Research Article Phase-Field Simulations at the Atomic...

Transcript of Research Article Phase-Field Simulations at the Atomic...

Hindawi Publishing CorporationThe Scientific World JournalVolume 2013 Article ID 564272 8 pageshttpdxdoiorg1011552013564272

Research ArticlePhase-Field Simulations at the Atomic Scale inComparison to Molecular Dynamics

Marco Berghoff Michael Selzer and Britta Nestler

Institute of Applied Materials Karlsruhe Institute of Technology 76133 Karlsruhe Germany

Correspondence should be addressed to Marco Berghoff marcoberghoffkitedu

Received 23 August 2013 Accepted 2 October 2013

Academic Editors O Balitskii and N Sekido

Copyright copy 2013 Marco Berghoff et alThis is an open access article distributed under the Creative CommonsAttribution Licensewhich permits unrestricted use distribution and reproduction in any medium provided the original work is properly cited

Early solidification is investigated using two different simulation techniques the molecular dynamics (MD) and the phase-field(PF) methods While the first describes the evolution of a system on the basis of motion equations of particles the second groundson the evolution of continuous local order parameter fieldThe aim of this study is to probe the ability of themesoscopic phase-fieldmethod tomake predictions of growth velocity at the nanoscopic length scale For this purpose the isothermal growth of a sphericalcrystalline cluster embedded in a melt is considered The system in study is Ni modeled with the embedded atom method (EAM)The bulk and interfacial properties required in the PF method are obtained from MD simulations Also the initial configurationobtained fromMDdata is used in the PF as input Results for the evolution of the cluster volume at high andmoderate undercoolingare presented

1 Introduction

The phase-field is a powerful method to describe solidifi-cation phenomena [1 2] on the mesoscopic length scale Ithas been used to model homogeneous and heterogeneousnucleation microstructure formation in solids and motionof grain boundaries The phase-field models includes formu-lations for pure substances [3] for multicomponent systems[4] and for polycrystalline structure [5] and solidificationin eutectic [6 7] peritectic [7] and monotectic [8] systemsOther simulation techniques for dendrite growth are cellularautomata [9] and hybrid methods such as the multiscalediffusion Monte Carlo (DMC) [10 11]

The phase-field method requires previous knowledge ofthe material properties of the system in study The inputincludes bulk properties such as density heat capacity andlatent heat and others such as interfacial and kinetic growthcoefficients being the latter properties which are hardlyaccessible in experiments Here molecular simulations play afundamental role since they provide a link between an inter-action potential and all the required properties Kineticcoefficients interfacial free energies and their dependenceon the crystal orientation of pure metals and alloys can be

directly obtained from simulations of inhomogeneous liquid-crystal systems [12ndash15]

There are previous phase-field studies in which thematerial parameters have been obtained frommolecular sim-ulations to model dendritic growth in pure Ni [16 17] CO

2

hydrates [18] and binary alloys In this work we compareMDand PF simulation results for the isothermal growth velocityof a nanoscopic spherical crystalline cluster of Ni embeddedin the melt For this purpose we use precise thermodynamicand kinetic data obtained from molecular dynamics and useequivalent initial configuration in the phase-field simula-tions

2 Properties of Ni (EAM)

The properties of Ni obtained from molecular dynamicsimulations are given in this section The embedded atompotential of Foiles [19] is used The thermal dependence ofbulk properties is determined from independent simulationsof equilibrated homogeneous systems at pressure 119901 = 0Liquid phase is prepared by melting of an initial crystallinephase by setting the temperature of the thermostat well abovethe melting temperature Crystalline phase is obtained by

2 The Scientific World Journal

relaxation of the perfect crystalline phase The samples areprepared in NpT simulation runs and the production in NVEensemble

Densities of the bulk phases are fitted to the function120588120572(119879) = 119886 + 119887 sdot 119879 + 119888 sdot 119879

2 for the fcc solid phase (120572 =

s) 119886 = 89016 kgm3 119887 = minus020379 kgm3 K and 119888 =

minus00000614202 kgm3 K2 while for the liquid phase (120572 = ℓ)119886 = 899226 kgm3 119887 = minus0667037 kgm3 K and 119888 =

00000331612 kgm3 K2The parameters were obtained in thetemperature intervals 1000K to 3000K for the liquid and300K to 1900K for the solid In both cases parts of themetastable phases are included in the fit procedure

The latent heat is obtained from the difference betweenthe enthalpy of the liquid and the solid and fitted to

0(119879) =

119886 + 119887 sdot 119879 + 119888 sdot 1198792 with 119886 = minus159802 Jkg 119887 = 324745 Jkg K

and 119888 = minus00810984 Jkg K2 These values are determined inthe range from 1000K to 1900K The latent heat expressedin units of energy per volume of the solid phase is given by119871s(119879) =

0(119879) sdot 120588

s(119879)

The specific heat capacity at constant volume is givenby 119888120572

V (119879) = 119886 + 119887 sdot 119879 where 119886 = 419452 Jkg K and 119887 =

0020388 Jkg K2 for the solid and 119886 = 563024 Jkg K and119887 = minus006952 Jkg K2 for the liquid

The thermal diffusivity for themodel is 21sdot10minus7m2s [20]while the experimental values range from 120 sdot 10

minus7m2s [21]to the recent value 87sdot10minus7m2s [22] (obtained inmicrograv-ity conditions)The value obtained from simulations is at least4 times lower than that in experiments and the differenceis due to the electronic contribution to thermal transportin metals which are not accounted in classical moleculardynamics

The melting temperature of the model is precisely esti-mated from simulations of inhomogeneous solid-liquid sys-tem at the point where the velocity of growth is zero For themodel 119879

119898= 1748K

The kinetic coefficient is estimated from linear relation-ship between planar growth velocity and undercooling closeto coexistence Growth velocities are obtained from inde-pendent simulations for the crystal orientations [100] [110]and [111] The kinetic growth coefficient depends also onthe orientation of the crystal Its orientational dependence isrepresented here by the expansion

119896 (119899)

1198960

= 1 minus 3120598119896+ 4120598119896119876 + 120575

119896(119875 + 30119878) (1)

with 119876 = 1198994

1+ 1198994

2+ 1198994

3 119875 = 119899

6

1+ 1198996

2+ 1198996

3 and 119878 = 119899

2

11198992

21198992

3

119899 = (1198991 1198992 1198993) is the unit vector normal to the interface

The parameter 1198960is a value of the magnitude of the kinetic

coefficient 120598119896and 120575119896are the strength of the anisotropy of the

kinetic coefficient The values for the model EAM F85 are1198960

= 0319205msK 120598119896

= minus0196511 and 120575119896

= 0230331estimated from the kinetic coefficients for different crystalorientations 119896

100= 033msK 119896

110= 023msK and 119896

111=

012msKThe interfacial stiffness and interfacial free energy were

obtained from the analysis of capillary waves spectrum oflarge solid-liquid interfaces at coexistence (ie at 119879 = 119879

119898for

119875 = 0) The orientational dependence of the interfacial freeenergy 120574 is described by a cubic harmonic expansion

120574 (119899)

1205740

= 1 + 1205981(119876 minus

3

5) + 1205982(3119876 + 66119878 minus

17

7)

+ 1205983(51198762minus 16119878 minus

94

13119876 +

33

13)

(2)

with 1205740being an orientational averaged value of the interfacial

free energy while the coefficients 120598119894describe the strength of

the anisotropy Interfacial stiffness is defined as 120574120572120573

= 120574 +

1205972120574120597119899120572120597119899120573 where 119899

120572and 119899120573indicate unit vectors tangent to

the interface plane [23] The parameters of (2) are obtainedfrom the system of equations for the stiffnesses 120574

120572120573and

their numerical values are obtained from the analysis of thecapillary waves spectrum [14] Here we consider the crys-tal orientations [100] [110]

[110] [110]

[001] and [111] the

interface energy for the [110] orientation depends on theparallel direction denoted by the subscripts In respect to thefour different interface energies we used a cubic harmonicexpansion with four fitting parameters Accurate values ofthese variables and parameters for the model EAM F85 are1205740

= 0302 Jm2 1205981

= 010191 1205982

= minus000134 and 1205983

=

000876

3 Phase-Field Model for Pure Material

Isothermal crystal growth for purematerial is modeled by thevariables of the internal energy density 119890 and of two phase-fields 0 le 120601s le 1 (solid) and 0 le 120601

ℓle 1 (liquid) The

phase-field variables fulfill the constraint 120601s + 120601ℓ

= 1 so asingle phase-field variable 120601 = 120601s is sufficient to describe theevolution of the phase boundaries in the system Note that120601ℓ= 1 minus 120601 The variable 120601( 119905) denotes the local fraction at

of the considered phase at time 119905The phase-field model is based on an entropy functional

to ensure consistency with classical irreversible thermody-namics

S (119890 120601) = intΩ

119904 (119890 120601) minus (120598119886 (120601 nabla120601) +1

120598119908 (120601)) 119889119909 (3)

The bulk entropy density 119904 depends on the internal energydensity 119890 and the phase-field variable 120601( 119905) The functions119886(120601 nabla120601) and 119908(120601) reflect the thermodynamics of the inter-faces and 120598 = 4 is a small length scale parameter related tothe thickness of the diffuse interface

In detail the gradient entropy with anisotropy is adoptedfrom (2) andmodeled by the factor (119860(119899))

2 depending on theorientation of the interface Consider the following

119886 (120601 nabla120601) =1205740

119879(119860 (119899))

21003816100381610038161003816nabla12060110038161003816100381610038162

= 120574 (119899)1003816100381610038161003816nabla120601

10038161003816100381610038162

(4)

where 119899 = minusnabla120601|nabla120601| is the normalized gradient vectorThe function120596(120601) = (16120587

2)(1205740119879)120601(1minus120601) is the obstacle

potential It is set that120596(120601) = infin for 120601 notin [0 1] Note that 1205740119879

is the interface entropy density

The Scientific World Journal 3

From (3) one derives the equations for the nonconservedphase-field variable 120601 by taking the functional derivatives inthe form

120591120598120597120601

120597119905=

120575S

120575120601 (5)

where 120591 = 120591(120601 nabla120601) is an anisotropic relaxation parameterdependant on temperature 120591(119899) = 119871(119879)119879119879

119898119896(119899) with (1)

and it is related to the kinetic coefficient 1198960

The evolution of the phase-field variables is described by

120591120598120597120601

120597119905= 120598(nabla sdot

120597119886 (120601 nabla120601)

120597nabla120601minus

120597119886 (120601 nabla120601)

120597120601) minus

1

120598

120597119908 (120601)

120597120601

+120597119904 (119890 120601)

120597120601

(6)

The thermodynamic relation 119890 = 119891+119879119904 gives us 120597119904(119890 120601)120597120601 =

minus(1119879)(120597119891(119879 120601)120597120601) detailed in [24] Here is the bulk freeenergy density

119891 (119879 120601) = sum

120572isinsℓ119871120572(119879)

119879 minus 119879119898

119879119898

ℎ (120601120572)

+ sum

120572isinsℓ(int

119879

119879119898

119904120572

V () 119889minus119879int

119879

119879119898

119904120572

V ()119889

) ℎ (120601

120572)

(7)

where ℎ(120601) is a monotonous function on [0 1] with ℎ(0) =

0 ℎ(1) = 1 and ℎ1015840(0) = ℎ

1015840(1) = 0 We chose ℎ(120601) =

1206013(61206012minus 15120601 + 10) 119871120572(119879) is the latent heat and 119904

120572

V (119879) =

120588120572(119879)119888120572

V (119879) is the volumetric heat capacity both dependingon the temperature 119879 119879

119898is the melting temperature

For the isothermal case we can define two constants119891(119879 120601) = sum

120572isinsℓ 119862120572

119879ℎ(120601120572) and consider here that the

free energy contribution to the equation of motion (6) is aconstant term 120597119891120597120601 = (119862

s119879

minus 119862ℓ

119879)ℎ1015840(120601) note that ℎ

1015840(120601s) =

minusℎ1015840(120601ℓ)

Equation (6) is solved by a time dependent forward eulerschemewith a second order spatial discretisation on a regularCartesian grid

4 Initial Configuration and Calibration

41 Preparation of the Sample Growth simulations beginfrom a configurationmade of a stabilized crystalline sphericalcluster embedded in the melt The preparation of the initialconfiguration involves a sequence of NpT simulation runsFirst the crystalline solid phase is equilibrated at 119901 = 0

starting from atoms arranged in a perfect fcc structure in acubic box with an initial density close to the experimentalvalue at room temperature (120588 = 89 gcm3) The temperaturein this step is chosen equal to the one used later in the sim-ulation of growth In the second step two regions are definedin the simulation box the melting zone and the atoms in thecrystalline phase (which is chosen here as a sphere of radius119903 = 25 A) The region outside the crystalline zone is melted

by increasing the temperature well above the melting pointwhile the atoms in the solid region are constrained to remainat fixed positionsThe temperature is linearly increased whilean isotropic barostat is applied In the next step the stablemelt at high temperature is cooled down to the temperatureof the crystal The melt reaches a metastable (undercooled)state At the end of this run a crystalline cluster embedded inthe liquid phase at the same temperature is obtained In thelast step the relaxation of the atoms at the interface ismade byanNpT simulation of some picoseconds in which all particlesare allowed to move

42 Local Order Parameter At microscopic level a configu-ration is described by positions and velocities of particles ata given time The crystalline and liquid regions in this con-figuration can be identified by a suitable definition of thelocal order parameter a function of the coordinates of aparticle and its neighbors which adopts different values in thecrystalline and in the disordered liquid phases Here we usethe bond local order parameter 119902

61199026[25 26]

11990261199026(119894) =

1

119885119894

119885119894

sum

119895=1

q6(119894) sdot q6(119895) (8)

The inner product in this sum is given by

q6(119894) sdot q6(119895) =

6

sum

119898=minus6

1199026119898

(119894) 1199026119898

(119895)lowast (9)

with

1199026119898

(119894) = 1198766119898

(119894) (

6

sum

119898=minus6

100381610038161003816100381610038161198766119898

(119894)10038161003816100381610038161003816

2

)

minus12

(10)

where 1198766119898

(119894) = (1119885119894) sum119885119894

119895=11198846119898

(120579( 119903119894119895) 120601( 119903119894119895)) 119885119894is the

number of neighboring atoms within a cut-off radius of336 A and 119884

6119898are 6th order spherical harmonic functions

In order to obtain an equivalent initial configuration forthe PFmethod the local order parameter values given at atompositions are mapped on a regular grid with cell-width of1 A The order parameter in a given grid point is given bythe average of all particles contained in cell u = (119894 119895 119896) andits first two neighbor cells k = (119898 119899 119897) with |u minus k| lt 2

The order parameter values obtained from MD simula-tion were scaled so that the volume of the crystal cluster isequal in the coarse-grained and in the original initial config-urations The distribution of the order parameter in the bulkphases is Gaussian centered at 120583 with standard deviation 120590The definition of order parameter in the phase-field methodis as follows 120601 = 0 if 119902

61199026

lt 119886 = 120583ℓminus 2120590ℓ and 120601 = 1 if

11990261199026gt 119887 = 120583s + 2120590s and 120601 = (119902

61199026minus 119886)(119887 minus 119886) otherwise

43 Planar Growth An analytic formulation of the phase-field method in the sharp interface limit assumes a temper-ature gradient at the interface The formulation reads

Δ119879 = 120573V + 120581Γ (11)

4 The Scientific World Journal

Table 1 Kinetic coefficient of Ni inmsK frommolecular-dynamicssimulations and phase-field simulation

Interface From (1) PF Sun et al [12][100] 033 032 0358 plusmn 0022

[110] 023 021 0255 plusmn 0016

[111] 012 011 0241 plusmn 004

here Δ119879 denotes the undercooling in the interface V is thevelocity and 120573 is a kinetic coefficient The curvature 120581 of atwo dimensional interface is the sum of the two principalcurvatures 1119903

1 11199032 so 120581 = 2119903 if 119903

1= 1199032

= 119903 The Gibbs-Thomson-coefficient Γ = 120590119879119871 with 120590 surface tension and 119871

being the latent heatIn equilibrium that is for V = 0 (11) reads as Δ119879 = 120581Γ =

Γ119903 (in 2D) It follows that the critical radius 119903119888

= ΓΔ119879 Asmall spherical cluster with radius 119903

119888is in equilibrium For

example at119879 = 1550K the critical radius 119903119888= 97 A A cluster

smaller than 119903119888meltsThephase-field simulations corroborate

this result for 119879 = 1550K the nucleus grows for 119903 = 10 A andmelts for 119903 = 95 A

For a planar interface (11) is simplified to Δ119879 = 120573V takingaccount of the absence of curvature The kinetic coefficientadapted from MD is 119896 = 1120573 So the phase-field relaxationparameter is

120591 (119899) =119871 (119879)

119879119879119898119896 (119899)

=1205910

119896 (119899) (12)

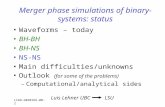

Simulations of a planar front in comparison to theanalytic solution and molecular dynamics simulations areshown in Figure 1 Additionally we list the kinetic coefficientin Table 1 Both methods converge at low undercooling tothe solution given by (11) At higher undercooling velocitiesobtained from PF simulations still exhibit a linear depen-dence with undercooling Δ119879 this is given in the range from1400K to 119879

119898 the fit of the kinetic coefficient is made in this

range and agrees with the expected kinetics from (1)The MD simulations indicate that this linearity is not

more valid the velocity is lower than that expected fromextrapolation of the linear relation V

119868= 119896Δ119879 This effect can

also be recognized in the results of Hoyt et al [15] Manyeffects influence the growth velocity of MD at higher under-cooling with the increase of order in the liquid bulk beingthe most important which leads to the formation of smallcrystalline clusters in the bulk liquid The phase-field showsthis nonlinearity only for very high undercoolings Δ119879 gt

500K

5 Spherical Cluster Growth

Growth simulations starting from the samples preparedas described in Section 41 are performed using both MDand PF methods At microscopic level NpT simulationsare performed at 119901 = 0 using the Andersen thermostat andbarostat The number of particles is 119873 = 256000 whichcorresponds to a cubic box of length of about 145 A Theinitial radius of the spherical crystalline cluster is 25 A whichcorresponds to about 55 sdot 10

3 particles (see Figure 2(a))

that is much larger than the size of the critical cluster at119879 = 1500K which is made of about 103 particles [27] For119879 ge 1600K the initial size of the cluster is lower than thecritical value and it melts as expected PF simulations areperformed imposing the isothermal condition starting withthe same configuration as in MD but converted as describedin Section 42 Results for the evolution of the cluster volumeare shown in Figure 3 snapshots from the MD and PFsimulations are shown in Figure 2 Atmoderate undercooling(119879 gt 1550K) the MD and PF show comparable growth ratesFor higher undercooling the growth in the phase-field modelis notably faster than in the MD method The discrepancybecomes more pronounced at lower temperature and highersimulation time Assuming that the cluster conserves itsspherical shape during the first stage of growth we definethe radius as 119903 = (31198814120587)

13 and the radial velocity as V =

119889119903119889119905 Figure 4 shows the evolution of radial velocity in theMD simulation three regimes can be identified initially thevelocity tends to decrease then exhibits a linear increaseand finally decreases again The first decrease is due to thepreparation method of the sample the system relaxes whilethe interface is formed Growth and relaxation cannot bedecoupled both occur simultaneously in this initial regimeIn the second regime the growth velocity increases linearlyin time The decrease of velocity in the last regime is due tothe finite size of the sample when the cluster is large enoughit interacts with its periodic images through the periodicboundaries of the simulation box and loses its sphericalshape In the PF simulation no extra relaxation regime isobserved the dynamic is determined by the initial definitionafter the interface is relaxated Moreover in the PF the clusteris not affected by finite size effects as in the MD simulationsince no periodic boundaries are required In comparison thePF exhibits an apparent linear increase from the beginningThis means that the starting radius of the nucleus is not thesame for both simulation methods so a comparison for thesame radius instead of the time is more adequate Figure 5shows the radial velocity versus cluster radius at differenttemperatures Results obtained from PF simulations are welldescribed by Gibbs-Thomson equation (11) The analyticalvelocity is V = 119896avg(Δ119879 minus 2Γ119903) So we use 119881

119879(119903) = 119886

119879+

119887119879119903 to fit the data with the parameters 119886

119879and 119887119879for each

temperature 119879 We applied the fit in the region startingwith 119903 = 30 A where the PF has relaxated the interfaceThese fits are also applied for the MD results in the secondregime of growth that is for crystalline clusters of size ofabout 40 A ≾ 119903 ≾ 60 A (the points in Figure 5) Accordingto the Gibbs-Thomson equation the radial velocity reaches anasymptotic value (V

119879infin= V119879119903rarrinfin

) an ideal situation wherethe cluster is large enough and conserves its shape This limitcannot be directly obtained from simulations first becausethe simulations are performed in a finite volume and alsobecause the crystalline cluster would adopt a nonsphericalshape due to the anisotropy of the interfacial energy andgrowth coefficient We estimate this hypothetical limit as abasis of comparison between the PF andMD simulations Forthis purpose we extrapolate the fit and obtain V

119879infin= 119886119879

one value is obtained at each temperature The asymptotic

The Scientific World Journal 5

0

50

100

150

200

250

1000 1100 1200 1300 1400 1500 1600 1700

Gro

wth

velo

city

(ms

)

Temperature (K)

PFFitted PFSun et al

Hoyt et al

MDk100ΔT

(a) [100]

0

50

100

150

200

250

1000 1100 1200 1300 1400 1500 1600 1700

Gro

wth

velo

city

(ms

)

Temperature (K)

PFFitted PFSun et al

Hoyt et alk110ΔT

(b) [110]

0

50

100

150

200

250

1000 1100 1200 1300 1400 1500 1600 1700

Gro

wth

velo

city

(ms

)

Temperature (K)

PFFitted PFSun et al

Hoyt et alk111ΔT

(c) [111]

PF [100]PF [110]PF [111]

Fitted [100]Fitted [110]Fitted [111]

0

50

100

150

200

250

1000 1100 1200 1300 1400 1500 1600 1700

Gro

wth

velo

city

(ms

)

Temperature (K)

(d) Phase-field

Figure 1 Growth velocity of a planar front at different temperatures for the interface orientations (a) [100] (b) [110] and (c) [111] in com-parison to molecular dynamic results The values of the kinetic coefficient can be found in Table 1 (d) shows the phase-field results for allorientations

radial velocities obtained from the PF and MD simulationsare shown in Figure 6 The results of both methods liebetween the linear relations V

100= 119896100

Δ119879 and V111

=

119896111

Δ119879 For the MD the results show a similar behavioras observed in the planar growth case the deviation fromthe linear relation at high undercooling observed in the PFsimulations is due to the correction introduced in the kineticcoefficient As shown in Section 43 the crystal grows indifferent crystal orientations with a different velocity In thePF the kinetic anisotropy is responsible for this The planarfront simulations fromFigure 1 show that the kinetics are very

well reproducible from the PF simulations If we assume thatwe have a perfect sphere the mean kinetic can be calculatedas a surface area integral of the unit sphere over the kineticcoefficient we get 119896avg = int

1198782119896(119899)119889119860 int

11987821119889119860 asymp 0175 So

V(Δ119879) = 119896avgΔ119879 is the excepted growth velocity for a sphereit is shown as the solid line in Figure 6

At this early stage of growing the crystal is very similar toa sphere The preferred growing in [100] directions and thesurface anisotropy formed the crystal to its equilibriumshape for Ni this is similar to an octahedron in the limitthis shape has only [111] directions So the area of the [100]

6 The Scientific World Journal

(a) (b) (c) (d)

(e) (f) (g) (h)

Figure 2 Snapshots of the simulations at 1550K MD simulations at (a) initial time 80 ps (c) 100 ps and (d) 220 ps The evolution of thecrystalline cluster from PF simulations with the same volume is shown in the sequence from (e) to (h)

0

2

4

6

8

10

12

0 50 100 150 200

PFPFPFPFPFPF

t (ps)

V(105

3)

1400K MD1450K MD1500K MD1525K MD1550K MD1575K MD

A

Figure 3 Evolution of the crystalline cluster volume at differenttemperatures MD results are the average over 8 independent simu-lation runs

orientations shrinks and the area of the [111] orientationsincreases it follows that the growth rate is between 119896avg and119896111

specially below 119896avg

0

10

20

30

40

0 50 100 150 200t (ps)

=drdt

(ms

)

MD 1400KMD 1450KMD 1500K

MD 1525KMD 1550KMD 1575K

Figure 4 Evolution of the radial velocity at different temperaturesobtained fromMD simulations

We use the sphericity 119904 as the measure for the sphericalityof the crystal as follow For a given volume 119881 and a givensurface area 119878 of the crystal we calculate the radius 119903

3=

31198814120587 from the volume assuming a sphere and calculate thesurface area 119878

119881= 4120587119903

2 for a sphere Then 119904 = 119878119881119878 [28]

The volume of the crystal is defined as 119881 = intΩ120601119889119881

and the surface area as 119878 = intΩnabla120601119889119881 this surface

The Scientific World Journal 7

0

10

20

30

40

50

60

30 35 40 45 50 55 60

=drdt

(ms

)

MD 1400KMD 1450KMD 1500K

MD 1525KMD 1550KMD 1575K

r (A)

(a)

PF 1400KPF 1450KPF 1500K

PF 1525KPF 1550KPF 1575K

0

10

20

30

40

50

60

30 35 40 45 50 55 60

=drdt

(ms

)

r (A)

(b)

Figure 5 Evolution of the radial velocity at different temperatures Molecular dynamic (a) and phase-field (b) In lines the fits V119879(119903) =

119886119879+ 119887119879119903

0

10

20

30

40

50

60

70

80

1350 1400 1450 1500 1550 1600 1650 1700 1750T (K)

PFMD

=drdt

(ms

)

k100ΔT

k111ΔT

k110ΔT

kavgΔT

Figure 6 Asymptotic radial velocity versus temperature Valuesof Vinfin

are obtained from the asymptotic limit of the fits shown inFigure 5

area measurement method assumes a smooth nondeformedinterface this is not given for PF interfaces if there are drivingforces like curvatures and undercoolings We use a factorestimated for a sphere of radius 25 A to correct this Thesurface area is multiplied by this factor 1089

Figure 7 shows the sphericity over the radius the crystalbecomes non spherical for longer growing and faster forhigher undercoolingsThismeans that the velocity of growing

095

096

097

098

099

1

25 30 35 40 45 50 55 60 65

1400K1450K

1500K1550K

Radius

Sphe

ricity

s

r (A)

Figure 7 Sphericity of the crystal for different undercoolings Thecontour shows the shape of the [100] cutting plane through thecenter of the crystal for 119879 = 1400K and 1550K

is below 119896avg especially for higher undercoolings The non-spherical shape is shown in Figure 2(h)

6 Conclusion

Many have shown the linking between MD and PF [16 17]So it is a common way to obtain MD parameters for PFsimulations The PF simulations on the natural PF scale forexample mesoscopic scale produce correct results compared

8 The Scientific World Journal

with experiments [29 30] We have confirmed that a PF withMD parameters is correct even on the atomistic scale This isnot surprising since we are very close to the sharp interfacelimitsThemesoscopic view at the atomistic scale provides thesame growth rates as an atomic simulation method althoughthe atoms are not resolved in the PF The fluctuations of theinterface on the atomistic length scale will be investigated ina consecutive work

However you will not simulate too high undercooledmelts where the mesoscopic view of the PF will not considerall the nonlinearity from the MD interface We have used thesphericity to measure the shape and explain the discrepancyto the analytic linear velocity

While it is known that PF works correctly on mesoscopicscale and with this study it is shown that PF also works onthe atomistic scale one is able to do multiscale simulationsstarting on the atomistic scale with one simulation method

Acknowledgments

The authors gratefully acknowledge the financial supportby the German Research Foundation (DFG) in the PriorityProgramSPP 1296They like to thank JHorbach andR Rozasfrom Heinrich Heine University of Dusseldorf for providingthe MD data

References

[1] L-Q Chen ldquoPhase-field models for microstructure evolutionrdquoAnnual Review of Materials Science vol 32 no 1 pp 113ndash1402002

[2] W J Boettinger J A Warren C Beckermann and A KarmaldquoPhase-field simulation of solidificationrdquo Annual Review ofMaterials Science vol 32 no 1 pp 163ndash194 2002

[3] A Karma andW-J Rappel ldquoQuantitative phase-field modelingof dendritic growth in two and three dimensionsrdquo PhysicalReview E vol 57 no 4 pp 4323ndash4349 1998

[4] B Nestler H Garcke and B Stinner ldquoMulticomponent alloysolidification phase-field modeling and simulationsrdquo PhysicalReview E vol 71 no 4 Article ID 041609 2005

[5] L Granasy T Pusztai and J A Warren ldquoModelling polycrys-talline solidification using phase field theoryrdquo Journal of PhysicsCondensed Matter vol 16 no 41 pp R1205ndashR1235 2004

[6] A Karma ldquoPhase-field model of eutectic growthrdquo PhysicalReview E vol 49 no 3 pp 2245ndash2250 1994

[7] B Nestler and A A Wheeler ldquoA multi-phase-field model ofeutectic and peritectic alloys numerical simulation of growthstructuresrdquo Physica D vol 138 no 1-2 pp 114ndash133 2000

[8] B Nestler A A Wheeler L Ratke and C Stocker ldquoPhase-fieldmodel for solidification of a monotectic alloy with convectionrdquoPhysica D vol 141 no 1-2 pp 133ndash154 2000

[9] M F Zhu andC PHong ldquoAmodified cellular automatonmodelfor the simulation of dendritic growth in solidification of alloysrdquoISIJ International vol 41 no 5 pp 436ndash445 2001

[10] P Zhu and RW Smith ldquoDynamic simulation of crystal growthby Monte Carlo method-I Model description and kineticsrdquoActaMetallurgica etMaterialia vol 40 no 4 pp 683ndash692 1992

[11] M Plapp and A Karma ldquoMultiscale finite-difference-diffusionMonte-Carlo method for simulating dendritic solidificationrdquoJournal of Computational Physics vol 165 no 2 pp 592ndash6192000

[12] D Y Sun M Asta and J J Hoyt ldquoKinetic coefficient of Nisolid-liquid interfaces from molecular-dynamics simulationsrdquoPhysical Review B vol 69 no 2 Article ID 024108 2004

[13] A Kerrache J Horbach and K Binder ldquoMolecular-dynamicscomputer simulation of crystal growth andmelting inAl

50Ni50rdquo

EPL vol 81 no 5 Article ID 58001 2008[14] R E Rozas and J Horbach ldquoCapillary wave analysis of rough

solid-liquid interfaces in nickelrdquo EPL vol 93 no 2 Article ID26006 2011

[15] J J Hoyt M Asta and A Karma ldquoAtomistic and continuummodeling of dendritic solidificationrdquo Materials Science andEngineering R vol 41 no 6 pp 121ndash163 2003

[16] J Bragard A Karma Y H Lee and M Plapp ldquoLinking phase-field and atomistic simulations tomodel dendritic solidificationin highly undercooled meltsrdquo Interface Science vol 10 no 2-3pp 121ndash136 2002

[17] B Nestler M Selzer and D Danilov ldquoPhase-field simulationsof nuclei and early stage solidification microstructuresrdquo Journalof Physics Condensed Matter vol 21 no 46 Article ID 4641072009

[18] G Tegze T Pusztai G Toth et al ldquoMultiscale approach to CO2

hydrate formation in aqueous solution phase field theory andmolecular dynamics Nucleation and growthrdquo The Journal ofChemical Physics vol 124 no 23 Article ID 234710 2006

[19] S M Foiles ldquoApplication of the embedded-atom method toliquid transition metalsrdquo Physical Review B vol 32 no 6 pp3409ndash3415 1985

[20] R E Rozas and J Horbach ldquoA comparison of EAM models ofNi close to the melting temperaturerdquo Submitted

[21] V Y Zinovrsquoyev V F Polev S G Taluts G P Zinovrsquoyeva and SA Ilrsquoinykh ldquoDiffusivity and thermal conductivity of 3D-tran-sition metals in solid and liquid statesrdquo Physics of Metals andMetallography vol 61 no 6 pp 85ndash92 1986

[22] K Nagata H Fukuyama K Taguchi H Ishii and M HayashildquoThermal conductivity of molten Al Si and Ni measured undermicrogravityrdquo High Temperature Materials and Processes vol22 no 5-6 pp 267ndash273 2003

[23] J J Hoyt M Asta T Haxhimali et al ldquoCrystal-melt interfacesand solidification morphologies in metals and alloysrdquo MRSBulletin vol 29 no 12 pp 935ndash939 2004

[24] H Garcke B Nestler and B Stinner ldquoA diffuse interface modelfor alloys with multiple components and phasesrdquo SIAM Journalon Applied Mathematics vol 64 no 3 pp 775ndash799 2004

[25] P J Steinhardt D R Nelson and M Ronchetti ldquoBond-orientational order in liquids and glassesrdquo Physical Review Bvol 28 no 2 pp 784ndash805 1983

[26] P R tenWoldeM J Ruiz-Montero andD Frenkel ldquoNumericalevidence for bcc ordering at the surface of a critical fcc nucleusrdquoPhysical Review Letters vol 75 no 14 pp 2714ndash2717 1995

[27] J Bokeloh R E Rozas J Horbach and G Wilde ldquoNucleationbarriers for the liquid-to-crystal transition in Ni experimentand simulationrdquo Physical Review Letters vol 107 no 14 ArticleID 145701 2011

[28] H Wadell ldquoVolume shape and roundness of quartz particlesrdquoThe Journal of Geology vol 43 no 3 pp 250ndash280 1935

[29] B Echebarria R Folch A Karma and M Plapp ldquoQuantitativephase-fieldmodel of alloy solidificationrdquo Physical Review E vol70 no 6 Article ID 061604 2004

[30] S Gurevich A Karma M Plapp and R Trivedi ldquoPhase-field study of three-dimensional steady-state growth shapesin directional solidificationrdquo Physical Review E vol 81 no 1Article ID 011603 2010

Submit your manuscripts athttpwwwhindawicom

ScientificaHindawi Publishing Corporationhttpwwwhindawicom Volume 2014

CorrosionInternational Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Polymer ScienceInternational Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

CeramicsJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

CompositesJournal of

NanoparticlesJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

International Journal of

Biomaterials

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

NanoscienceJournal of

TextilesHindawi Publishing Corporation httpwwwhindawicom Volume 2014

Journal of

NanotechnologyHindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Journal of

CrystallographyJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

The Scientific World JournalHindawi Publishing Corporation httpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

CoatingsJournal of

Advances in

Materials Science and EngineeringHindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Smart Materials Research

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

MetallurgyJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

BioMed Research International

MaterialsJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Nano

materials

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Journal ofNanomaterials

2 The Scientific World Journal

relaxation of the perfect crystalline phase The samples areprepared in NpT simulation runs and the production in NVEensemble

Densities of the bulk phases are fitted to the function120588120572(119879) = 119886 + 119887 sdot 119879 + 119888 sdot 119879

2 for the fcc solid phase (120572 =

s) 119886 = 89016 kgm3 119887 = minus020379 kgm3 K and 119888 =

minus00000614202 kgm3 K2 while for the liquid phase (120572 = ℓ)119886 = 899226 kgm3 119887 = minus0667037 kgm3 K and 119888 =

00000331612 kgm3 K2The parameters were obtained in thetemperature intervals 1000K to 3000K for the liquid and300K to 1900K for the solid In both cases parts of themetastable phases are included in the fit procedure

The latent heat is obtained from the difference betweenthe enthalpy of the liquid and the solid and fitted to

0(119879) =

119886 + 119887 sdot 119879 + 119888 sdot 1198792 with 119886 = minus159802 Jkg 119887 = 324745 Jkg K

and 119888 = minus00810984 Jkg K2 These values are determined inthe range from 1000K to 1900K The latent heat expressedin units of energy per volume of the solid phase is given by119871s(119879) =

0(119879) sdot 120588

s(119879)

The specific heat capacity at constant volume is givenby 119888120572

V (119879) = 119886 + 119887 sdot 119879 where 119886 = 419452 Jkg K and 119887 =

0020388 Jkg K2 for the solid and 119886 = 563024 Jkg K and119887 = minus006952 Jkg K2 for the liquid

The thermal diffusivity for themodel is 21sdot10minus7m2s [20]while the experimental values range from 120 sdot 10

minus7m2s [21]to the recent value 87sdot10minus7m2s [22] (obtained inmicrograv-ity conditions)The value obtained from simulations is at least4 times lower than that in experiments and the differenceis due to the electronic contribution to thermal transportin metals which are not accounted in classical moleculardynamics

The melting temperature of the model is precisely esti-mated from simulations of inhomogeneous solid-liquid sys-tem at the point where the velocity of growth is zero For themodel 119879

119898= 1748K

The kinetic coefficient is estimated from linear relation-ship between planar growth velocity and undercooling closeto coexistence Growth velocities are obtained from inde-pendent simulations for the crystal orientations [100] [110]and [111] The kinetic growth coefficient depends also onthe orientation of the crystal Its orientational dependence isrepresented here by the expansion

119896 (119899)

1198960

= 1 minus 3120598119896+ 4120598119896119876 + 120575

119896(119875 + 30119878) (1)

with 119876 = 1198994

1+ 1198994

2+ 1198994

3 119875 = 119899

6

1+ 1198996

2+ 1198996

3 and 119878 = 119899

2

11198992

21198992

3

119899 = (1198991 1198992 1198993) is the unit vector normal to the interface

The parameter 1198960is a value of the magnitude of the kinetic

coefficient 120598119896and 120575119896are the strength of the anisotropy of the

kinetic coefficient The values for the model EAM F85 are1198960

= 0319205msK 120598119896

= minus0196511 and 120575119896

= 0230331estimated from the kinetic coefficients for different crystalorientations 119896

100= 033msK 119896

110= 023msK and 119896

111=

012msKThe interfacial stiffness and interfacial free energy were

obtained from the analysis of capillary waves spectrum oflarge solid-liquid interfaces at coexistence (ie at 119879 = 119879

119898for

119875 = 0) The orientational dependence of the interfacial freeenergy 120574 is described by a cubic harmonic expansion

120574 (119899)

1205740

= 1 + 1205981(119876 minus

3

5) + 1205982(3119876 + 66119878 minus

17

7)

+ 1205983(51198762minus 16119878 minus

94

13119876 +

33

13)

(2)

with 1205740being an orientational averaged value of the interfacial

free energy while the coefficients 120598119894describe the strength of

the anisotropy Interfacial stiffness is defined as 120574120572120573

= 120574 +

1205972120574120597119899120572120597119899120573 where 119899

120572and 119899120573indicate unit vectors tangent to

the interface plane [23] The parameters of (2) are obtainedfrom the system of equations for the stiffnesses 120574

120572120573and

their numerical values are obtained from the analysis of thecapillary waves spectrum [14] Here we consider the crys-tal orientations [100] [110]

[110] [110]

[001] and [111] the

interface energy for the [110] orientation depends on theparallel direction denoted by the subscripts In respect to thefour different interface energies we used a cubic harmonicexpansion with four fitting parameters Accurate values ofthese variables and parameters for the model EAM F85 are1205740

= 0302 Jm2 1205981

= 010191 1205982

= minus000134 and 1205983

=

000876

3 Phase-Field Model for Pure Material

Isothermal crystal growth for purematerial is modeled by thevariables of the internal energy density 119890 and of two phase-fields 0 le 120601s le 1 (solid) and 0 le 120601

ℓle 1 (liquid) The

phase-field variables fulfill the constraint 120601s + 120601ℓ

= 1 so asingle phase-field variable 120601 = 120601s is sufficient to describe theevolution of the phase boundaries in the system Note that120601ℓ= 1 minus 120601 The variable 120601( 119905) denotes the local fraction at

of the considered phase at time 119905The phase-field model is based on an entropy functional

to ensure consistency with classical irreversible thermody-namics

S (119890 120601) = intΩ

119904 (119890 120601) minus (120598119886 (120601 nabla120601) +1

120598119908 (120601)) 119889119909 (3)

The bulk entropy density 119904 depends on the internal energydensity 119890 and the phase-field variable 120601( 119905) The functions119886(120601 nabla120601) and 119908(120601) reflect the thermodynamics of the inter-faces and 120598 = 4 is a small length scale parameter related tothe thickness of the diffuse interface

In detail the gradient entropy with anisotropy is adoptedfrom (2) andmodeled by the factor (119860(119899))

2 depending on theorientation of the interface Consider the following

119886 (120601 nabla120601) =1205740

119879(119860 (119899))

21003816100381610038161003816nabla12060110038161003816100381610038162

= 120574 (119899)1003816100381610038161003816nabla120601

10038161003816100381610038162

(4)

where 119899 = minusnabla120601|nabla120601| is the normalized gradient vectorThe function120596(120601) = (16120587

2)(1205740119879)120601(1minus120601) is the obstacle

potential It is set that120596(120601) = infin for 120601 notin [0 1] Note that 1205740119879

is the interface entropy density

The Scientific World Journal 3

From (3) one derives the equations for the nonconservedphase-field variable 120601 by taking the functional derivatives inthe form

120591120598120597120601

120597119905=

120575S

120575120601 (5)

where 120591 = 120591(120601 nabla120601) is an anisotropic relaxation parameterdependant on temperature 120591(119899) = 119871(119879)119879119879

119898119896(119899) with (1)

and it is related to the kinetic coefficient 1198960

The evolution of the phase-field variables is described by

120591120598120597120601

120597119905= 120598(nabla sdot

120597119886 (120601 nabla120601)

120597nabla120601minus

120597119886 (120601 nabla120601)

120597120601) minus

1

120598

120597119908 (120601)

120597120601

+120597119904 (119890 120601)

120597120601

(6)

The thermodynamic relation 119890 = 119891+119879119904 gives us 120597119904(119890 120601)120597120601 =

minus(1119879)(120597119891(119879 120601)120597120601) detailed in [24] Here is the bulk freeenergy density

119891 (119879 120601) = sum

120572isinsℓ119871120572(119879)

119879 minus 119879119898

119879119898

ℎ (120601120572)

+ sum

120572isinsℓ(int

119879

119879119898

119904120572

V () 119889minus119879int

119879

119879119898

119904120572

V ()119889

) ℎ (120601

120572)

(7)

where ℎ(120601) is a monotonous function on [0 1] with ℎ(0) =

0 ℎ(1) = 1 and ℎ1015840(0) = ℎ

1015840(1) = 0 We chose ℎ(120601) =

1206013(61206012minus 15120601 + 10) 119871120572(119879) is the latent heat and 119904

120572

V (119879) =

120588120572(119879)119888120572

V (119879) is the volumetric heat capacity both dependingon the temperature 119879 119879

119898is the melting temperature

For the isothermal case we can define two constants119891(119879 120601) = sum

120572isinsℓ 119862120572

119879ℎ(120601120572) and consider here that the

free energy contribution to the equation of motion (6) is aconstant term 120597119891120597120601 = (119862

s119879

minus 119862ℓ

119879)ℎ1015840(120601) note that ℎ

1015840(120601s) =

minusℎ1015840(120601ℓ)

Equation (6) is solved by a time dependent forward eulerschemewith a second order spatial discretisation on a regularCartesian grid

4 Initial Configuration and Calibration

41 Preparation of the Sample Growth simulations beginfrom a configurationmade of a stabilized crystalline sphericalcluster embedded in the melt The preparation of the initialconfiguration involves a sequence of NpT simulation runsFirst the crystalline solid phase is equilibrated at 119901 = 0

starting from atoms arranged in a perfect fcc structure in acubic box with an initial density close to the experimentalvalue at room temperature (120588 = 89 gcm3) The temperaturein this step is chosen equal to the one used later in the sim-ulation of growth In the second step two regions are definedin the simulation box the melting zone and the atoms in thecrystalline phase (which is chosen here as a sphere of radius119903 = 25 A) The region outside the crystalline zone is melted

by increasing the temperature well above the melting pointwhile the atoms in the solid region are constrained to remainat fixed positionsThe temperature is linearly increased whilean isotropic barostat is applied In the next step the stablemelt at high temperature is cooled down to the temperatureof the crystal The melt reaches a metastable (undercooled)state At the end of this run a crystalline cluster embedded inthe liquid phase at the same temperature is obtained In thelast step the relaxation of the atoms at the interface ismade byanNpT simulation of some picoseconds in which all particlesare allowed to move

42 Local Order Parameter At microscopic level a configu-ration is described by positions and velocities of particles ata given time The crystalline and liquid regions in this con-figuration can be identified by a suitable definition of thelocal order parameter a function of the coordinates of aparticle and its neighbors which adopts different values in thecrystalline and in the disordered liquid phases Here we usethe bond local order parameter 119902

61199026[25 26]

11990261199026(119894) =

1

119885119894

119885119894

sum

119895=1

q6(119894) sdot q6(119895) (8)

The inner product in this sum is given by

q6(119894) sdot q6(119895) =

6

sum

119898=minus6

1199026119898

(119894) 1199026119898

(119895)lowast (9)

with

1199026119898

(119894) = 1198766119898

(119894) (

6

sum

119898=minus6

100381610038161003816100381610038161198766119898

(119894)10038161003816100381610038161003816

2

)

minus12

(10)

where 1198766119898

(119894) = (1119885119894) sum119885119894

119895=11198846119898

(120579( 119903119894119895) 120601( 119903119894119895)) 119885119894is the

number of neighboring atoms within a cut-off radius of336 A and 119884

6119898are 6th order spherical harmonic functions

In order to obtain an equivalent initial configuration forthe PFmethod the local order parameter values given at atompositions are mapped on a regular grid with cell-width of1 A The order parameter in a given grid point is given bythe average of all particles contained in cell u = (119894 119895 119896) andits first two neighbor cells k = (119898 119899 119897) with |u minus k| lt 2

The order parameter values obtained from MD simula-tion were scaled so that the volume of the crystal cluster isequal in the coarse-grained and in the original initial config-urations The distribution of the order parameter in the bulkphases is Gaussian centered at 120583 with standard deviation 120590The definition of order parameter in the phase-field methodis as follows 120601 = 0 if 119902

61199026

lt 119886 = 120583ℓminus 2120590ℓ and 120601 = 1 if

11990261199026gt 119887 = 120583s + 2120590s and 120601 = (119902

61199026minus 119886)(119887 minus 119886) otherwise

43 Planar Growth An analytic formulation of the phase-field method in the sharp interface limit assumes a temper-ature gradient at the interface The formulation reads

Δ119879 = 120573V + 120581Γ (11)

4 The Scientific World Journal

Table 1 Kinetic coefficient of Ni inmsK frommolecular-dynamicssimulations and phase-field simulation

Interface From (1) PF Sun et al [12][100] 033 032 0358 plusmn 0022

[110] 023 021 0255 plusmn 0016

[111] 012 011 0241 plusmn 004

here Δ119879 denotes the undercooling in the interface V is thevelocity and 120573 is a kinetic coefficient The curvature 120581 of atwo dimensional interface is the sum of the two principalcurvatures 1119903

1 11199032 so 120581 = 2119903 if 119903

1= 1199032

= 119903 The Gibbs-Thomson-coefficient Γ = 120590119879119871 with 120590 surface tension and 119871

being the latent heatIn equilibrium that is for V = 0 (11) reads as Δ119879 = 120581Γ =

Γ119903 (in 2D) It follows that the critical radius 119903119888

= ΓΔ119879 Asmall spherical cluster with radius 119903

119888is in equilibrium For

example at119879 = 1550K the critical radius 119903119888= 97 A A cluster

smaller than 119903119888meltsThephase-field simulations corroborate

this result for 119879 = 1550K the nucleus grows for 119903 = 10 A andmelts for 119903 = 95 A

For a planar interface (11) is simplified to Δ119879 = 120573V takingaccount of the absence of curvature The kinetic coefficientadapted from MD is 119896 = 1120573 So the phase-field relaxationparameter is

120591 (119899) =119871 (119879)

119879119879119898119896 (119899)

=1205910

119896 (119899) (12)

Simulations of a planar front in comparison to theanalytic solution and molecular dynamics simulations areshown in Figure 1 Additionally we list the kinetic coefficientin Table 1 Both methods converge at low undercooling tothe solution given by (11) At higher undercooling velocitiesobtained from PF simulations still exhibit a linear depen-dence with undercooling Δ119879 this is given in the range from1400K to 119879

119898 the fit of the kinetic coefficient is made in this

range and agrees with the expected kinetics from (1)The MD simulations indicate that this linearity is not

more valid the velocity is lower than that expected fromextrapolation of the linear relation V

119868= 119896Δ119879 This effect can

also be recognized in the results of Hoyt et al [15] Manyeffects influence the growth velocity of MD at higher under-cooling with the increase of order in the liquid bulk beingthe most important which leads to the formation of smallcrystalline clusters in the bulk liquid The phase-field showsthis nonlinearity only for very high undercoolings Δ119879 gt

500K

5 Spherical Cluster Growth

Growth simulations starting from the samples preparedas described in Section 41 are performed using both MDand PF methods At microscopic level NpT simulationsare performed at 119901 = 0 using the Andersen thermostat andbarostat The number of particles is 119873 = 256000 whichcorresponds to a cubic box of length of about 145 A Theinitial radius of the spherical crystalline cluster is 25 A whichcorresponds to about 55 sdot 10

3 particles (see Figure 2(a))

that is much larger than the size of the critical cluster at119879 = 1500K which is made of about 103 particles [27] For119879 ge 1600K the initial size of the cluster is lower than thecritical value and it melts as expected PF simulations areperformed imposing the isothermal condition starting withthe same configuration as in MD but converted as describedin Section 42 Results for the evolution of the cluster volumeare shown in Figure 3 snapshots from the MD and PFsimulations are shown in Figure 2 Atmoderate undercooling(119879 gt 1550K) the MD and PF show comparable growth ratesFor higher undercooling the growth in the phase-field modelis notably faster than in the MD method The discrepancybecomes more pronounced at lower temperature and highersimulation time Assuming that the cluster conserves itsspherical shape during the first stage of growth we definethe radius as 119903 = (31198814120587)

13 and the radial velocity as V =

119889119903119889119905 Figure 4 shows the evolution of radial velocity in theMD simulation three regimes can be identified initially thevelocity tends to decrease then exhibits a linear increaseand finally decreases again The first decrease is due to thepreparation method of the sample the system relaxes whilethe interface is formed Growth and relaxation cannot bedecoupled both occur simultaneously in this initial regimeIn the second regime the growth velocity increases linearlyin time The decrease of velocity in the last regime is due tothe finite size of the sample when the cluster is large enoughit interacts with its periodic images through the periodicboundaries of the simulation box and loses its sphericalshape In the PF simulation no extra relaxation regime isobserved the dynamic is determined by the initial definitionafter the interface is relaxated Moreover in the PF the clusteris not affected by finite size effects as in the MD simulationsince no periodic boundaries are required In comparison thePF exhibits an apparent linear increase from the beginningThis means that the starting radius of the nucleus is not thesame for both simulation methods so a comparison for thesame radius instead of the time is more adequate Figure 5shows the radial velocity versus cluster radius at differenttemperatures Results obtained from PF simulations are welldescribed by Gibbs-Thomson equation (11) The analyticalvelocity is V = 119896avg(Δ119879 minus 2Γ119903) So we use 119881

119879(119903) = 119886

119879+

119887119879119903 to fit the data with the parameters 119886

119879and 119887119879for each

temperature 119879 We applied the fit in the region startingwith 119903 = 30 A where the PF has relaxated the interfaceThese fits are also applied for the MD results in the secondregime of growth that is for crystalline clusters of size ofabout 40 A ≾ 119903 ≾ 60 A (the points in Figure 5) Accordingto the Gibbs-Thomson equation the radial velocity reaches anasymptotic value (V

119879infin= V119879119903rarrinfin

) an ideal situation wherethe cluster is large enough and conserves its shape This limitcannot be directly obtained from simulations first becausethe simulations are performed in a finite volume and alsobecause the crystalline cluster would adopt a nonsphericalshape due to the anisotropy of the interfacial energy andgrowth coefficient We estimate this hypothetical limit as abasis of comparison between the PF andMD simulations Forthis purpose we extrapolate the fit and obtain V

119879infin= 119886119879

one value is obtained at each temperature The asymptotic

The Scientific World Journal 5

0

50

100

150

200

250

1000 1100 1200 1300 1400 1500 1600 1700

Gro

wth

velo

city

(ms

)

Temperature (K)

PFFitted PFSun et al

Hoyt et al

MDk100ΔT

(a) [100]

0

50

100

150

200

250

1000 1100 1200 1300 1400 1500 1600 1700

Gro

wth

velo

city

(ms

)

Temperature (K)

PFFitted PFSun et al

Hoyt et alk110ΔT

(b) [110]

0

50

100

150

200

250

1000 1100 1200 1300 1400 1500 1600 1700

Gro

wth

velo

city

(ms

)

Temperature (K)

PFFitted PFSun et al

Hoyt et alk111ΔT

(c) [111]

PF [100]PF [110]PF [111]

Fitted [100]Fitted [110]Fitted [111]

0

50

100

150

200

250

1000 1100 1200 1300 1400 1500 1600 1700

Gro

wth

velo

city

(ms

)

Temperature (K)

(d) Phase-field

Figure 1 Growth velocity of a planar front at different temperatures for the interface orientations (a) [100] (b) [110] and (c) [111] in com-parison to molecular dynamic results The values of the kinetic coefficient can be found in Table 1 (d) shows the phase-field results for allorientations

radial velocities obtained from the PF and MD simulationsare shown in Figure 6 The results of both methods liebetween the linear relations V

100= 119896100

Δ119879 and V111

=

119896111

Δ119879 For the MD the results show a similar behavioras observed in the planar growth case the deviation fromthe linear relation at high undercooling observed in the PFsimulations is due to the correction introduced in the kineticcoefficient As shown in Section 43 the crystal grows indifferent crystal orientations with a different velocity In thePF the kinetic anisotropy is responsible for this The planarfront simulations fromFigure 1 show that the kinetics are very

well reproducible from the PF simulations If we assume thatwe have a perfect sphere the mean kinetic can be calculatedas a surface area integral of the unit sphere over the kineticcoefficient we get 119896avg = int

1198782119896(119899)119889119860 int

11987821119889119860 asymp 0175 So

V(Δ119879) = 119896avgΔ119879 is the excepted growth velocity for a sphereit is shown as the solid line in Figure 6

At this early stage of growing the crystal is very similar toa sphere The preferred growing in [100] directions and thesurface anisotropy formed the crystal to its equilibriumshape for Ni this is similar to an octahedron in the limitthis shape has only [111] directions So the area of the [100]

6 The Scientific World Journal

(a) (b) (c) (d)

(e) (f) (g) (h)

Figure 2 Snapshots of the simulations at 1550K MD simulations at (a) initial time 80 ps (c) 100 ps and (d) 220 ps The evolution of thecrystalline cluster from PF simulations with the same volume is shown in the sequence from (e) to (h)

0

2

4

6

8

10

12

0 50 100 150 200

PFPFPFPFPFPF

t (ps)

V(105

3)

1400K MD1450K MD1500K MD1525K MD1550K MD1575K MD

A

Figure 3 Evolution of the crystalline cluster volume at differenttemperatures MD results are the average over 8 independent simu-lation runs

orientations shrinks and the area of the [111] orientationsincreases it follows that the growth rate is between 119896avg and119896111

specially below 119896avg

0

10

20

30

40

0 50 100 150 200t (ps)

=drdt

(ms

)

MD 1400KMD 1450KMD 1500K

MD 1525KMD 1550KMD 1575K

Figure 4 Evolution of the radial velocity at different temperaturesobtained fromMD simulations

We use the sphericity 119904 as the measure for the sphericalityof the crystal as follow For a given volume 119881 and a givensurface area 119878 of the crystal we calculate the radius 119903

3=

31198814120587 from the volume assuming a sphere and calculate thesurface area 119878

119881= 4120587119903

2 for a sphere Then 119904 = 119878119881119878 [28]

The volume of the crystal is defined as 119881 = intΩ120601119889119881

and the surface area as 119878 = intΩnabla120601119889119881 this surface

The Scientific World Journal 7

0

10

20

30

40

50

60

30 35 40 45 50 55 60

=drdt

(ms

)

MD 1400KMD 1450KMD 1500K

MD 1525KMD 1550KMD 1575K

r (A)

(a)

PF 1400KPF 1450KPF 1500K

PF 1525KPF 1550KPF 1575K

0

10

20

30

40

50

60

30 35 40 45 50 55 60

=drdt

(ms

)

r (A)

(b)

Figure 5 Evolution of the radial velocity at different temperatures Molecular dynamic (a) and phase-field (b) In lines the fits V119879(119903) =

119886119879+ 119887119879119903

0

10

20

30

40

50

60

70

80

1350 1400 1450 1500 1550 1600 1650 1700 1750T (K)

PFMD

=drdt

(ms

)

k100ΔT

k111ΔT

k110ΔT

kavgΔT

Figure 6 Asymptotic radial velocity versus temperature Valuesof Vinfin

are obtained from the asymptotic limit of the fits shown inFigure 5

area measurement method assumes a smooth nondeformedinterface this is not given for PF interfaces if there are drivingforces like curvatures and undercoolings We use a factorestimated for a sphere of radius 25 A to correct this Thesurface area is multiplied by this factor 1089

Figure 7 shows the sphericity over the radius the crystalbecomes non spherical for longer growing and faster forhigher undercoolingsThismeans that the velocity of growing

095

096

097

098

099

1

25 30 35 40 45 50 55 60 65

1400K1450K

1500K1550K

Radius

Sphe

ricity

s

r (A)

Figure 7 Sphericity of the crystal for different undercoolings Thecontour shows the shape of the [100] cutting plane through thecenter of the crystal for 119879 = 1400K and 1550K

is below 119896avg especially for higher undercoolings The non-spherical shape is shown in Figure 2(h)

6 Conclusion

Many have shown the linking between MD and PF [16 17]So it is a common way to obtain MD parameters for PFsimulations The PF simulations on the natural PF scale forexample mesoscopic scale produce correct results compared

8 The Scientific World Journal

with experiments [29 30] We have confirmed that a PF withMD parameters is correct even on the atomistic scale This isnot surprising since we are very close to the sharp interfacelimitsThemesoscopic view at the atomistic scale provides thesame growth rates as an atomic simulation method althoughthe atoms are not resolved in the PF The fluctuations of theinterface on the atomistic length scale will be investigated ina consecutive work

However you will not simulate too high undercooledmelts where the mesoscopic view of the PF will not considerall the nonlinearity from the MD interface We have used thesphericity to measure the shape and explain the discrepancyto the analytic linear velocity

While it is known that PF works correctly on mesoscopicscale and with this study it is shown that PF also works onthe atomistic scale one is able to do multiscale simulationsstarting on the atomistic scale with one simulation method

Acknowledgments

The authors gratefully acknowledge the financial supportby the German Research Foundation (DFG) in the PriorityProgramSPP 1296They like to thank JHorbach andR Rozasfrom Heinrich Heine University of Dusseldorf for providingthe MD data

References

[1] L-Q Chen ldquoPhase-field models for microstructure evolutionrdquoAnnual Review of Materials Science vol 32 no 1 pp 113ndash1402002

[2] W J Boettinger J A Warren C Beckermann and A KarmaldquoPhase-field simulation of solidificationrdquo Annual Review ofMaterials Science vol 32 no 1 pp 163ndash194 2002

[3] A Karma andW-J Rappel ldquoQuantitative phase-field modelingof dendritic growth in two and three dimensionsrdquo PhysicalReview E vol 57 no 4 pp 4323ndash4349 1998

[4] B Nestler H Garcke and B Stinner ldquoMulticomponent alloysolidification phase-field modeling and simulationsrdquo PhysicalReview E vol 71 no 4 Article ID 041609 2005

[5] L Granasy T Pusztai and J A Warren ldquoModelling polycrys-talline solidification using phase field theoryrdquo Journal of PhysicsCondensed Matter vol 16 no 41 pp R1205ndashR1235 2004

[6] A Karma ldquoPhase-field model of eutectic growthrdquo PhysicalReview E vol 49 no 3 pp 2245ndash2250 1994

[7] B Nestler and A A Wheeler ldquoA multi-phase-field model ofeutectic and peritectic alloys numerical simulation of growthstructuresrdquo Physica D vol 138 no 1-2 pp 114ndash133 2000

[8] B Nestler A A Wheeler L Ratke and C Stocker ldquoPhase-fieldmodel for solidification of a monotectic alloy with convectionrdquoPhysica D vol 141 no 1-2 pp 133ndash154 2000

[9] M F Zhu andC PHong ldquoAmodified cellular automatonmodelfor the simulation of dendritic growth in solidification of alloysrdquoISIJ International vol 41 no 5 pp 436ndash445 2001

[10] P Zhu and RW Smith ldquoDynamic simulation of crystal growthby Monte Carlo method-I Model description and kineticsrdquoActaMetallurgica etMaterialia vol 40 no 4 pp 683ndash692 1992

[11] M Plapp and A Karma ldquoMultiscale finite-difference-diffusionMonte-Carlo method for simulating dendritic solidificationrdquoJournal of Computational Physics vol 165 no 2 pp 592ndash6192000

[12] D Y Sun M Asta and J J Hoyt ldquoKinetic coefficient of Nisolid-liquid interfaces from molecular-dynamics simulationsrdquoPhysical Review B vol 69 no 2 Article ID 024108 2004

[13] A Kerrache J Horbach and K Binder ldquoMolecular-dynamicscomputer simulation of crystal growth andmelting inAl

50Ni50rdquo

EPL vol 81 no 5 Article ID 58001 2008[14] R E Rozas and J Horbach ldquoCapillary wave analysis of rough

solid-liquid interfaces in nickelrdquo EPL vol 93 no 2 Article ID26006 2011

[15] J J Hoyt M Asta and A Karma ldquoAtomistic and continuummodeling of dendritic solidificationrdquo Materials Science andEngineering R vol 41 no 6 pp 121ndash163 2003

[16] J Bragard A Karma Y H Lee and M Plapp ldquoLinking phase-field and atomistic simulations tomodel dendritic solidificationin highly undercooled meltsrdquo Interface Science vol 10 no 2-3pp 121ndash136 2002

[17] B Nestler M Selzer and D Danilov ldquoPhase-field simulationsof nuclei and early stage solidification microstructuresrdquo Journalof Physics Condensed Matter vol 21 no 46 Article ID 4641072009

[18] G Tegze T Pusztai G Toth et al ldquoMultiscale approach to CO2

hydrate formation in aqueous solution phase field theory andmolecular dynamics Nucleation and growthrdquo The Journal ofChemical Physics vol 124 no 23 Article ID 234710 2006

[19] S M Foiles ldquoApplication of the embedded-atom method toliquid transition metalsrdquo Physical Review B vol 32 no 6 pp3409ndash3415 1985

[20] R E Rozas and J Horbach ldquoA comparison of EAM models ofNi close to the melting temperaturerdquo Submitted

[21] V Y Zinovrsquoyev V F Polev S G Taluts G P Zinovrsquoyeva and SA Ilrsquoinykh ldquoDiffusivity and thermal conductivity of 3D-tran-sition metals in solid and liquid statesrdquo Physics of Metals andMetallography vol 61 no 6 pp 85ndash92 1986

[22] K Nagata H Fukuyama K Taguchi H Ishii and M HayashildquoThermal conductivity of molten Al Si and Ni measured undermicrogravityrdquo High Temperature Materials and Processes vol22 no 5-6 pp 267ndash273 2003

[23] J J Hoyt M Asta T Haxhimali et al ldquoCrystal-melt interfacesand solidification morphologies in metals and alloysrdquo MRSBulletin vol 29 no 12 pp 935ndash939 2004

[24] H Garcke B Nestler and B Stinner ldquoA diffuse interface modelfor alloys with multiple components and phasesrdquo SIAM Journalon Applied Mathematics vol 64 no 3 pp 775ndash799 2004

[25] P J Steinhardt D R Nelson and M Ronchetti ldquoBond-orientational order in liquids and glassesrdquo Physical Review Bvol 28 no 2 pp 784ndash805 1983

[26] P R tenWoldeM J Ruiz-Montero andD Frenkel ldquoNumericalevidence for bcc ordering at the surface of a critical fcc nucleusrdquoPhysical Review Letters vol 75 no 14 pp 2714ndash2717 1995

[27] J Bokeloh R E Rozas J Horbach and G Wilde ldquoNucleationbarriers for the liquid-to-crystal transition in Ni experimentand simulationrdquo Physical Review Letters vol 107 no 14 ArticleID 145701 2011

[28] H Wadell ldquoVolume shape and roundness of quartz particlesrdquoThe Journal of Geology vol 43 no 3 pp 250ndash280 1935

[29] B Echebarria R Folch A Karma and M Plapp ldquoQuantitativephase-fieldmodel of alloy solidificationrdquo Physical Review E vol70 no 6 Article ID 061604 2004

[30] S Gurevich A Karma M Plapp and R Trivedi ldquoPhase-field study of three-dimensional steady-state growth shapesin directional solidificationrdquo Physical Review E vol 81 no 1Article ID 011603 2010

Submit your manuscripts athttpwwwhindawicom

ScientificaHindawi Publishing Corporationhttpwwwhindawicom Volume 2014

CorrosionInternational Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Polymer ScienceInternational Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

CeramicsJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

CompositesJournal of

NanoparticlesJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

International Journal of

Biomaterials

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

NanoscienceJournal of

TextilesHindawi Publishing Corporation httpwwwhindawicom Volume 2014

Journal of

NanotechnologyHindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Journal of

CrystallographyJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

The Scientific World JournalHindawi Publishing Corporation httpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

CoatingsJournal of

Advances in

Materials Science and EngineeringHindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Smart Materials Research

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

MetallurgyJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

BioMed Research International

MaterialsJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Nano

materials

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Journal ofNanomaterials

The Scientific World Journal 3

From (3) one derives the equations for the nonconservedphase-field variable 120601 by taking the functional derivatives inthe form

120591120598120597120601

120597119905=

120575S

120575120601 (5)

where 120591 = 120591(120601 nabla120601) is an anisotropic relaxation parameterdependant on temperature 120591(119899) = 119871(119879)119879119879

119898119896(119899) with (1)

and it is related to the kinetic coefficient 1198960

The evolution of the phase-field variables is described by

120591120598120597120601

120597119905= 120598(nabla sdot

120597119886 (120601 nabla120601)

120597nabla120601minus

120597119886 (120601 nabla120601)

120597120601) minus

1

120598

120597119908 (120601)

120597120601

+120597119904 (119890 120601)

120597120601

(6)

The thermodynamic relation 119890 = 119891+119879119904 gives us 120597119904(119890 120601)120597120601 =

minus(1119879)(120597119891(119879 120601)120597120601) detailed in [24] Here is the bulk freeenergy density

119891 (119879 120601) = sum

120572isinsℓ119871120572(119879)

119879 minus 119879119898

119879119898

ℎ (120601120572)

+ sum

120572isinsℓ(int

119879

119879119898

119904120572

V () 119889minus119879int

119879

119879119898

119904120572

V ()119889

) ℎ (120601

120572)

(7)

where ℎ(120601) is a monotonous function on [0 1] with ℎ(0) =

0 ℎ(1) = 1 and ℎ1015840(0) = ℎ

1015840(1) = 0 We chose ℎ(120601) =

1206013(61206012minus 15120601 + 10) 119871120572(119879) is the latent heat and 119904

120572

V (119879) =

120588120572(119879)119888120572

V (119879) is the volumetric heat capacity both dependingon the temperature 119879 119879

119898is the melting temperature

For the isothermal case we can define two constants119891(119879 120601) = sum

120572isinsℓ 119862120572

119879ℎ(120601120572) and consider here that the

free energy contribution to the equation of motion (6) is aconstant term 120597119891120597120601 = (119862

s119879

minus 119862ℓ

119879)ℎ1015840(120601) note that ℎ

1015840(120601s) =

minusℎ1015840(120601ℓ)

Equation (6) is solved by a time dependent forward eulerschemewith a second order spatial discretisation on a regularCartesian grid

4 Initial Configuration and Calibration

41 Preparation of the Sample Growth simulations beginfrom a configurationmade of a stabilized crystalline sphericalcluster embedded in the melt The preparation of the initialconfiguration involves a sequence of NpT simulation runsFirst the crystalline solid phase is equilibrated at 119901 = 0

starting from atoms arranged in a perfect fcc structure in acubic box with an initial density close to the experimentalvalue at room temperature (120588 = 89 gcm3) The temperaturein this step is chosen equal to the one used later in the sim-ulation of growth In the second step two regions are definedin the simulation box the melting zone and the atoms in thecrystalline phase (which is chosen here as a sphere of radius119903 = 25 A) The region outside the crystalline zone is melted

by increasing the temperature well above the melting pointwhile the atoms in the solid region are constrained to remainat fixed positionsThe temperature is linearly increased whilean isotropic barostat is applied In the next step the stablemelt at high temperature is cooled down to the temperatureof the crystal The melt reaches a metastable (undercooled)state At the end of this run a crystalline cluster embedded inthe liquid phase at the same temperature is obtained In thelast step the relaxation of the atoms at the interface ismade byanNpT simulation of some picoseconds in which all particlesare allowed to move