical Approval ETA09/0375.

Manufacture in U.S.A.

NZ and Australian Distributor: ROOFLOGIC Ltd, PO Box 1848, Wellington, ph 04 4757663, [email protected]

NZ and

PART LENGTH (See Chart ) THREAD LENGTH (See Chart)

#3 PHILLIPS FLAT

TRUSS HEAD

1 2 m m

Major Diameter 7mm 5 Threads/cm

Material: SAE C1022, heat treated Coating: Tru-KoteTM Epoxy E-Coat

62

38

38 82

10040

43120º

910995

(Effective Cover)182

(Reverse Run) (Standard)

Underlap support leg

Twin capillary break

Convex top to rib

Substrate Material Steel Aluminium

Thickness .40mm BMT .55mm BMT .70mm BMT .90mm BMT

Approx weight per lineal metre for Zincalume based material (kg/lm) 4.05 5.48 2.39 3.07

Purlin Spacings - General Refer to separate section. Refer to separate section.

Unsupported Overhang (mm) 250 350 200 300

This technical data sheet is for steel and aluminium based substrates. RL Topdeck T can also be manufactured in other metals such as Copper or Titanium Zinc. Refer to RoofLogic.

RL Topdeck T

Information Table

Minimum PitchThe minimum roof pitch for RL Topdeck T is 3 degrees (approx 1:20). Any variation from the above should be referred to RoofLogic.When a combination of sheets provide a run of in excess of 40 metres and up to 60 metres the roof pitch should be increased by 1 degree. Longer lengths require specific design.When rainfall intensity exceeds 100mm/hour the minimum pitches need to be increased by a further 1 degree for every 10 metres of run over 40 metres.The building design pitch may need to be higher to take into account any cumulative deflections of the frame, purlin and roof sheeting or penetrations.With curved roofing the roof cladding must not terminate at a pitch lower than permitted above.Side laps of curved sheets must be sealed to any areas below the minimum pitches permitted above.

Description

RLTopdeck T lap

RL Topdeck T Dimensioned Drawing

(All dimensions are nominal and in mm)

RL Topdeck T

Technical Data Sheet

Building Design / Performance CriteriaProduct Selection

During the design of buildings, it is necessary for the designer to take into account a number of issues to ensure that the most appropriate roofing and cladding product is chosen.

Whilst aesthetics and product availability do play a part, the chosen profile must meet certain performance criteria. These are centred around the profile’s ability to shed water from the roof and the ability of the product to span purlin and girt spacings and meet design criteria. The minimum pitch for this profile is outlined elsewhere within this literature.

In terms of purlin spans and girt spacing it is necessary to follow due process.

If a building is being designed and constructed in full accordance with E2/AS1 and roofing and cladding products as covered by that document are chosen, then it is necessary for the design spans and fixing methodology to comply with those of E2/AS1. However E2/AS1 states that the use of the manufacturers information may provide a more optimum spacing of fixings, and this is recommended by RoofLogic.

Further, where a building is outside of the scope of E2/AS1 and the building or parts thereof are of specific design, then it is necessary for the roofing and cladding to be suitable for the design and vice versa.

Loadings referred to in RoofLogic graphs are the result of testing to a serviceability limit state which is more conservative than an ultimate limit state as quoted by some manufacturers.

Our Design Graphs are presented in a form to allow the designer to select suitable products and purlin spacings.

For most roof installations the purlin spacings will be limited by the trafficable limitations of the RL Base Deck which is used as a trafficable deck for installation of the UltraTherm MSR system. It is then necessary for the designer to calculate the design wind load for the roofing and cladding in accordance with generally acceptable practice, by reference to AS/NZS 1170.2: 2011, and/or NZS 3604: 2011 as appropriate.

The purlin spacings should be limited to the lower of the trafficable limitations and design wind load with the capacity of the structure being greater than the design load for the application. However, for roofs that are not able to be walked on the trafficable limitations may be exceeded providing the design wind loading criteria is met. This should be done with caution as it may require considerable extra secondary fasteners within the laps.

When a roof is subject to extensive foot traffic, exposed to snow loads or used to support mechanical plant, purlin spacing should be reduced accordingly. Consideration also needs to be given to limitations of purlin spacings for any translucent sheeting.

Primary Fixing Methods

A - Fixed every purlin, every rib with approved screws & neos, load spreading profiled metal washers and EPDM washers.

B - Fixed every purlin with the same pattern, (hi t -miss-hi t -hi t -miss-hi t ) with approved screws &and neos, load spreading profiled metal washers and EPDM washers. End purlins and periphery of roof to be fixed every rib.

C - Fixed every purlin with the same pattern, (hi t -miss-hi t -hi t -miss-hi t ) with approved screws and neos and 25mm Aluminium embossed washers. End purlins and periphery of roof to be fixed every rib.

D - Fixed every purlin with the same pattern, (hi t -miss-hi t -hi t -miss-hi t ) with approved screws and neos without washers. End purlins and periphery of roof to be fixed every rib.

Snow Loads

When the possibility of snow exists it is necessary to allow for the extra imposed snow loads by increasing the strength of the structure, and/or minimising the build up of snow, and this is generally achieved by increasing the roof pitch by allowing easier shedding of the snow or otherwise as the designer determines.

The objective is to simplify rather complex loading patterns while remaining adequately cautious. The design loads should take account of drifting snow due to wind, but wind loads are not required to be combined with snow loads.

As snow loads are uniformly distributed loads they are similar to wind loads.

Snow loadings are not required to be taken into account for the North Island of New Zealand north of a line drawn from Opotiki to Turangi and New Plymouth.

However for other areas snow loadings may need to be taken into account dependent on the area and altitude of the proposed project. A fuller reference including a map and chart is available from the NZ Metal Roofing Roof and Wall Cladding Code of Practice Section 3.5.

RL Topdeck T

2

WIND & CONCENTRATED LOAD SPAN DESIGN GRAPH

Steel Based Material

0.55 Steel G550 High Strength0.40 Steel G550 High Strength

• Intermediate span in metres.• End spans to be a maximum of 2/3 of this span.• A, B, C and D represent alternative primary fixing methods

1) The solid line represents where walking is permitted within300mm of the purlin line or in the pan of the profile. Thereforefor a normal roof, providing wind load requirements are met,purlin spans are limited to:

Type 2B “Restricted Access” Classification

2) The broken line represents untrafficable roof areas and is wind loading only and has a Type 3 Classification.

In areas of heavy roof traffic, snow loadings or containing items such as air conditioning units purlin spacing should be reduced accordingly.

1.5 2.0 2.5 3.0 3.5 4.0

6.0

5.5

5.0

4.5

4.0

3.5

3.0

2.5

2.0

1.5

1.0

0.5

0

kPa

Trafficable (1)

Wind load only ( 2 )

C

A

B

D

Ref # MRRC2

Maximum Spans 0.40 mm BMT

Intermediate 2.4 metres End 1.6 metres

• Intermediate span in metres.• End spans to be a maximum of 2/3 of this span.• A, B, C and D represent alternative primary fixing methods

1) The solid line represents where walking is permitted within300mm of the purlin line or in the pan of the profile. Thereforefor a normal roof, providing wind load requirements are met,purlin spans are limited to:

Type 2B “Restricted Access” Classification

Maximum Spans 0.55 mm BMT

Intermediate 3.4 metres End 2.0 metres

1.5 2.0 2.5 3.0 3.5 4.0

6.0

5.5

5.0

4.5

4.0

3.5

3.0

2.5

2.0

1.5

1.0

0.5

0

kPa

Trafficable (1)

C

A

B

D

Ref # MRRC1

3) Use of RL Liner Deck (0.55BMT) allows purlin spacing to amaximum of 2.60m.

4) Use of RL Liner Deck HD (0.75BMT) allows purlin spacingto a maximum of 3.40m

-----------------------------------------------------------

(3)

-------------------------------------------------

(4)

-----------------------------------------------------------(2)

-------------------------------------------------

(3)

2) Use of RL Liner Deck (0.55BMT) allows purlin spacing to amaximum of 2.60m.

3) Use of RL Liner Deck HD (0.75BMT) allows purlin spacingto a maximum of 3.40m

RL Topdeck T

3

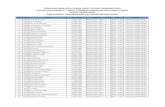

WIND & CONCENTRATED LOAD SPAN DESIGN SUMMARY CHART FOR ROOFING SPANS IN STEEL Incorporating Wind and Concentrated Load Span Design, Primary Fixing Methods and Foot Traffic

0.40mm BMT Steel

WIND DESIGN LOADINGS - kPa’s

Purlin Spacing (mtrs) Fixing Method A Fixing Method B Fixing Method C Fixing Method D Foot TrafficIntermediate End Int. End Int (P) Int. End Int (P) Int. End Int (P) Int. End Int (P)

1.2 0.8 4.5 4.7 4.5 2.3 2.4 4.5 1.9 2.2 2.8 1.2 1.3 2.6

Unrestricted

1.5 1.0 4.3 4.5 4.3 2.2 2.3 4.3 1.8 2.1 2.7 1.2 1.2 2.5 1.75 1.17 3.7 4.5 3.7 2.0 2.3 3.7 1.7 2.1 2.4 1.1 1.2 2.252.00 1.33 3.2 4.4 3.2 1.8 2.2 3.2 1.5 2.1 2.2 1.0 1.2 2.02.25 1.5 2.7 4.3 2.7 1.6 2.2 2.7 1.4 1.9 2.0 0.9 1.2 1.82.4 1.6 2.5 4.0 2.5 1.55 2.1 2.5 1.3 1.8 1.8 0.9 1.2 1.72.5 1.67 2.4 3.8 2.4 1.5 2.1 2.4 1.2 1.8 1.8 0.9 1.1 1.6 2.75 1.83 2.0 3.4 2.0 1.3 1.95 2.0 1.1 1.7 1.5 0.8 1.1 1.4 Restricted2.9 1.9 1.8 3.3 1.8 1.2 1.9 1.8 1.0 1.6 1.4 0.8 1.00 1.25

0.55mm BMT Steel

WIND DESIGN LOADINGS - kPa’s

Purlin Spacing (mtrs) Fixing Method A Fixing Method B Fixing Method C Fixing Method D Foot TrafficIntermediate End Int. End Int (P) Int. End Int (P) Int. End Int (P) Int. End Int (P)

1.2 0.8 6.0 6.0 6.0 3.5 3.5 6.0 3.3 3.3 5.5 2.7 2.7 5.0 1.5 1.0 5.5 6.0 5.5 3.2 3.5 5.5 2.9 3.3 5.0 2.5 2.7 4.6 1.75 1.17 4.9 5.9 4.9 2.8 3.4 4.9 2.65 3.2 4.4 2.25 2.6 4.0 2.0 1.33 4.4 5.7 4.4 2.6 3.3 4.4 2.3 3.1 3.7 2.0 2.5 3.4 2.25 1.5 4.0 5.5 4.0 2.3 3.2 4.0 2.1 2.9 3.3 1.8 2.5 3.0 2.4 1.6 3.6 5.3 3.6 2.15 3.1 3.6 1.9 2.8 2.9 1.65 2.4 2.7 2.5 1.67 3.5 5.1 3.5 2.1 3.0 3.5 1.8 2.7 2.8 1.6 2.3 2.6 2.75 1.83 3.3 4.7 3.3 1.8 2.75 3.3 1.6 2.5 2.4 1.45 2.2 2.2 2.9 1.9 3.0 4.6 3.0 1.75 2.7 3.0 1.5 2.4 2.2 1.4 2.1 2.0 3.0 2.0 2.9 4.4 2.9 1.70 2.6 2.9 1.4 2.3 2.1 1.3 2.0 1.9 3.25 2.16 2.6 4.3 2.6 1.50 2.5 2.6 1.2 2.2 1.8 1.25 1.9 1.653.5 2.33 2.3 3.8 2.3 1.35 2.2 2.3 1.1 2.0 1.5 1.0 1.75 1.43.75 2.5 2.2 3.5 2.2 1.25 2.1 2.2 0.95 1.8 0.9 0.8 1.6 0.8

Restricted AccessWalk within 300mm of Purlins or in pan of roof

Unrestricted

Notes:1) Use of RoofLogic Liner Deck (0.55BMT) allows purlin spacing to a maximum of 3.00m2) Use of RoofLogic Liner Deck HD (0.75BMT) allows purlin spacing to a maximum of 4.00m3) In areas of heavy roof traffic, snow loadings or containing items such as air conditioning units, purlin spacing should be reduced

accordingly.

RL Topdeck T

4

PRIMARY FIXING CHART

Roofing - Crest fixed (To be read in conjunction with Roof Expansion Provisions and Load Span Design Graph)

Wood Purlins Steel Purlins or girtsup to 1.5mm

Steel Purlins or girts1.5-4.5mm

Steel Purlins or girts 4.5-12mm

Washers(When required)

Steel Based Material

14-10 x 200 Class 4Type 17 Woodtekswith neos

12-14 x 175 Class 4Steelteks with neos

12-14 x 175 Class 4Steelteks with neos

12-24 x 175 Class 4Series 500 Steeltekswith neos

RL Topdeck load spreading profile Steeland 36mm EPDM or 25mm Aluminium embossed washer

Aluminium Based Material

14-11 x 200 Alutite with bonded washer with RL Topdeck load spreading profile 1.2mm Aliwashers and 36mm EPDM or Stainless steel grade 316, 14-10 x 100 Type 17 with neos through a 10mm dia. clearance hole with RL Topdeck load spreading profile 1.2mm Aliwasher & 36mm EPDM

Stainless steel grade 304, 14-14 x 175 Steelteksand bonded washerthrough a 10mm dia.clearance hole with RLTopdeck loadspreading pro ile1.2mm Ali washer &36mm EPDM

Stainless steel grade 304, 14-14 x 175 Steelteksand bonded washerthrough a 10mm dia.clearance holewith RL Topdeck loadspreading profile1.2mm Ali washer& 36mm EPDM

Fabco stainless steel grade 304, 14-14 x 175 Type Bscrew and bondedwasher through a 10mmdia. clearance hole withRL Topdeck loadspreading profile 1.2mmAli washer & 36mm EPDM

RL Topdeck load spreading profile 1.20mm Ali and 36mm EPDM

Note: All primary fasteners to have a minimum embedment into structural timber of 30mm. Adjust fastener length for both timber and steel fixings when necessary for battens etc. When using load spreading profile washers or 25mm Aluminium embossed washers for roofing fix ridging, roof flashings etc. using a 25mm Aluminium embossed washer and appropriate screw.

Secondary Fasteners: (To be used in accordance with the NZ Metal Roof and Wall Cladding Code of Practice.)These should be:• Aluminium Blind Rivets AS5-3 x 4mm minimum (Residential)• Aluminium Blind Rivets AS 6-3 x 4.8mm minimum (Commercial)• Aluminium Bulb-tite Rivets

• 12-11x35 Alutites• 12-11x25 Class 4 Type 17 Woodteks (Steel based material only)

RL Topdeck T

5

ROOF EXPANSION PROVISIONS

Fix with recommended fasteners and systems from the Primary Fixing Chart and additionally allow for the following where applicable.

Steel Based Material

E2/AS1 Compliance

Sheet Lengths Up to 8 metres >8-12 metres >12-18 metres >18 metres

No special provision. Lower 50 % of the roof should be fixed using oversize holes at fastening points with approved load spreading profile washer, and 36mm EPDM washers.

Not Applicable.

NZ Metal Roof and Wall Cladding Code of Practice Compliance

Sheet Lengths Up to 15 metres >15-18 metres >18-25 metres >25-30 metres

Zincalume and light colours No special provision. No special provision Solid fix from the ridge down 12 metres and oversize holes should be used for the remainder of the sheet with approved load spreading profile washers, and a 36mm EPDM or approved 25mm Aluminium embossed washer.

Solid fix from the ridge down 12 metres & oversize holes should be used for the remainder of the sheet with approved load spreading profile washers, and a 36mm EPDM or approved 25mm Aluminium embossed washer used for the entire sheet

Dark Colours No special provision. Solid fix from the ridge down 12 metres and oversize holes should be used for the remainder of the sheet with approved load spreading profile washers, and a 36mm EPDM washer or approved 25mm Aluminium embossed washers

Not recommended

For sheet lengths in excess of the above a step joint or other special provision for expansion is required. Refer to RoofLogic. When using load spreading profile washers or 25mm Aluminium embossed washers for roofing fix ridging, roof flashings etc. using a 25mm Aluminium embossed washer and appropriate screw.

Oversize holes should be 3mm greater diameter than the screw or as per the Primary Fixing Chart for stainless steel screws.For further information on the fixing of Multirib refer to E2/AS1 of the NZ Building Code and NZ Metal Roof and Wall Cladding Code of Practice, www.metalroofing.org.nz. These publications along with the foregoing technical data should form the basis of the design and installation of metal roofing and cladding.

Also refer to our suite of detail drawings, and to NZ Steel Ltd and Pacific Coilcoaters literature.

RL Topdeck T

6

ROOF EXPANSION PROVISIONS

Fix with recommended fasteners & systems from the Primary Fixing Chart & additionally allow for the following where applicable.

Aluminium

Sheet Lengths Up to 10 metres 10-12 metres 12-15 metres >15 metres

Plain Aluminium & lighter colours in Favourable Installations (Refer NZMRM C.O.P. Section 4.1.6)

Fix using oversize holes with screws and approved load spreading profile Ali washers, and 36mm EPDM washers

Not recommended

Dark Coloured Aluminium in Favourable Installations (Refer NZMRM C.O.P. Section 4.1.6)

Fix using oversize holes with screws and approved load spreading profile Ali washers, and 36mm EPDM washers

Not recommended

Plain Aluminium & lighter colours in Unfavourable Installations (Refer NZMRM C.O.P. Section 4.1.6)

Fix using oversize holes with screws and approved load spreading profile Ali washers, and 30mm EPDM washers

Not recommended

Dark Coloured Aluminium in Unfavourable Installations (Refer NZMRM C.O.P. Section 4.1.6)

Fix using oversize holes with screws and approved load spreading profile Ali washers, and 30mm EPDM washers.

Not recommended

For sheet lengths in excess of the above a step joint or other special provision for expansion is required. Refer to RoofLogic. When using load spreading profile washers or 25mm Aluminium embossed washers for roofing fix ridging, roof flashings etc. using a 25mm Aluminium embossed washer and appropriate screw.

Oversize holes should be 3mm greater diameter than the screw or as per the Primary Fixing Chart for stainless steel screws.For further information on the fixing of Multirib refer to E2/AS1 of the NZ Building Code and NZ Metal Roof and Wall Cladding Code of Practice, www.metalroofing.org.nz. These publications along with the foregoing technical data should form the basis of the design and installation of metal roofing and cladding.

Also refer to our suite of detail drawings, and to NZ Steel Ltd and Pacific Coilcoaters literature.

RL Topdeck T

7

Australia and New Zealand Distributor: ROOFLOGIC Limited2 Cashew Street, PO Box 1848, Wellington / 04 4757663 / technical @rooflogic.co.nz

(All dimensions are nominal and in mm)RL Topdeck C Dimensioned Drawing

RL Topdeck C lap

3

5022550

500520

(Effective Cover)

10 12

250

RL Topdeck hidden fixing clip

RL Topdeck C

Minimum Pitch

Substrate Material Steel Aluminium

Thickness .48mm BMT .55mm BMT .90mm BMT

Approx weight per lineal metre for Zincalume based material (kg/lm) 2.94 3.35 1.85

Purlin Spacings -General Refer to separate section. Refer to separate section.

Unsupported Overhang (mm) 150 250 200

Technical Data Sheet

The minimum roof pitch for RL Topdeck C is 3 degrees (approx 1:20). Any variation from the above should be referred to Roofing Industries

It is recommended when a combination of sheets provide a run of in excess of 40 meters and up to 60 meters the roof pitch should be increased by 1 degree or when rainfall intensity exceeds 100mm/hour the minimum pitches need to be increased by a further 1 degree for every 10 metres of run over 40 metres

The building design pitch may need to be higher to take into account any cumulative deflections of the frame, purlin and roof sheeting or penetrations.

With curved roofing the roof cladding must not terminate at a pitch lower than permitted above.

Side laps of curved sheets must be sealed to any areas below the minimum pitches permitted above.

Information Table

This technical data sheet is for steel and aluminium based substrates. RL Topdeck C can also be manufactured in other metals such as Copper or Titanium Zinc. Refer to RoofLogic.

Description

RL Topdeck C

During the design of buildings, it is necessary for the designer to take into account a number of issues to ensure that the most appropriate roofing and cladding product is chosen.

Whilst aesthetics and product availability do play a part, the chosen profile must meet certain performance criteria. These are centered around the profile’s ability to shed water from the roof and the ability of the product to span purlin and girt spacings and meet design criteria. The minimum pitch for this profile is outlined elsewhere within this literature.

In terms of purlin spans and girt spacing it is necessary to follow due process.

If a building is being designed in accordance with E2/AS1 and roofing and cladding products as covered by that document are chosen, then it is necessary for the design spans and fixing methodology to comply with those of E2/AS1. For RL Topdeck C or similar profile E2/AS1 states that the manufacturers recommendation can be used for fixing patterns and spans, as the acceptable solution is based on a different pan width.

Further where a building or products are outside of the scope of E2/AS1 and the building or parts thereof are of specific design then it is necessary for the roofing and cladding to be suitable for the design and vice versa.

Loadings referred to in RoofLogic tables are the result of testing to a serviceability limit state which is more conservative than an ultimate limit state as quoted by some manufacturers.

Our Design Tables are presented in a form to allow the designer to select suitable products and purlin spacings.

For most roof installations the purlin spacings will be limited by the trafficable limitations of the profile or the structural design. It is then necessary for the designer to calculate the design wind load for the roofing and cladding in accordance with generally acceptable practice, by reference to AS/NZS 1170.2 2011, and/or NZS 3604: 2011 as appropriate.

The purlin spacings should be limited to the lower of the trafficable limitations and design wind load with the capacity of the structure being greater than the design load for the application. When a roof is subject to extensive foot traffic, exposed to snow loads or used to support mechanical plant, purlin spacing should be reduced accordingly. Consideration also needs to be given to limitations of purlin spacings for any translucent sheeting.

Building Design / Performance Criteria / Product Selection

When the possibility of snow exists it is necessary to allow for the extra imposed snow loads by increasing the strength of the structure, and/or minimising the build up of snow, and this is generally achieved by increasing the roof pitch by allowing easier shedding of the snow or otherwise as the designer determines.

The objective is to simplify rather complex loading patterns while remaining adequately cautious. The design loads should take account of drifting snow due to wind,but wind loads are not required to be combined with snow loads.

As snow loads are uniformly distributed loads they are similar to wind loads.

Snow loadings are not required to be taken into account for the North Island of New Zealand north of a line drawn from Opotiki to Turangi and New Plymouth.

However for other areas snow loadings may need to be taken into account dependent on the area and altitude of the proposed project. A fuller reference including a map and chart is available from the NZ Metal Roofing Roof and Wall Cladding Code of Practice Section 3.5.

Snow Loads

RL Topdeck C

1

SUMMARY CHART FOR ROOF AND WALL CLADDING SPANS IN STEEL

Incorporating Wind and Concentrated Load Span Design, Primary Fixing Methods and Foot Traffic

0.48mm BMT Steel

WIND DESIGN LOADINGS - kPa’s

Purlin Spacing (mtrs) Fixing Method A Foot TrafficIntermediate End Intermediate End End Periphery

0.5 0.35 2.8 3.0 2.8 0.75 0.5 2.6 2.8 2.6 1.0 0.67 2.5 2.7 2.5 1.2 0.8 2.35 2.55 2.35 1.25 0.84 2.3 2.5 2.3 1.5 1.0 2.1 2.45 2.11.6 1.1 2.05 2.4 2.051.75 1.17 1.95 2.35 1.952.0 1.33 1.8 2.25 1.82.25 1.5 1.7 2.1 1.72.5 1.67 1.55 2.0 1.552.75 1.83 1.4 1.9 1.43.0 2.0 1.3 1.8 1.3

Non Accessible

0.55mm BMT Steel

WIND DESIGN LOADINGS - kPa’s

Purlin Spacing (mtrs) Fixing Method A Foot TrafficIntermediate End Intermediate End End Periphery

0.5 0.35 3.85 4.0 3.85 0.75 0.5 3.6 3.9 3.6 1.0 0.67 3.3 3.7 3.3 1.25 0.84 3.1 3.5 3.1 1.5 1.0 2.85 3.3 2.851.75 1.17 2.7 3.2 2.71.8 1.2 2.65 3.15 2.652.0 1.33 2.5 3.1 2.52.25 1.5 2.3 2.8 2.32.5 1.67 2.1 2.7 2.12.75 1.83 2.05 2.6 2.053.0 2.0 1.85 2.5 1.85

Unrestricted

Unrestricted

Restricted Access Walk within 300mm of Purlins or in pan of roof

RL Topdeck C

2

PRIMARY FIXING CHART (normally 1 RL Topdeck C clip per purlin per sheet)

Wood Purlins Steel Purlins or girtsup to 1.5mm

Steel Purlins or girts1.5-4.5mm

Steel Purlins or girts 4.5-12mm

Steel Based Material

Zincalume RL Roofdeck Clips with two 10-12x160 Class 3 wafer head Timberteks with square drive per clip

Zincalume RL Roofdeck Clips with two 10-16x135 Class 3 wafer head Steelteks per clip

Zincalume RL Roofdeck Clips with two 10-16x135 Class 3 wafer head Steelteks per clip (pre-drill if necessary)

Zincalume RL Roofdeck Clips with two 10-16x135 Class 3 wafer head Steelteks per clip (pre-drill if necessary)

Aluminium Based Material

Zincalume RL Roofdeck Clips with two 10-12x160 Class 3 wafer head Timberteks with square drive per clip. Paint clips with an approved primer and top coat system and provide an isolation barrier to the fixing screws in a corrosive environment

Zincalume RL Roofdeck Clips with two 10-16x135 Class 3 wafer head Steelteks per clip. Paint clips with an approved primer and top coat system and provide an isolation barrier to the fixing screws in a corrosive environment

Zincalume RL Roofdeck Clips with two 10-16x135 Class 3 wafer head Steelteks per clip (pre-drill if necessary). Paint clips with an approved primer and top coat system and provide an isolation barrier to the fixing screws in a corrosive environment

Zincalume RL Roofdeck Clips with two 10-16x135 Class 3 wafer head Steelteks per clip (pre-drill if necessary). Paint clips with an approved primer and top coat system and provide an isolation barrier to the fixing screws in a corrosive environment

Notes: All primary fasteners to have a minimum embedment into structural timber of 30mm. When sheet lengths exceed 12 metres for Zincalume and light coloured and 8 metres for dark coloured steel based material and 8 metres for Aluminium based material, fix ridging, roof flashings etc. using a 25mm Aluminium embossed washer and appropriate screw.

Secondary Fasteners: (To be used in accordance with the NZ Metal Roof and Wall Cladding Code of Practice.)These should be:

• Aluminium Blind Rivets AS5-3 x 4mm minimum (Residential)• Aluminium Blind Rivets AS 6-3 x 4.8mm minimum (Commercial)• Aluminium Bulb-tite Rivets

• 12-11x35 Alutites• 12-11x25 Class 4 Type 17 Woodteks (Steel based material only)

3

Top Deck C slides onto the Top Deck Clip and this provides longitudinal expansion. Lateral expansion is Taken up within the profile itself.

Steel Based MaterialZincalume and lighter colours are subject to less expansion than dark colours so the former are recommended when sheeting lengths exceed 24 metres. Top Deck C can be manufactured to lengths within the availability of transport limitation, generally up to 30 metres, but can be manufactured longer subject to the availability of specialised transport. For steel based sheets in excess of 30 metre sheet lengths refer to Roofing Industries

AluminiumPlain aluminium and light colours are subject to less expansion than dark colours so the former are recommended when sheeting lengths exceed 18 metres. Maximum recommended sheet lengths for plain and light coloured aluminium is 24 metres.

Ridging and FlashingsWhen sheet lengths exceed 12 metres for zincalume and light coloured steel and 8 metres for dark coloured steel based material and 8 metres for aluminium based material, fix ridges, roof flashings, etc, using a 25mm aluminium embossed washer.

For further information on the fixing of Top Deck C refer to E2/AS1 of the NZ Building Code and NZ Metal Roof and Wall Cladding Code of Practice, www.metalroofing.co.nz. These publications, along with the foregoing technical data should form the basis if the design and installation of metal roofing and cladding. Also refer to our suite of detail drawings and to NZ Steel Ltd and Pacific Coilcoaters literature.

ROOF EXPANSION PROVISIONS

Australia and New Zealand Distributor: ROOFLOGIC Limited2 Cashew Street, PO Box 1848, Wellington / 04 4757663 / technical @rooflogic.co.nz