Research Article Measuring the Biodegradability of Plastic...

Transcript of Research Article Measuring the Biodegradability of Plastic...

Research ArticleMeasuring the Biodegradability of Plastic Polymers inOlive-Mill Waste Compost with an Experimental Apparatus

Francesco Castellani12 Alessandro Esposito1 Vitale Stanzione1 and Roberto Altieri1

1Consiglio Nazionale delle Ricerche Istituto per i Sistemi Agricoli e Forestali del Mediterraneo Via Madonna Alta 12806128 Perugia Italy2Chair of Production and Logistics Georg-August-Universitat Gottingen Platz der Gottinger Sieben 3 37073 Gottingen Germany

Correspondence should be addressed to Roberto Altieri robertoaltiericnrit

Received 18 August 2016 Accepted 18 October 2016

Academic Editor Peter Chang

Copyright copy 2016 Francesco Castellani et al This is an open access article distributed under the Creative Commons AttributionLicense which permits unrestricted use distribution and reproduction in any medium provided the original work is properlycited

The use of biodegradable polymers is spreading in agriculture to replace those materials derived from petroleum thus reducingthe environmental concerns However to issue a significant assessment biodegradation rate must be measured in case-specificstandardized conditions In accordance with ISO 14855-1 we designed and used an experimental apparatus to evaluate thebiodegradation rate of three biopolymers based on renewable resources two poly(120576-caprolactone) (PCL) composites and acompatibilized polylactic acid and polybutyrate (PLAPBAT) blend Biodegradation tests were carried out under compostingcondition using mature olive-mill waste (OMW) compost as inoculum Carbon dioxide emissions were automatically recordedby infrared gas detectors and also trapped in saturated Ba(OH)

2solution and evaluated via a standard titration method to check

the results Some of the samples reached more than 80 biodegradation in less than 20 days Both the experimental apparatus andthe OMW compost showed to be suitable for the cases studied

1 Introduction

In the last years the worldwide production of plastic wastehas increased enormously [1] Following the motto ldquoReduce-Reuse-Recyclerdquo European directives have therefore estab-lished plastic waste recovery as the first choice in the wastemanagement hierarchy [2] Consequently industries are pay-ing increased attention to innovative materials that can berecycled or biodegraded at the end of their life-cycle

Ever since a first generation of degradable plastics wasintroduced in the 1980s [3] researchers have been attemptingto evaluate the authentic biodegradability of these products[4] Today the global competition to produce biodegradablematerials is attracting the attention of a variety of scientificbranches and commercial sectors (food packaging and agro-industries) and it has become even more crucial to identifythe true biodegradability of new goods put on the marketmdashsome of which are merely self-proclaimed ldquobiodegradablerdquoBiodegradation results from the action of naturally occurringheterotrophic microorganisms such as bacteria and fungi

These use biodegradable compounds as food convertingthem into metabolic by-products that have chemical struc-tures remarkably different than the original materials [5]

To evaluate the biodegradability of biopolymers differentstandard methods have been defined [6 7] These are basedmainly on measuring carbon dioxide (CO

2) emissions or

oxygen consumption under environmentally controlled con-ditions [8] Based on these standard methods several exper-imental apparatus have even been proposed Jayasekara et al[9] for instance developed a CO

2monitoring system able to

manage up to 36 vessel outlets Subsequently Kijchavengkulet al [10] also tested their own respirometric apparatusAnd more recently Pantani and Sorrentino [11] carriedout biodegradation tests using a homemade respirometricmachine equipped with 3 L glass flasks and an infrared gasanalyser However very few studies checked their equipmentwith other methods [12] and analysed different kinds of plas-tics in the same conditions [13]

Previous literature and our experience in prototyping[14] laid the foundations for our design of an experimental

Hindawi Publishing CorporationAdvances in Materials Science and EngineeringVolume 2016 Article ID 6909283 7 pageshttpdxdoiorg10115520166909283

2 Advances in Materials Science and Engineering

Temp transducer

Inlet air

Pressuretransducer

scrubbers

Vessels(up to 12)

Sample

12 needle valves

Manifold(up to 12 valves)

Filters

Fresh air

Outlet air

Watercondenser

Dryer

Humidifiers(up to 12)

Water

Drainvalve

Vent

Flow meter

Method 2Titration test

Temperaturetransducer

Method 1

CO2

Thermostated chamber (58∘C)

Ba(OH)2

CO2 evolved

IRGA1 IRGA2

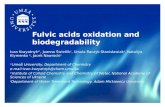

Figure 1 Schematic diagram of the experimental apparatus CO2evolved (method 1) and titration test (method 2) are used to evaluate the

biodegradation of samples

apparatus for evaluating the biodegradability of biopolymersusing OMW compost as inoculum

In this study we(i) describe in detail an experimental apparatus designed

and assembled to assess the biodegradation rate ofplastic materials under controlled composting condi-tions in accordance with the ISO 14855-12012 [15]

(ii) test the apparatus by evaluating with infrared gasanalysis (IRGA) the cumulative CO

2evolution of

three biopolymers made of renewable materials foragricultural applications

(iii) check the accuracy of the data by measuring theamount of CO

2released during biodegradation with

barium hydroxide Ba(OH)2 titration method

2 Materials and Methods

21 Apparatus The apparatus combines a pneumatic andan electric system In the pneumatic system compressed airis used to stimulate aerobic biodegradation of the sampleswhich are kept in air-tight closed vessels (bioreactors) andexposed to mature compost throughout the trials The com-post (called ldquoinoculumrdquo) rich in living microorganisms pro-motes the biodegradation of the samples thus producing

CO2 CO2measurements are performed on the exhausted

air by means of the appropriate IRGA sensors A customizedsoftware was developed in LabVIEW (National InstrumentsUSA) environment for the automatic control of the apparatusThe schematic diagram of the pneumatic system is shown inFigure 1 During trials the pressurized system ensures opti-mal aerobic conditions and prevents undesired anaerobic fer-mentation We used polymethylmethacrylate air-tight tubes(4mm internal diameter) for the pneumatic system and con-trolled pressure by means of a double-stage regulator (FestoAG amp Co Germany) Before entering the vessels air flowsinto a CO

2scrubber consisting of a series of two 2 L vessels

filled with soda lime (Sofnolime 2550USP Grade) By reduc-ing the inlet air CO

2concentration to about 10 ppm the CO

2

scrubber allows the exhausted air to ultimately match therange of measurement for the CO

2IRGA sensors used (sen-

sors described below)Weused a pressure transducer (DwyerGermany) to monitor the airflow and highlight possibleundesired pressure drops which are promptly displayed onvideo by the software CO

2-free air is distributed to the vessels

via needle valves which control the flowTwelve 2 L glass vessels are placed inside an environmen-

tal chamber (Gallenkamp UK) outfitted with a temperaturecontroller and equipped with a suitable passage for the air-tight tubes (Figure 2) The chamber temperature is also

Advances in Materials Science and Engineering 3

Figure 2 Environmental chamber of the experimental apparatus setat 58 plusmn 2∘C

Air-tight container

Coarse bubblediffuser

Filter

Cone-shaped cap

Holes

Figure 3 Prototyped arrangement for the vessels

recorded by means of a thermocouple type T (Tersid Italy)which is properly connected to the PC Each vessel isconnected in-line with another 2 L vessel containing distilledwater used to humidify the inlet air Both humidifiers andvessels are equipped with handmade coarse bubble diffusersThese are arranged in a circular scheme and contain multiplefine holes to permit uniform diffusion of the airflow (Fig-ure 3)

An outlet manifold equipped with low-power micro-solenoid-valves and placed inside the chamber to avoid watercondensation from the flowing air drives the air exhaustedfrom each vessel towards themeasuring line where the IRGAsensors are located Airflow blockage was prevented usingplastic filters of 90 120583mmesh (Preferred Products Design IncUSA) which were placed in-line on the flows escaping fromeach vessel The tube that drives exhausted air to IRGA sen-sors and located outside the chamber is thermally insulatedand reduced to a minimum length to prevent water fromcondense and undesired interference on the flow rate

A water condenser was placed in the measuring linebefore the IRGA sensors It is made of a copper serpentinecontaining a circulating liquid (mixture 1 1 vv water ethy-lene glycol) refrigerated by a cryostat (ScienceElectronicsUSA) to a temperature below the dew point inserted in poly-methylmethacrylate air-tight tubing the condensed water isautomatically discharged by gravity thanks to a solenoid valvethat opens periodically

A second in-line dryer consisting of a polymethylmetha-crylate air-tight tube (diameter 3 cm) containing granularcalcium chloride (SIGMA-Aldrich USA) removes the resid-ual moisture from the exhausted air before it enters theIRGA sensors Drying the exhaust air is necessary to ensure acorrect operation of the IRGA sensorsThe system is providedwith two sequential IRGA sensors for measuring the CO

2

concentration in the outflow air (method 1 Figure 1) a Ley-bold-Heraeus Binos (Germany) for measurements withinthe range 0ndash3000 ppm and an accuracy of 1 and aGascheck by Edinburgh Sensors (UK) for concentrations upto 100000 ppm and an accuracy of 3The IRGA sensors areautomatically switched in order to achieve the highest accu-racy of CO

2concentrationmeasurements andwere calibrated

using three certified mixes (SOL group Italy) of air contain-ingCO

2at known concentration (824 2970 and 80600 ppm)

After each CO2concentration measurement the line is

flushedwithCO2-free air At the end of the pneumatic circuit

adjacent to the IRGA sensors there is a gas mass flow meter(Dwyer Germany) with a flow range of 0ndash80 L hminus1 and anin-line thermocouple (Tersid Italy)Themass flowmeter wascalibrated using a soap bubble glass flow meter (500mL)following the procedure adopted by Levy [16] and the ther-mocouple calculates the CO

2concentration at Lab working

conditions To ensure the continuous and reliable measure-ment of all parameters the system was checked for gas leaksat each connection point using a diluted soap solution

Analog sensor signals are converted and recorded bymeans of a data logging system Here a computer monitorsthe results a bus-powered multifunction DAQ (NI USB-6009 National Instruments USA) acquires analog signalsand a digital output module (NI USB-6501 National Instru-ments USA) controls the solenoid valves via a multiple-relaymodule board

22 Software The automation and monitoring of all param-eters is performed by means of a customized software devel-oped within a LabVIEW environmentThe parameters mon-itored are inlet air pressure environmental chamber tem-perature CO

2concentration temperature and airflow rate

of the exhausted airAn appropriate measuringcleaning sequence is ensured

to monitor the parameters of the exhausted air Since thesequence lasts 20 minutes for each vessel a complete mea-surement cycle for 12 vessels lasts 4 hours thus providing 6series of data per day for each vessel

In the first 5min of each sequence (time required formea-sured signals to reach steady state) the air valve opens andthe detector is thus purged with CO

2-free air During the

cleaning cycle a drain valve located at the bottomof the watercondenser opens for 30 seconds to discharge the condensed

4 Advances in Materials Science and Engineering

water accumulated in the previous set of analyses Next thevalve associated with the selected vessel opens for 15 minuteswhile the air valve closes The exhaust air of the selectedvessel enters the infrared sensors until a steady state patternis reached In the last minute of this steady state phase thesoftware acquires the analog signals released every secondfrom each sensor and converts them into average values

Data for each sample is recorded plotted and displayedin final tables graphs and spreadsheetsThe software is struc-tured with a front panel that monitors the trial and showsthe results in real time possible errors occurring during thetrialmdashsuch as flow line blockage or unexpected temperatureor pressure line drops in the chambermdashare continuouslychecked by the software If called for a specific alarm signalappears on the screen for each vessel

23 Experimental Conditions In keepingwith severalmetho-dologies reported in the literature [17] our trials wereconducted in triplicate 3 vessels contained the inoculum3 vessels contained compost plus a reference biodegradablematerial (namely cellulose Sigma-Aldrich) and 3 vesselscontained compost plus specimen Since the apparatus coulddrive up to 12 vessels each trial involved two samples

We carried out two biodegradation trials on three bio-polymers two different poly(120576-caprolactone) (PCL) compos-ites (sample A and sample B) and a commercially availablecompatibilized polylactic acid and polybutyrate (PLAPBAT) blend (sample C ECOVIO IS 1335 BASF Germany)A polyethylene (PE) film (sample D) was used as negativereference Each vessel charge included 276 g of inoculum (wetweight) which filled about two-thirds of the internal volumeplus 23 g of the specimen or reference material (Table 1)Twenty-three g (dry weight) of agricultural perlite previouslyhumidified up to its maximum water retention (765)was added to each vessel to reduce the bulk density of theinoculum and provide better air circulation in it The plasticspecimenwasmilled (lt1mm) and thoroughlymixedwith theinoculum at the start of trial ensuring a 1 6 plastic ino-culum weight ratio on a dry matter basis Throughout thetrial we shook the samples manually once per week toachieve more homogeneity in the degradation process of thespecimenThemoisture content of the inoculumwas adjustedto about 50 (ww) at the start of the trials and held constantby means of inlet air humidification However during theweekly shaking proceduremoisturewas controlled byweigh-ing each vessel and distilled water was added if necessaryThecarbon and nitrogen content of the samples was determinedusing a CHNS analyser (Macro Cube Elemental Germany)equipped with selective traps for CO

2 H2O and SO

2and

detected by thermal conductivity The ash content was deter-mined as weight loss at 650∘C for 24 h in a muffle furnaceon samples previously oven dried at 105∘C The inoculumemployed in the biodegradation trials was the compostobtained at the end of a static composting procedure set upfor OMWmanagement as described in Altieri and Esposito[18] and Altieri et al [19] The OMW compost used asinoculum was produced in 2013 and stored dry until the daybefore use when it was moistened to about 50 for the trialThis procedure keeps alive the microorganism populations

that drive the biodegradation of the plastic samplesThe envi-ronmental chamber was set at 58 plusmn 2∘C which is representa-tive of full-scale composting Vessel flows were set at 20 L hminus1and fresh air at 60 L hminus1 to adequately clean up the measure-ment line

The degree of biodegradation is determined from theamount of specimen carbon converted to CO

2by the end

of the trial CO2emissions automatically calculated for each

measurement cycle and then cumulated are converted tomass values with the following general equation

CO2sample =

119876 sdot CO2sdot Δ119905 sdot 119872 (CO

2)

119881119898

(1)

where 119876 is the flow rate measured with the gas mass meterCO2is the CO

2concentration measured with the IRGA

sensors and corrected for the background CO2concentration

of the inlet CO2-free air Δ119905 is the period of the measurement

cycle 119872 (CO2) is the molar mass of CO

2 and 119881

119898is the

volume occupied by one mole of CO2at the exhaust-air

temperature as determined by the local in-line sensor Themolar volume of CO

2is calculated using the following

119881119898= 119877 sdot119879out119875atm (2)

where 119877 is the ideal gas constant 119879out is the temperature ofthe outlet flow and 119875atm is the atmospheric air pressure

The percentage of biodegradation for each specimen iscalculated as

119863sample =CO2sample minus CO2inoculum

ThCO2

(3)

where CO2sample and CO2inoculum are both calculated with (1)

and ThCO2is the theoretical (maximum) amount of CO

2

released from the fully mineralized sample calculated on thebasis of its organic carbon content

24 Check of the CO2 Emissions by the Titration Method Inorder to confirm the results obtained by the experimentalapparatus the amount of CO

2released during biodegrada-

tion was also checked using the standard titration methodreported in ISO 175562012 [20] The comparison of themethodswas based on a fixed observation time Exhausted airfrom a randomly chosen vessel was directed towards a seriesof three 2-L vessels fitted with gas diffusers and containingsaturated Ba(OH)

2solution able to capture the CO

2(method

2 Figure 1) In fact when CO2enters the scrubbing vessels it

reacts as follows

Ba (OH)2+ CO2997888rarr BaCO

3+H2O (4)

The barium carbonate formed is insoluble and precipitatesThe excess of Ba(OH)

2in the three CO

2scrubbing vessels

was then determined by end-point titration with HCl usingphenolphthalein as indicator according to the followingequation

Ba (OH)2+ 2HCl 997888rarr BaCl

2+ 2H2O (5)

Advances in Materials Science and Engineering 5

Table 1 Characteristics of the samples used in the trials of the experimental apparatus

Inoculum A B C D RefCompost PCL PCL PLAPBAT PE

Amount g vesselminus1 2760 230 230 230 230 230Moisture 5110 114 275 041 046 0Ashlowast 1800 121 207 590 035 0Carbonlowast 447 605 590 584 840 444Nitrogenlowast 450 256 376 018 109 0ThCO

2g vesselminus1 2212 504 484 490 705 374

lowastData are referred on dry matter base PCL poly(120576-caprolactone) composite PLAPBAT compatibilized polylactic acid and polybutyrate blend PEpolyethylene (negative reference) Ref reference (pure cellulose Sigma-Aldrich) ThCO2 theoretical CO2 emission

From (4) and (5) one can calculate the number of mmoles ofCO2produced in a fixed time as follows

mmolesCO2= mmolesBa (OH)

2minusmmolesHCl2 (6)

where mmoles Ba(OH)2is the initial number of mmoles

of Ba(OH)2 The CO

2scrubbing solution was prepared by

dissolving Ba(OH)2in distilled water filtering it and sealing

it to prevent absorption of CO2from the atmosphere It was

then stored as standard clear solution However since it isquite unstable the actual concentration of the initial solutionwas determined by titrationwith a standardHCl 005Mpriorto each use

3 Results and Discussion

Thefindings of the biodegradation experiment carried out onA and B plastic polymers (Table 1) are given in Figures 4 and5 Both graphics show average values with related standarderror evaluated every four hours and calculated using (1)(CO2emission per vessel) and by (3) (degree of biodegrada-

tion) Figure 4 shows a very high degradation rate for bothplastic polymers testedmdasheven higher than that of the biodeg-radable standard (cellulose)mdashstarting right from the earlystages of the trial In fact after about 20 days both plasticsreached a percentage of biodegradation higher than 80(Figure 5) about double that of cellulose (about 45) Thehigh nitrogen levels of specimens A and B (Table 1) mightexplain their more rapid biodegradation indeed biomasshaving a lower CN ratio is more easily degraded bymicroor-ganisms which can then find an appropriate source ofnitrogen for supporting their metabolism and reproduction

In the first trial after 10 days the inoculum showed acumulated emission of 94 plusmn 01 gCO

2vesselminus1 which corre-

sponds to 863 plusmn 13mgCO2per gram of volatile solidsmdasha

value falling in the range prescribed by ISO 14855-12012 andconsidered optimal for successfully conducting biodegrada-tion tests under composting conditions [17] Thus compostbased on OMW as inoculum showed to be adequately rich inmicroorganisms that drive biodegradation of the specimenstested At the end of the first trial a cumulated emission equalto 310 plusmn 33 gCO

2vesselminus1 was registered for the reference

material (cellulose) which corresponds to 450 plusmn 92 bio-degradation (coefficient of variation CV = 205) At that

60

50

40

30

20

10

0

Time (day)0 5 10 15 20

AB

InoculumRef

Carb

on d

ioxi

de ev

olve

d (g

CO

2v

esse

l)

Figure 4 First biodegradation trial cumulated CO2emissions per

vessel (A B) PCL composites (Ref) reference cellulose Error barsrefer to standard error (119899 = 3)

Time (day)0 5 10 15 20

AB

Ref

Biod

egra

datio

n (

)

100

90

80

70

60

50

40

30

20

10

0

Figure 5 First biodegradation trial percentage of mineralization ofpolymers tested (A B) PCL composites (Ref) reference celluloseError bars refer to standard error (119899 = 3)

6 Advances in Materials Science and EngineeringCa

rbon

dio

xide

evol

ved

(gCO

2v

esse

l) 60

50

40

30

20

10

00 5 10 15 20 25 30 35 40 45 50

Time (day)

CD Inoculum

Ref

Figure 6 Second biodegradation trial cumulated CO2emissions

per vessel (C) PLAPBAT blend (D) polyethylene film negativereference (Ref) reference cellulose Error bars refer to standarderror (119899 = 3)

time point the amount of cumulated CO2emission for the

inoculum triplicates was 147 plusmn 04 gCO2vesselminus1 which is

the value subtracted from the cumulated CO2emissions

registered both for the reference and specimen vessels asspecified in (3) At the end of the first trial a cumulatedCO2emission equal to 591 plusmn 20 gCO

2vesselminus1 and 523 plusmn

18 gCO2vesselminus1 was found for specimens A and B respec-

tively This corresponds to 921 plusmn 41 and 829 plusmn 40biodegradation Moreover the low variability among thereplicates corroborates the validity of the first trial

The results of the second biodegradation trial performedon specimens C (a commercial plastic polymer) and D (poly-ethylene as negative reference) are shown in Figures 6 and 7Here the rate of biodegradation for specimen C was muchlower than that of the reference at least in the first ten daysof the trial (Figure 6) It was also much lower than the ratesregistered in the first trial for specimens A and B (Figure 4)As expected the rate for the negative reference was almostzero (Figure 6) Due to the lower biodegradation rate trialtwo was necessarily longer it lasted 465 days the time pointat which both specimen C and cellulose reached about 80biodegradation (Figure 7) In the second trial a cumulatedCO2emission of 107 plusmn 24 gCO

2vesselminus1 corresponding to

964 plusmn 216mgCO2per gram of volatile solid was registered

after ten daysThis value is comparable to that of the first trialthus confirming the repeatability of the test and the suitabilityof the OMW compost as inoculum At the end of the secondtrial a cumulated CO

2emission of 495 plusmn 39 gCO

2vesselminus1

was registered in the reference vessels corresponding to790 plusmn 103 biodegradation and a 13 coefficient of vari-ability At the end of the second biodegradation trial acumulated CO

2emission for the inoculum triplicates equal

to 199 plusmn 39 gCO2vesselminus1 was also detected a value then

subtracted from the total cumulated CO2emissions recorded

for the reference and specimen vessels as specified in (3)

Biod

egra

datio

n (

)

90

80

70

60

50

40

30

20

10

00 5 10 15 20 25 30 35 40 45 50

Time (day)

CD

Ref

Figure 7 Second biodegradation trial percentage ofmineralizationof polymers tested (C) PLAPBAT blend (D) polyethylene filmnegative reference (Ref) reference cellulose Error bars refer tostandard error (119899 = 3)

Furthermore cumulated emissions of 596plusmn38 gCO2vesselminus1

and 219 plusmn 20 gCO2vesselminus1 were found for specimens C

and D (negative reference) respectively which correspondto 811 plusmn 77 and 28 plusmn 28 biodegradation These resultsconfirm the validity of the second test since specimen Cexhibited an acceptable variability (95 CV) and specimenD as expected underwent no significant biodegradationAlthough the respiration activity of the inoculum should becarefully considered when comparing results the cumulatedCO2emission registered for the inoculum and the reference

material in both biodegradation trials agreed with thosereported in the literature [10]

Check-tests using the titration method to measure CO2

emissions were performed on the outflows from cellulosevessel and polymer A vessel and lasted 139 and 225 min-utes respectively In 139 minutes cellulose vessel emit-ted 2135mgCO

2according to the titration method and

2108mgCO2according to the IRGA Thus the agreement

was very good (124) In 225 minutes polymer A vesselemitted 2878mgCO

2according to the titration method and

2667mgCO2according to the IRGA a difference of 733 It

is worth noting that the check-testswere performedondays 11and 12 of the trial during a very active biodegradation phaseTitration tests confirmed the reliability of the apparatusdesigned and built for assessing the ultimate biodegradationof plastic polymers under composting condition

4 Conclusions

In this study we developed an experimental apparatus foranalysing the biodegradability of plastic polymers undercontrolled composting conditions Using direct infrared gasanalysis we evaluated the cumulative carbon dioxide emis-sions of two poly(120576-caprolactone) (PCL) composites and acompatibilized polylactic acid and polybutyrate (PLAPBAT)

Advances in Materials Science and Engineering 7

blend which are made of renewable materials and canbe used for specific applications in the agricultural sectorTheir biodegradation conducted in olive-mill waste compostused as inoculum was proved in a very short time Ourfindings were checked (CV lt 10) by means of a cumulativemeasurement technique performed simultaneously during afixed time and based on acid-base titration using saturatedBa(OH)

2to trap the evolved carbon dioxide

The apparatus proves to be quite flexible in fact differentenvironments can be simulated by means of small changessuch as the design of the vessels the inoculum used (eg soilor water instead of compost) or the environmental param-eters under control (eg oxygen) This makes it possible toevaluate a wide range of different biodegradation scenariosMoreover it reduces the likelihood of systematic errors thatmight result from use of the laborious technique necessaryfor the standard acidimetric titrations

This studymay serve as basis for further investigations onbiopolymer degradation in different composting conditionsand environment Furthermore laboratory data may be usedfor upscaling results in order to mitigate plastic waste issuesof the agricultural sector towards an efficient use of renewableresources

Competing Interests

The authors declare that they have no competing interests

Acknowledgments

This research was carried out within the framework of IGANECO-POT project funded by Regione Toscana Italy (PSR2007ndash2013) and was partially supported by the DFG RTG1703 ldquoResource Efficiency in Interorganizational Networksrdquo

References

[1] R A Gross and B Kalra ldquoBiodegradable polymers for the envi-ronmentrdquo Science vol 297 no 5582 pp 803ndash807 2002

[2] EC EU Focus onWaste Management Directorate-General Envi-ronment Nuclear Safety and Civil Protection Office for OfficialPublications of the European Communities EC LuxembourgCity Luxembourg 1999

[3] J-C Huang A S Shetty andM-SWang ldquoBiodegradable plas-tics a reviewrdquoAdvances in Polymer Technology vol 10 no 1 pp23ndash30 1990

[4] M Alexander ldquoBiodegradation of chemicals of environmentalconcernrdquo Science vol 211 no 4478 pp 132ndash138 1981

[5] A Wojtowicz Biodegradability and Compostability of Biopoly-mers John Wiley amp Sons New York NY USA 2009

[6] International Organization for Standardization (ISO) ldquoSpecifi-cation for compostable plasticsrdquo ISO 170882012 InternationalOrganization for Standardization (ISO) Geneva Switzerland2012

[7] EuropeanCommittee for Standardization (CEN) ldquoPackagingmdashrequirements for packaging recoverable through compostingand biodegradationmdashtest scheme and evaluation criteria for thefinal acceptance of packagingrdquo CEN EN 134322000 2000

[8] R Barrena T Gea S Ponsa et al ldquoCategorizing raw organicmaterial biodegradability via respiration activity measurementa reviewrdquo Compost Science amp Utilization vol 19 no 2 pp 105ndash113 2011

[9] R Jayasekara G T Lonergan I Harding I Bowater P Halleyand G B Christie ldquoAn automated multi-unit composting faci-lity for biodegradability evaluationsrdquo Journal of Chemical Tech-nology and Biotechnology vol 76 no 4 pp 411ndash417 2001

[10] T Kijchavengkul R Auras M Rubino M Ngouajio and RThomas Fernandez ldquoDevelopment of an automatic laboratory-scale respirometric system to measure polymer biodegradabil-ityrdquo Polymer Testing vol 25 no 8 pp 1006ndash1016 2006

[11] R Pantani and A Sorrentino ldquoInfluence of crystallinity on thebiodegradation rate of injection-moulded poly(lactic acid) sam-ples in controlled composting conditionsrdquoPolymerDegradationand Stability vol 98 no 5 pp 1089ndash1096 2013

[12] P Drımal J Hoffmann and M Druzbık ldquoEvaluating the aer-obic biodegradability of plastics in soil environments throughGC and IR analysis of gaseous phaserdquo Polymer Testing vol 26no 6 pp 729ndash741 2007

[13] A Ohtaki and K Nakasaki ldquoReport ultimate degradabilityof various kinds of biodegradable plastics under controlledcomposting conditionsrdquoWaste Management and Research vol18 no 2 pp 184ndash189 2000

[14] F Castellani A Esposito V Stanzione and R Altieri ldquoAnalysisof emissions from lab-scale composting equipment data for asustainability challengerdquo in Proceedings of the 14th InternationalConference on Environmental Science and Technology T DLekkas Ed Rhodes Greece September 2015

[15] International Organization for Standardization (ISO) ldquoDeter-mination of the ultimate aerobic biodegradability of plasticmaterials under controlled composting conditionsmdashmethod byanalysis of evolved carbon dioxidemdashpart 1 general methodrdquoISO 14855-12012 International Organization for Standardiza-tion (ISO) Geneva Switzerland 2012

[16] A Levy ldquoThe accuracy of the bubble meter method for gas flowmeasurementsrdquo Journal of Scientific Instruments vol 41 no 7pp 449ndash453 1964

[17] U Pagga ldquoTesting biodegradability with standardized meth-odsrdquo Chemosphere vol 35 no 12 pp 2953ndash2972 1997

[18] R Altieri and A Esposito ldquoOlive orchard amended with twoexperimental olive mill wastes mixtures effects on soil organiccarbon plant growth and yieldrdquo Bioresource Technology vol 99no 17 pp 8390ndash8393 2008

[19] R Altieri A Esposito and T Nair ldquoNovel static compostingmethod for bioremediation of olive mill wasterdquo InternationalBiodeterioration amp Biodegradation vol 65 no 6 pp 786ndash7892011

[20] International Organization for Standardization (ISO) ldquoPlas-ticsmdashdetermination of the ultimate aerobic biodegradability ofplastic materials in soil by measuring the oxygen demand in arespirometer or the amount of carbon dioxide evolvedrdquo ISO175562012 International Organization for Standardization(ISO) Geneva Switzerland 2012

Submit your manuscripts athttpwwwhindawicom

ScientificaHindawi Publishing Corporationhttpwwwhindawicom Volume 2014

CorrosionInternational Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Polymer ScienceInternational Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

CeramicsJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

CompositesJournal of

NanoparticlesJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

International Journal of

Biomaterials

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

NanoscienceJournal of

TextilesHindawi Publishing Corporation httpwwwhindawicom Volume 2014

Journal of

NanotechnologyHindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Journal of

CrystallographyJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

The Scientific World JournalHindawi Publishing Corporation httpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

CoatingsJournal of

Advances in

Materials Science and EngineeringHindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Smart Materials Research

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

MetallurgyJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

BioMed Research International

MaterialsJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Nano

materials

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Journal ofNanomaterials

2 Advances in Materials Science and Engineering

Temp transducer

Inlet air

Pressuretransducer

scrubbers

Vessels(up to 12)

Sample

12 needle valves

Manifold(up to 12 valves)

Filters

Fresh air

Outlet air

Watercondenser

Dryer

Humidifiers(up to 12)

Water

Drainvalve

Vent

Flow meter

Method 2Titration test

Temperaturetransducer

Method 1

CO2

Thermostated chamber (58∘C)

Ba(OH)2

CO2 evolved

IRGA1 IRGA2

Figure 1 Schematic diagram of the experimental apparatus CO2evolved (method 1) and titration test (method 2) are used to evaluate the

biodegradation of samples

apparatus for evaluating the biodegradability of biopolymersusing OMW compost as inoculum

In this study we(i) describe in detail an experimental apparatus designed

and assembled to assess the biodegradation rate ofplastic materials under controlled composting condi-tions in accordance with the ISO 14855-12012 [15]

(ii) test the apparatus by evaluating with infrared gasanalysis (IRGA) the cumulative CO

2evolution of

three biopolymers made of renewable materials foragricultural applications

(iii) check the accuracy of the data by measuring theamount of CO

2released during biodegradation with

barium hydroxide Ba(OH)2 titration method

2 Materials and Methods

21 Apparatus The apparatus combines a pneumatic andan electric system In the pneumatic system compressed airis used to stimulate aerobic biodegradation of the sampleswhich are kept in air-tight closed vessels (bioreactors) andexposed to mature compost throughout the trials The com-post (called ldquoinoculumrdquo) rich in living microorganisms pro-motes the biodegradation of the samples thus producing

CO2 CO2measurements are performed on the exhausted

air by means of the appropriate IRGA sensors A customizedsoftware was developed in LabVIEW (National InstrumentsUSA) environment for the automatic control of the apparatusThe schematic diagram of the pneumatic system is shown inFigure 1 During trials the pressurized system ensures opti-mal aerobic conditions and prevents undesired anaerobic fer-mentation We used polymethylmethacrylate air-tight tubes(4mm internal diameter) for the pneumatic system and con-trolled pressure by means of a double-stage regulator (FestoAG amp Co Germany) Before entering the vessels air flowsinto a CO

2scrubber consisting of a series of two 2 L vessels

filled with soda lime (Sofnolime 2550USP Grade) By reduc-ing the inlet air CO

2concentration to about 10 ppm the CO

2

scrubber allows the exhausted air to ultimately match therange of measurement for the CO

2IRGA sensors used (sen-

sors described below)Weused a pressure transducer (DwyerGermany) to monitor the airflow and highlight possibleundesired pressure drops which are promptly displayed onvideo by the software CO

2-free air is distributed to the vessels

via needle valves which control the flowTwelve 2 L glass vessels are placed inside an environmen-

tal chamber (Gallenkamp UK) outfitted with a temperaturecontroller and equipped with a suitable passage for the air-tight tubes (Figure 2) The chamber temperature is also

Advances in Materials Science and Engineering 3

Figure 2 Environmental chamber of the experimental apparatus setat 58 plusmn 2∘C

Air-tight container

Coarse bubblediffuser

Filter

Cone-shaped cap

Holes

Figure 3 Prototyped arrangement for the vessels

recorded by means of a thermocouple type T (Tersid Italy)which is properly connected to the PC Each vessel isconnected in-line with another 2 L vessel containing distilledwater used to humidify the inlet air Both humidifiers andvessels are equipped with handmade coarse bubble diffusersThese are arranged in a circular scheme and contain multiplefine holes to permit uniform diffusion of the airflow (Fig-ure 3)

An outlet manifold equipped with low-power micro-solenoid-valves and placed inside the chamber to avoid watercondensation from the flowing air drives the air exhaustedfrom each vessel towards themeasuring line where the IRGAsensors are located Airflow blockage was prevented usingplastic filters of 90 120583mmesh (Preferred Products Design IncUSA) which were placed in-line on the flows escaping fromeach vessel The tube that drives exhausted air to IRGA sen-sors and located outside the chamber is thermally insulatedand reduced to a minimum length to prevent water fromcondense and undesired interference on the flow rate

A water condenser was placed in the measuring linebefore the IRGA sensors It is made of a copper serpentinecontaining a circulating liquid (mixture 1 1 vv water ethy-lene glycol) refrigerated by a cryostat (ScienceElectronicsUSA) to a temperature below the dew point inserted in poly-methylmethacrylate air-tight tubing the condensed water isautomatically discharged by gravity thanks to a solenoid valvethat opens periodically

A second in-line dryer consisting of a polymethylmetha-crylate air-tight tube (diameter 3 cm) containing granularcalcium chloride (SIGMA-Aldrich USA) removes the resid-ual moisture from the exhausted air before it enters theIRGA sensors Drying the exhaust air is necessary to ensure acorrect operation of the IRGA sensorsThe system is providedwith two sequential IRGA sensors for measuring the CO

2

concentration in the outflow air (method 1 Figure 1) a Ley-bold-Heraeus Binos (Germany) for measurements withinthe range 0ndash3000 ppm and an accuracy of 1 and aGascheck by Edinburgh Sensors (UK) for concentrations upto 100000 ppm and an accuracy of 3The IRGA sensors areautomatically switched in order to achieve the highest accu-racy of CO

2concentrationmeasurements andwere calibrated

using three certified mixes (SOL group Italy) of air contain-ingCO

2at known concentration (824 2970 and 80600 ppm)

After each CO2concentration measurement the line is

flushedwithCO2-free air At the end of the pneumatic circuit

adjacent to the IRGA sensors there is a gas mass flow meter(Dwyer Germany) with a flow range of 0ndash80 L hminus1 and anin-line thermocouple (Tersid Italy)Themass flowmeter wascalibrated using a soap bubble glass flow meter (500mL)following the procedure adopted by Levy [16] and the ther-mocouple calculates the CO

2concentration at Lab working

conditions To ensure the continuous and reliable measure-ment of all parameters the system was checked for gas leaksat each connection point using a diluted soap solution

Analog sensor signals are converted and recorded bymeans of a data logging system Here a computer monitorsthe results a bus-powered multifunction DAQ (NI USB-6009 National Instruments USA) acquires analog signalsand a digital output module (NI USB-6501 National Instru-ments USA) controls the solenoid valves via a multiple-relaymodule board

22 Software The automation and monitoring of all param-eters is performed by means of a customized software devel-oped within a LabVIEW environmentThe parameters mon-itored are inlet air pressure environmental chamber tem-perature CO

2concentration temperature and airflow rate

of the exhausted airAn appropriate measuringcleaning sequence is ensured

to monitor the parameters of the exhausted air Since thesequence lasts 20 minutes for each vessel a complete mea-surement cycle for 12 vessels lasts 4 hours thus providing 6series of data per day for each vessel

In the first 5min of each sequence (time required formea-sured signals to reach steady state) the air valve opens andthe detector is thus purged with CO

2-free air During the

cleaning cycle a drain valve located at the bottomof the watercondenser opens for 30 seconds to discharge the condensed

4 Advances in Materials Science and Engineering

water accumulated in the previous set of analyses Next thevalve associated with the selected vessel opens for 15 minuteswhile the air valve closes The exhaust air of the selectedvessel enters the infrared sensors until a steady state patternis reached In the last minute of this steady state phase thesoftware acquires the analog signals released every secondfrom each sensor and converts them into average values

Data for each sample is recorded plotted and displayedin final tables graphs and spreadsheetsThe software is struc-tured with a front panel that monitors the trial and showsthe results in real time possible errors occurring during thetrialmdashsuch as flow line blockage or unexpected temperatureor pressure line drops in the chambermdashare continuouslychecked by the software If called for a specific alarm signalappears on the screen for each vessel

23 Experimental Conditions In keepingwith severalmetho-dologies reported in the literature [17] our trials wereconducted in triplicate 3 vessels contained the inoculum3 vessels contained compost plus a reference biodegradablematerial (namely cellulose Sigma-Aldrich) and 3 vesselscontained compost plus specimen Since the apparatus coulddrive up to 12 vessels each trial involved two samples

We carried out two biodegradation trials on three bio-polymers two different poly(120576-caprolactone) (PCL) compos-ites (sample A and sample B) and a commercially availablecompatibilized polylactic acid and polybutyrate (PLAPBAT) blend (sample C ECOVIO IS 1335 BASF Germany)A polyethylene (PE) film (sample D) was used as negativereference Each vessel charge included 276 g of inoculum (wetweight) which filled about two-thirds of the internal volumeplus 23 g of the specimen or reference material (Table 1)Twenty-three g (dry weight) of agricultural perlite previouslyhumidified up to its maximum water retention (765)was added to each vessel to reduce the bulk density of theinoculum and provide better air circulation in it The plasticspecimenwasmilled (lt1mm) and thoroughlymixedwith theinoculum at the start of trial ensuring a 1 6 plastic ino-culum weight ratio on a dry matter basis Throughout thetrial we shook the samples manually once per week toachieve more homogeneity in the degradation process of thespecimenThemoisture content of the inoculumwas adjustedto about 50 (ww) at the start of the trials and held constantby means of inlet air humidification However during theweekly shaking proceduremoisturewas controlled byweigh-ing each vessel and distilled water was added if necessaryThecarbon and nitrogen content of the samples was determinedusing a CHNS analyser (Macro Cube Elemental Germany)equipped with selective traps for CO

2 H2O and SO

2and

detected by thermal conductivity The ash content was deter-mined as weight loss at 650∘C for 24 h in a muffle furnaceon samples previously oven dried at 105∘C The inoculumemployed in the biodegradation trials was the compostobtained at the end of a static composting procedure set upfor OMWmanagement as described in Altieri and Esposito[18] and Altieri et al [19] The OMW compost used asinoculum was produced in 2013 and stored dry until the daybefore use when it was moistened to about 50 for the trialThis procedure keeps alive the microorganism populations

that drive the biodegradation of the plastic samplesThe envi-ronmental chamber was set at 58 plusmn 2∘C which is representa-tive of full-scale composting Vessel flows were set at 20 L hminus1and fresh air at 60 L hminus1 to adequately clean up the measure-ment line

The degree of biodegradation is determined from theamount of specimen carbon converted to CO

2by the end

of the trial CO2emissions automatically calculated for each

measurement cycle and then cumulated are converted tomass values with the following general equation

CO2sample =

119876 sdot CO2sdot Δ119905 sdot 119872 (CO

2)

119881119898

(1)

where 119876 is the flow rate measured with the gas mass meterCO2is the CO

2concentration measured with the IRGA

sensors and corrected for the background CO2concentration

of the inlet CO2-free air Δ119905 is the period of the measurement

cycle 119872 (CO2) is the molar mass of CO

2 and 119881

119898is the

volume occupied by one mole of CO2at the exhaust-air

temperature as determined by the local in-line sensor Themolar volume of CO

2is calculated using the following

119881119898= 119877 sdot119879out119875atm (2)

where 119877 is the ideal gas constant 119879out is the temperature ofthe outlet flow and 119875atm is the atmospheric air pressure

The percentage of biodegradation for each specimen iscalculated as

119863sample =CO2sample minus CO2inoculum

ThCO2

(3)

where CO2sample and CO2inoculum are both calculated with (1)

and ThCO2is the theoretical (maximum) amount of CO

2

released from the fully mineralized sample calculated on thebasis of its organic carbon content

24 Check of the CO2 Emissions by the Titration Method Inorder to confirm the results obtained by the experimentalapparatus the amount of CO

2released during biodegrada-

tion was also checked using the standard titration methodreported in ISO 175562012 [20] The comparison of themethodswas based on a fixed observation time Exhausted airfrom a randomly chosen vessel was directed towards a seriesof three 2-L vessels fitted with gas diffusers and containingsaturated Ba(OH)

2solution able to capture the CO

2(method

2 Figure 1) In fact when CO2enters the scrubbing vessels it

reacts as follows

Ba (OH)2+ CO2997888rarr BaCO

3+H2O (4)

The barium carbonate formed is insoluble and precipitatesThe excess of Ba(OH)

2in the three CO

2scrubbing vessels

was then determined by end-point titration with HCl usingphenolphthalein as indicator according to the followingequation

Ba (OH)2+ 2HCl 997888rarr BaCl

2+ 2H2O (5)

Advances in Materials Science and Engineering 5

Table 1 Characteristics of the samples used in the trials of the experimental apparatus

Inoculum A B C D RefCompost PCL PCL PLAPBAT PE

Amount g vesselminus1 2760 230 230 230 230 230Moisture 5110 114 275 041 046 0Ashlowast 1800 121 207 590 035 0Carbonlowast 447 605 590 584 840 444Nitrogenlowast 450 256 376 018 109 0ThCO

2g vesselminus1 2212 504 484 490 705 374

lowastData are referred on dry matter base PCL poly(120576-caprolactone) composite PLAPBAT compatibilized polylactic acid and polybutyrate blend PEpolyethylene (negative reference) Ref reference (pure cellulose Sigma-Aldrich) ThCO2 theoretical CO2 emission

From (4) and (5) one can calculate the number of mmoles ofCO2produced in a fixed time as follows

mmolesCO2= mmolesBa (OH)

2minusmmolesHCl2 (6)

where mmoles Ba(OH)2is the initial number of mmoles

of Ba(OH)2 The CO

2scrubbing solution was prepared by

dissolving Ba(OH)2in distilled water filtering it and sealing

it to prevent absorption of CO2from the atmosphere It was

then stored as standard clear solution However since it isquite unstable the actual concentration of the initial solutionwas determined by titrationwith a standardHCl 005Mpriorto each use

3 Results and Discussion

Thefindings of the biodegradation experiment carried out onA and B plastic polymers (Table 1) are given in Figures 4 and5 Both graphics show average values with related standarderror evaluated every four hours and calculated using (1)(CO2emission per vessel) and by (3) (degree of biodegrada-

tion) Figure 4 shows a very high degradation rate for bothplastic polymers testedmdasheven higher than that of the biodeg-radable standard (cellulose)mdashstarting right from the earlystages of the trial In fact after about 20 days both plasticsreached a percentage of biodegradation higher than 80(Figure 5) about double that of cellulose (about 45) Thehigh nitrogen levels of specimens A and B (Table 1) mightexplain their more rapid biodegradation indeed biomasshaving a lower CN ratio is more easily degraded bymicroor-ganisms which can then find an appropriate source ofnitrogen for supporting their metabolism and reproduction

In the first trial after 10 days the inoculum showed acumulated emission of 94 plusmn 01 gCO

2vesselminus1 which corre-

sponds to 863 plusmn 13mgCO2per gram of volatile solidsmdasha

value falling in the range prescribed by ISO 14855-12012 andconsidered optimal for successfully conducting biodegrada-tion tests under composting conditions [17] Thus compostbased on OMW as inoculum showed to be adequately rich inmicroorganisms that drive biodegradation of the specimenstested At the end of the first trial a cumulated emission equalto 310 plusmn 33 gCO

2vesselminus1 was registered for the reference

material (cellulose) which corresponds to 450 plusmn 92 bio-degradation (coefficient of variation CV = 205) At that

60

50

40

30

20

10

0

Time (day)0 5 10 15 20

AB

InoculumRef

Carb

on d

ioxi

de ev

olve

d (g

CO

2v

esse

l)

Figure 4 First biodegradation trial cumulated CO2emissions per

vessel (A B) PCL composites (Ref) reference cellulose Error barsrefer to standard error (119899 = 3)

Time (day)0 5 10 15 20

AB

Ref

Biod

egra

datio

n (

)

100

90

80

70

60

50

40

30

20

10

0

Figure 5 First biodegradation trial percentage of mineralization ofpolymers tested (A B) PCL composites (Ref) reference celluloseError bars refer to standard error (119899 = 3)

6 Advances in Materials Science and EngineeringCa

rbon

dio

xide

evol

ved

(gCO

2v

esse

l) 60

50

40

30

20

10

00 5 10 15 20 25 30 35 40 45 50

Time (day)

CD Inoculum

Ref

Figure 6 Second biodegradation trial cumulated CO2emissions

per vessel (C) PLAPBAT blend (D) polyethylene film negativereference (Ref) reference cellulose Error bars refer to standarderror (119899 = 3)

time point the amount of cumulated CO2emission for the

inoculum triplicates was 147 plusmn 04 gCO2vesselminus1 which is

the value subtracted from the cumulated CO2emissions

registered both for the reference and specimen vessels asspecified in (3) At the end of the first trial a cumulatedCO2emission equal to 591 plusmn 20 gCO

2vesselminus1 and 523 plusmn

18 gCO2vesselminus1 was found for specimens A and B respec-

tively This corresponds to 921 plusmn 41 and 829 plusmn 40biodegradation Moreover the low variability among thereplicates corroborates the validity of the first trial

The results of the second biodegradation trial performedon specimens C (a commercial plastic polymer) and D (poly-ethylene as negative reference) are shown in Figures 6 and 7Here the rate of biodegradation for specimen C was muchlower than that of the reference at least in the first ten daysof the trial (Figure 6) It was also much lower than the ratesregistered in the first trial for specimens A and B (Figure 4)As expected the rate for the negative reference was almostzero (Figure 6) Due to the lower biodegradation rate trialtwo was necessarily longer it lasted 465 days the time pointat which both specimen C and cellulose reached about 80biodegradation (Figure 7) In the second trial a cumulatedCO2emission of 107 plusmn 24 gCO

2vesselminus1 corresponding to

964 plusmn 216mgCO2per gram of volatile solid was registered

after ten daysThis value is comparable to that of the first trialthus confirming the repeatability of the test and the suitabilityof the OMW compost as inoculum At the end of the secondtrial a cumulated CO

2emission of 495 plusmn 39 gCO

2vesselminus1

was registered in the reference vessels corresponding to790 plusmn 103 biodegradation and a 13 coefficient of vari-ability At the end of the second biodegradation trial acumulated CO

2emission for the inoculum triplicates equal

to 199 plusmn 39 gCO2vesselminus1 was also detected a value then

subtracted from the total cumulated CO2emissions recorded

for the reference and specimen vessels as specified in (3)

Biod

egra

datio

n (

)

90

80

70

60

50

40

30

20

10

00 5 10 15 20 25 30 35 40 45 50

Time (day)

CD

Ref

Figure 7 Second biodegradation trial percentage ofmineralizationof polymers tested (C) PLAPBAT blend (D) polyethylene filmnegative reference (Ref) reference cellulose Error bars refer tostandard error (119899 = 3)

Furthermore cumulated emissions of 596plusmn38 gCO2vesselminus1

and 219 plusmn 20 gCO2vesselminus1 were found for specimens C

and D (negative reference) respectively which correspondto 811 plusmn 77 and 28 plusmn 28 biodegradation These resultsconfirm the validity of the second test since specimen Cexhibited an acceptable variability (95 CV) and specimenD as expected underwent no significant biodegradationAlthough the respiration activity of the inoculum should becarefully considered when comparing results the cumulatedCO2emission registered for the inoculum and the reference

material in both biodegradation trials agreed with thosereported in the literature [10]

Check-tests using the titration method to measure CO2

emissions were performed on the outflows from cellulosevessel and polymer A vessel and lasted 139 and 225 min-utes respectively In 139 minutes cellulose vessel emit-ted 2135mgCO

2according to the titration method and

2108mgCO2according to the IRGA Thus the agreement

was very good (124) In 225 minutes polymer A vesselemitted 2878mgCO

2according to the titration method and

2667mgCO2according to the IRGA a difference of 733 It

is worth noting that the check-testswere performedondays 11and 12 of the trial during a very active biodegradation phaseTitration tests confirmed the reliability of the apparatusdesigned and built for assessing the ultimate biodegradationof plastic polymers under composting condition

4 Conclusions

In this study we developed an experimental apparatus foranalysing the biodegradability of plastic polymers undercontrolled composting conditions Using direct infrared gasanalysis we evaluated the cumulative carbon dioxide emis-sions of two poly(120576-caprolactone) (PCL) composites and acompatibilized polylactic acid and polybutyrate (PLAPBAT)

Advances in Materials Science and Engineering 7

blend which are made of renewable materials and canbe used for specific applications in the agricultural sectorTheir biodegradation conducted in olive-mill waste compostused as inoculum was proved in a very short time Ourfindings were checked (CV lt 10) by means of a cumulativemeasurement technique performed simultaneously during afixed time and based on acid-base titration using saturatedBa(OH)

2to trap the evolved carbon dioxide

The apparatus proves to be quite flexible in fact differentenvironments can be simulated by means of small changessuch as the design of the vessels the inoculum used (eg soilor water instead of compost) or the environmental param-eters under control (eg oxygen) This makes it possible toevaluate a wide range of different biodegradation scenariosMoreover it reduces the likelihood of systematic errors thatmight result from use of the laborious technique necessaryfor the standard acidimetric titrations

This studymay serve as basis for further investigations onbiopolymer degradation in different composting conditionsand environment Furthermore laboratory data may be usedfor upscaling results in order to mitigate plastic waste issuesof the agricultural sector towards an efficient use of renewableresources

Competing Interests

The authors declare that they have no competing interests

Acknowledgments

This research was carried out within the framework of IGANECO-POT project funded by Regione Toscana Italy (PSR2007ndash2013) and was partially supported by the DFG RTG1703 ldquoResource Efficiency in Interorganizational Networksrdquo

References

[1] R A Gross and B Kalra ldquoBiodegradable polymers for the envi-ronmentrdquo Science vol 297 no 5582 pp 803ndash807 2002

[2] EC EU Focus onWaste Management Directorate-General Envi-ronment Nuclear Safety and Civil Protection Office for OfficialPublications of the European Communities EC LuxembourgCity Luxembourg 1999

[3] J-C Huang A S Shetty andM-SWang ldquoBiodegradable plas-tics a reviewrdquoAdvances in Polymer Technology vol 10 no 1 pp23ndash30 1990

[4] M Alexander ldquoBiodegradation of chemicals of environmentalconcernrdquo Science vol 211 no 4478 pp 132ndash138 1981

[5] A Wojtowicz Biodegradability and Compostability of Biopoly-mers John Wiley amp Sons New York NY USA 2009

[6] International Organization for Standardization (ISO) ldquoSpecifi-cation for compostable plasticsrdquo ISO 170882012 InternationalOrganization for Standardization (ISO) Geneva Switzerland2012

[7] EuropeanCommittee for Standardization (CEN) ldquoPackagingmdashrequirements for packaging recoverable through compostingand biodegradationmdashtest scheme and evaluation criteria for thefinal acceptance of packagingrdquo CEN EN 134322000 2000

[8] R Barrena T Gea S Ponsa et al ldquoCategorizing raw organicmaterial biodegradability via respiration activity measurementa reviewrdquo Compost Science amp Utilization vol 19 no 2 pp 105ndash113 2011

[9] R Jayasekara G T Lonergan I Harding I Bowater P Halleyand G B Christie ldquoAn automated multi-unit composting faci-lity for biodegradability evaluationsrdquo Journal of Chemical Tech-nology and Biotechnology vol 76 no 4 pp 411ndash417 2001

[10] T Kijchavengkul R Auras M Rubino M Ngouajio and RThomas Fernandez ldquoDevelopment of an automatic laboratory-scale respirometric system to measure polymer biodegradabil-ityrdquo Polymer Testing vol 25 no 8 pp 1006ndash1016 2006

[11] R Pantani and A Sorrentino ldquoInfluence of crystallinity on thebiodegradation rate of injection-moulded poly(lactic acid) sam-ples in controlled composting conditionsrdquoPolymerDegradationand Stability vol 98 no 5 pp 1089ndash1096 2013

[12] P Drımal J Hoffmann and M Druzbık ldquoEvaluating the aer-obic biodegradability of plastics in soil environments throughGC and IR analysis of gaseous phaserdquo Polymer Testing vol 26no 6 pp 729ndash741 2007

[13] A Ohtaki and K Nakasaki ldquoReport ultimate degradabilityof various kinds of biodegradable plastics under controlledcomposting conditionsrdquoWaste Management and Research vol18 no 2 pp 184ndash189 2000

[14] F Castellani A Esposito V Stanzione and R Altieri ldquoAnalysisof emissions from lab-scale composting equipment data for asustainability challengerdquo in Proceedings of the 14th InternationalConference on Environmental Science and Technology T DLekkas Ed Rhodes Greece September 2015

[15] International Organization for Standardization (ISO) ldquoDeter-mination of the ultimate aerobic biodegradability of plasticmaterials under controlled composting conditionsmdashmethod byanalysis of evolved carbon dioxidemdashpart 1 general methodrdquoISO 14855-12012 International Organization for Standardiza-tion (ISO) Geneva Switzerland 2012

[16] A Levy ldquoThe accuracy of the bubble meter method for gas flowmeasurementsrdquo Journal of Scientific Instruments vol 41 no 7pp 449ndash453 1964

[17] U Pagga ldquoTesting biodegradability with standardized meth-odsrdquo Chemosphere vol 35 no 12 pp 2953ndash2972 1997

[18] R Altieri and A Esposito ldquoOlive orchard amended with twoexperimental olive mill wastes mixtures effects on soil organiccarbon plant growth and yieldrdquo Bioresource Technology vol 99no 17 pp 8390ndash8393 2008

[19] R Altieri A Esposito and T Nair ldquoNovel static compostingmethod for bioremediation of olive mill wasterdquo InternationalBiodeterioration amp Biodegradation vol 65 no 6 pp 786ndash7892011

[20] International Organization for Standardization (ISO) ldquoPlas-ticsmdashdetermination of the ultimate aerobic biodegradability ofplastic materials in soil by measuring the oxygen demand in arespirometer or the amount of carbon dioxide evolvedrdquo ISO175562012 International Organization for Standardization(ISO) Geneva Switzerland 2012

Submit your manuscripts athttpwwwhindawicom

ScientificaHindawi Publishing Corporationhttpwwwhindawicom Volume 2014

CorrosionInternational Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Polymer ScienceInternational Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

CeramicsJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

CompositesJournal of

NanoparticlesJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

International Journal of

Biomaterials

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

NanoscienceJournal of

TextilesHindawi Publishing Corporation httpwwwhindawicom Volume 2014

Journal of

NanotechnologyHindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Journal of

CrystallographyJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

The Scientific World JournalHindawi Publishing Corporation httpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

CoatingsJournal of

Advances in

Materials Science and EngineeringHindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Smart Materials Research

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

MetallurgyJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

BioMed Research International

MaterialsJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Nano

materials

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Journal ofNanomaterials

Advances in Materials Science and Engineering 3

Figure 2 Environmental chamber of the experimental apparatus setat 58 plusmn 2∘C

Air-tight container

Coarse bubblediffuser

Filter

Cone-shaped cap

Holes

Figure 3 Prototyped arrangement for the vessels

recorded by means of a thermocouple type T (Tersid Italy)which is properly connected to the PC Each vessel isconnected in-line with another 2 L vessel containing distilledwater used to humidify the inlet air Both humidifiers andvessels are equipped with handmade coarse bubble diffusersThese are arranged in a circular scheme and contain multiplefine holes to permit uniform diffusion of the airflow (Fig-ure 3)

An outlet manifold equipped with low-power micro-solenoid-valves and placed inside the chamber to avoid watercondensation from the flowing air drives the air exhaustedfrom each vessel towards themeasuring line where the IRGAsensors are located Airflow blockage was prevented usingplastic filters of 90 120583mmesh (Preferred Products Design IncUSA) which were placed in-line on the flows escaping fromeach vessel The tube that drives exhausted air to IRGA sen-sors and located outside the chamber is thermally insulatedand reduced to a minimum length to prevent water fromcondense and undesired interference on the flow rate

A water condenser was placed in the measuring linebefore the IRGA sensors It is made of a copper serpentinecontaining a circulating liquid (mixture 1 1 vv water ethy-lene glycol) refrigerated by a cryostat (ScienceElectronicsUSA) to a temperature below the dew point inserted in poly-methylmethacrylate air-tight tubing the condensed water isautomatically discharged by gravity thanks to a solenoid valvethat opens periodically

A second in-line dryer consisting of a polymethylmetha-crylate air-tight tube (diameter 3 cm) containing granularcalcium chloride (SIGMA-Aldrich USA) removes the resid-ual moisture from the exhausted air before it enters theIRGA sensors Drying the exhaust air is necessary to ensure acorrect operation of the IRGA sensorsThe system is providedwith two sequential IRGA sensors for measuring the CO

2

concentration in the outflow air (method 1 Figure 1) a Ley-bold-Heraeus Binos (Germany) for measurements withinthe range 0ndash3000 ppm and an accuracy of 1 and aGascheck by Edinburgh Sensors (UK) for concentrations upto 100000 ppm and an accuracy of 3The IRGA sensors areautomatically switched in order to achieve the highest accu-racy of CO

2concentrationmeasurements andwere calibrated

using three certified mixes (SOL group Italy) of air contain-ingCO

2at known concentration (824 2970 and 80600 ppm)

After each CO2concentration measurement the line is

flushedwithCO2-free air At the end of the pneumatic circuit

adjacent to the IRGA sensors there is a gas mass flow meter(Dwyer Germany) with a flow range of 0ndash80 L hminus1 and anin-line thermocouple (Tersid Italy)Themass flowmeter wascalibrated using a soap bubble glass flow meter (500mL)following the procedure adopted by Levy [16] and the ther-mocouple calculates the CO

2concentration at Lab working

conditions To ensure the continuous and reliable measure-ment of all parameters the system was checked for gas leaksat each connection point using a diluted soap solution

Analog sensor signals are converted and recorded bymeans of a data logging system Here a computer monitorsthe results a bus-powered multifunction DAQ (NI USB-6009 National Instruments USA) acquires analog signalsand a digital output module (NI USB-6501 National Instru-ments USA) controls the solenoid valves via a multiple-relaymodule board

22 Software The automation and monitoring of all param-eters is performed by means of a customized software devel-oped within a LabVIEW environmentThe parameters mon-itored are inlet air pressure environmental chamber tem-perature CO

2concentration temperature and airflow rate

of the exhausted airAn appropriate measuringcleaning sequence is ensured

to monitor the parameters of the exhausted air Since thesequence lasts 20 minutes for each vessel a complete mea-surement cycle for 12 vessels lasts 4 hours thus providing 6series of data per day for each vessel

In the first 5min of each sequence (time required formea-sured signals to reach steady state) the air valve opens andthe detector is thus purged with CO

2-free air During the

cleaning cycle a drain valve located at the bottomof the watercondenser opens for 30 seconds to discharge the condensed

4 Advances in Materials Science and Engineering

water accumulated in the previous set of analyses Next thevalve associated with the selected vessel opens for 15 minuteswhile the air valve closes The exhaust air of the selectedvessel enters the infrared sensors until a steady state patternis reached In the last minute of this steady state phase thesoftware acquires the analog signals released every secondfrom each sensor and converts them into average values

Data for each sample is recorded plotted and displayedin final tables graphs and spreadsheetsThe software is struc-tured with a front panel that monitors the trial and showsthe results in real time possible errors occurring during thetrialmdashsuch as flow line blockage or unexpected temperatureor pressure line drops in the chambermdashare continuouslychecked by the software If called for a specific alarm signalappears on the screen for each vessel

23 Experimental Conditions In keepingwith severalmetho-dologies reported in the literature [17] our trials wereconducted in triplicate 3 vessels contained the inoculum3 vessels contained compost plus a reference biodegradablematerial (namely cellulose Sigma-Aldrich) and 3 vesselscontained compost plus specimen Since the apparatus coulddrive up to 12 vessels each trial involved two samples

We carried out two biodegradation trials on three bio-polymers two different poly(120576-caprolactone) (PCL) compos-ites (sample A and sample B) and a commercially availablecompatibilized polylactic acid and polybutyrate (PLAPBAT) blend (sample C ECOVIO IS 1335 BASF Germany)A polyethylene (PE) film (sample D) was used as negativereference Each vessel charge included 276 g of inoculum (wetweight) which filled about two-thirds of the internal volumeplus 23 g of the specimen or reference material (Table 1)Twenty-three g (dry weight) of agricultural perlite previouslyhumidified up to its maximum water retention (765)was added to each vessel to reduce the bulk density of theinoculum and provide better air circulation in it The plasticspecimenwasmilled (lt1mm) and thoroughlymixedwith theinoculum at the start of trial ensuring a 1 6 plastic ino-culum weight ratio on a dry matter basis Throughout thetrial we shook the samples manually once per week toachieve more homogeneity in the degradation process of thespecimenThemoisture content of the inoculumwas adjustedto about 50 (ww) at the start of the trials and held constantby means of inlet air humidification However during theweekly shaking proceduremoisturewas controlled byweigh-ing each vessel and distilled water was added if necessaryThecarbon and nitrogen content of the samples was determinedusing a CHNS analyser (Macro Cube Elemental Germany)equipped with selective traps for CO

2 H2O and SO

2and

detected by thermal conductivity The ash content was deter-mined as weight loss at 650∘C for 24 h in a muffle furnaceon samples previously oven dried at 105∘C The inoculumemployed in the biodegradation trials was the compostobtained at the end of a static composting procedure set upfor OMWmanagement as described in Altieri and Esposito[18] and Altieri et al [19] The OMW compost used asinoculum was produced in 2013 and stored dry until the daybefore use when it was moistened to about 50 for the trialThis procedure keeps alive the microorganism populations

that drive the biodegradation of the plastic samplesThe envi-ronmental chamber was set at 58 plusmn 2∘C which is representa-tive of full-scale composting Vessel flows were set at 20 L hminus1and fresh air at 60 L hminus1 to adequately clean up the measure-ment line

The degree of biodegradation is determined from theamount of specimen carbon converted to CO

2by the end

of the trial CO2emissions automatically calculated for each

measurement cycle and then cumulated are converted tomass values with the following general equation

CO2sample =

119876 sdot CO2sdot Δ119905 sdot 119872 (CO

2)

119881119898

(1)

where 119876 is the flow rate measured with the gas mass meterCO2is the CO

2concentration measured with the IRGA

sensors and corrected for the background CO2concentration

of the inlet CO2-free air Δ119905 is the period of the measurement

cycle 119872 (CO2) is the molar mass of CO

2 and 119881

119898is the

volume occupied by one mole of CO2at the exhaust-air

temperature as determined by the local in-line sensor Themolar volume of CO

2is calculated using the following

119881119898= 119877 sdot119879out119875atm (2)

where 119877 is the ideal gas constant 119879out is the temperature ofthe outlet flow and 119875atm is the atmospheric air pressure

The percentage of biodegradation for each specimen iscalculated as

119863sample =CO2sample minus CO2inoculum

ThCO2

(3)

where CO2sample and CO2inoculum are both calculated with (1)

and ThCO2is the theoretical (maximum) amount of CO

2

released from the fully mineralized sample calculated on thebasis of its organic carbon content

24 Check of the CO2 Emissions by the Titration Method Inorder to confirm the results obtained by the experimentalapparatus the amount of CO

2released during biodegrada-

tion was also checked using the standard titration methodreported in ISO 175562012 [20] The comparison of themethodswas based on a fixed observation time Exhausted airfrom a randomly chosen vessel was directed towards a seriesof three 2-L vessels fitted with gas diffusers and containingsaturated Ba(OH)

2solution able to capture the CO

2(method

2 Figure 1) In fact when CO2enters the scrubbing vessels it

reacts as follows

Ba (OH)2+ CO2997888rarr BaCO

3+H2O (4)

The barium carbonate formed is insoluble and precipitatesThe excess of Ba(OH)

2in the three CO

2scrubbing vessels

was then determined by end-point titration with HCl usingphenolphthalein as indicator according to the followingequation

Ba (OH)2+ 2HCl 997888rarr BaCl

2+ 2H2O (5)

Advances in Materials Science and Engineering 5

Table 1 Characteristics of the samples used in the trials of the experimental apparatus

Inoculum A B C D RefCompost PCL PCL PLAPBAT PE

Amount g vesselminus1 2760 230 230 230 230 230Moisture 5110 114 275 041 046 0Ashlowast 1800 121 207 590 035 0Carbonlowast 447 605 590 584 840 444Nitrogenlowast 450 256 376 018 109 0ThCO

2g vesselminus1 2212 504 484 490 705 374

lowastData are referred on dry matter base PCL poly(120576-caprolactone) composite PLAPBAT compatibilized polylactic acid and polybutyrate blend PEpolyethylene (negative reference) Ref reference (pure cellulose Sigma-Aldrich) ThCO2 theoretical CO2 emission

From (4) and (5) one can calculate the number of mmoles ofCO2produced in a fixed time as follows

mmolesCO2= mmolesBa (OH)

2minusmmolesHCl2 (6)

where mmoles Ba(OH)2is the initial number of mmoles

of Ba(OH)2 The CO

2scrubbing solution was prepared by

dissolving Ba(OH)2in distilled water filtering it and sealing

it to prevent absorption of CO2from the atmosphere It was

then stored as standard clear solution However since it isquite unstable the actual concentration of the initial solutionwas determined by titrationwith a standardHCl 005Mpriorto each use

3 Results and Discussion

Thefindings of the biodegradation experiment carried out onA and B plastic polymers (Table 1) are given in Figures 4 and5 Both graphics show average values with related standarderror evaluated every four hours and calculated using (1)(CO2emission per vessel) and by (3) (degree of biodegrada-

tion) Figure 4 shows a very high degradation rate for bothplastic polymers testedmdasheven higher than that of the biodeg-radable standard (cellulose)mdashstarting right from the earlystages of the trial In fact after about 20 days both plasticsreached a percentage of biodegradation higher than 80(Figure 5) about double that of cellulose (about 45) Thehigh nitrogen levels of specimens A and B (Table 1) mightexplain their more rapid biodegradation indeed biomasshaving a lower CN ratio is more easily degraded bymicroor-ganisms which can then find an appropriate source ofnitrogen for supporting their metabolism and reproduction

In the first trial after 10 days the inoculum showed acumulated emission of 94 plusmn 01 gCO

2vesselminus1 which corre-

sponds to 863 plusmn 13mgCO2per gram of volatile solidsmdasha

value falling in the range prescribed by ISO 14855-12012 andconsidered optimal for successfully conducting biodegrada-tion tests under composting conditions [17] Thus compostbased on OMW as inoculum showed to be adequately rich inmicroorganisms that drive biodegradation of the specimenstested At the end of the first trial a cumulated emission equalto 310 plusmn 33 gCO

2vesselminus1 was registered for the reference

material (cellulose) which corresponds to 450 plusmn 92 bio-degradation (coefficient of variation CV = 205) At that

60

50

40

30

20

10

0

Time (day)0 5 10 15 20

AB

InoculumRef