Resistance to Staining and Reagents National Average...

Transcript of Resistance to Staining and Reagents National Average...

CO

MM

ER

CIA

L F

LO

OR

ING

–2

010

PR

OD

UC

T P

OR

TF

OL

IO

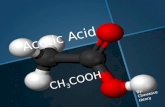

Organic SolventsAcetoneChloroformEthyl AcetateEthyl (Denatured) AlcoholEthyl EtherEthylene Glycol (Antifreeze)Formaldehyde – 10%GasolineIsopropyl AlcoholKeroseneMethylene ChlorideMethyl ethyl ketone (M.E.K.)Mineral SpiritsPerchloroethyleneTolueneTrichloroethyleneTurpentineXyleneAlkali (Bases)Ammonium Hydroxide – 30%Potassium Hydroxide – 15%Sodium Hydroxide – 50%AcidsAcetic Acid – 28%Acetic Acid – GlacialHydrochloric – 38%Lactic Acid – 10%Nitric Acid – 15%Phosphoric Acid – 85%Sulfuric Acid – 40%Sulfuric Acid – 10%Salt SolutionsCalcium Chloride – Sat’dCopper Sulfate – 10%Ferric Chloride – 10%Silver Nitrate – 1%Medical Stains & ReagentsAniline Blue – 2.5%Auramine RhodamineBasic FuchsinBetadine® Skin CleanserBetadine Solution – 10%Bromcresol GreenCarbol FuchsinEosin – 1%Gentian Violet – 2%GlutaraldehydeIodine TinctureIodine Gram StainIodoform – 1%Lugol’s SolutionMerthiolate TinctureMethylene BluePicric Acid – 1%Potassium Permanganate – 0.5%Tincture of BenzoinUrea SolutionWright’s Blood StainEmbalming ChemicalsPretresol – Pre-injectionKelcavex – CavityKelspecial® – ArterialPresinol – ArterialDisinfectants and CleanersClorox®

Comet® Bathroom CleanerHydrogen PeroxideLysol® Liquid DisinfectantFood ServiceCatsupCoffee – Hot BlackCola DrinkFrench DressingMustardRed Food ColorRed WineSoy SauceSpaghetti SauceTea – Hot BlackTomato PasteOfficeBall Pen InkCarbon Paper SmudgeFountain Pen InkLead PencilPermanent Black MarkerPhoto Copy Toner (Powder)Red CrayonRed Tempura PaintOilsBeef Tallow – HotCanola OilCottonseed OilBrake FluidDextron Transmission FluidMineral OilOlive OilSAE #10 Oil30 wt. Non-Detergent OilUsed Motor OilMiscellaneousAsphalt Driveway SealerBlue ChalkBlack Rit DyeEye ShadowHair ColorLipstickPerfumeRed Candle WaxRed Nail PolishShoe Polish – Liquid BrownShoe Polish – Paste Brown

00000000000

0, D000000

00, D0, D

00000000

0000

023112123033032233

3, R03

0000

0000

00002200000

31013020

0000000000

3, R030300

2, R3, R

02, R

000000000000000000

000

00000000

0000

011001112031032113

3, R02

1000

0000

0000120

0000

20003020

0000000000

3, R110200

2, R3, R

13, R

0, D0, D0, D0, D0, D

000

0, D0

0, D0, D

00

0, D0, D0, D0, D

000

00, D0, D0, D0, D0, D

00

0000

022111112033032223

3, R03

00, D

01

0, Bl000

00002200000

32013030

0000000000

3, R13031

0, D3, R3, R

13, R

000000000000000000

030

00000

0, D0, Bl

0

0011

033222123033032233

3, R03

0000

0000

00002200000

20013020

0000000000

3, R030320

3, R3, R

03, R

000000000000000000

00, D0, D

00000000

0000

02311212303303

2223

3, R03

0000

0000

00002200000

30003020

0000000000

3, R030310

2, R3, R

03, R

0, D0, D0, D0, D0, D

000

0, D0

0, D0, D

00

0, D0, D0, D0, D

000

00, D0, D0, D0, D0, D

00

0000

022111112033032223

3, R03

00, D

01

0, Bl000

00002200000

32013030

0000000000

3, R13031

0, D3, R3, R

13, R

NATURALCREATIONS®

MEDINTECH®

TANDEM®POSSIBILITIES®

Petit Point™ConnectionCORLON®MEDINTONE™,

MEDINTECH®, MEDLEY™

0, S, D0, S, D0, S, D0, D0, D

000

0, D0

0, S, D0, S, D

00, D

0, S, D0, S, D0, D

0, S, D

01, D0

0, Bl1, D0, Bl

0, Bl, R0, Bl

0, Bl, R0, Bl, R0, Bl, R

0122

122111313032033232

3, R03

0, D0, D0, D

0

0, D0, D0, D0, D

01002110110

32213021

000

0, D000001

1130321

2, R3, R

13, R

LINOLEUM LVT

0, Bl0, Bl0, Bl

000000

0, Bl0, Bl0, Bl

00, Bl0, Bl0, Bl

00, Bl

000

0, D0, D0, D1, Bl

01, Bl1, Bl1, Bl

0120

123111313032032222

2, R02

0, D0, D0, D0, D

00, D

00, D

00002210010

32223021

000

0, D000000

111311

0, Bl1

3, R13

MIGRATIONS™

BBT®SHEETHOMOGENEOUS

SHEETINLAID

National Average Installed Cost per Square Foot

Samples were tested as manufactured (no additional surface treatments). All samples were exposed to reagents for four hours (uncovered), then cleaned with a neutral commercial cleaner and cotton cloth. A key for interpreting results is found above. It is important to note that in some cases residual stain, residues and surface dulling may be further reduced or eliminated with different or more aggressive cleaning procedures and/or cleaning agents than the commonmethod used for this multi-product comparison. For further details on appropriate cleaning methods and care for specific products, please consult the care and maintenance guidelines for the specific product at armstrong.com/flooring.

Betadine® is a registered trademark of Purdue Products, L.P. Kelspecial® is a registered trademark of Kelco Supply Company. Clorox® is a registered trademark of The Clorox Company. Comet® is a registered trademark of The Comet Products Corporation. Lysol® is a registered trademark of Linden Corporation.

0: No Stain 1: Slight 2: Moderate 3: Severe Bl: Bleaching D: Dulling S: Softening R: Reagent left a residue

EXCELON®

ARTEFFECTS®

Standard EXCELON®

WithNATURCote™

VCT

000000000000000000

00, D0, D

00000000

0000

033000123032033223

3, R03

0000

0000

00001100000

20003021

0000000000

3, R0202

2, R0

2, R3, R

01,R

00, D

00000

0, D02

0, D0, D

20, D0, D0, D0, D0, D

00, D

0

1, D1, D0, D1, D1, D1, D1, D0, D

0011

110110111032032230

3, R01

0, D0, D0, D0, D

00, D0, D0, D

0, D00

0, D10001

0, D0, D

22223000

0, D0, D0, D0, D1, D0, D0, D0, D0, D1, D

0110110

2, R3, R

02

PERSPECTIVES®, TIMBERLINE®,TRANSLATIONS™

Rubber Tile / Treads

000000000000000000

000

00102010

0000

223000313000001101101

0000

0000

00000000000

30102001

0000000000

00000100

3, R01

000000000000000000

000

00

1, Bl0

1, Bl000

0010

001000001000000000101

0000

0000

00000000000

20000301

0000000000

00000000

3, R00

000000000000000000

00

1, Bl

00

2, Bl0

2, Bl1, D00

0000

000000000011000001

2, R00

0000

0000

0000000000

0

10000010

0000000000

00000000

3, R00

COMMERCIALLAMINATE

0, S, D0, S, D0, S, D

0000000

0, S, D0, S, D

00, D

0, S, D0, S, D

00, S, D

0, D33

0, D00

0, R0, D, R0, Bl, R0, Bl, R

0, D

0023

122222223032033333

3, R03

0, D0, D

02

0000

00002210100

31203010

0000000001

3, R130321

3, R3, R

13, R

SHEETHETEROGENEOUS

ACCESSORIES

SDT™

SPECIALTYESD

00, Bl

00100000

0, Bl0000000

010

00000000

0000

122201223032013122203

0000

0000

00002300100

22123111

0, D000000000

11303211

3, R13

SAFEGUARD™

00

1, R000000020000000

000

00000

0, D00

0000

012001213121021221202

0000

0000

00001100000

21113010

0000000000

11302101

3, R13

SAFEGUARD Spa™

SPECIALTYSLIP-RETARDANT*

Commercial Hardwood – Engineered

Commercial Hardwood – Solid

Acrylic Impregnation, Permion® Finish

PREMIER PERFORMANCE™ $9.00 – $14.50 C$10.50 – C$16.75

Permion Finish

HERITAGE CLASSICS™ $7.00 – $9.50 C$8.25 – C$11.25

VALENZA™ COLLECTION $8.00 – $11.50 C$9.50 – C$13.50

METRO CLASSICS™ $7.00 – $10.00 C$8.25 – C$12.00

BECKFORD™ $4.00 – $7.00 C$5.00 – C$8.25

CENTURY FARM™ $9.50 – $13.00 C$11.50 – C$15.00

Acrylic Impregnation, HartWood™ Finish

HARTWOOD® PARQUET $7.00 – $10.00 C$8.25 – C$12.00

Commercial Laminate

PREMIUM LUSTRE COLLECTION $6.00 – $8.00 C$7.00 – C$10.00

PREMIUM COLLECTION $6.00 – $8.00 C$7.00 – C$10.00

TRADITIONAL COLLECTION $6.00 – $8.00 C$7.00 – C$10.00

Resilient

Prices are approximations only. Actual prices will vary based on competitive bidding, local labor costs and job conditions. Estimated prices include material and labor figuredon a 500-square-foot (46.45-square-meter) open-area installation without any special cuttings or special subfloor preparation.

Linoleum US Dollars Canadian Dollars

MARMORETTE™ 0.080 in. (2.0 mm) $4.00 – $4.50 C$3.75 – C$4.25

MARMORETTE 0.100 in. (2.5 mm) $4.50 – $5.00 C$4.00 – C$4.50

COLORETTE™ 0.100 in. (2.5 mm) $4.50 – $5.00 C$4.00 – C$4.50

LINORETTE 0.100 in. (2.5 mm) $4.50 – $5.00 C$3.75 – C$4.25

GRANETTE™ 0.100 in. (2.5 mm) $4.50 – $5.00 C$4.00 – C$4.50

MARMORETTE 0.125 in. (3.2 mm) $4.50 – $5.00 C$4.75 – C$5.25

COLORETTE 0.125 in. (3.2 mm) $5.00 – $5.50 C$4.75 – C$5.25

UNI WALTON™ 0.100 in. (2.5 mm) $5.00 – $5.50 C$5.00 – C$5.50

UNI WALTON 0.125 in. (3.2 mm) $5.50 – $6.00 C$5.25 – C$6.00

BioBased Tile® (BBT®)

MIGRATIONS™ 0.125 in. (3.2 mm) $2.50 – $3.00 C$2.80 – C$3.30

Vinyl Composition Tile (VCT)

ARTEFFECTS® $2.25 – $2.75 C$3.00 – C$3.50

EXCELON® Companion Square® $2.25 – $2.75 C$3.00 – C$3.50

EXCELON Stonetex® $2.25 – $2.75 C$3.00 – C$3.50

Standard EXCELON Imperial® Texture $1.75 – $2.25 C$1.75 – C$2.25

Standard EXCELON Imperial Texture Classics $1.75 – $2.25 C$1.75 – C$2.25

Standard EXCELON Imperial Texture Rave $1.75 – $2.25 C$1.75 – C$2.25

Standard EXCELON MultiColor™ $1.75 – $2.25 C$1.75 – C$2.25

Feature Tile Black $2.50 – $3.00 C$3.25 – C$3.75

Feature Tile Colors $3.00 – $3.50 C$3.50 – C$4.00

Luxury Vinyl Tile

NATURAL CREATIONS $4.75 – $5.25 C$6.25 – C$6.75

Vinyl Sheet

ABODE™ $3.00 – $3.50 C$3.50 – C$4.00

Connection CORLON® $3.00 – $3.50 C$3.25 – C$3.75

POSSIBILITIES® Petit Point™ $3.50 – $4.00 C$4.00 – C$4.50

MEDINTECH® Tandem® $3.75 – $4.25 C$4.50 – C$5.00

MEDLEY™ $4.00 – $4.50 C$4.25 – C$4.75

TRANSLATIONS™ $4.00 – $4.50 C$4.75 – C$5.25

PERSPECTIVES® $4.75 – $5.25 C$5.50 – C$6.25

MEDINTONE™ $4.75 – $5.25 C$5.25 – C$6.00

MEDINTECH $4.75 – $5.25 C$5.25 – C$6.00

TIMBERLINE® $4.75 – $5.25 C$5.25 – C$6.00

PERSPECTIVES Tile $4.75 – $5.25 C$5.75 – C$6.25

Specialty Flooring

SAFEGUARD™ $5.00 – $5.50 C$5.75 – C$6.25

SAFEGUARD Spa™ $5.00 – $5.50 C$6.00 – C$6.50

SAFETY ZONE™ $3.25 – $3.75 C$4.50 – C$5.00

SDT™ $5.50 – $6.00 C$6.50 – C$7.00

F-4249-1010

Printed in United States of America© 2010 AWI Licensing Company

The Armstrong logo, EXCELON®, and LEED® are registered in the United States and Canada.

ArborArt®, ARTEFFECTS®, Between us, ideas become reality®, COMMISSION®, Companion Square®, Connection CORLON®, EarthCuts®, HartWood®, Imperial®, MEDINTECH®, Mystix®, NATURAL CREATIONS®, PATTERN PLUS®, Permion®, PERSPECTIVES®, POSSIBILITIES®, RAVE®, STONETEX®, Tandem®, and TIMBERLINE® are registered in the United States only.

All trademarks owned by AWI Licensing Company or Armstrong Hardwood Flooring Company.FloorScore™ is a trademark of the Resilient Floor Covering Institute. EcoScorecardSM is a servicemark of Viridity.

LEED® is a registered trademark of the United States Green Building Council.

Colors pictured in this catalog are as accurate as possible but may not be identical to the actual product due to the printing process. For true color representation, order product samples before specifying.This publication was printed on FSC-certified paper.

The knowledge and technical support youneed to bring your vision to life.

Visit armstrong.com/flooring or

Call 1 877 ARMSTRONG (276 7876)Choose option 2 to:

Talk to a TechLine Flooring Expert

Contact your Local Armstrong Flooring Representative

Order Samples and Literature

0, S, D0, S, D0, S, D

0000000

0, S, D0, S, D

00, S0, S0, S0

0, S

011

00000

0, D0, D0, D

0022

122111322032032222

3, R03

0001

0000

00002200111

30103021

0000000001

3, R120310

3, R3, R

13, R

SAFETY ZONE™

Resistance to Staining and Reagents

LIGHT MEDIUM DARK

2010 PRODUCT PORTFOLIOBetween Us, Ideas Become Reality®

Healthcare/Hospital (a)Cafeteria, Dining Area (e)ChapelCorridorsCritical/Intensive CareDialysis ( i) Dry Physical TherapyElevatorsEmergency Room AreasExam/Procedure RoomsGift ShopHydro Physical TherapyHyperbaric RoomLabor Delivery RoomsLaboratoriesLobbiesNurses StationOffice/Administrative/Conf. RoomsOperating Rooms (b)Patient RoomsPharmacyRamps/Ramped Corridors (Dry)Scrub AreasStairways/LandingsStaff LoungeUtility/Storage RoomWaiting RoomsAssisted Living/Military Housing/Light CommercialActivity Rooms/Common AreasBeauty Salon/Barber ShopCorridorsDaycare AreasDining AreasDoctor/Dentist OfficeResidence Bathrooms (i)Residence Kitchens (e)Residence Rooms/BarracksEducation/InstitutionalAuditoriumsCafeteria, Dining Area (e)Classrooms/Lecture HallsComputer RoomsCorridorsDormitory RoomsFood Service Area (e)GymnasiumLaboratoriesLavatoriesLibraryLocker Rooms (No Spikes)Multipurpose Room/CafetoriumsOffice/Administrative/Conf. RoomsRamps/Ramped Corridors (Dry)Showers/Shower RoomsStairways/LandingsTeacher’s LoungeUtility/Storage AreasVestibule/Entryway/Foyers (i)MercantileAutomobile ShowroomsCheckout/Cash WrapFood Service (e)Frozen FoodIndoor Mall Common AreasProduce AreaSales Floor – Department StoresSales Floor – GrocerySales Floor – Mass MerchantSpecialty Shops/AreasOfficeComputer RoomCorridorsElevatorsLavatoriesLobbyLunchrooms (e)Offices/Conference RoomsStairways/LandingsUtility/Storage RoomsHospitalityAround Whirlpool/SpasCorridorsDining Room (e)ElevatorsExercise RoomsGuest Bathrooms (i)Guest RoomsLobbyLoungeStairways/LandingsVending Areas (i)Light Industrial (g)Clean RoomsComputer Repair LabElectronic Testing LabElectronics ManufacturingEnvironmental Conditioning Unit (m)Photo ProcessingProduction LaboratoryResearch LaboratorySmall Parts AssemblySterile PackagingWarehouse (n)TransportationAirport/Railway/Bus TerminalsCivic/Convention CentersMuseums/Cultural Centers

Visit armstrong.com/flooring • Call 1 877 ARMSTRONG

Recommended Applications Recommended Applications – SpecialtyThis chart provides an overview of recommendations by end-use market and for specific spaces. Use these recommendations as a guideline for selecting Armstrong™ flooring for your application.

RRNNNRNNNN

N (3)N (6)

NNNNRNRR

N (3)NRRRN

RNNRRNN

R (e)R

RRR

R (6)RRNNNNR

N (3)RR

N (3)N (3)

RRRN

NNNNNNNNNN

N (6)NNNNRRRR

N (3)NRNNNRNRRN

NN (6)N (6)N (6)

NNNNNNN

NNN

HHHHNHRRRH

N (3)N (6)

RRRHHNHH

N (3)NRHRH

RRHRRRN

R (e)R

HHH

R (6)

HR

R (i)HRNH

N (3)HH

N (3)N (3)

RHRN

RR

R (i) RNNHRHH

N (6)HRNRHHRR

N (3)HHRRNRRHRR

NN (6)N (6)N (6)

NRRRRNN

NNR

HHHHNHHRRH

N (3)N (6)

RRHHHNHH

N (3)NRHRH

HRHRHRN

R (e)H

HHH

R (6)HR

R (i)HRNH

N (3)HH

N (3)N (3)

RH RN

HH

R (i) RRNHRHH

N (6)HHNHHHRR

N (3)HHHHNRHHRR

NN (6)N (6)N (6)

NRRRRNN

RRH

HHHHNHRRRH

N (3)N (6)

RRRHHNHH

N (3)NRHRH

RRHRRRN

R (e)R

HHH

R (6)HR

R (i)HRNH

N (3)HH

N (3)N (3)

RHRN

RR

R (i) RNNHRHH

N (6)HRNRHHRR

N (3)HHRRNRRHRR

NN (6)N (6)N (6)

NRRRRNN

NNR

RRRRNRRRRR

N (3)N (6)

RRRRRNRH

N (3)NRHRR

RRRRRRN

R (e)R

RRR

R (6)RR

R (i)RRNR

N (3)RR

N (3)N (3)

RRRN

NR

R (i) RNNRRRR

N (6)RRNRRRRR

N (3)RRRRNRRRRR

NN (6)N (6)N (6)

NRRRRNN

NNR

RRRRNRRRRR

N (3)N (6)

RRRRHNRH

N (3)NRHRR

HRRRHRN

R (e)H

RRR

R (6)RR

R (i)RRNR

N (3)RH

N (3)N (3)

RRRN

RR

R (i) RNNRRRR

N (6)RRNHHHRR

N (3)RRRHNRRRRR

NN (6)N (6)N (6)

NRRRRNN

NNR

HHHHNHRRRH

N (3)N (6)

RRRHHNHH

N (3)NRHRH

RRHRRRN

R (e)R

HHH

R (6)HR

R (i)HRNH

N (3)HH

N (3)N (3)

RHRN

RR

R (i) RNNHRHH

N (6)HRNRHHRR

N (3)HHRRNRRHRR

NN (6)N (6)N (6)

NRRRRNN

NNR

HHHHNHHRRH

N (3)N (6)

RNHHHNHH

N (3)NRHRH

HRHRHRN

R (e)H

HHH

R (6)HR

R (i)HRNH

N (3)HH

N (3)N (3)

RHRN

HH

R (i) RRNHRHH

N (6)HHNHHHRR

N (3)HHHHNRHHRR

NN (6)N (6)N (6)

NRRRRNN

RRH

RRRRNRRRRR

N (3)N (6)

RRRRHNRH

N (3)NRRRR

RRRRRRN

R (e)R

RRR

R (6)RR

R (i)RRNR

N (3)RR

N (3)N (3)

RRRN

RR

R (i) RNNRRRR

N (6)RRNRRRRR

N (3)RRRNNRRRRR

NN (6)N (6)N (6)

NRRRRNN

NNR

RRRRNRRRRR

N (3)N (6)

RRRRHNRH

N (3)NRRRR

HRRRHRN

R (e)R

RRR

R (6)RR

R (i)RRNR

N (3)RR

N (3)N (3)

RRRN

RR

R (i) RNNRRRR

N (6)RRNRRRRR

N (3)RRRNNRRRRR

NN (6)N (6)N (6)

NRRRRNN

NNR

2.0 2.5 3.2 2.5 2.5 3.2 2.5 3.2 2.5 3.2

MARMORETTE™ LINORETTE™

RRHR

N (2)HRRRR

N (3)N (6)

NR (l)

RHR

N (1)RH

N (3)N (1)

RRHR

HHHHRRR

R (e)R

HRH

R (6)HH

R (i)H

R (I)RR

N (3)HR

N (3)N (3)

RHHN

RH

H (i) HNRHHHR

N (6)HRRRHRRH

N (3)HRRRRRRRRR

NN (6)N (6)N (6)

NR

R (l)R (l)

RRN

NNH

RRHR

N (2)HRRRR

N (3)N (6)

NR (l)

RHR

N (1)RH

N (3)N (1)

RRRR

HHHHRRR

R (e)R

HRH

R (6)HH

R (i)H

R (I)RR

N (3)HR

N (3)N (3)

RHHN

RH

H (i) HNRHHHR

N (6)HRRRHRRR

N (3)HRRRRRRRRR

NN (6)N (6)N (6)

NR

R (l)R (l)

RRN

NNH

RRHR

N (2)HNRRR

N (3)N (6)

NR (l)

RRR

N (1)RH

N (3)N (1)

RRRR

RRHRRRR

R (e)R

RRR

R (6)HR

R (i)R

R (I)RR

N (3)RR

N (3)N (3)

RRRN

RR

H (i) HNRRRRR

N (6)HNRRRRRR

N (3)HRNRRRRRRR

NN (6)N (6)N (6)

NR

R (l)R (l)

RRN

NNR

RRH

RN (2)

HRRRR

N (3)N (6)

NR (l)

RHR

N (1)RH

N (3)N (1)

RRHR

HHHHRRR

R (e)R

HRH

R (6)HH

R (i)H

R (I)RR

N (3)HR

N (3)N (3)

RHHN

RH

H (i) HNRHHHR

N (6)HRRRHRRH

N (3)HRRRRRRRRR

NN (6)N (6)N (6)

NR

R (l)R (l)

RRN

NNH

RRHR

N (2)RRRRR

N (3)N (6)

NR (l)

RHR

N (1)RH

N (3)N (1)

NRRR

HHHHRRR

R (e)R

HRR

R (6)RH

R (i)H

R (I)RR

N (3)HR

N (3)N (3)

NRRN

RR

R (i) RNRRRRR

N (6)HRRRHRNR

N (3)HRRRRRRRNR

NN (6)N (6)N (6)

NR

R (l)R (l)

RRN

NNH

RHR

N (1)NHHNNH

N (3)N (6)

RNH

RHNRR

N (3)NRHRH

HHRHHHN

R (e)R

RRR

R (6)RR

R (i)RNNH

N (3)RH

N (3)N (3)

RHRN

RR

H (i) RNRHRRH

N (6)RHNHRHRR

N (3)RHHRNRHHRR

NN (6)N (6)N (6)

NNNNNNN

NNR

RRRHHHRHHR

N (3)N (6)

RHRRR

R (k)RH

N (3)R (i)

RRRR

HRRRRRH

R (e)R

HRR

R (6)NR

R (i)RHHR

N (3)HR

N (3)N (3)

RRRN

RR

R (i) RNRRRRR

N (6)RRHRRRRR

N (3)RRRRHRRRRR

HN (6)N (6)N (6)

NHHHRRN

NNR

HHHHHHHHHH

N (3)N (6)

HHHHR

R (k)HH

N (3)R (h, i)

RRRH

HHHHHHH

H (e)H

HHH

R (6)HH

R (i)RHHR

N (3)HH

N (3)N (3)

RHRN

HH

H (i) RNRRRRH

N (6)HHHHHHRR

N (3)HRHRHHHHRR

HN (6)N (6)N (6)

NHHHHHN

NNR

HHHHHHRHHH

N (3)N (6)

RHHRR

R (k)HH

N (3)R (i, k)

RRRR

HHHHRHH

H (e)H

HHH

R (6)HH

R (i)RRHR

N (3)HR

N (3)N (3)

RHRN

HR

R (i) RNRRRRH

N (6)HHHRHRRR

N (3)HRRRHHRHRR

RN (6)N (6)N (6)

NHRRRRN

NNR

RRHHHHHHHR

N (3)N (6)

RHRHRHHH

N (3)H (i)

RRRR

HRHRHRH

R (e)R

HRR

R (6)HR

R (i)RHHR

N (3)HR

N (3)N (3)

RRRN

HR

R (i) RNRRRRR

N (6)HHHRRRRR

N (3)HRHHHRRRRR

HN (6)N (6)N (6)

HHHHHHN

NNH

RRHHHHHHHR

N (3)N (6)

RHRHRHHH

N (3)H (i)

RRRR

HRHRHRH

R (e)R

HRR

R (6)HR

R (i)RHHR

N (3)HR

N (3)N (3)

RRRN

HR

R (i) RNRRRRR

N (6)HHHRRRRR

N (3)HRHHHRRRRR

HN (6)N (6)N (6)

HHHHHHN

NNH

HHHHHHHHHH

N (3)N (6)

HHHHH

R (h)HH

N (3)R (i, k)

RHRH

HHHHHHH

H (e)H

HHH

R (6)HH

R (i)HHHH

N (3)HH

N (3)N (3)

RHRN

RH

H (i) RNRRRRH

N (6)HHHHHHRR

N (3)HRHRHHHHRR

HN (6)N (6)N (6)

RHHHHHN

NNH

HHHHHHHHHH

N (3)N (6)

HHHHH

R (h)HH

N (3)R (i, k)

RH

RH

HHHHHHH

H (e)H

HHH

R (6)HH

R (i)HHHH

N (3)HH

N (3)N (3)

RHRN

RH

H (i) RNRRRRH

N (6)HHHHHHRR

N (3)HRHRHHHHRR

HN (6)N (6)N (6)

RHHHHHN

NNH

HHHHHHHHHH

N (3)N (6)

HHHHH

R (h)HH

N (3)R (i, k)

RHRH

HHHHHHH

H (e)H

HHH

R (6)HH

R (i)HHHH

N (3)HH

N (3)N (3)

RHRN

RH

H (i) RNRRRRH

N (6)HHHHHHRR

N (3)HRHRHHHHRR

HN (6)N (6)N (6)

RHHHHHN

NNH

NNNNNNNNNN

N (3)N (6)

NNNNN

N (1)NN

N (3)NNNNN

HHRHHHH

H (e)H

NNNNNRNNNNN

N (3)NN

N (3)N (3)

NNNN

NNNNNNNNNN

N (6)N

NNNHNNN

N (3)NNNNHHNNNN

NN (6)N (6)N (6)

NNNNNNN

NNN

N (4)NR

N (4)NRRNNRNNN

R (l)RN

N (4)N

N (4)NRNHNRR

N (4)NN

N (4)N (4)

NNNN

N (4)N (4)N (4)N (4)

RN

R (i)N

R (l)RRN

N (4)N (4)

RNHNRR

RR

R (i)RNNRRRR

N (6)RRRR

N (4)N (4)

HR

N (3)R

N (4)RRNNRRHR

NN (6)N (6)N (6)

NR

R (l)R (l)

RRN

RRR

MIGRATIONS™EXCELON®

Companion Square®

Stonetex®ARTEFFECTS®

Standard EXCELON®

MultiColor™

Imperial® Texture / Rave™

EXCELON®

Feature™ Tile& Strips (d)

NATURALCREATIONS®

SAFETYZONE™

MEDINTECH®

TANDEM®POSSIBILITIES®

Petit Point™ConnectionCORLON®MEDINTONE™ MEDINTECH®

RRHHHHHHHR

N (3)N (6)

RHRHRHHH

N (3)H (i)

RRRR

HRHRHRH

R (e)R

HRR

R (6)HR

R (i)RHHR

N (3)HR

N (3)N (3)

RRRN

HR

R (i) RNRRRRR

N (6)HHHRRRRR

N (3)HRHHHRRRRR

HN (6)N (6)N (6)

HHHHHHN

NNH

MEDLEY™ PERSPECTIVES® TIMBERLINE® TRANSLATIONS™ ABODE™ Rubber Tile /Treads

COLORETTE™ GRANETTE™ UNI WALTON™ (d)

LINOLEUM SPECIALTY – SLIP-RETARDANTBBT VCTLVTSHEET–LIGHTCOMMERCIAL

HHH

N (1)NRHNRH

N (3)N (6)

RRRHHNRR

N (3)NRHHH

RRHHHRR

R (e)H

RRH

R (6)HH

N (i)RHNR

R (3)HH

N (3)N (3)

RHHR

NR

R (i)NRNHRRH

R (6)RHNRHHRH

N (3)RHHRNHRHRR

NN (6)N (6)N (6)

NHHHHRR

NRH

COMMERCIALLAMINATE

SHEETHETEROGENEOUS

SHEETHOMOGENEOUS

SHEETINLAID

ACCESSORIES

SAFEGUARD™ SAFEGUARDSpa™ (j)

SPECIALTYESD

*Do not use Maple PREMIER PERFORMANCE in the following spaces:

• Healthcare/Hospital – Patient rooms • Educational/ Institutional – Cafeterias, food service and dining room • Mercantile – Food service and street level entries • Office – Lunchrooms • Hospitality – Street level entries, dining, hospitality and lounges

**Recommendation is based upon the use of walk-off mats in entryways and over key pivot points.

***Protective mats should be used under rolling chairs.

NNRRRNRRNN

R (i)R (l)NNNH

N (1)R

RN

NRRRR

H (i)R (l)R (i)R (i)H

N (2)RH

RNNRNR

H (i)HHRHNRHRH

RRRR

R (i)R

NRRRNH

RR (l)R (l)

R

NNNNRRRRNN

R (i)R (l)NNNHRR

RN

NNNRR

H (i)R (l)R (i)R (i)H

N (3)RR

RRNNNR

H (i)NRNRNRRR

R (i)

NNRR

R (i)R

NNRRNH

RR (l)R (l)

R

H = Highly Recommended R = Recommended N = Not Recommended

The best flooring choice(s) for the space. Flooring choice(s) that are suitable for the space. Flooring that should not be used for the space.

• The ratings of H, R or N are based on an evaluation of the performance, cost and aesthetic requirements of the space.

NRNNNNNNNNHNNNNNRN

NR

NNNNNNNNHNHNN

NNNNNNNNNNNNNNNN

NNNNNN

NNNNRN

NNNN

NOTES:

• Numerical footnotes apply to the spacerequirements.

• Alpha footnotes apply to the product’s suitabilityfor the space. The numerical and alphafootnotes are consistent across allRecommended Applications Charts [e.g., (a) isthe same footnote for linoleum as it is for vinyl,etc.]. Depending upon the category, productand space requirements, some footnotes maynot appear.

In addition to spaces listed on these charts:• Armstrong floors may be used on stair steps,

risers and landings. A manufacturedslip-retardant nosing should always be appliedon steps.

• Most Armstrong commercial sheet floors can beflash coved (integral cove). Most building codesconsider flash coving in the same category asbaseboard trim with respect to fire rating.Consult applicable codes for the particularproject to determine the interpretation ofallowable height for flash cove.

• Armstrong floors are not recommended forexterior use, for interior spaces where pointedspike golf or track shoes will be used, or inareas where the floor will be subjected tounusually concentrated static or dynamic loads.

• Armstrong floors should not be used as wallcovering or wall surfacing.

(a) In most cases veterinary applications are similar

(b) Only operating rooms not requiringconductive flooring

(c) Approximate installed cost, full fieldinstallation

(d) Only recommended for accents andborders

(e) Armstrong floors are not recommended for commercial kitchens and commercial food processing areas, including behindfast-food counters

(g) Most Armstrong floors are notrecommended for heavy industrial areas

(h) Heat Weld recommended

(i) No standing water walk-off mats required

(j) SAFEGUARD Spa™ is only recommendedfor certain areas where people will bewalking with wet bare feet or soft-soledfootware. SAFEGUARD Spa is notrecommended for areas over 150 squarefeet, nor around swimming pools

(k) Heat weld only

(l) Not recommended in laboratories thatrequire special decontamination procedureson surfaces, including floors.

(m) Only MEDINTECH® is recommended in lowtemperature environmental conditioningunits NOT below 34º F (1.0º C)

(o) ABODE™ is recommended only for lightcommercial spaces including daycare,beauty salons and hotel/motel bathrooms

(1) Aseptic Area – Hygienic conditions are ofcritical importance

(2) Water resistance – Wet area installation isneeded (flash coving, sealed seams)

(3) Slip Retardance – A more secure walkingsurface is required

(4) Surface Uneveness – The flooring surfaceshould not interfere with chair or cartmovements

(5) Static control flooring is normally required inthis area

(6) Not recommended in areas that requireelectrostatic discharge control

Recommended Applications – Commercial Hardwood

PREMIERPERFORMANCE™

VALENZA™

COLLECTIONHERITAGECLASSICS™

CENTURYFARM™

METROCLASSICS™ BECKFORD™

HARDWOOD – ENGINEERED SOLID

*Do not use Maple PREMIER PERFORMANCE in the following spaces:

• Health Care/Hospital – Patient rooms

• Educational/ Institutional – Cafeterias, food service and dining room

• Mercantile – Food service and street level entries

• Office – Lunchrooms

• Hospitality – Street level entries, dining, hospitality and lounges

**Recommendation is based upon the use of walk-off mats in entryways and over key pivot points.

***Protective mats should be used under rolling chairs.

HARTWOOD®

PARQUET

Educational/InstitutionalCafeterias / Dining AreasClassroomsComputer LabsCorridorsDormitory Rooms***Food ServiceLibrariesMultipurpose RoomsUtility/Storage AreasMercantileCheckout/Cash Wrap**Entryways**Food ServiceIndoor Mall Common AreasSales Floor – Department StoresSales Floor – Mass Merchant/DrugSpecialty Shops/AreasOfficeComputer RoomsConference RoomsCorridorsElevatorsEntryways**LobbiesLunchroomsOfficesUtility/Storage RoomsVestibulesHospitalityCorridorsDining AreasElevatorsEntryways**HospitalityLobbiesLoungesVending AreasVestibules**

Healthcare/HospitalAround Swimming PoolsAround Whirlpools/SpasCafeteria, Dining Area (e)Commercial Parking Garages WalkwaysCorridorsDialysis ( i) Dry Physical TherapyElevatorsEmergency Room AreasExam/Procedure RoomsHydro Physical TherapyLaboratoriesLavatoriesOperating RoomsPatient RoomsRamps/Ramped Corridors (Dry)Scrub AreasUtility/Storage RoomAssisted Living/Military Housing/Light CommercialCorridorsResidence Bathrooms (i)EducationAround Swimming PoolsCafeteria, Dining Area (e)Commercial Parking Garages WalkwaysCorridorsElevatorsFood Service Area (e)LaboratoriesLavatoriesLocker Rooms (No Spikes)Ramps/Ramped Corridors (Dry)Showers/Shower RoomsUtility/Storage RoomsVestibule/Entryway/Foyers (i)MercantileBehind BarsBehind Deli CounterBehind Fast Food CounterCheckout/Cash WrapCommercial KitchensFloral Areas/Garden Centers (i)Food Service Area (e)Frozen FoodIn Front of Deli CountersIn Front of Fast Food CounterLaundromatsMeat/Fish Counter (behind)Meat/Fish Counter (front)Pet ShopsPhoto ProcessingProduce AreaOfficeCafeteria, Dining Area (e)Commercial Parking Garages/WalkwaysCorridorsElevatorsLavatoriesUtility/Storage RoomsHospitalityAround Swimming PoolsCommercial Parking Garages/WalkwaysCorridorsElevatorsGuest Bathrooms (i)Vending Areas (i)Light Industrial (g)Photo ProcessingProduction Laboratory (l)Research Laboratory (l)Small Parts Assembly

SDT™

HRRRHRRR

HHRRRRRR

RRR

HHRRRR

RHHRRHHRRRRRRR

Healthcare/HospitalComputer RoomComputer TrainingData WarehousingExam/Procedure RoomsHyperbaric RoomLaboratories (l)Offices/Conference RoomsTelecommunications CenterEducationComputer Repair LabComputer RoomComputer TrainingData WarehousingLaboratories (l)Multipurpose RoomOffices/Conference RoomsTelecommunications CenterMercantileComputer Specialty Shops/AreasGame RoomsPhoto ProcessingOfficeComputer Repair LabComputer RoomComputer TrainingData WarehousingOffices/Administrative/Conference RoomsTelecommunications CenterLight Industrial (g)Clean RoomsComputer Repair LabComputer RoomComputer TrainingData WarehousingElectronic Testing LabElectronics ManufacturingOffices/Conference RoomsPhoto ProcessingProduction Laboratory (l)Research Laboratory (l)Small Parts AssemblySterile PackagingTelecommunications Center

Linoleum ............................................ 12 – 23

MARMORETTE™ ...................................................... 14 – 16

LINORETTE™ .................................................................... 17

COLORETTE™ ................................................................. 18

GRANETTE™ .................................................................... 19

UNI WALTON™ ................................................................ 20

Specification Charts .............................................. 22 – 23

BBT® .................................................. 82 – 87

MIGRATIONS® ........................................................ 84 – 85

Specification Charts .............................................. 86 – 87

VCT .................................................. 88 – 103

EXCELON® Stonetex® ........................................... 90 – 92

ARTEFFECTS® ................................................................ 93

EXCELON Companion Square® ................................... 94

Standard EXCELON Imperial® Texture Rave® ............. 95

Standard EXCELON Imperial Texture .................. 96 – 97

Standard EXCELON Imperial Texture Classics ............98

Standard EXCELON MultiColor™ .................................. 99

EXCELON Feature™ Tile & Strips ................................ 100

EXCELON Tile Insets ..................................................... 101

Specification Charts ........................................... 102 – 103

Specialty .......................................... 104 – 111

SAFEGUARD™ ............................................................... 106

SAFEGUARD Spa™ ....................................................... 107

SAFETY ZONE™ ............................................................ 108

SDT™ .............................................................................. 109

Specification Charts ............................................. 110 – 111

Accessories .................................... 112 – 123

Stair Treads / Risers / Rubber Tiles ............................. 114

Transition Strips ............................................................. 115

Wall Base .............................................................. 116 – 117

Weld Rods ............................................................ 118 – 119

Hardwood Trim & Molding .......................................... 120

Laminate Trim & Molding ............................................. 121

Adhesives ............................................................ 122 – 123

Resources ..................................... 124 – 128

Commercial Floors Warranty ...................................... 125

Commercial Hardwood Warranty .............................. 126

Product Index ..................................................... 127 – 128

Comprehensive Product Charts – Inside Back Cover

Everything ............... armstrong.com/flooring

Sheet ................................................ 24 – 43MEDINTONE™ ........................................................ 26 – 28

MEDINTECH®/MEDINTECH Tandem® ......................... 29

MEDLEY™ ................................................................ 30 – 31

Connection CORLON® .................................................. 32

POSSIBILITIES® Petit Point™ .................................. 34 – 35

TRANSLATIONS™ ........................................................... 36

PERSPECTIVES® ............................................................ 37

TIMBERLINE® ................................................................. 38

ABODE™ .................................................................. 40 – 41

Specification Charts .............................................. 42 – 43

LVT .................................................... 44 – 57NATURAL CREATIONS® EarthCuts® ............................ 46

NATURAL CREATIONS ArborArt® ........................ 48 – 50

NATURAL CREATIONS Mystix® ............................ 52 – 55

Specification Charts .............................................. 56 – 57

Commercial Hardwood ..................... 58 – 73PREMIER PERFORMANCE™ ................................. 60 – 63

HARTWOOD® PARQUET ............................................... 64

VALENZA™ COLLECTION .............................................. 65

HERITAGE CLASSICS™ .................................................. 66

CENTURY FARM™ .......................................................... 67

METRO CLASSICS™ .............................................. 68 – 69

BECKFORD™ ................................................................... 71

Specification Charts .............................................. 72 – 73

Commercial Laminate ....................... 74 – 81PREMIUM LUSTRE COLLECTION ................................ 76

PREMIUM COLLECTION ............................................... 77

TRADITIONAL COLLECTION ......................................... 78

Specification Charts ............................................... 80 – 81

TABLE OF CONTENTS

Visit armstrong.com/flooring • Call 1 877 ARMSTRONG

1Visit armstrong.com/flooring • Call 1 877 ARMSTRONG

PRODUCT PORTFOLIO

More than 900 Colors

The industry’s most comprehensive lineup of commercial flooring

With 45 product lines across nine categories and the trust that comes with the Armstrong

brand, you can specify with confidence.

2 Visit armstrong.com/flooring • Call 1 877 ARMSTRONG

The System• A breadth of choices which include neutrals, colors, naturals and colored neutrals

• A process for optimizing color selection across all products

The Benefits• It simplifies and expedites the specification process, saving time and money

• It offers greater design flexibility from product that’s systematically organized

The BeginningMARMORETTE™ • GRANETTE™ • Stonetex® • MEDINTONE™

In 2009 Armstrong’s CONTINUUM color system debuted in Linoleum’s MARMORETTE™ and

GRANETTE™ lines. The concept continues to expand across Armstrong’s commercial portfolio

with its introduction to VCT’s Stonetex® line and Homogeneous Sheet’s MEDINTONE™ line.

Our love of color has driven us to develop a simple, organized tonal step color system. This expanded and

flexible range of color optimizes color selections across our entire portfolio of commercial flooring products.

Armstrong® commercial flooring is proud to present CONTINUUM™.

What’s New

New ProductsThe yellow band helps to

identify pages that include

new products. Additionally,

every new individual swatch

color in the catalog is also

labeled as “new.”

Sustainability ........4 – 5An overview of our green

history and current efforts.

Snapshots ............6 – 9A showcase of the full range

of products in our portfolio.

Specification ChartsThe last two pages of each

product section include

specification charts and

other valuable information.

HERE TO HELP

new productnew

Visit armstrong.com/flooring • Call 1 877 ARMSTRONG 3

100 Years of Linoleum andMore Than 75 New Colors

We’re introducing more than 75 new colors

as we celebrate the 100th anniversary of

our linoleum products.

Stonetex® – The BIG Difference

New 18 in. x 18 in. tile size re-energizes VCT

with more colors, more impressive visuals,

and more design options.

Commercial Laminate

We’re launching an entirely new category of

commercial laminate with 20 visuals in three

unique product lines.

Swatch Books

A new visual tool with colors organized in

CONTINUUM™ tonal steps to help designers

specify more easily. Available through your

Armstrong representative.

18 ˝

12˝

Product Index / ChartA comprehensive product

index can be found at the

end of the catalog. The back

cover also includes a folding

chart that provides an overall

product comparison.

OUR OPERATIONS

We target and measure our performance on vital

sustainability initiatives, with a focus on reducing our

resource utilization:

• Energy. Our Energy Management System enables us

to measure and reduce our energy use

• Water. We are conscious of the increasing demands

our growing global population imposes on fresh

water. We are measuring and reducing our usage of

this precious resource.

• Forests. We recognize that wood is only a truly

renewable natural resource if forests from which it is

harvested are managed responsibly, and replenished.

We abide by our commitment to replant at least as

much as we utilize every year.

OUR PRODUCTS

Armstrong procures in excess of 90% of the wood for

our flooring from North American timber operations,

grown and harvested in strict compliance with

responsible forestry management practices. We hold

our importation supply chain to equally high standards,

and actively verify compliance.

• Sourcing. Our wood products are sourced in

compliance with the Lacey Act.

• Our wood flooring is subject to, and compliant

with, CARB II standards.

• Since its inception in 1999, Armstrong’s Ceiling

Recycling Program has diverted more than 70 million

square feet – 35,000 tons – of old acoustical ceiling

tiles from landfills.

OUR CUSTOMERS EXPECTATIONS

Armstrong customers expect our leadership to extend

to aspects of building products that enable them to

meet their sustainability objectives. As such, Armstrong

demonstrates that leadership via:

• BioBased Tile® – For details on this innovative,

eco-friendly product line, see the BBT® tab

• Linoleum – For details on this innovative, eco-friendly

product line, see the Linoleum tab

ECOSCORECARDSM

Use our ecoScorecard to search, evaluate and

document a product’s environmental attributes

according to key industry rating systems, including

all balloted versions of LEED®.

To start go to armstrong.com/ecoscorecard.

4 Visit armstrong.com/flooring • Call 1 877 ARMSTRONG

LEADERSHIP IN SUSTAINABILITY

Target Performance

Energy

Reduce total

greenhouse gas

emissions by

10% by 2015

On Track

Water

Reduce fresh water

usage by

10% by 2015

On Track

Forests

Replant and

replenish forest

to fully offset

annual harvest

2008

Achieved

2009

On Track

Armstrong is committed to sourcing, manufacturing and conducting business

as an ecologically responsible company.

BUILDING GREEN BEGINS AT HOME

We’re committed to leading by example, as evidenced by the U.S. Green Building Council’s Platinum

LEED Certification of our headquarters building in 2007. It was only the sixth building to earn the

highest possible certification and the first outside of California.

5Visit armstrong.com/flooring • Call 1 877 ARMSTRONG

Category Armstrong Products LEED Credits

Linoleum MARMORETTE™, LINORETTE™, COLORETTE™, UNI WALTON™, GRANETTE™ EQ4.3, MR4.0, MR6.0

SheetMEDINTONE™, MEDINTECH®, MEDLEY™, MEDINTECH® Tandem®, POSSIBILITIES® Petit Point™, Connection CORLON®, TRANSLATIONS™, PERSPECTIVES™, TIMBERLINE®, ABODE™, SAFEGUARD™, SAFEGUARD Spa™

EQ4.3

LVT NATURAL CREATIONS®, ArborArt® , EarthCuts® ,Mystix® EQ4.3

Commercial HardwoodPREMIER PERFORMANCE™, HERITAGE CLASSICS™ COLLECTION, METRO CLASSICS™,BECKFORD™, HARTWOOD® PARQUET

MR5.0*

Commercial Laminate PREMIUM LUSTRE COLLECTION, PREMIUM COLLECTION MR4.0, MR6.0

Commercial Laminate TRADITIONAL COLLECTION MR6.0

BioBased Tile® MIGRATIONS® EQ4.3, MR4.0, MR5.0*, MR6.0

VCTARTEFFECTS®, Standard EXCELON®, Imperial® Texture Rave®, Imperial Texture , Imperial TextureClassics, MultiColor™, EXCELON®, Stonetex®, Companion Square®, Feature™ Tile & StripsSAFETY ZONE™, SDT™

EQ4.3, MR4.0, MR5.0*

Adhesives All Armstrong Adhesives EQ4.1

*Depends on project location.LEED® is a registered trademark of the United States Green Building Council.

ARMSTRONG® PRODUCTS THAT CONTRIBUTE TO OR COMPLY WITH LEED® CREDITS

6 Visit armstrong.com/flooring • Call 1 877 ARMSTRONG

INSPIRATION

Education – K-12

VCT – Imperial® Texture page 96

Linoleum – MARMORETTE™

page 14LVT – NATURAL CREATIONS®

page 46

VCT – Imperial Texture page 96

Linoleum – MARMORETTE page 14

VCT – Imperial Texture RAVE®

page 95

VCT – Imperial Texture page 96

VCT – Imperial Texture page 96

Linoleum – MARMORETTE page 14

7Visit armstrong.com/flooring • Call 1 877 ARMSTRONG

Education – Higher

Hardwood – PREMIER PERFORMANCE™

page 60

VCT – Standard EXCELON® MultiColor™

page 99

Linoleum – MARMORETTE™

page 14

VCT – Stonetex®

page 90

VCT – Stonetex page 90

Sheet – TIMBERLINE®

page 38

8 Visit armstrong.com/flooring • Call 1 877 ARMSTRONG

Healthcare

Laminate – TRADITIONAL COLLECTIONpage 78

BBT® – MIGRATIONS®

page 84

LVT – NATURAL CREATIONS®

page 52

Linoleum – MARMORETTE™

page 14

Sheet - TIMBERLINE®

page 38

Sheet – MEDINTONE™

page 26VCT – Imperial® Texture page 96

INSPIRATION

9Visit armstrong.com/flooring • Call 1 877 ARMSTRONG

Healthcare

Sheet – TIMBERLINE®, POSSIBILITIES®

pages 34, 38Sheet – MEDINTECHpage 29

Linoleum – MARMORETTE™

page 14

Sheet – MEDINTECH®

page 29

Sheet – PERSPECTIVES®

page 37

Linoleum – MARMORETTE™

page 14

Retail

Sheet – TRANSLATIONS™

page 36Specialty – SAFETY ZONE™

page 108Linoleum – MARMORETTE™

page 14

VCT – Imperial® Texture RAVE®

page 95

LVT – NATURAL CREATIONS®

page 46

Laminate – PREMIUM LUSTRE COLLECTION page 76

Hardwood – VALENZA™ COLLECTIONpage 65

Hardwood – PREMIER PEFORMANCE™

page 60Sheet – PERSPECTIVES®

page 37

INSPIRATION

10 Visit armstrong.com/flooring • Call 1 877 ARMSTRONG

11Visit armstrong.com/flooring • Call 1 877 ARMSTRONG

Retail

Sheet – PERSPECTIVES®

page 37

Specialty – SAFETY ZONE™

page 108

Sheet – TRANSLATIONS™, TIMBERLINE®

pages 36, 38

Sheet – PERSPECTIVES page 37

LVT – NATURAL CREATIONSpage 48

LVT – NATURAL CREATIONS®

page 52

MARMORETTE™

LP022 caspian blue, LP050 silver gray, LP068 blue spa, LP072 goldenrod, LP525 hey sailor

LinoleumUnsurpassed Color

• MARMORETTE™ and GRANETTE™, featuring

CONTINUUM™, a simple, organized tonal step system

that unites hue, value and chroma. This expanded and

flexible range of color options offers fast and easy

color selection.

Superior Performance

Exclusive NATURCote™ UV-cured coating

• Non-strippable

• Dirt resistant

• Resists discoloration from high pH cleaners

• Improves scuff resistance

• Reduces damage from scratching

• Reduces water, chemicals and labor needed for

routine maintenance

Natural Sustainability

• Made from rapidly renewable raw materials comprised

of cork, linseed oil and jute backing

• Recycled content

• Low VOC emissions – California Section 01350 compliant,

third-party FloorScore™ certification and LEED® eligibility

13

with NATURCote™

LIN

OL

EU

M

MARMORETTE™

• Classic, sophisticated marbling featuring CONTINUUM™, an exclusive color system organized in tonal steps to unitehue, value and chroma

• Lower-cost install method and seamless design appearance with patented S-761 non-heat weld seaming system

• Low VOC emissions – California Section 01350 compliant, third-party FloorScore certification and LEED eligibility

with NATURCote™

LEED®

MR4.0 �

MR5.0

MR6.0 �

EQ4.3 �

*Special order; variable lead times (contact COS), no minimum quantity. †Special order; variable lead times (contact COS), minimum quantity of 1,000 sq. yd.

LP553smoke

LP053gull gray

LP091mushroom

LP092sand

LP045parchment beige

LP084hide

W1253 W1356 W1255 W1791 W1792 W1245 W1784

Construction

Online: armstrong.com / linoleum

14 Visit armstrong.com/flooring • Call 1 877 ARMSTRONG

LP040cream

W1270

FloorScore™ certified

Linoleum with NATURCote.™

Width & Length Sheet: 6 ft. 7 in. (2.0 m) wide, up to 98.4 ft. (30 m) long.

Thickness 0.080 in. (2.0 mm), 0.100 in. (2.5 mm), 0.125 in. (3.2 mm). Size availability below.

National Avg. Installed Cost US: $4.00 – $4.50 sq. ft. Canada: C$4.00 – C$4.50 sq. ft. Based on 0.080 in. thickness. See page 21.

LP552stone white

W1252

LP050silver gray

LP090pumice gray

LP065light chocolate

W1257 W1250 W1258 W1790 W1287 W1271 W1240

LP070bamboo tan

W1070

LP096obsidian

LP059charcoal gray

LP089lava

LP003cocoa brown

W1796 W1380 W1207 W1789 W1285 W1703 W1289

LP066oak brown

W1262

2.5mm

2.0mm*2.5mm3.2mm†

2.5mm

2.5mm 2.5mm 2.5mm 2.5mm 2.5mm 2.5mm 2.5mm

2.5mm 2.5mm 2.5mm

2.0mm*2.5mm3.2mm†

2.0mm*2.5mm3.2mm†

2.0mm*2.5mm3.2mm†

2.0mm*2.5mm3.2mm†

2.0mm*2.5mm3.2mm†

2.5mm 2.5mm 2.5mm 2.5mm2.0mm*2.5mm

2.0mm*2.5mm3.2mm†

2.5mm

new new

new new new new

new new new

LP507under the boardwalk

LP509summer camp

LP546barefoot

LP506the boardwalk

LP556atmosphere

LP555constellation

LP554smolder

LP557nebula

new colorsnew

featuring

1

15Visit armstrong.com/flooring • Call 1 877 ARMSTRONG

LP076yellow straw

LP098fool’s gold

W1276 W1798 W1275 W1204 W1238 W1201 W1288 W1281

LP049bluebird

W1249

W1282

LP072goldenrod

LP008aztec red

LP048firebird red

W1272 W1274 W1219 W1708 W1510 W1202 W1286

LP018cherry red

W1283 W1273 W1205 W1242 W1718 W1203 W1284

2.5mm3.2mm†

2.0mm*2.5mm3.2mm† 2.5mm

2.5mm

2.5mm 2.5mm 2.5mm 2.5mm 2.5mm

2.0mm*2.5mm3.2mm†

2.0mm*2.5mm3.2mm†

2.0mm*2.5mm3.2mm†

2.0mm*2.5mm3.2mm†

2.0mm*2.5mm3.2mm†

2.0mm*2.5mm3.2mm†2.5mm

2.5mm 2.5mm 2.5mm 2.5mm 2.5mm 2.5mm 2.5mm 2.5mm

new new new new new new

new new new new

new new new new new new new

LP575melon head

LP510not so innocent

LP516miss behavin’

LP512slightly frivolous

LP522purple mountains

LP547summer lovin’ blue

LP523purple people eater

LP513amped up

LP519blast off

LP571summer morning

LP570gold digger

LP573meltdown

LP515pop rocket

LP511brick house

LP514dandy

LP528it’s magic

LP548stars at night

MARMORETTE™ LP096 obsidian, LP040 cream, LP525 hey sailor

LIN

OL

EU

M

16 Visit armstrong.com/flooring • Call 1 877 ARMSTRONG

new

LP007blue wave

LP020sweet grass

W1220 W1206 W1215 W1707 W1720 W1256

LP023serene blue

LP026delft blue

LP068blue spa

LP099tidal blue

LP000parrot green

W1223 W1224 W1768 W1799 W1032 W1711

LP022caspian blue

LP525hey sailor

LP527twilight

W1222 W1208 W1246 W1232 W1237 W1266

2.5mm2.5mm2.5mm2.5mm2.5mm2.5mm

2.0mm*2.5mm3.2mm†

2.0mm*2.5mm3.2mm†

2.0mm*2.5mm3.2mm†

2.0mm*2.5mm3.2mm†

2.0mm*2.5mm3.2mm† 2.5mm

2.5mm2.5mm2.5mm2.5mm2.5mm

2.0mm*2.5mm3.2mm†

newnewnewnew

new

newnewnewnew

LP532new wave

LP544green horn

LP531tree hugger

LP521pale blue eyes

LP524cookie monster

LP526ocean breeze

LP530tree frog

LP543home turf

MARMORETTE™ (cont.)

• Classic, sophisticated marbling featuring CONTINUUM™, an exclusive color system organized in tonal steps to unitehue, value and chroma

• Lower-cost install method and seamless design appearance with patented S-761 non-heat weld seaming system

• Low VOC emissions – California Section 01350 compliant, third-party FloorScore certification and LEED eligibility

with NATURCote™

LEED®

MR4.0 �

MR5.0

MR6.0 �

EQ4.3 �

*Special order; variable lead times (contact COS), no minimum quantity. †Special order; variable lead times (contact COS), minimum quantity of 1,000 sq. yd.

Construction

Online: armstrong.com / linoleum

FloorScore™ certified

Linoleum with NATURCote.™

Width & Length Sheet: 6 ft. 7 in. (2.0 m) wide, up to 98.4 ft. (30 m) long.

Thickness 0.080 in. (2.0 mm), 0.100 in. (2.5 mm), 0.125 in. (3.2 mm). Size availability below.

National Avg. Installed Cost US: $4.00 – $4.50 sq. ft. Canada: C$4.00 – C$4.50 sq. ft. Based on 0.080 in. thickness. See page 21.

new colorsnew

featuring

1

17Visit armstrong.com/flooring • Call 1 877 ARMSTRONG

LP410odessa red

LP460grand canyon

LP470gibraltar gold

W1610 W1660 W1670

LP450madagascar violet

W1652

W1604

LP440hudson valley blue

LP402brisbane blue

W1642

W1602

LP401yuka tan

LP420serengeti green

W1601

W1620

W1605

LP425andes brown

W1625

LP403gobi sand

W1603

LINORETTE™

• A bold blend of highlights and contrasts that coordinates with Armstrong’s portfolio of flooring solutions

• Lower-cost install method and seamless design appearance with our patented S-761 non-heat weld seaming system

• Low VOC emissions – California Section 01350 compliant, third-party FloorScore certification and LEED eligibility

with NATURCote™

LEED®

MR4.0 �

MR5.0

MR6.0 �

EQ4.3 �

Construction

Online: armstrong.com / linoleum

FloorScore™ certified

Linoleum with NATURCote.™

Width & Length Sheet: 6 ft. 7 in. (2.0 m) wide, up to 98.4 ft. (30 m) long.

Thickness 0.100 in. (2.5 mm).

National Avg. Installed Cost US: $4.50 – $5.00 sq. ft. Canada: C$3.75 – C$4.25 sq. ft. See page 21.

LINORETTE LP475 silver city

2.5mm

2.5mm

2.5mm

2.5mm 2.5mm 2.5mm

2.5mm 2.5mm

2.5mm 2.5mm

2.5mm 2.5mm

new

new

LP475silver city

LP476yukon desert

new colorsnew

LIN

OL

EU

M

18 Visit armstrong.com/flooring • Call 1 877 ARMSTRONG

COLORETTE™

• Dynamic colors with subtle accents that coordinate with Armstrong’s portfolio of flooring solutions

• Lower-cost install method and seamless design appearance with our patented S-761 non-heat weld seaming system

• Low VOC emissions – California Section 01350 compliant, third-party FloorScore certification and LEED eligibility

with NATURCote™

LEED®

MR4.0 �

MR5.0

MR6.0 �

EQ4.3 �

Construction

Online: armstrong.com / linoleum

Linoleum with NATURCote.™

Width & Length Sheet: 6 ft. 7 in. (2.0 m) wide, up to 98.4 ft. (30 m) long.

Thickness 0.100 in. (2.5 mm) and 0.125 (3.2 mm). Size availability below.

National Avg. Installed Cost US: $4.50 – $5.00 sq. ft. Canada: C$4.00 – C$4.50 sq. ft. Based on 0.100 in. thickness. See page 21.

FloorScore™ certified

*Special order; variable lead times (contact COS), no minimum quantity. †Special order; variable lead times (contact COS), minimum quantity of 1,000 sq. yd.

LP360cherry

W1360W1320 W1325

LP303watermelon

LP306lime

W1303 W1306

W1359

W1321

W1350

W1302

LP301 lemon

W1301

LP330snorkel

LP308scuba

W1324

W1308

W1371

W1339

W1309

W1316

W1323

W1328

W1310

W1305

2.5mm 2.5mm2.5mm

2.5mm

2.5mm3.2mm*

2.5mm

new new new new new new

new new

new new

new new new new

new

new

LP352here kitty

LP382lighten up

2.5mm2.5mm3.2mm*

LP359hot tin roof

LP312sell out

LP371half baked

LP378cremecicle

LP320starlet

LP321shallow end

2.5mm 2.5mm 2.5mm 2.5mm 2.5mm2.5mm3.2mm*

LP381black cat

LP343concrete decision

LP339twice baked

LP316orange jules

LP328rock star

LP305deep end

2.5mm3.2mm*

2.5mm3.2mm*

2.5mm3.2mm*

2.5mm3.2mm*

2.5mm3.2mm*

2.5mm3.2mm*

new colorsnew

1

19Visit armstrong.com/flooring • Call 1 877 ARMSTRONG

GRANETTE™

• Linear, natural granite appearance featuring CONTINUUM™, an exclusive color system organized in tonal steps to unite hue, value and chroma

• Lower-cost install method and seamless design appearance with our patented S-761 non-heat weld seaming system

• Low VOC emissions – California Section 01350 compliant, third-party FloorScore certification and LEED eligibility

with NATURCote™

LEED®

MR4.0 �

MR5.0

MR6.0 �

EQ4.3 �

Construction

Online: armstrong.com / linoleum

Linoleum with NATURCote.™

Width & Length Sheet: 6 ft. 7 in. (2.0 m) wide, up to 98.4 ft. (30 m) long.

Thickness 0.100 in. (2.5 mm).

National Avg. Installed Cost US: $4.50 – $5.00 sq. ft. Canada: C$4.00 – C$4.50 sq. ft. Based on 0.100 in. thickness. See page 21.

FloorScore™ certified

W1167 W1160 W1158

W1168

W1169

W1161

W1162

W1159

W1163

W1171

W1172

W1173

W1154

W1156

W1157

W1164

W1165

W1166

new new new new new new

new new new new new new

new new new new new new

LP151spider webs

2.5mm LP164falling rock

2.5mm LP167seedling

LP170pollen

LP124looks like rain

LP137prickly pear

2.5mm 2.5mm 2.5mm 2.5mm

LP152itsy bitsy spider

LP165mudslide

LP168branching out

LP171bees knees

LP125light showers

LP138stinging nettle

2.5mm2.5mm2.5mm2.5mm2.5mm2.5mm

LP153black widow

LP166peat

LP169tree bark

LP173wax on

LP127perfect storm

LP139holly go lightly

2.5mm 2.5mm 2.5mm 2.5mm 2.5mm 2.5mm

new colorsnew

featuring

LIN

OL

EU

M

20 Visit armstrong.com/flooring • Call 1 877 ARMSTRONG

with NATURCote™UNI WALTON™

• Solid color linoleum for creating borders, accents, insets and custom effects

• Lower-cost install method and seamless design appearance with our patented S-761 non-heat weld seaming system

• Low VOC emissions – California Section 01350 compliant, third-party FloorScore certification and LEED eligibility

LEED®

MR4.0 �

MR5.0

MR6.0 �

EQ4.3 �

Construction

Online: armstrong.com / linoleum

Linoleum with NATURCote.™

Width & Length Sheet: 6 ft. 7 in. (2.0 m) wide, up to 98.4 ft. (30 m) long.

Thickness 0.100 in. (2.5 mm) and 0.125 (3.2 mm). Size availability below.

National Avg. Installed Cost US: $5.00 – $5.50 sq. ft. Canada: C$5.00 – C$5.50 sq. ft. Based on 0.100 in. thickness. See page 21.

FloorScore™ certified

*Special order; variable lead times (contact COS), no minimum quantity. †Special order; variable lead times (contact COS), minimum quantity of 1,000 sq. yd.

LP259white

LP207mustard

LP208night blue

W1059 W1007 W1008

LP282gray

LP280black

W1003

W1280

LP210orange red

LP260warm brown

W1510

W1060

LP230dark green

LP236moss

W1231

W1001 UNI WALTON LP259 white, LP280 black MARMORETTE™ LP048 firebird red,LP076 yellow straw, LP516 miss behavin’

2.5mm3.2mm* 2.5mm 2.5mm

2.5mm2.5mm3.2mm*

2.5mm3.2mm*

2.5mm3.2mm*

2.5mm3.2mm* 2.5mm

new

new new

new new

new colorsnew

1

MARMORETTE™

LP059 charcoal gray, LP096 obsidian, LP530 tree frog 21

LIN

OL

EU

M

Visit armstrong.com/flooring • Call 1 877 ARMSTRONG

22 Visit armstrong.com/flooring • Call 1 877 ARMSTRONG

TECHNICAL INFORMATION

1. Overall and wear layer thicknesses are nominal and subject tonormal manufacturing variances.

2. PSI: lbs./sq. in. (kg/cm2):a) ASTM F 970 < 0.005 in. residual indentation.b) ASTM F 970, subjective visual, no visually apparent indentation.

3. Subjective ratings (Excellent, Very Good, Good, Fair) are in relation to other Armstrong® commercial resilient floors. Ratings are not directly related to any one test. They arebroadly based on tests and experience of Armstrong R & Dunder varying conditions and circumstances. These ratingsshould NOT be used for comparison to ratings used by other manufacturers to rank their own products.

4. Reference Specifications: Armstrong products are manufactured to meet or exceed specification requirements,except as noted.

5. All products meet the following Fire Test Data:a) ASTM E 648 Flooring Radiant Panel Critical Radiant Flux –

0.45 watts/cm2 or more, Class Ib) ASTM E 662 Smoke Chamber Specific Optical Smoke

Density – 450 or less. Numerical flammability ratings alone may not define product performance under actual fire conditions. These ratings are provided only for use in the selection ofproducts to meet specified limits.

6. UNI WALTON is recommended only for decorative bordersand accents.

Comparative Data

Adhesives

*Heat-welding is required when installing over radiant-heated subfloors in areas exposed to topical moisture and/or temperature fluctuations and when using S-240 Epoxy.

Products (5)

Overall Thickness (nominal) (1)

Static Load Limit PSI (kg/cm2)(2, 2a, 2b)

Durability(3)

Maintainability(3)

Resilience(3)

ReferenceSpecs (4)

MARMORETTE™0.080 in. (2.0 mm)

0.100 in. (2.5 mm)

0.125 in. (3.2 mm)

450 (31.6) (2a)

250 (17.6) (2b)

G

VG

E

E

E

E

G

G

VG

ASTM F 2034, Type I

LINORETTE™ 0.100 in. (2.5 mm)450 (31.6) (2a)

250 (17.6) (2b)VG E G ASTM F 2034, Type I

COLORETTE™0.100 in. (2.5 mm)

0.125 in. (3.2 mm)

450 (31.6) (2a)

125 (8.8) (2b)

VG

E

VG

VG

G

VGASTM F 2034, Type I

GRANETTE™ 0.100 in. (2.5 mm)450 (31.6) (2a, b)

250 (17.6) (2b)VG E G ASTM F 2034, Type I

UNI WALTON™0.100 in. (2.5 mm)

0.125 in. (3.2 mm)

450 (31.6) (2a)

125 (8.8) (2b)

VG

E

G (6)

G (6)

G

VGASTM F 2034, Type I

Product Adhesives Seams

MARMORETTE

LINORETTE

COLORETTE

GRANETTE

UNI WALTON

S-780 full-spread;

S-580 optional

in flash cove areas only

S-240 in heavy static

and dynamic load areas

Recess scribe;

heat-weld* or

S-761 Seam

Adhesive

Adhesive/Seaming System Options

SpaceFull SpreadS-780 withHeat Weld

Full SpreadS-780 withS-761

Full SpreadS-780

Full Spread S-240 with Heat Weld

Aseptic areas Highly recommended Not recommended Not recommended Optional*

Medium to heavy commercial traffic Recommended Recommended Optional Not recommended

Light to medium commercial traffic Recommended Recommended Optional Not recommended

Heavy static and dynamic load areas Optional Optional Not recommended Recommended

Heavy industrial areas Not recommended Not recommended Not recommended Not recommended

*Only when heavy static and dynamic loads are used.

Gauge Availability

Pattern 2.0 mmNo Minimum

2.5 mmStocked

3.2 mmNo Minimum

3.2 mmMin 1,000 Sq Yds

MARMORETTE

All Patterns: LP000, LP003, LP007, LP008, LP018, LP020, LP022, LP023, LP026, LP040, LP045, LP048, LP049, LP050,LP053, LP059, LP065, LP066, LP068, LP070, LP072, LP076, LP084, LP089, LP090, LP091, LP092, LP096, LP098,LP099, LP506, LP507, LP509, LP510, LP511, LP512, LP513, LP514, LP515, LP516, LP519, LP521, LP522, LP523,LP524, LP525, LP526, LP527, LP528, LP530, LP531, LP532, LP543, LP544, LP546, LP547, LP548, LP552, LP553,LP554, LP555, LP556, LP557, LP570, LP571, LP573, LP575

X

LP000, LP008, LP022, LP023, LP026, LP040, LP045, LP048, LP049, LP050, LP053, LP059, LP068, LP070, LP072,LP098, LP099, LP513, LP546, LP553, LP571

X

LP000, LP008, LP022, LP023, LP026, LP040, LP048, LP049, LP050, LP053, LP059, LP068, LP070, LP072, LP076,LP098, LP099, LP513, LP546, LP553, LP571

X

LINORETTE

All Patterns: LP401, LP402, LP403, LP410, LP420, LP425, LP440, LP450, LP460, LP470, LP475, LP476 X

COLORETTE

All Patterns: LP301, LP303, LP305, LP306, LP308, LP312, LP316, LP320, LP321, LP328, LP330, LP339, LP343, LP352,LP359, LP360, LP371, LP378, LP381, LP382

X

LP305, LP308, LP316, LP328, LP339, LP343, LP352, LP359, LP381 X

GRANETTE

All Patterns: LP124, LP125, LP127, LP137, LP138, LP139, LP151, LP152, LP153, LP164, LP165, LP166, LP167, LP168,LP169, LP170, LP171, LP173

X

UNI WALTON

All Patterns: LP207, LP208, LP210, LP230, LP236, LP259, LP260, LP280, LP282 X

LP210, LP230, LP259, LP260, LP280 X

1

23Visit armstrong.com/flooring • Call 1 877 ARMSTRONG

Before making your color selection, expose linoleum

samples to sunlight for at least four hours to

remove the yellow cast that occurs naturally as

part of the linoleum production process.

Maintenance*

*See Armstrong publication F-8663 for further information.

ProductCleaners andPolishes

Polish

Low-Maintenance Options

No PolishSpray Buff

No PolishDry Buff

MARMORETTE

LINORETTE

COLORETTE

UNI WALTON

GRANETTE

S-401, S-403,

S-480, S-485,

and S-495

� � Not recommended

Light Reflectivity Values in Percent

Measured under incandescent illumination (ASTM 1347). Types and patterns tested here are those most suited to commercial interiors where reflectivity is a major factor. Ratings for other patterns available upon specific request.

National Average Installed Costs per Square Foot

Prices are approximations only. Actual prices will vary based on competitive bidding, local labor costs and job conditions. Estimated prices include material and labor figured on a 500-square-foot(46.45-square-meter) open-area installation without any special cuttings or special subfloor preparation.

0-9 10-14 15-19 20-24 25-29 30-34 35-39 40-44 45-49 50-54 55-59

LP018 LP022 LP003 LP068 LP000 LP065 LP007 LP020 LP040 LP098 LP259

LP059 LP048 LP008 LP099 LP023 LP124 LP070 LP091 LP045 LP382

LP096 LP049 LP026 LP125 LP053 LP151 LP072 LP092 LP076

LP208 LP089 LP050 LP138 LP090 LP164 LP084 LP312 LP170

LP230 LP153 LP066 LP152 LP168 LP171 LP137 LP378 LP301

LP260 LP166 LP127 LP172 LP330 LP316 LP167 LP403 LP352

LP280 LP169 LP139 LP236 LP343 LP321 LP207 LP470 LP371

LP381 LP210 LP165 LP282 LP401 LP475 LP335 LP530 LP552

LP328 LP308 LP303 LP425 LP526 LP521 LP546 LP555

LP360 LP402 LP305 LP440 LP556 LP571 LP575

LP507 LP410 LP306 LP476 LP570

LP511 LP450 LP320 LP506

LP514 LP509 LP359 LP510

LP525 LP513 LP420 LP512

LP527 LP523 LP460 LP516

LP528 LP531 LP515 LP519

LP548 LP532 LP522 LP543

LP544 LP524 LP553

LP554 LP547 LP573

LP557

Linoleum US Dollars Canadian Dollars

MARMORETTE™ 0.080 in. (2.0 mm) $4.00 – $4.50 C$4.00 – C$4.50

MARMORETTE0.100 in. (2.5 mm) $4.50 – $5.00 C$4.00 – C$4.50

COLORETTE™ 0.100 in. (2.5 mm) $4.50 – $5.00 C$4.00 – C$4.50

LINORETTE™ 0.100 in. (2.5 mm) $4.50 – $5.00 C$3.75 – C$4.25

GRANETTE™ 0.100 in. (2.5 mm) $4.50 – $5.00 C$4.00 – C$4.50

UNI WALTON™ 0.100 in. (2.5 mm) $5.00 – $5.50 C$5.00 – C$5.50

MARMORETTE0.125 in. (3.2 mm) $5.00 – $5.50 C$4.75 – C$5.25

COLORETTE0.125 in. (3.2 mm) $5.00 – $5.50 C$4.75 – C$5.25

UNI WALTON0.125 in. (3.2 mm) $5.50 – $6.00 C$5.25 – C$6.00

LIN

OL

EU

M

MEDLEY™

H8614 orange pop, H8633 green salad, H8672 duck bill yellowMEDINTECH®/MEDINTECH Tandem®

88451/87451 golden glow

1

25

SheetMore Choices

• Broad range of designs and colors, including a newly

expanded homogeneous collection

• MEDINTONE™ featuring CONTINUUM™, a simple,

organized tonal step system that unites hue, value

and chroma. This expanded and flexible range of color

options offers fast and easy color selection.

Proven Performance

• UV-cured urethane coating protects floor’s

appearance and improves scuff mark resistance

• Static load and abrasion resistant

• Heat weld and flash-cove for spaces requiring

seamless installations and superior infection control

• S-761 adhesive seaming for non-aseptic spaces

saves installation time, materials and costs

• Low maintenance methods and materials conserve

energy and natural resources

• Floors stand up to strong cleaning agents and

aggressive cleaning methods for longer service life

Low VOC Emissions

• Low VOC emissions – California Section 01350 compliant,

third-party FloorScore™ certification and LEED® eligibility

SH

EE

T

H8301gray light

H8304natural gray light

H8308rock dust mid

H8312natural

H8316powder chocolate

H8319sand light

H8322amber light

WM301 W0854 WM304 W0880 WM308 W0739 WM312 W0917 WM316 W0921 WM319 W0081 WM322 W0927

H8302deep gray

H8305natural gray

H8309rock dust

H8313natural tone

H8317milk chocolate

H8320sand mid

H8323amber mid

WM302 W0859 WM305 W0889 WM309 W0904 WM313 W0918 WM317 W0922 WM320 W0925 WM323 W0928

H8303almost black

H8306natural gray dark

H8310rock brown

H8314natural brown

H8318chocolate brown

H8321sand

H8324amber

WM303 W0646 WM306 W0894 WM310 W0909 WM314 W0919 WM318 W0923 WM321 W0926 WM324 W0929

26 Visit armstrong.com/flooring • Call 1 877 ARMSTRONG

H8307rock dust light

WM307 W0900

H8311natural white

WM311 W0288

H8315light chocolate

WM315 W0920

H8300cool white

WM300 W0011

MEDINTONE™

• Sophisticated, natural appearance with complete range of neutrals and colors featuring CONTINUUM™, an exclusive color system organized in tonal steps to unite hue, value and chroma

• Superior durability with a UV-cured coating that provides a low-maintenance finish

• Provides excellent aseptic qualities when heat welded

• Low VOC emissions – California Section 01350 compliant, third-party FloorScore certification and LEED eligibility

LEED®

MR4.0

MR5.0

MR6.0

EQ4.3 �

Construction

Online: armstrong.com / sheet

FloorScore™ certified

Homogeneous.

Width & Length Sheet: 6 ft. (1.83 m) wide, up to 82.5 ft (25 m) long.

Thickness 0.080 in. (2.0 mm) overall, 0.080 in. (2.0 mm) wear layer.

National Avg. Installed Cost US: $4.75 – $5.25 sq. ft. Canada: C$5.25 – C$6.00 sq. ft.

new productnew

featuring

Patterned Weld Rod: WM____ Solid Weld Rod: W0____2

S-543 High-moisture warranty available. See page 122 for details.

H8325purple brown light

H8328grayed blue light

H8331tea green light

H8334gold dust light

H8337orange spice light

H8340terracotta light

H8343brick red light

WM325 W0930 WM328 W0936 WM331 W0950 WM334 W0955 WM337 W0959 WM340 W0962 WM343 W0966

H8326purple brown mid

H8329grayed blue mid

H8332tea green mid

H8335gold dust mid

H8338orange spice mid

H8341terracotta mid

H8344brick red mid

WM326 W0931 WM329 W0947 WM332 W0951 WM335 W0956 WM338 W0960 WM341 W0964 WM344 W0967

H8327purple brown

H8330grayed blue

H8333tea green

H8336gold dust

H8339orange spice

H8342terracotta

H8345brick red

WM327 W0934 WM330 W0949 WM333 W0954 WM336 W0958 WM339 W0961 WM342 W0965 WM345 W0969

27Visit armstrong.com/flooring • Call 1 877 ARMSTRONG

MEDINTONE™ H8301 gray light, H8302 deep gray, H8303 almost black, H8345 brick red

SH

EE

T

28 Visit armstrong.com/flooring • Call 1 877 ARMSTRONG

H8346violet mist light

H8349indigo light

H8352water blue light

H8355woodland blue light

H8358soft green light

H8361refresh green light

WM346 W0975 WM349 W0978 WM352 W0981 WM355 W0984 WM358 W0987 WM361 W0991

H8347violet mist mid

H8350indigo mid

H8353 water blue mid

H8356woodland blue mid

H8359soft green mid

H8362refresh green mid

WM347 W0976 WM350 W0979 WM353 W0982 WM356 W0985 WM359 W0989 WM362 W0994

H8348violet mist

H8351indigo

H8354water blue

H8357woodland blue

H8360soft green

H8363refresh green

WM348 W0977 WM351 W0980 WM354 W0983 WM357 W0986 WM360 W0990 WM363 W0997

MEDINTONE™ (cont.)

• Sophisticated, natural appearance with complete range of neutrals and colors featuring CONTINUUM™, an exclusive color system organized in tonal steps to unite hue, value and chroma

• Superior durability with a UV-cured coating that provides a low-maintenance finish

• Provides excellent aseptic qualities when heat welded

• Low VOC emissions – California Section 01350 compliant, third-party FloorScore certification and LEED eligibility

LEED®

MR4.0

MR5.0

MR6.0

EQ4.3 �

Construction

Online: armstrong.com / sheet

FloorScore™ certified

Homogeneous.

Width & Length Sheet: 6 ft. (1.83 m) wide, up to 82.5 ft (25 m) long.

Thickness 0.080 in. (2.0 mm) overall, 0.080 in. (2.0 mm) wear layer.

National Avg. Installed Cost US: $4.75 – $5.25 sq. ft. Canada: C$5.25 – C$6.00 sq. ft.

new productnew

featuring

Patterned Weld Rod: WM____ Solid Weld Rod: W0____2

S-543 High-moisture warranty available. See page 122 for details.

29Visit armstrong.com/flooring • Call 1 877 ARMSTRONG

LEED®

MR4.0

MR5.0

MR6.0

EQ4.3 �

88419/87419silver gray

88416/87416almond

88476/87476ixia

88485/87485freesia pearl

WM419 W0432 WM416 W0177 WM476 W0410 WM485 W0177

88441/87441color fleck

88451/87451golden glow

88486/87486campanula buff

88497/87497brushed sand

88450/87450sandalwood

88448/87448blue skies

88455/87455garden sage

WM441 W0177 WM451 W0411 WM486 W0013 WM497 W0025 WM450 W0485 WM448 W0206 WM455 W0726

88412/87412oatmeal

88432/87432pumice stone

88439/87439desert gold

88495/87495carthamus champagne

88488/87488dahlia sky

88474/87474delphinium

88496/87496tea garden green

WM412 W0411 WM432 W0105 WM439 W0358 WM495 W0633 WM488 W0352 WM474 W0409 WM496 W0140

MEDINTECH® / MEDINTECH Tandem®

• Proven industry standard with colors that coordinate with Armstrong’s portfolio of flooring solutions

• Homogeneous MEDINTECH and inlaid MEDINTECH Tandem sheet complement one another for area-to-area color and visual coordination, and lower costs

• Superior durability with a UV-cured coating that provides a low-maintenance finish

• Felt backing on MEDINTECH Tandem for help hiding minor subfloor irregularities

• Low VOC emissions – California Section 01350 compliant, third-party FloorScore certification and LEED eligibility

FloorScore™ certified

Patterned Weld Rod: WM____ Solid Weld Rod: W0____

MEDINTECH: 88____ MEDINTECH Tandem: 87____

Construction

Online: armstrong.com / sheet

MEDINTECH: Homogeneous. MEDINTECH Tandem: Inlaid.

Width & Length Sheet: 6 ft. (1.83 m) wide, up to 82.5 ft (25 m) long.

ThicknessMEDINTECH: 0.080 in. (2.0 mm) overall, 0.080 in. (2.0 mm) wear layer. MEDINTECH Tandem: 0.080 in. (2.0 mm) overall, 0.060 in. (1.52 mm) wear layer.

National Avg. Installed CostMEDINTECH: US: $4.75 – $5.25 sq. ft. Canada: C$5.25 – C$6.00 sq. ft.MEDINTECH Tandem: US: $3.75 – $4.25 sq. ft. Canada: C$4.50 – C$5.00 sq. ft.

SH

EE

T

S-543 High-moisture warranty available. See page 122 for details.

30 Visit armstrong.com/flooring • Call 1 877 ARMSTRONG

MEDLEY™

• Contrasting chip visuals designed for superior hiding power from dirt and subfloor imperfections

• Provides excellent aseptic qualities when heat welded