Rich. Klinger Dichtungstechnik Company Presentation

-

Upload

ilma-llc -

Category

Technology

-

view

353 -

download

4

description

Transcript of Rich. Klinger Dichtungstechnik Company Presentation

WELCOME

KLINGER Dichtungstechnik

GmbH & Co KG

Who is Klinger Dichtungstechnik?

Family-owned company built up in Gumpoldskirchen (Austria) in 1893

Manufacturer of asbestos free fibre reinforced sealing gaskets and PTFE-sealing materials

Market leader in Europe

Part of the Klinger-Group, a manufacturer of industrial gaskets and valves

Our core competence

• Professional support for gasket selection

• High grade reliable products for the given applications

• Technological leadership

• Worldwide service and sales

• Huge experience:– More than 100 years with sealing technologies– More than 30 years with asbestos-free materials

Our laboratory

• The only Research and Development for gasket sealings within the Klinger-Group

• Quality assurance for every batch→ ~ 6.000 batches per year→ ~ 30.000 tests per year

• Tests of materials produced in all other manufacturing plants every quarter

Product Range

Asbestos free gasket materials

www.klingerquantum.com

Unique flexibility at high temperatures

A vision becomes realityKnown fibre-reinforced gasket materialsgenerally have not been able to fulfil theexpectations with regard to flexibility athigher temperatures.

In 2009, KLINGER revolutionizes thecapability of fibre reinforced gasketmaterials.

Long time flexibility test for 1200 h

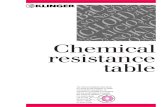

Chemical resistance

Suitable also with following media

• Amines• Sulfur compounds• Additives for fuels• different Acids (Sulfuric acid, Nitric acid, hydrochloric acid, etc.)

Better resistance against Radioactivity

Approvals and certificates

BAM (65ºC, 160 bar) - Oxygen KTW (also for hot water) - Water DIN-DVGW - Gas TA-Luft (300 ºC) Fire Safe acc. to DIN EN ISO 10497

Engineered PTFE gasketsKLINGER®top-chem

Materialbasis

Modified PTFE material with unique load bearing properties.Exceptional performance in applications with high mechanical requirements at high temperatures

Decrease in thickness at 250 °C and 50 MPa:

Standard modified PTFE KLINGER®top-chem2000

~ 35 % ~5 %

KLINGER®top-chem 2000

Advantages of KLINGER®top-chem2000

Maximum service temperature260 °C

No embrittlement

High residual stress

Long service life because of highstress retention

BAM-approval for oxygen 100 bar and 200 °C, also for liquid oxygen

No equivalent material to KLINGER®top-chem2000available worldwide

KLINGER®top-chem 2000

Applications where KLINGER®top-chem2000 is used:

KLINGER®top-chem 2000

Medium Temperature Pressure

Thermal oil 250°C 5 bar

Liquid oxygen -196°C 40 bar

Nitrobenzene 210°C 5 bar

Steam 255°C 42 bar

Approvals and Certificates

BAM certificate (100 bar, 200 ºC, also liquid oxygen)

KTW approval

DIN-DVGW

FDA conformity

TA-Luft

Fire Safe certificate

KLINGER®top-chem 2000

Case history 1:

A chemical plant manufactures nitric acid. A competitor’s PTFE gasket had been found to give the best service life …

6 months.

KLINGER®top-chem 2000

The Hot Compression test is an excellent screening method for determining the crush resistance of gasketing products.

Actual photograph of gasket

previously installed in this plant.

Actual photograph of

KLINGER®top-chem-2000

gasket now used in this plant.

KLINGER®top-chem 2000

SUMMARY of the Nitric acid Plant:

2003: Testing begins using KLINGER®top-chem-2000 gaskets.

2004: KLINGER®top-chem-2000 becomes the plant wide gasket.

2007:Performance was checked.

Gasket lifetimes TRIPLED!

KLINGER®top-chem 2000

Case history 2:

A chemical plant continued to use it’s “best service life” gasket despite continued and

Serious gasket blow-outs.

KLINGER®top-chem 2000

This is an actual photograph of a used KLINGER®top-chem-2000 gasket from this plant.

These are actual photographs of the other gaskets from this plant.

KLINGER®top-chem 2000

SUMMARY of the Chemical Plant:

1997: Testing begins using KLINGER®top-chem-2000 gaskets.

1998: KLINGER®top-chem-2000 becomes the standard.

1999:Performance was measured.

Gasket purchases were reduced by 70%!

KLINGER®top-chem 2000

KLINGER®expert

Calculation tool for Klinger-gaskets

• Free download on www.klinger.co.at

• Also in Russian-Language available

• Quick calculation for required surface pressures

Worldwide leader in gasket technology

www.klinger.co.at