Research Article Improvement of L-Arabinose Fermentation...

Transcript of Research Article Improvement of L-Arabinose Fermentation...

Hindawi Publishing CorporationBioMed Research InternationalVolume 2013 Article ID 461204 9 pageshttpdxdoiorg1011552013461204

Research ArticleImprovement of L-Arabinose Fermentation by Modifying theMetabolic Pathway and Transport in Saccharomyces cerevisiae

Chengqiang Wang Yu Shen Yanyan Zhang Fan Suo Jin Hou and Xiaoming Bao

The State Key Laboratory of Microbial Technology Shandong University Shan Da Nan Road No 27 Jinan 250100 China

Correspondence should be addressed to Xiaoming Bao bxmsdueducn

Received 18 June 2013 Accepted 25 August 2013

Academic Editor Gotthard Kunze

Copyright copy 2013 Chengqiang Wang et al This is an open access article distributed under the Creative Commons AttributionLicense which permits unrestricted use distribution and reproduction in any medium provided the original work is properlycited

TheL-arabinose utilization pathwaywas established in Saccharomyces cerevisiae by expressing the codon-optimized araA araB andaraD genes of Lactobacillus plantarum After overexpressing the TAL1 TKL1 RPE1 RKI1 and GAL2 genes and adaptive evolutionthe L-arabinose utilization of the recombinant strain became efficient The resulting strain displayed a maximum specific growthrate of 0075 hminus1 a maximum specific L-arabinose consumption rate of 061 g hminus1 gminus1 dry cell weight and a promising ethanol yieldof 043 g gminus1 from L-arabinose fermentation

1 Introduction

To reduce the dependence on fossil fuels the worldwideproduction of bioethanol was increased from sim45 millionliters in 2005 to sim113 billion liters in 2012 [1ndash3] The futurelarge-scale production of fuel ethanol will most likely bebased on abundant lignocellulosic materials instead of sugarand grain which are food for humans and animals [4]Cost-effective fuel ethanol production from lignocellulosicmaterials requires the full use of the raw materials Onegoal of bioethanol production is to endow the fermentationmicroorganism with the capacity to convert all of the sugarsin lignocellulosic materials [5 6] Approximately 3ndash15 L-arabinose component can be recovered from lignocellulosicmaterials [7] It is therefore necessary to construct an L-arabinose fermenting microorganism to increase the utiliza-tion of this sugar [8]

Two types of L-arabinose metabolic pathways exist infungi and bacteria The aldose reductase (AR) L-arabitol-4-dehydrogenase (LAD) L-xylulose reductase (LXR) andD-xylitol dehydrogenase (XDH) constitute the fungal L-arabinose metabolic pathway The reaction catalyzed by ARand LXR is coupled with the oxidation of NADPH toNADP+ and the LAD and XDH use NAD+ as a cofactor[9] The xylulose produced is phosphorylated and enters the

pentose-phosphate pathway (PPP)The bacterial L-arabinosemetabolic pathway is cofactor independent and consistsof L-arabinose isomerase (AraA) L-ribulokinase (AraB)and L-ribulose-5-phosphate 4-epimerase (AraD) The D-xylulose-5-phosphate produced enters the PPP [9 10] BothL-arabinose metabolic pathways were established in Saccha-romyces cerevisiae which is the traditional ethanol-producingmicroorganism with excellent sugar fermenting capacity andtolerance to the harsh environment but it cannot ferment L-arabinose [11] Not surprisingly a redox imbalance occurs inthe recombinant S cerevisiae strain containing the fungal L-arabinose metabolic pathway The yield of the by-product L-arabitol was as high as 048 g gminus1 of pentose sugar consumedin the D-xylose and L-arabinose cofermentation althoughthe strain expressing NADH preferred AR and LXR todecrease the redox imbalance [12]

Compared to the fungal L-arabinose metabolic pathwaythe bacterial pathway is simpler and cofactor independentHowever because of the lack of effective activity assays forenzymes involved in the bacterial L-arabinose metabolicpathway the optimization of this pathway in S cerevisiaewas not straightforward The S cerevisiae strain expressingthe araA araB and araD genes of Escherichia coli could notutilize L-arabinose However after the E coli L-arabinoseisomerase gene was replaced with the araA cloned from

2 BioMed Research International

Bacillus subtilis the strain could grow and produce ethanolon L-arabinose after several circles of adaptive growth [1314] Furthermore the L-arabinose utilization was furtherimproved by changing the codon usage of the bacterial araAaraB and araD genes to the preferred yeast codons [15]The L-arabinose metabolic genes of Lactobacillus plantarummatched the codon usage of S cerevisiae more closely thanthe genes previously reported Wisselink et al [8] introducedmultiple copies of araA and araD and a single copy ofaraB of L plantarum into S cerevisiae After overexpressingthe genes encoding the enzymes of nonoxidative PPP andextensive adaptive evolution the resulting strain exhibited ahigh ethanol yield up to 043 g gminus1 during anaerobic growthon L-arabinose with a high arabinose consumption rate(070 g hminus1 gminus1 dry cell weight (DCW)) [8] The metabolometranscriptome and metabolic flux analysis of a more evolvedstrain revealed that higher expression levels of the galactosetransporter transketolase and transaldolase isoenzymes ben-efit the growth of S cerevisiae on L-arabinose [16]

In the present work the unique codon-optimized araAaraB and araD genes of L plantarum were expressed inthe S cerevisiae strain CENPK102-3A at different levelsNext the genes TAL1 TKL1 RPE1 and RKI1 involved inPPP were overexpressed in this recombinant strain Theresulting strain was sequentially selected on L-arabinoseunder aerobic conditions and in oxygen-limited conditionsA strain with a significantly enhanced L-arabinose utilizationcapacity was obtained The L-arabinose metabolic capacityof the evolved strains and the strain that also overexpressedthe transporter gene GAL2 were investigated The factorsaffecting L-arabinose metabolism efficiency are discussed

2 Materials and Methods

21 Media and Culture Conditions The yeast synthetic com-plete medium (SC) containing 17 g Lminus1 yeast nitrogen base(YNB Sangon China) and 5 g Lminus1 ammonium sulfate (San-gon China) with additional carbon sources of glucose (San-gon China) or L-arabinose (Sinopharm China) was usedfor yeast cultivation The complete supplement mixture077 g Lminus1 CSM-URAor 067 g Lminus1 CSM-LEU-URA (MPBio-medicals Solon OH) was added to maintain the requiredplasmids with auxotrophic selection when necessary Forstrains with the KanMX4 marker the medium was suppliedwith 200120583gmLminus1 of the antibiotic G418 sulfate (PromegaMadison WI USA) All yeasts were cultivated at 30∘C

22 Codon Adaptation Index Analysis The codon adapta-tion index (CAI) is used to illustrate the preference ofcodon usage in specific species [24] For the CAI analysisCODONW (httpmobylepasteurfrcgi-binMobylePortalportalpyform=codonw) [15] was used

23 Plasmid and Strain Construction E coli DH5120572 [12] wasused for subcloning S cerevisiae strains and plasmids used inthis study are listed in Table 1 The primers used in this studyare listed in Table 2

The unique codon-optimized araA araB and araD genesencoding the L-arabinose isomerase (GenBank CCC805171)L-ribulokinase (GenBank CCC805191) and L-ribulose-5-phosphate 4-epimerase (GenBank CCC805181) of L Plan-tarum were artificially synthesized and ligated between theHXT7 promoter and PGK1 terminator sequences of plasmidpHX which was constructed by substituting the PGK1p ofplasmid YEp24-PGKp [20] with HXT7p containing sites forthe restriction enzymes Kpn I and Sma I The HXT7p-araD-PGK1t fragment was amplified by PCR with terminal sitesfor the restriction enzymes Hind III and Bln I and theninserted into the Hind III and Nhe I sites of YIp5 resultingin plasmid YIp5-araD The HXT7p-araA-PGK1t fragmentcontaining terminal Bgl II and Sal I sites was inserted into theBamH I and Sal I sites of YIp5-araD resulting in the plasmidYIp5-araAD The HXT7p-araB-PGK1t fragment with Eag Iand Stu I sites was inserted into the Eag I and Stu I sites ofYIp5-araAD resulting in the plasmid YIp5-ara (Figure 1(a))The TEF1 promoter fragment (with terminal sites for HindIII and Sal I) and the PGK1 terminator fragment (withterminal sites for BamH I andHind III) were cloned from theplasmids pJFE3 [23] and pYMIKP [25] respectively Thesetwo fragments were ligated and inserted into the plasmidpYX242 to construct a vector pYX242-WS with two sitesthat can be used to express genes Then the gene araA wasinserted between the Sal I and Sac I sites of this vector undercontrol of the TEF1 promoter and the PloyA terminator for itsexpression and the resulting plasmid was named pYX2422-TEF1araA (Figure 1(b)) The plasmid pYX2422-HXT7araA(Figure 1(b))was constructed using the fragment ofHXT7p todisplace the TEF1p fragment of plasmid pYX2422-TEF1araAthe joints were BamH I and Sal I recognition sequencesThe gene GAL2 was cloned from the chromosomal DNA ofCENPK102-3A and then inserted into the Xba I and Sal Isites of plasmid pJFE3 resulting in plasmid pJFE3-GAL2TheURA3 fragment of plasmid pJFE3-GAL2 between the Nde IandApa I siteswas replaced by theKanMX4 gene cloned frompUG6 [18] resulting in plasmid pJFE318-GAL2 (Figure 1(c))

The yeast transformation was performed using the lith-ium acetate transformation method [26] The plasmid YIp5-ara was linearized at the Stu I site and then transformedinto CENPK102-3A The transformants with the araA araBand araD genes integrated into the chromosomalURA3 genewere selected in SCmedium containing CSM-URA and afterbeing confirmed by sequencing the desired transformantwasnamed BSW1A1 Plasmids pYX242 pYX2422-HXT7araAand pYX2422-TEF1araA were transformed into BSW1A1resulting in BSW1AY BSW1A7 and BSW1AT respectivelyThe linearized pJPPP3 which contains the expression framesof genes TAL1 TKL1 RPE1 and RKI1 [19] was integratedinto the chromosome of BSW1AT at the GRE3 gene locusresulting in strain BSW2APThe strain BSW2APwas adaptedon 20 g Lminus1 L-arabinose under aerobic conditions and thenunder oxygen-limited conditions Once the stationary phasewas reached a new batch was initiated by transferringthe culture into fresh medium with an initial biomassof 015 gDCWLminus1 When the doubling time of the strainstabilized mutant BSW3AP was selected from the adapted

BioMed Research International 3

Table 1 S cerevisiae strains and plasmids used in this study

Relevant genotype SourcereferenceStrain

CENPK102-3A MAT120572 leu2-3 112 ura3-52 [17]BSW1A1 CENPK102-3A derivative YIp5-ara This workBSW1AY CENPK102-3A derivative YIp5-ara pYX242 This workBSW1A7 CENPK102-3A derivative YIp5-ara pYX2422-HXT7araA This workBSW1AT CENPK102-3A derivative YIp5-ara pYX2422-TEF1araA This work

BSW2AP BSW1AT gre3 (minus241 +338)TPI1p-RKI1-RKI1t-PGK1p-TAL1-TAL1t-FBA1p-TKL1-TKL1t-ADH1p-RPE1-RPE1t-loxP This work

BSW3AP BSW2AP selected for oxygen-limited growth on L-arabinose This workBSW3AG BSW3AP derivative pJFE318-GAL2 This work

PlasmidpUG6 E coli plasmid with segment LoxP-KanMX4-LoxP [18]

pJPPP3pUC19-based yeast integration plasmid containing GRE3-targeting recombinant armsoverexpression cassette of Sc-TAL1 Sc-TKL1 Sc-RPE1 Sc-RKI1 and selectable markerloxP-KanMX4-loxP

[19]

YEp24-PGKp 2120583 URA3 [20]pHX YEp24-PGKp PGK1pHXT7p This workYIp5 Integration plasmid Ura3 [21]

YIp5-ara YIp5-HXT7p-araA-PGK1t-HXT7p-araB-PGK1t-HXT7p-araD-PGK1t and selectablemarker loxP-KanMX4-loxP This work

pYX242 2120583 LEU2 [22]pYX242-WS pYX242-PGK1t-TEF1p This workpYX2422-TEF1araA pYX242-PGK1t-TEF1p-araA This workpYX2422-HXT7araA pYX242-PGK1t-HXT7p-araA This workpJFE3 2120583 URA3 [23]pJFE3-GAL2 pJFE3-TEF1p-GAL2-PGK1t This workpJFE318-GAL2 pJFE3-GAL2 URA3KanMX4 This work

mutants based on its excellent growth on L-arabinose Theplasmid pJFE318-GAL2 was then transformed into strainBSW3AP resulting in strain BSW3AG

24 Real-Time Quantitative PCR The cells were culturedin SC medium containing 20 g Lminus1 glucose and collectedwhen the OD

600

of cultures reached 1 The total RNA wasextracted using TRIzol reagent (Sangon China) The firststrand of cDNA was reverse transcribed from 1 120583g of totalRNA using PrimeScript RT reagent kits with gDNA Eraser(Takara Japan) Diluted cDNA products were used for real-time quantitative PCR using the SYBR Green Real-timePCR Master Mix (TOYOBO Japan) and the LightCyclePCR System (RocheMolecular Biochemicals Germany)Theactin-encoding gene ACT1 was used as the reference genefor normalization The data of real-time PCR was calculatedaccording to the 2minusΔΔCT method [19 27] The primers forthese PCR were listed in Table 2

25 Fermentation A single colony was cultured overnightin SC medium containing 20 g Lminus1 glucose A sample ofthe overnight culture was diluted to an initial OD

600

of 05

in SC medium containing 10 g Lminus1 glucose and 10 g Lminus1 L-arabinose After 10 h cultivation the cells were collected andused for fermentation All the shaker flask fermentationswere performed at 30∘C 200 rminminus1 in 200mL shaker flaskscontaining 40mL medium The oxygen-limited conditionwas maintained by using a rubber stopper The batch fer-mentations under anaerobic conditions were performed in14 L fermentors (Infors AG Switzerland) with a workingvolume of 900mL Anaerobic conditions were maintained bysparging with nitrogen (01 Lminminus1) the agitation rate was500 rminminus1 The pH was maintained at 50 by automaticallypumping 1mol Lminus1 NaOH and 1mol Lminus1 H

3

PO4

[19] Theinitial biomass was 02 gDCWLminus1 The carbon source in theSC plus CSM-LEU-URA medium was 20 g Lminus1 L-arabinose200120583gmLminus1 G418 was supplied in the fermentation of strainBSW3AG The dry cell weight of evolved strains and theunevolved strains were calculated according to the formulaof dry weight (mgmLminus1) = 0266 times OD

600

minus 00762 and dryweight (mgmLminus1) = 02365 times OD

600

+ 01149 respectively

26 Analysis of Fermentation Products The high perfor-mance liquid chromatography (HPLC) Prominence LC-20A (Shimadzu Japan) equipped with the refractive index

4 BioMed Research International

Table2Oligon

ucleotides

used

inthiswork

Prim

ers

Sequ

ence

(51015840

-31015840

)Pu

rpose

Hxt7up

stream-H

XCA

TAGAT

CTCT

CACA

AAT

TAGAG

CTTC

AAT

TTAAT

Clon

ingthefragm

ento

fHXT

7p-araA-

PGKt1

Pgk6

downstre

am-S

CATG

TCGAC

AGCA

ATTT

AAC

TGTG

ATAAAC

TACC

GClon

ingthefragm

ento

fHXT

7p-araA-

PGKt1

Hxt7up

stream-EEB

CATC

GGCC

GAG

ATCT

CCTA

GGCT

CACA

AAT

TAGAG

CTTC

AAT

TTAAT

Clon

ingthefragm

ento

fHXT

7p-araB-PG

Kt1

Pgk6

downstre

am-S

CATG

TCGAC

AGCA

ATTT

AAC

TGTG

ATAAAC

TACC

GClon

ingthefragm

ento

fHXT

7p-araB-PG

Kt1

Hxt7up

stream

CATC

CTAG

GCT

CACA

AAT

TAGAG

CTTC

AAT

TTAAT

Clon

ingthefragm

ento

fHXT

7p-araD-PGKt1

Pgk6

downstre

amCA

TCCT

AGGAG

CAAT

TTAAC

TGTG

ATAAAC

TACC

GClon

ingthefragm

ento

fHXT

7p-araD-PGKt1

HXT

7p-F

CCCA

AGCT

TCTC

ACAAAT

TAGAG

CTTC

AAT

TClon

ingHXT

7pHXT

7p-R

ACGCG

TCGAC

ATTG

GAT

CTAG

ATGCA

TTCG

CGClon

ingHXT

7pTE

F1W

upCC

CAAG

CTTC

ACAAT

GCA

TACT

TTGTA

CGTT

Clon

ingTE

F1p

TEF1

Wdo

wn

GCG

CGTC

GAC

TTGTA

ATTA

AAAC

TTAG

ATTA

GClon

ingTE

F1p

AraAW

upAC

GCG

TCGAC

ATGTT

ATCT

GTT

CCTG

ATTA

TGClon

ingaraA

AraAW

down-His

TACG

AGTC

TTTA

GTG

GTG

GTG

GTG

GTG

GTG

TTTT

AAAAAT

GCT

TTTG

TCA

Clon

ingaraA

AraA-

FCA

AGCA

GGTG

GTG

GTC

ATCA

TAC

Forq

uantitativ

ereal-tim

ePCR

ofaraA

AraA-

RTA

CCAAC

CATT

GTA

GCG

TAAT

CTTC

CFo

rquantitativ

ereal-tim

ePCR

ofaraA

AraB-1F

ATGCA

GCA

TTCG

CACC

TTTG

Forq

uantitativ

ereal-tim

ePCR

ofaraB

AraB-1R

CCTT

CACC

TGCT

GTG

GAC

ATFo

rquantitativ

ereal-tim

ePCR

ofaraB

AraD-1F

CCAG

CTGCA

GAT

GCA

TTAAC

TFo

rquantitativ

ereal-tim

ePCR

ofaraD

AraD-1R

ACAG

CCTT

AGCT

GGTG

TTGG

Forq

uantitativ

ereal-tim

ePCR

ofaraD

Gal2up

GCT

CTAG

AAT

GGCA

GTT

GAG

GAG

AAC

AAT

ATGC

Clon

ingGAL

2Gal2do

wn

ACGCG

TCGAC

TTAT

TCTA

GCA

TGGCC

TTGTA

CClon

ingGAL

2pG

418-Ap

aIup

AGTG

GGCC

CTAG

GTC

TAGAG

ATCT

GTT

TAGC

Clon

ingKa

nMX4

pG418-Nde

Idow

nGGAAT

TCCA

TATG

ATTA

AGGGTT

CTCG

AGAG

CTCG

Clon

ingKa

nMX4

BioMed Research International 5

bla

ori

YIp5-ara

HXT7p-araD-PGK1t

HXT7p-araA-PGK1t

URA3

HXT7p-araB-PGK1t

(a)

araAPoly A

ori

LEU2

2120583

blaCol E1

TPIp

PGK1t

TEF1pHXT7p

pYX2422-TEF1araAHXT7araA

(b)

ori

GAL22120583

bla

KanMX4

PGK1t

TEF1p

pJFE318-GAL2

(c)

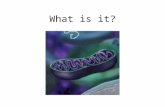

Figure 1 The physical maps of the plasmids (a) YIp5-ara (b) pYX2422-TEF1araAHXT7araA and (c) pJFE318-GAL2

detector RID-10A (Shimadzu Japan) was used to determinethe concentrations of sugars and metabolites The AminexHPX-87P ion exchange column (Bio-Rad USA) was usedto analyze L-arabinose arabitol and ethanol at 80∘C with amobile phase of water at a flow rate of 06mLminminus1 TheAminex HPX-87H ion exchange column (Bio-Rad HerculesUSA) was used to analyze glycerol and acetate at 45∘C using5mmol Lminus1 H

2

SO4

as the mobile phase [12]

3 Results

31 Expression of the Codon-Optimized Genes Involvedin the L-Arabinose Pathway in S cerevisiae Based onthe amino acid sequence of L-arabinose isomerase (Gen-Bank accession no CCC805171) L-ribulokinase (GenBankaccession no CCC805191) and L-ribulose-5-phosphate 4-epimerase (GenBank accession no CCC805181) recorded inthe National Center for Biotechnology Information (NCBIhttpwwwncbinlmnihgov) the araA araB and araDgenes of L plantarum were artificially synthesized using Scerevisiae preferred codons The CAIs of codon-optimizedaraA araB and araD were 0599 0580 and 0646 respec-tively which were higher than those of the native sequences(0324 0223 and 0243 resp)

The expression cassettes of codon-optimized araAaraB and araD were integrated into the chromosome ofstrain CENPK102-3A resulting in strain BSW1A1 However

BSW1A1 could not grow on L-arabinose although the tran-scribedmRNAs of these geneswere all detectableThenmorecopies of araA were introduced into BSW1A1 carried by theepisomal plasmid pYX242 and expressed under control of theHXT7 andTEF1 promotersThe transcriptional levels of araAin the resulting strains BSW1A7 and BSW1AT were 129 plusmn29-fold and 325plusmn07-fold higher than in the reference strainBSW1AY carrying only the integrated expressed araA TheBSW1A7 and BSW1AT strains were aerobically incubated onL-arabinose and the growth of strain BSW1AT was observedafter sim150 h whereas BSW1A7 could not grow even whencultured longer

32 Improvement of the L-Arabinose Utilization in S cerevisiaeby Engineering and Evolution The TAL1 TKL1 RPE1 andRKI1 genes involved in the nonoxidative pentose phosphatepathway were overexpressed in a single colony isolated fromthe BSW1AT 150 h culture by integrating the linearized plas-mid pJPPP3 [19] into the chromosome The resulting strainBSW2AP was evolved on L-arabinose After 9 transfersin aerobic conditions and 12 transfers in oxygen-limitedconditions the doubling time of the culture decreased from22 h to 45 h The mutants were screened on L-arabinoseplates and a large colony was selected and named BSW3AP

The transcriptional levels of genes in the recombinantstrains BSW1AT BSW2AP andBSW3APwere determined byreal-time quantitative PCR (Figure 2) The araA expression

6 BioMed Research International

0

1

2

3

4

5

6

7

BSW1AT BSW2AP BSW3AP

Relat

ive e

xpre

ssio

n

araAaraBaraD

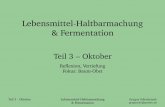

Figure 2The expression of araA (black bars) araB (gray bars) andaraD (blank bars) of strains BSW2AP and BSW3AP compared tostrain BSW1AT The fold-changes of mRNA levels of these genesare normalized to the expression of ACT1 The tested strains werecultivated on 20 g Lminus1 glucose The values given are obtained fromthree independent measurements

level in BSW2APwas 2-fold higher than in BSW1AT whereasthe expression levels of araB and araD in BSW2AP werelowerThese changesmight be due tomutations that occurredduring the cultivation of BSW1AT on L-arabinose In theevolved strain BSW3AP all three geneswere expressed at highlevelsThe araA araB and araD expression levels in BSW3APwere 41-fold 16-fold and 25-fold higher than those in strainBSW1AT respectively

The L-arabinose utilization of strains BSW1AT BSW2APand BSW3AP was compared in shaker-flasks under oxygen-limited conditions (Figure 3) the initial OD

600

was 05 Nogrowth of BSW1AT was observed within 120 h The strainBSW2AP grew on L-arabinose with a maximum specificgrowth rate (120583max) of 0011 hminus1 44 g Lminus1 L-arabinose wasconsumed and 12 g Lminus1 ethanol was produced in 120 h offermentation In contrast the 120583max of the evolved strainBSW3AP increased to 023 hminus1 After 120 h of fermentation186 g Lminus1 L-arabinose had been consumed with a maximumspecific consumption rate of 07 g hminus1 gminus1DCW 69 g Lminus1ethanol had been produced and the ethanol yield was043 g gminus1 only 013 g Lminus1 L-arabitol had accumulated

33 Overexpression of GAL2 Improved the L-Arabinose Anaer-obic Fermentation of the Evolved Strain The galactose per-mease gene GAL2 was overexpressed in BSW3AP resultingin strain BSW3AG The anaerobic L-arabinose fermentationproperties of strain BSW3AP and BSW3AG were studied(Figure 4 and Table 3) in bioreactors Strain BSW3AP grewon L-arabinose with a maximum specific growth rate of

0067 hminus1 The maximum specific consumption rate of L-arabinose was 049 g hminus1 gminus1DCW Ethanol was producedat a maximum specific rate of 020 g hminus1 gminus1DCW with ayield of 042 g gminus1 The overexpression of GAL2 significantlyimproved the L-arabinose fermentation capacity The maxi-mum specific growth rate of BSW3AG was 0075 hminus1 whichwas 12 faster than that of BSW3APThe L-arabinose specificconsumption rate of BSW3AGwas 061 g hminus1 gminus1DCWwhichwas 24 faster than that of BSW3AP The ethanol produc-tion rate was 027 g hminus1 gminus1DCW and the ethanol yield was043 g gminus1 Furthermore both BSW3AP and BSW3AG pro-duced small amounts of glycerol (14 g Lminus1 for both strains)and almost undetectable amounts of arabitol and acetate

4 Discussion

The complete conversion of sugars is important for efficientand cost-effective fuel ethanol production from lignocel-lulosic materials Even small improvements in substrateutilization can significantly decrease the costs of the wholeprocess [28] L-arabinose is an important component oflignocellulosic materials Expression of the L plantarum L-arabinose pathway has proven to be effective in constructingL-arabinose utilizing S cerevisiae [8] Given that the codon-optimized genes might lead to increased expression of theproteins [15 29] in the present work the original araAaraB and araD genes of L plantarum were modified tomatch the codon usage of S cerevisiae and then integratedinto the chromosome of strain CENPK102-3A Howeverthis recombinant strain could not grow on L-arabinoseMore copies of the araA gene were then introduced into therecombinant strain under the control of the HXT7 and TEF1promoters When the two resulting strains were culturedon L-arabinose growth was only observed in cultures ofthe strain expressing araA under the control of the TEF1promoter in which the araA transcriptional level was 14-foldhigher than in the strain expressing araA controlled by theHXT7 promoterWe suggest that only when the transcriptionlevel of araA is higher than a certain level can growth onL-arabinose occur In contrast only one copy of araB andaraD was introduced into this recombinant strain and thetranscriptional levels of these genes were lower than in theparental strain These phenomena indicated that araB andaraD were less important for growth on L-arabinose becauseonly one copy of these genes allowed the recombinant strainto grow on L-arabinose

Adaptive evolution was proven to be a powerful methodto enhance the strainsrsquo metabolic efficiency [8 13] In thepresent study the evolved strain BSW3AP shows significantlyimproved L-arabinose metabolizing capacity The increasedtranscription levels of all the three genes (araA araB andaraD) might contribute to the enhancement Compared toaraA and araD the expression level of araB was lowerBecker and Boles [13] reported that a mutant on L-arabinosedecreased the L-ribulokinase activity expressed by araB Therelatively lower expression of araB avoids the overconsump-tion of ATP which would benefit the growth of the strain onL-arabinose

BioMed Research International 7

0

2

4

6

8

10

12

14

0 20 40 60 80 100 120 140Time (h)

OD600

(a)

0

3

6

9

12

15

18

21

24

0 20 40 60 80 100 120 140Time (h)

Ara

bino

se (g

Lminus1)

(b)

0

02

04

06

08

1

0 20 40 60 80 100 120 140Time (h)

Ara

bito

l (g L

minus1)

(c)

0

1

2

3

4

5

6

7

8

0 20 40 60 80 100 120 140Time (h)

Etha

nol (

g Lminus1)

(d)

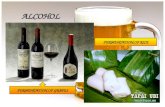

Figure 3The L-arabinose fermentation of strains in shaker flasks Growth capacity (a) L-arabinose consumption (b) arabitol formation (c)and ethanol formation (d) by BSW1AT (998771) BSW2AP (◼) and BSW3AP (e) The strains were cultured in 40mL SC medium with 20 g Lminus1L-arabinose at 30∘C 200 rminminus1 with an initial OD

600

of 05 The data are the averages of three independent experiments

Table 3 The maximum specific growth rates (120583max) the maximum specific L-arabinose-consumption rate the ethanol production rate andthe ethanol yield for BSW3AP and BSW3AG on 20 g Lminus1 L-arabinose

Strain 120583max (hminus1)

The maximum specificL-arabinose consumption rate

(g hminus1 gminus1 DCW)

Ethanol production rate(g hminus1 gminus1 DCW)

Ethanol yield(g gminus1 L-arabinose consumed)

BSW3AP 0067 049 020 042BSW3AG 0075 061 027 043

8 BioMed Research International

0

2

4

6

8

10

12

0

3

6

9

12

15

18

21

24

0 20 40 60 80Time (h)

Ara

bino

se e

than

ol g

lyce

rol

acet

ate

OD600

(g Lminus1)

(a)

0

2

4

6

8

10

12

0

3

6

9

12

15

18

21

24

0 20 40 60 80Time (h)

Ara

bino

se e

than

ol g

lyce

rol

acet

ate

OD600

(g Lminus1)

(b)

Figure 4 The anaerobic batch fermentation of BSW3AP (a) and BSW3AG (b) on 20 g Lminus1 arabinose Levels of OD600

(◼) arabinose(X) ethanol (998771) Glycerol (e) and acetate (times) The fermentation was performed in 14 L fermentors with a working volume of 900mLAnaerobic conditions were maintained by sparging nitrogen (01 Lminminus1) the agitation rate was 500 rminminus1 The pH was maintained at 50by automatically pumping in 1mol Lminus1 NaOH and 1mol Lminus1 H

3

PO4

The initial biomass was 0 2 gDCWLminus1 The 20 g Lminus1 L-arabinose wasused as the carbon source in SC plus CSM-LEU-URA medium and 200120583gmLminus1 G418 was supplied in the fermentation of strain BSW3AGThe data are the average of duplicate determinations

L-arabinose is a novel carbon source for S cerevisiaeThe uptake of L-arabinose in S cerevisiaemainly depends onthe nonspecific transport by the hexose transporter Gal2pThe Hxt9p and Hxt10p also can transport L-arabinose butthe efficiency is very low [30] It was reported that overex-pressing GAL2 improves the L-arabinose utilization [13 16]In this study overexpressing GAL2 notably increased thegrowth rate and L-arabinose consumption rate of our evolvedstrain BSW3AP This result suggested that the theoreticalL-arabinose metabolic flux was higher than we detected inBSW3APTheL-arabinose utilization of BSW3APwas limitedby its absorption rate When the GAL2 was overexpressedmore Gal2p in the plasma membrane lead to an increasedL-arabinose uptake and then promote the L-arabinose uti-lization Our result further confirmed the importance oftransporters for L-arabinose utilization however the affinityof Gal2p for L-arabinose is low and glucose competitivelyinhibited its binding to L-arabinose [30] Improving theefficiency of the L-arabinose specific transporter remains tobe conducted

5 Conclusions

With multiple steps of genetic engineering and adaptiveevolution we obtained the strain BSW3AG which grows on

L-arabinose with a 120583max of 0075 hminus1 The maximum specific

L-arabinose consumption rate is 027 g hminus1 gminus1DCW and themaximum ethanol yield is 043 g gminus1 L-arabinose consumedwhich is 843 of the theoretical amount A high level of araAexpression is notably important in establishing an efficient L-arabinose pathway in S cerevisiae and more efficient trans-porters are necessary to improve the L-arabinose absorptioncapacity of the evolved strains

Conflict of Interests

The authors declare that they have no conflict of interests

Acknowledgments

This work was supported by the National Key Basic ResearchProgram (2011CB707405) the National High-TechnologyResearch and Development Program of China under Grant(2012AA022106) the National Natural Science Foundation ofChina (30970091 31070096 and 31270151) and the Interna-tional SampT Cooperation Program of China (2010DFA32560)The authors thank Dr Peter Kotter from Johann WolfgangGoethe-University Frankfurt for the strain CENPK102-3A

BioMed Research International 9

References

[1] R den Haan H Kroukamp M Mert M Bloom J F Gorgensand W H van Zyl ldquoEngineering Saccharomyces cerevisiaefor next generation ethanol productionrdquo Journal of ChemicalTechnology amp Biotechnology vol 88 no 6 pp 983ndash991 2013

[2] W E Mabee ldquoPolicy options to support biofuel productionrdquoAdvances in Biochemical EngineeringBiotechnology vol 108 pp329ndash357 2007

[3] A E Farrell R J Plevin B T Turner A D Jones M OrsquoHareand D M Kammen ldquoEthanol can contribute to energy andenvironmental goalsrdquo Science vol 311 no 5760 pp 506ndash5082006

[4] B Hahn-Hagerdal M Galbe M F Gorwa-Grauslund GLiden and G Zacchi ldquoBio-ethanolmdashthe fuel of tomorrow fromthe residues of todayrdquoTrends in Biotechnology vol 24 no 12 pp549ndash556 2006

[5] M Galbe and G Zacchi ldquoA review of the production of ethanolfrom softwoodrdquo Applied Microbiology and Biotechnology vol59 no 6 pp 618ndash628 2002

[6] S R Kim S Ha N Wei E J Oh and Y Jin ldquoSimultaneousco-fermentation of mixed sugars a promising strategy forproducing cellulosic ethanolrdquo Trends in Biotechnology vol 30no 5 pp 274ndash282 2012

[7] B Seiboth and B Metz ldquoFungal arabinan and L-arabinosemetabolismrdquo Applied Microbiology and Biotechnology vol 89no 6 pp 1665ndash1673 2011

[8] H W Wisselink M J Toirkens M D R F Berriel et alldquoEngineering of Saccharomyces cerevisiae for efficient anaerobicalcoholic fermentation of L-arabinoserdquo Applied and Environ-mental Microbiology vol 73 no 15 pp 4881ndash4891 2007

[9] B Hahn-Hagerdal K Karhumaa M Jeppsson and M FGorwa-Grauslund ldquoMetabolic engineering for pentose uti-lization in Saccharomyces cerevisiaerdquo Advances in BiochemicalEngineeringBiotechnology vol 108 pp 147ndash177 2007

[10] R Schleif ldquoRegulation of the L-arabinose operon of Escherichiacolirdquo Trends in Genetics vol 16 no 12 pp 559ndash565 2000

[11] C Fonseca R Romao H R de Sousa B Hahn-Hagerdal andI Spencer-Martins ldquoL-arabinose transport and catabolism inyeastrdquo FEBS Journal vol 274 no 14 pp 3589ndash3600 2007

[12] M Bettiga O Bengtsson B Hahn-Hagerdal and M F Gorwa-Grauslund ldquoArabinose and xylose fermentation by recombinantSaccharomyces cerevisiae expressing a fungal pentose utilizationpathwayrdquoMicrobial Cell Factories vol 8 article 40 2009

[13] J Becker and E Boles ldquoA modified Saccharomyces cerevisiaestrain that consumes L-arabinose and produces ethanolrdquo Ap-plied and Environmental Microbiology vol 69 no 7 pp 4144ndash4150 2003

[14] M Sedlak and N W Y Ho ldquoExpression of E coliaraBADoperon encoding enzymes for metabolizing L-arabinose inSaccharomyces cerevisiaerdquo Enzyme and Microbial Technologyvol 28 no 1 pp 16ndash24 2001

[15] BWiedemann and E Boles ldquoCodon-optimized bacterial genesimprove L-arabinose fermentation in recombinant Saccha-romyces cerevisiaerdquo Applied and Environmental Microbiologyvol 74 no 7 pp 2043ndash2050 2008

[16] HWWisselink C Cipollina B Oud et al ldquoMetabolome tran-scriptome andmetabolic flux analysis of arabinose fermentationby engineered Saccharomyces cerevisiaerdquoMetabolic Engineeringvol 12 no 6 pp 537ndash551 2010

[17] K D Entian and P Kotter ldquo23 yeast mutant and plasmidcollectionsrdquo in Methods in Microbiology J P B Alistair and

TMick Eds pp 431ndash449Academic PressNewYorkNYUSA1998

[18] U Guldener S Heck T Fiedler J Beinhauer and J H Hege-mann ldquoA new efficient gene disruption cassette for repeated usein budding yeastrdquo Nucleic Acids Research vol 24 no 13 pp2519ndash2524 1996

[19] B Peng Y Shen X Li X Chen J Hou and X Bao ldquoImprove-ment of xylose fermentation in respiratory-deficient xylose-fermenting Saccharomyces cerevisiaerdquo Metabolic Engineeringvol 14 no 1 pp 9ndash18 2012

[20] MWalfridsson M Anderlund X Bao and B Hahn-HagerdalldquoExpression of different levels of enzymes from the PichiastipitisXYL1 andXYL2 genes in Saccharomyces cerevisiae and itseffects on product formation during xylose utilisationrdquo AppliedMicrobiology and Biotechnology vol 48 no 2 pp 218ndash224 1997

[21] K Struhl D T Stinchcomb S Scherer and RW Davis ldquoHigh-frequency transformation of yeast autonomous replication ofhybrid DNAmoleculesrdquo Proceedings of the National Academy ofSciences of the United States of America vol 76 no 3 pp 1035ndash1039 1979

[22] X Liu X Zhang C Wang L Liu M Lei and X Bao ldquoGeneticand comparative transcriptome analysis of bromodomain factor1 in the salt stress response of Saccharomyces cerevisiaerdquoCurrentMicrobiology vol 54 no 4 pp 325ndash330 2007

[23] Y Shen X Chen B Peng L Chen J Hou and X Bao ldquoAnefficient xylose-fermenting recombinant Saccharomyces cere-visiae strain obtained through adaptive evolution and its globaltranscription profilerdquo Applied Microbiology and Biotechnologyvol 96 no 4 pp 1079ndash1091 2012

[24] PM Sharp andW Li ldquoThe codon adaptation indexmdashameasureof directional synonymous codon usage bias and its potentialapplicationsrdquoNucleic Acids Research vol 15 no 3 pp 1281ndash12951987

[25] L Ji Y Shen L Xu B Peng Y Xiao and X Bao ldquoEnhancedresistance of Saccharomyces cerevisiae to vanillin by expressionof lacA fromTrametes sp AH28-2rdquo Bioresource Technology vol102 no 17 pp 8105ndash8109 2011

[26] R D Gietz R H Schiestl A R Willems and R A WoodsldquoStudies on the transformation of intact yeast cells by theLiAcSS-DNAPEGprocedurerdquoYeast vol 11 no 4 pp 355ndash3601995

[27] K J Livak and T D Schmittgen ldquoAnalysis of relative geneexpression data using real-time quantitative PCR and the2

minus998779998779CT methodrdquoMethods vol 25 no 4 pp 402ndash408 2001[28] M von Sivers and G Zacchi ldquoEthanol from lignocellulosics a

review of the economyrdquo Bioresource Technology vol 56 no 2-3pp 131ndash140 1996

[29] G Wu Y Zheng I Qureshi et al ldquoSGDB a database ofsynthetic genes re-designed for optimizing protein over-expres-sionrdquo Nucleic Acids Research vol 35 supplement 1 pp D76ndashD79 2007

[30] T Subtil and E Boles ldquoImproving L-arabinose utilizationof pentose fermenting Saccharomyces cerevisiae cells by het-erologous expression of L-arabinose transporting sugar trans-portersrdquo Biotechnology for Biofuels vol 4 p 38 2011

Submit your manuscripts athttpwwwhindawicom

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Anatomy Research International

PeptidesInternational Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporation httpwwwhindawicom

International Journal of

Volume 2014

Zoology

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Molecular Biology International

GenomicsInternational Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

The Scientific World JournalHindawi Publishing Corporation httpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

BioinformaticsAdvances in

Marine BiologyJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Signal TransductionJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

BioMed Research International

Evolutionary BiologyInternational Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Biochemistry Research International

ArchaeaHindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Genetics Research International

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Advances in

Virolog y

Hindawi Publishing Corporationhttpwwwhindawicom

Nucleic AcidsJournal of

Volume 2014

Stem CellsInternational

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Enzyme Research

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

International Journal of

Microbiology

2 BioMed Research International

Bacillus subtilis the strain could grow and produce ethanolon L-arabinose after several circles of adaptive growth [1314] Furthermore the L-arabinose utilization was furtherimproved by changing the codon usage of the bacterial araAaraB and araD genes to the preferred yeast codons [15]The L-arabinose metabolic genes of Lactobacillus plantarummatched the codon usage of S cerevisiae more closely thanthe genes previously reported Wisselink et al [8] introducedmultiple copies of araA and araD and a single copy ofaraB of L plantarum into S cerevisiae After overexpressingthe genes encoding the enzymes of nonoxidative PPP andextensive adaptive evolution the resulting strain exhibited ahigh ethanol yield up to 043 g gminus1 during anaerobic growthon L-arabinose with a high arabinose consumption rate(070 g hminus1 gminus1 dry cell weight (DCW)) [8] The metabolometranscriptome and metabolic flux analysis of a more evolvedstrain revealed that higher expression levels of the galactosetransporter transketolase and transaldolase isoenzymes ben-efit the growth of S cerevisiae on L-arabinose [16]

In the present work the unique codon-optimized araAaraB and araD genes of L plantarum were expressed inthe S cerevisiae strain CENPK102-3A at different levelsNext the genes TAL1 TKL1 RPE1 and RKI1 involved inPPP were overexpressed in this recombinant strain Theresulting strain was sequentially selected on L-arabinoseunder aerobic conditions and in oxygen-limited conditionsA strain with a significantly enhanced L-arabinose utilizationcapacity was obtained The L-arabinose metabolic capacityof the evolved strains and the strain that also overexpressedthe transporter gene GAL2 were investigated The factorsaffecting L-arabinose metabolism efficiency are discussed

2 Materials and Methods

21 Media and Culture Conditions The yeast synthetic com-plete medium (SC) containing 17 g Lminus1 yeast nitrogen base(YNB Sangon China) and 5 g Lminus1 ammonium sulfate (San-gon China) with additional carbon sources of glucose (San-gon China) or L-arabinose (Sinopharm China) was usedfor yeast cultivation The complete supplement mixture077 g Lminus1 CSM-URAor 067 g Lminus1 CSM-LEU-URA (MPBio-medicals Solon OH) was added to maintain the requiredplasmids with auxotrophic selection when necessary Forstrains with the KanMX4 marker the medium was suppliedwith 200120583gmLminus1 of the antibiotic G418 sulfate (PromegaMadison WI USA) All yeasts were cultivated at 30∘C

22 Codon Adaptation Index Analysis The codon adapta-tion index (CAI) is used to illustrate the preference ofcodon usage in specific species [24] For the CAI analysisCODONW (httpmobylepasteurfrcgi-binMobylePortalportalpyform=codonw) [15] was used

23 Plasmid and Strain Construction E coli DH5120572 [12] wasused for subcloning S cerevisiae strains and plasmids used inthis study are listed in Table 1 The primers used in this studyare listed in Table 2

The unique codon-optimized araA araB and araD genesencoding the L-arabinose isomerase (GenBank CCC805171)L-ribulokinase (GenBank CCC805191) and L-ribulose-5-phosphate 4-epimerase (GenBank CCC805181) of L Plan-tarum were artificially synthesized and ligated between theHXT7 promoter and PGK1 terminator sequences of plasmidpHX which was constructed by substituting the PGK1p ofplasmid YEp24-PGKp [20] with HXT7p containing sites forthe restriction enzymes Kpn I and Sma I The HXT7p-araD-PGK1t fragment was amplified by PCR with terminal sitesfor the restriction enzymes Hind III and Bln I and theninserted into the Hind III and Nhe I sites of YIp5 resultingin plasmid YIp5-araD The HXT7p-araA-PGK1t fragmentcontaining terminal Bgl II and Sal I sites was inserted into theBamH I and Sal I sites of YIp5-araD resulting in the plasmidYIp5-araAD The HXT7p-araB-PGK1t fragment with Eag Iand Stu I sites was inserted into the Eag I and Stu I sites ofYIp5-araAD resulting in the plasmid YIp5-ara (Figure 1(a))The TEF1 promoter fragment (with terminal sites for HindIII and Sal I) and the PGK1 terminator fragment (withterminal sites for BamH I andHind III) were cloned from theplasmids pJFE3 [23] and pYMIKP [25] respectively Thesetwo fragments were ligated and inserted into the plasmidpYX242 to construct a vector pYX242-WS with two sitesthat can be used to express genes Then the gene araA wasinserted between the Sal I and Sac I sites of this vector undercontrol of the TEF1 promoter and the PloyA terminator for itsexpression and the resulting plasmid was named pYX2422-TEF1araA (Figure 1(b)) The plasmid pYX2422-HXT7araA(Figure 1(b))was constructed using the fragment ofHXT7p todisplace the TEF1p fragment of plasmid pYX2422-TEF1araAthe joints were BamH I and Sal I recognition sequencesThe gene GAL2 was cloned from the chromosomal DNA ofCENPK102-3A and then inserted into the Xba I and Sal Isites of plasmid pJFE3 resulting in plasmid pJFE3-GAL2TheURA3 fragment of plasmid pJFE3-GAL2 between the Nde IandApa I siteswas replaced by theKanMX4 gene cloned frompUG6 [18] resulting in plasmid pJFE318-GAL2 (Figure 1(c))

The yeast transformation was performed using the lith-ium acetate transformation method [26] The plasmid YIp5-ara was linearized at the Stu I site and then transformedinto CENPK102-3A The transformants with the araA araBand araD genes integrated into the chromosomalURA3 genewere selected in SCmedium containing CSM-URA and afterbeing confirmed by sequencing the desired transformantwasnamed BSW1A1 Plasmids pYX242 pYX2422-HXT7araAand pYX2422-TEF1araA were transformed into BSW1A1resulting in BSW1AY BSW1A7 and BSW1AT respectivelyThe linearized pJPPP3 which contains the expression framesof genes TAL1 TKL1 RPE1 and RKI1 [19] was integratedinto the chromosome of BSW1AT at the GRE3 gene locusresulting in strain BSW2APThe strain BSW2APwas adaptedon 20 g Lminus1 L-arabinose under aerobic conditions and thenunder oxygen-limited conditions Once the stationary phasewas reached a new batch was initiated by transferringthe culture into fresh medium with an initial biomassof 015 gDCWLminus1 When the doubling time of the strainstabilized mutant BSW3AP was selected from the adapted

BioMed Research International 3

Table 1 S cerevisiae strains and plasmids used in this study

Relevant genotype SourcereferenceStrain

CENPK102-3A MAT120572 leu2-3 112 ura3-52 [17]BSW1A1 CENPK102-3A derivative YIp5-ara This workBSW1AY CENPK102-3A derivative YIp5-ara pYX242 This workBSW1A7 CENPK102-3A derivative YIp5-ara pYX2422-HXT7araA This workBSW1AT CENPK102-3A derivative YIp5-ara pYX2422-TEF1araA This work

BSW2AP BSW1AT gre3 (minus241 +338)TPI1p-RKI1-RKI1t-PGK1p-TAL1-TAL1t-FBA1p-TKL1-TKL1t-ADH1p-RPE1-RPE1t-loxP This work

BSW3AP BSW2AP selected for oxygen-limited growth on L-arabinose This workBSW3AG BSW3AP derivative pJFE318-GAL2 This work

PlasmidpUG6 E coli plasmid with segment LoxP-KanMX4-LoxP [18]

pJPPP3pUC19-based yeast integration plasmid containing GRE3-targeting recombinant armsoverexpression cassette of Sc-TAL1 Sc-TKL1 Sc-RPE1 Sc-RKI1 and selectable markerloxP-KanMX4-loxP

[19]

YEp24-PGKp 2120583 URA3 [20]pHX YEp24-PGKp PGK1pHXT7p This workYIp5 Integration plasmid Ura3 [21]

YIp5-ara YIp5-HXT7p-araA-PGK1t-HXT7p-araB-PGK1t-HXT7p-araD-PGK1t and selectablemarker loxP-KanMX4-loxP This work

pYX242 2120583 LEU2 [22]pYX242-WS pYX242-PGK1t-TEF1p This workpYX2422-TEF1araA pYX242-PGK1t-TEF1p-araA This workpYX2422-HXT7araA pYX242-PGK1t-HXT7p-araA This workpJFE3 2120583 URA3 [23]pJFE3-GAL2 pJFE3-TEF1p-GAL2-PGK1t This workpJFE318-GAL2 pJFE3-GAL2 URA3KanMX4 This work

mutants based on its excellent growth on L-arabinose Theplasmid pJFE318-GAL2 was then transformed into strainBSW3AP resulting in strain BSW3AG

24 Real-Time Quantitative PCR The cells were culturedin SC medium containing 20 g Lminus1 glucose and collectedwhen the OD

600

of cultures reached 1 The total RNA wasextracted using TRIzol reagent (Sangon China) The firststrand of cDNA was reverse transcribed from 1 120583g of totalRNA using PrimeScript RT reagent kits with gDNA Eraser(Takara Japan) Diluted cDNA products were used for real-time quantitative PCR using the SYBR Green Real-timePCR Master Mix (TOYOBO Japan) and the LightCyclePCR System (RocheMolecular Biochemicals Germany)Theactin-encoding gene ACT1 was used as the reference genefor normalization The data of real-time PCR was calculatedaccording to the 2minusΔΔCT method [19 27] The primers forthese PCR were listed in Table 2

25 Fermentation A single colony was cultured overnightin SC medium containing 20 g Lminus1 glucose A sample ofthe overnight culture was diluted to an initial OD

600

of 05

in SC medium containing 10 g Lminus1 glucose and 10 g Lminus1 L-arabinose After 10 h cultivation the cells were collected andused for fermentation All the shaker flask fermentationswere performed at 30∘C 200 rminminus1 in 200mL shaker flaskscontaining 40mL medium The oxygen-limited conditionwas maintained by using a rubber stopper The batch fer-mentations under anaerobic conditions were performed in14 L fermentors (Infors AG Switzerland) with a workingvolume of 900mL Anaerobic conditions were maintained bysparging with nitrogen (01 Lminminus1) the agitation rate was500 rminminus1 The pH was maintained at 50 by automaticallypumping 1mol Lminus1 NaOH and 1mol Lminus1 H

3

PO4

[19] Theinitial biomass was 02 gDCWLminus1 The carbon source in theSC plus CSM-LEU-URA medium was 20 g Lminus1 L-arabinose200120583gmLminus1 G418 was supplied in the fermentation of strainBSW3AG The dry cell weight of evolved strains and theunevolved strains were calculated according to the formulaof dry weight (mgmLminus1) = 0266 times OD

600

minus 00762 and dryweight (mgmLminus1) = 02365 times OD

600

+ 01149 respectively

26 Analysis of Fermentation Products The high perfor-mance liquid chromatography (HPLC) Prominence LC-20A (Shimadzu Japan) equipped with the refractive index

4 BioMed Research International

Table2Oligon

ucleotides

used

inthiswork

Prim

ers

Sequ

ence

(51015840

-31015840

)Pu

rpose

Hxt7up

stream-H

XCA

TAGAT

CTCT

CACA

AAT

TAGAG

CTTC

AAT

TTAAT

Clon

ingthefragm

ento

fHXT

7p-araA-

PGKt1

Pgk6

downstre

am-S

CATG

TCGAC

AGCA

ATTT

AAC

TGTG

ATAAAC

TACC

GClon

ingthefragm

ento

fHXT

7p-araA-

PGKt1

Hxt7up

stream-EEB

CATC

GGCC

GAG

ATCT

CCTA

GGCT

CACA

AAT

TAGAG

CTTC

AAT

TTAAT

Clon

ingthefragm

ento

fHXT

7p-araB-PG

Kt1

Pgk6

downstre

am-S

CATG

TCGAC

AGCA

ATTT

AAC

TGTG

ATAAAC

TACC

GClon

ingthefragm

ento

fHXT

7p-araB-PG

Kt1

Hxt7up

stream

CATC

CTAG

GCT

CACA

AAT

TAGAG

CTTC

AAT

TTAAT

Clon

ingthefragm

ento

fHXT

7p-araD-PGKt1

Pgk6

downstre

amCA

TCCT

AGGAG

CAAT

TTAAC

TGTG

ATAAAC

TACC

GClon

ingthefragm

ento

fHXT

7p-araD-PGKt1

HXT

7p-F

CCCA

AGCT

TCTC

ACAAAT

TAGAG

CTTC

AAT

TClon

ingHXT

7pHXT

7p-R

ACGCG

TCGAC

ATTG

GAT

CTAG

ATGCA

TTCG

CGClon

ingHXT

7pTE

F1W

upCC

CAAG

CTTC

ACAAT

GCA

TACT

TTGTA

CGTT

Clon

ingTE

F1p

TEF1

Wdo

wn

GCG

CGTC

GAC

TTGTA

ATTA

AAAC

TTAG

ATTA

GClon

ingTE

F1p

AraAW

upAC

GCG

TCGAC

ATGTT

ATCT

GTT

CCTG

ATTA

TGClon

ingaraA

AraAW

down-His

TACG

AGTC

TTTA

GTG

GTG

GTG

GTG

GTG

GTG

TTTT

AAAAAT

GCT

TTTG

TCA

Clon

ingaraA

AraA-

FCA

AGCA

GGTG

GTG

GTC

ATCA

TAC

Forq

uantitativ

ereal-tim

ePCR

ofaraA

AraA-

RTA

CCAAC

CATT

GTA

GCG

TAAT

CTTC

CFo

rquantitativ

ereal-tim

ePCR

ofaraA

AraB-1F

ATGCA

GCA

TTCG

CACC

TTTG

Forq

uantitativ

ereal-tim

ePCR

ofaraB

AraB-1R

CCTT

CACC

TGCT

GTG

GAC

ATFo

rquantitativ

ereal-tim

ePCR

ofaraB

AraD-1F

CCAG

CTGCA

GAT

GCA

TTAAC

TFo

rquantitativ

ereal-tim

ePCR

ofaraD

AraD-1R

ACAG

CCTT

AGCT

GGTG

TTGG

Forq

uantitativ

ereal-tim

ePCR

ofaraD

Gal2up

GCT

CTAG

AAT

GGCA

GTT

GAG

GAG

AAC

AAT

ATGC

Clon

ingGAL

2Gal2do

wn

ACGCG

TCGAC

TTAT

TCTA

GCA

TGGCC

TTGTA

CClon

ingGAL

2pG

418-Ap

aIup

AGTG

GGCC

CTAG

GTC

TAGAG

ATCT

GTT

TAGC

Clon

ingKa

nMX4

pG418-Nde

Idow

nGGAAT

TCCA

TATG

ATTA

AGGGTT

CTCG

AGAG

CTCG

Clon

ingKa

nMX4

BioMed Research International 5

bla

ori

YIp5-ara

HXT7p-araD-PGK1t

HXT7p-araA-PGK1t

URA3

HXT7p-araB-PGK1t

(a)

araAPoly A

ori

LEU2

2120583

blaCol E1

TPIp

PGK1t

TEF1pHXT7p

pYX2422-TEF1araAHXT7araA

(b)

ori

GAL22120583

bla

KanMX4

PGK1t

TEF1p

pJFE318-GAL2

(c)

Figure 1 The physical maps of the plasmids (a) YIp5-ara (b) pYX2422-TEF1araAHXT7araA and (c) pJFE318-GAL2

detector RID-10A (Shimadzu Japan) was used to determinethe concentrations of sugars and metabolites The AminexHPX-87P ion exchange column (Bio-Rad USA) was usedto analyze L-arabinose arabitol and ethanol at 80∘C with amobile phase of water at a flow rate of 06mLminminus1 TheAminex HPX-87H ion exchange column (Bio-Rad HerculesUSA) was used to analyze glycerol and acetate at 45∘C using5mmol Lminus1 H

2

SO4

as the mobile phase [12]

3 Results

31 Expression of the Codon-Optimized Genes Involvedin the L-Arabinose Pathway in S cerevisiae Based onthe amino acid sequence of L-arabinose isomerase (Gen-Bank accession no CCC805171) L-ribulokinase (GenBankaccession no CCC805191) and L-ribulose-5-phosphate 4-epimerase (GenBank accession no CCC805181) recorded inthe National Center for Biotechnology Information (NCBIhttpwwwncbinlmnihgov) the araA araB and araDgenes of L plantarum were artificially synthesized using Scerevisiae preferred codons The CAIs of codon-optimizedaraA araB and araD were 0599 0580 and 0646 respec-tively which were higher than those of the native sequences(0324 0223 and 0243 resp)

The expression cassettes of codon-optimized araAaraB and araD were integrated into the chromosome ofstrain CENPK102-3A resulting in strain BSW1A1 However

BSW1A1 could not grow on L-arabinose although the tran-scribedmRNAs of these geneswere all detectableThenmorecopies of araA were introduced into BSW1A1 carried by theepisomal plasmid pYX242 and expressed under control of theHXT7 andTEF1 promotersThe transcriptional levels of araAin the resulting strains BSW1A7 and BSW1AT were 129 plusmn29-fold and 325plusmn07-fold higher than in the reference strainBSW1AY carrying only the integrated expressed araA TheBSW1A7 and BSW1AT strains were aerobically incubated onL-arabinose and the growth of strain BSW1AT was observedafter sim150 h whereas BSW1A7 could not grow even whencultured longer

32 Improvement of the L-Arabinose Utilization in S cerevisiaeby Engineering and Evolution The TAL1 TKL1 RPE1 andRKI1 genes involved in the nonoxidative pentose phosphatepathway were overexpressed in a single colony isolated fromthe BSW1AT 150 h culture by integrating the linearized plas-mid pJPPP3 [19] into the chromosome The resulting strainBSW2AP was evolved on L-arabinose After 9 transfersin aerobic conditions and 12 transfers in oxygen-limitedconditions the doubling time of the culture decreased from22 h to 45 h The mutants were screened on L-arabinoseplates and a large colony was selected and named BSW3AP

The transcriptional levels of genes in the recombinantstrains BSW1AT BSW2AP andBSW3APwere determined byreal-time quantitative PCR (Figure 2) The araA expression

6 BioMed Research International

0

1

2

3

4

5

6

7

BSW1AT BSW2AP BSW3AP

Relat

ive e

xpre

ssio

n

araAaraBaraD

Figure 2The expression of araA (black bars) araB (gray bars) andaraD (blank bars) of strains BSW2AP and BSW3AP compared tostrain BSW1AT The fold-changes of mRNA levels of these genesare normalized to the expression of ACT1 The tested strains werecultivated on 20 g Lminus1 glucose The values given are obtained fromthree independent measurements

level in BSW2APwas 2-fold higher than in BSW1AT whereasthe expression levels of araB and araD in BSW2AP werelowerThese changesmight be due tomutations that occurredduring the cultivation of BSW1AT on L-arabinose In theevolved strain BSW3AP all three geneswere expressed at highlevelsThe araA araB and araD expression levels in BSW3APwere 41-fold 16-fold and 25-fold higher than those in strainBSW1AT respectively

The L-arabinose utilization of strains BSW1AT BSW2APand BSW3AP was compared in shaker-flasks under oxygen-limited conditions (Figure 3) the initial OD

600

was 05 Nogrowth of BSW1AT was observed within 120 h The strainBSW2AP grew on L-arabinose with a maximum specificgrowth rate (120583max) of 0011 hminus1 44 g Lminus1 L-arabinose wasconsumed and 12 g Lminus1 ethanol was produced in 120 h offermentation In contrast the 120583max of the evolved strainBSW3AP increased to 023 hminus1 After 120 h of fermentation186 g Lminus1 L-arabinose had been consumed with a maximumspecific consumption rate of 07 g hminus1 gminus1DCW 69 g Lminus1ethanol had been produced and the ethanol yield was043 g gminus1 only 013 g Lminus1 L-arabitol had accumulated

33 Overexpression of GAL2 Improved the L-Arabinose Anaer-obic Fermentation of the Evolved Strain The galactose per-mease gene GAL2 was overexpressed in BSW3AP resultingin strain BSW3AG The anaerobic L-arabinose fermentationproperties of strain BSW3AP and BSW3AG were studied(Figure 4 and Table 3) in bioreactors Strain BSW3AP grewon L-arabinose with a maximum specific growth rate of

0067 hminus1 The maximum specific consumption rate of L-arabinose was 049 g hminus1 gminus1DCW Ethanol was producedat a maximum specific rate of 020 g hminus1 gminus1DCW with ayield of 042 g gminus1 The overexpression of GAL2 significantlyimproved the L-arabinose fermentation capacity The maxi-mum specific growth rate of BSW3AG was 0075 hminus1 whichwas 12 faster than that of BSW3APThe L-arabinose specificconsumption rate of BSW3AGwas 061 g hminus1 gminus1DCWwhichwas 24 faster than that of BSW3AP The ethanol produc-tion rate was 027 g hminus1 gminus1DCW and the ethanol yield was043 g gminus1 Furthermore both BSW3AP and BSW3AG pro-duced small amounts of glycerol (14 g Lminus1 for both strains)and almost undetectable amounts of arabitol and acetate

4 Discussion

The complete conversion of sugars is important for efficientand cost-effective fuel ethanol production from lignocel-lulosic materials Even small improvements in substrateutilization can significantly decrease the costs of the wholeprocess [28] L-arabinose is an important component oflignocellulosic materials Expression of the L plantarum L-arabinose pathway has proven to be effective in constructingL-arabinose utilizing S cerevisiae [8] Given that the codon-optimized genes might lead to increased expression of theproteins [15 29] in the present work the original araAaraB and araD genes of L plantarum were modified tomatch the codon usage of S cerevisiae and then integratedinto the chromosome of strain CENPK102-3A Howeverthis recombinant strain could not grow on L-arabinoseMore copies of the araA gene were then introduced into therecombinant strain under the control of the HXT7 and TEF1promoters When the two resulting strains were culturedon L-arabinose growth was only observed in cultures ofthe strain expressing araA under the control of the TEF1promoter in which the araA transcriptional level was 14-foldhigher than in the strain expressing araA controlled by theHXT7 promoterWe suggest that only when the transcriptionlevel of araA is higher than a certain level can growth onL-arabinose occur In contrast only one copy of araB andaraD was introduced into this recombinant strain and thetranscriptional levels of these genes were lower than in theparental strain These phenomena indicated that araB andaraD were less important for growth on L-arabinose becauseonly one copy of these genes allowed the recombinant strainto grow on L-arabinose

Adaptive evolution was proven to be a powerful methodto enhance the strainsrsquo metabolic efficiency [8 13] In thepresent study the evolved strain BSW3AP shows significantlyimproved L-arabinose metabolizing capacity The increasedtranscription levels of all the three genes (araA araB andaraD) might contribute to the enhancement Compared toaraA and araD the expression level of araB was lowerBecker and Boles [13] reported that a mutant on L-arabinosedecreased the L-ribulokinase activity expressed by araB Therelatively lower expression of araB avoids the overconsump-tion of ATP which would benefit the growth of the strain onL-arabinose

BioMed Research International 7

0

2

4

6

8

10

12

14

0 20 40 60 80 100 120 140Time (h)

OD600

(a)

0

3

6

9

12

15

18

21

24

0 20 40 60 80 100 120 140Time (h)

Ara

bino

se (g

Lminus1)

(b)

0

02

04

06

08

1

0 20 40 60 80 100 120 140Time (h)

Ara

bito

l (g L

minus1)

(c)

0

1

2

3

4

5

6

7

8

0 20 40 60 80 100 120 140Time (h)

Etha

nol (

g Lminus1)

(d)

Figure 3The L-arabinose fermentation of strains in shaker flasks Growth capacity (a) L-arabinose consumption (b) arabitol formation (c)and ethanol formation (d) by BSW1AT (998771) BSW2AP (◼) and BSW3AP (e) The strains were cultured in 40mL SC medium with 20 g Lminus1L-arabinose at 30∘C 200 rminminus1 with an initial OD

600

of 05 The data are the averages of three independent experiments

Table 3 The maximum specific growth rates (120583max) the maximum specific L-arabinose-consumption rate the ethanol production rate andthe ethanol yield for BSW3AP and BSW3AG on 20 g Lminus1 L-arabinose

Strain 120583max (hminus1)

The maximum specificL-arabinose consumption rate

(g hminus1 gminus1 DCW)

Ethanol production rate(g hminus1 gminus1 DCW)

Ethanol yield(g gminus1 L-arabinose consumed)

BSW3AP 0067 049 020 042BSW3AG 0075 061 027 043

8 BioMed Research International

0

2

4

6

8

10

12

0

3

6

9

12

15

18

21

24

0 20 40 60 80Time (h)

Ara

bino

se e

than

ol g

lyce

rol

acet

ate

OD600

(g Lminus1)

(a)

0

2

4

6

8

10

12

0

3

6

9

12

15

18

21

24

0 20 40 60 80Time (h)

Ara

bino

se e

than

ol g

lyce

rol

acet

ate

OD600

(g Lminus1)

(b)

Figure 4 The anaerobic batch fermentation of BSW3AP (a) and BSW3AG (b) on 20 g Lminus1 arabinose Levels of OD600

(◼) arabinose(X) ethanol (998771) Glycerol (e) and acetate (times) The fermentation was performed in 14 L fermentors with a working volume of 900mLAnaerobic conditions were maintained by sparging nitrogen (01 Lminminus1) the agitation rate was 500 rminminus1 The pH was maintained at 50by automatically pumping in 1mol Lminus1 NaOH and 1mol Lminus1 H

3

PO4

The initial biomass was 0 2 gDCWLminus1 The 20 g Lminus1 L-arabinose wasused as the carbon source in SC plus CSM-LEU-URA medium and 200120583gmLminus1 G418 was supplied in the fermentation of strain BSW3AGThe data are the average of duplicate determinations

L-arabinose is a novel carbon source for S cerevisiaeThe uptake of L-arabinose in S cerevisiaemainly depends onthe nonspecific transport by the hexose transporter Gal2pThe Hxt9p and Hxt10p also can transport L-arabinose butthe efficiency is very low [30] It was reported that overex-pressing GAL2 improves the L-arabinose utilization [13 16]In this study overexpressing GAL2 notably increased thegrowth rate and L-arabinose consumption rate of our evolvedstrain BSW3AP This result suggested that the theoreticalL-arabinose metabolic flux was higher than we detected inBSW3APTheL-arabinose utilization of BSW3APwas limitedby its absorption rate When the GAL2 was overexpressedmore Gal2p in the plasma membrane lead to an increasedL-arabinose uptake and then promote the L-arabinose uti-lization Our result further confirmed the importance oftransporters for L-arabinose utilization however the affinityof Gal2p for L-arabinose is low and glucose competitivelyinhibited its binding to L-arabinose [30] Improving theefficiency of the L-arabinose specific transporter remains tobe conducted

5 Conclusions

With multiple steps of genetic engineering and adaptiveevolution we obtained the strain BSW3AG which grows on

L-arabinose with a 120583max of 0075 hminus1 The maximum specific

L-arabinose consumption rate is 027 g hminus1 gminus1DCW and themaximum ethanol yield is 043 g gminus1 L-arabinose consumedwhich is 843 of the theoretical amount A high level of araAexpression is notably important in establishing an efficient L-arabinose pathway in S cerevisiae and more efficient trans-porters are necessary to improve the L-arabinose absorptioncapacity of the evolved strains

Conflict of Interests

The authors declare that they have no conflict of interests

Acknowledgments

This work was supported by the National Key Basic ResearchProgram (2011CB707405) the National High-TechnologyResearch and Development Program of China under Grant(2012AA022106) the National Natural Science Foundation ofChina (30970091 31070096 and 31270151) and the Interna-tional SampT Cooperation Program of China (2010DFA32560)The authors thank Dr Peter Kotter from Johann WolfgangGoethe-University Frankfurt for the strain CENPK102-3A

BioMed Research International 9

References

[1] R den Haan H Kroukamp M Mert M Bloom J F Gorgensand W H van Zyl ldquoEngineering Saccharomyces cerevisiaefor next generation ethanol productionrdquo Journal of ChemicalTechnology amp Biotechnology vol 88 no 6 pp 983ndash991 2013

[2] W E Mabee ldquoPolicy options to support biofuel productionrdquoAdvances in Biochemical EngineeringBiotechnology vol 108 pp329ndash357 2007

[3] A E Farrell R J Plevin B T Turner A D Jones M OrsquoHareand D M Kammen ldquoEthanol can contribute to energy andenvironmental goalsrdquo Science vol 311 no 5760 pp 506ndash5082006

[4] B Hahn-Hagerdal M Galbe M F Gorwa-Grauslund GLiden and G Zacchi ldquoBio-ethanolmdashthe fuel of tomorrow fromthe residues of todayrdquoTrends in Biotechnology vol 24 no 12 pp549ndash556 2006

[5] M Galbe and G Zacchi ldquoA review of the production of ethanolfrom softwoodrdquo Applied Microbiology and Biotechnology vol59 no 6 pp 618ndash628 2002

[6] S R Kim S Ha N Wei E J Oh and Y Jin ldquoSimultaneousco-fermentation of mixed sugars a promising strategy forproducing cellulosic ethanolrdquo Trends in Biotechnology vol 30no 5 pp 274ndash282 2012

[7] B Seiboth and B Metz ldquoFungal arabinan and L-arabinosemetabolismrdquo Applied Microbiology and Biotechnology vol 89no 6 pp 1665ndash1673 2011

[8] H W Wisselink M J Toirkens M D R F Berriel et alldquoEngineering of Saccharomyces cerevisiae for efficient anaerobicalcoholic fermentation of L-arabinoserdquo Applied and Environ-mental Microbiology vol 73 no 15 pp 4881ndash4891 2007

[9] B Hahn-Hagerdal K Karhumaa M Jeppsson and M FGorwa-Grauslund ldquoMetabolic engineering for pentose uti-lization in Saccharomyces cerevisiaerdquo Advances in BiochemicalEngineeringBiotechnology vol 108 pp 147ndash177 2007

[10] R Schleif ldquoRegulation of the L-arabinose operon of Escherichiacolirdquo Trends in Genetics vol 16 no 12 pp 559ndash565 2000

[11] C Fonseca R Romao H R de Sousa B Hahn-Hagerdal andI Spencer-Martins ldquoL-arabinose transport and catabolism inyeastrdquo FEBS Journal vol 274 no 14 pp 3589ndash3600 2007

[12] M Bettiga O Bengtsson B Hahn-Hagerdal and M F Gorwa-Grauslund ldquoArabinose and xylose fermentation by recombinantSaccharomyces cerevisiae expressing a fungal pentose utilizationpathwayrdquoMicrobial Cell Factories vol 8 article 40 2009

[13] J Becker and E Boles ldquoA modified Saccharomyces cerevisiaestrain that consumes L-arabinose and produces ethanolrdquo Ap-plied and Environmental Microbiology vol 69 no 7 pp 4144ndash4150 2003

[14] M Sedlak and N W Y Ho ldquoExpression of E coliaraBADoperon encoding enzymes for metabolizing L-arabinose inSaccharomyces cerevisiaerdquo Enzyme and Microbial Technologyvol 28 no 1 pp 16ndash24 2001

[15] BWiedemann and E Boles ldquoCodon-optimized bacterial genesimprove L-arabinose fermentation in recombinant Saccha-romyces cerevisiaerdquo Applied and Environmental Microbiologyvol 74 no 7 pp 2043ndash2050 2008

[16] HWWisselink C Cipollina B Oud et al ldquoMetabolome tran-scriptome andmetabolic flux analysis of arabinose fermentationby engineered Saccharomyces cerevisiaerdquoMetabolic Engineeringvol 12 no 6 pp 537ndash551 2010

[17] K D Entian and P Kotter ldquo23 yeast mutant and plasmidcollectionsrdquo in Methods in Microbiology J P B Alistair and

TMick Eds pp 431ndash449Academic PressNewYorkNYUSA1998

[18] U Guldener S Heck T Fiedler J Beinhauer and J H Hege-mann ldquoA new efficient gene disruption cassette for repeated usein budding yeastrdquo Nucleic Acids Research vol 24 no 13 pp2519ndash2524 1996

[19] B Peng Y Shen X Li X Chen J Hou and X Bao ldquoImprove-ment of xylose fermentation in respiratory-deficient xylose-fermenting Saccharomyces cerevisiaerdquo Metabolic Engineeringvol 14 no 1 pp 9ndash18 2012

[20] MWalfridsson M Anderlund X Bao and B Hahn-HagerdalldquoExpression of different levels of enzymes from the PichiastipitisXYL1 andXYL2 genes in Saccharomyces cerevisiae and itseffects on product formation during xylose utilisationrdquo AppliedMicrobiology and Biotechnology vol 48 no 2 pp 218ndash224 1997

[21] K Struhl D T Stinchcomb S Scherer and RW Davis ldquoHigh-frequency transformation of yeast autonomous replication ofhybrid DNAmoleculesrdquo Proceedings of the National Academy ofSciences of the United States of America vol 76 no 3 pp 1035ndash1039 1979

[22] X Liu X Zhang C Wang L Liu M Lei and X Bao ldquoGeneticand comparative transcriptome analysis of bromodomain factor1 in the salt stress response of Saccharomyces cerevisiaerdquoCurrentMicrobiology vol 54 no 4 pp 325ndash330 2007

[23] Y Shen X Chen B Peng L Chen J Hou and X Bao ldquoAnefficient xylose-fermenting recombinant Saccharomyces cere-visiae strain obtained through adaptive evolution and its globaltranscription profilerdquo Applied Microbiology and Biotechnologyvol 96 no 4 pp 1079ndash1091 2012

[24] PM Sharp andW Li ldquoThe codon adaptation indexmdashameasureof directional synonymous codon usage bias and its potentialapplicationsrdquoNucleic Acids Research vol 15 no 3 pp 1281ndash12951987

[25] L Ji Y Shen L Xu B Peng Y Xiao and X Bao ldquoEnhancedresistance of Saccharomyces cerevisiae to vanillin by expressionof lacA fromTrametes sp AH28-2rdquo Bioresource Technology vol102 no 17 pp 8105ndash8109 2011

[26] R D Gietz R H Schiestl A R Willems and R A WoodsldquoStudies on the transformation of intact yeast cells by theLiAcSS-DNAPEGprocedurerdquoYeast vol 11 no 4 pp 355ndash3601995

[27] K J Livak and T D Schmittgen ldquoAnalysis of relative geneexpression data using real-time quantitative PCR and the2

minus998779998779CT methodrdquoMethods vol 25 no 4 pp 402ndash408 2001[28] M von Sivers and G Zacchi ldquoEthanol from lignocellulosics a

review of the economyrdquo Bioresource Technology vol 56 no 2-3pp 131ndash140 1996

[29] G Wu Y Zheng I Qureshi et al ldquoSGDB a database ofsynthetic genes re-designed for optimizing protein over-expres-sionrdquo Nucleic Acids Research vol 35 supplement 1 pp D76ndashD79 2007

[30] T Subtil and E Boles ldquoImproving L-arabinose utilizationof pentose fermenting Saccharomyces cerevisiae cells by het-erologous expression of L-arabinose transporting sugar trans-portersrdquo Biotechnology for Biofuels vol 4 p 38 2011

Submit your manuscripts athttpwwwhindawicom

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Anatomy Research International

PeptidesInternational Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporation httpwwwhindawicom

International Journal of

Volume 2014

Zoology

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Molecular Biology International

GenomicsInternational Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

The Scientific World JournalHindawi Publishing Corporation httpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

BioinformaticsAdvances in

Marine BiologyJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Signal TransductionJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

BioMed Research International

Evolutionary BiologyInternational Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Biochemistry Research International

ArchaeaHindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Genetics Research International

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Advances in

Virolog y

Hindawi Publishing Corporationhttpwwwhindawicom

Nucleic AcidsJournal of

Volume 2014

Stem CellsInternational

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Enzyme Research

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

International Journal of

Microbiology

BioMed Research International 3

Table 1 S cerevisiae strains and plasmids used in this study

Relevant genotype SourcereferenceStrain

CENPK102-3A MAT120572 leu2-3 112 ura3-52 [17]BSW1A1 CENPK102-3A derivative YIp5-ara This workBSW1AY CENPK102-3A derivative YIp5-ara pYX242 This workBSW1A7 CENPK102-3A derivative YIp5-ara pYX2422-HXT7araA This workBSW1AT CENPK102-3A derivative YIp5-ara pYX2422-TEF1araA This work

BSW2AP BSW1AT gre3 (minus241 +338)TPI1p-RKI1-RKI1t-PGK1p-TAL1-TAL1t-FBA1p-TKL1-TKL1t-ADH1p-RPE1-RPE1t-loxP This work

BSW3AP BSW2AP selected for oxygen-limited growth on L-arabinose This workBSW3AG BSW3AP derivative pJFE318-GAL2 This work

PlasmidpUG6 E coli plasmid with segment LoxP-KanMX4-LoxP [18]

pJPPP3pUC19-based yeast integration plasmid containing GRE3-targeting recombinant armsoverexpression cassette of Sc-TAL1 Sc-TKL1 Sc-RPE1 Sc-RKI1 and selectable markerloxP-KanMX4-loxP

[19]

YEp24-PGKp 2120583 URA3 [20]pHX YEp24-PGKp PGK1pHXT7p This workYIp5 Integration plasmid Ura3 [21]

YIp5-ara YIp5-HXT7p-araA-PGK1t-HXT7p-araB-PGK1t-HXT7p-araD-PGK1t and selectablemarker loxP-KanMX4-loxP This work

pYX242 2120583 LEU2 [22]pYX242-WS pYX242-PGK1t-TEF1p This workpYX2422-TEF1araA pYX242-PGK1t-TEF1p-araA This workpYX2422-HXT7araA pYX242-PGK1t-HXT7p-araA This workpJFE3 2120583 URA3 [23]pJFE3-GAL2 pJFE3-TEF1p-GAL2-PGK1t This workpJFE318-GAL2 pJFE3-GAL2 URA3KanMX4 This work

mutants based on its excellent growth on L-arabinose Theplasmid pJFE318-GAL2 was then transformed into strainBSW3AP resulting in strain BSW3AG

24 Real-Time Quantitative PCR The cells were culturedin SC medium containing 20 g Lminus1 glucose and collectedwhen the OD

600

of cultures reached 1 The total RNA wasextracted using TRIzol reagent (Sangon China) The firststrand of cDNA was reverse transcribed from 1 120583g of totalRNA using PrimeScript RT reagent kits with gDNA Eraser(Takara Japan) Diluted cDNA products were used for real-time quantitative PCR using the SYBR Green Real-timePCR Master Mix (TOYOBO Japan) and the LightCyclePCR System (RocheMolecular Biochemicals Germany)Theactin-encoding gene ACT1 was used as the reference genefor normalization The data of real-time PCR was calculatedaccording to the 2minusΔΔCT method [19 27] The primers forthese PCR were listed in Table 2

25 Fermentation A single colony was cultured overnightin SC medium containing 20 g Lminus1 glucose A sample ofthe overnight culture was diluted to an initial OD

600

of 05

in SC medium containing 10 g Lminus1 glucose and 10 g Lminus1 L-arabinose After 10 h cultivation the cells were collected andused for fermentation All the shaker flask fermentationswere performed at 30∘C 200 rminminus1 in 200mL shaker flaskscontaining 40mL medium The oxygen-limited conditionwas maintained by using a rubber stopper The batch fer-mentations under anaerobic conditions were performed in14 L fermentors (Infors AG Switzerland) with a workingvolume of 900mL Anaerobic conditions were maintained bysparging with nitrogen (01 Lminminus1) the agitation rate was500 rminminus1 The pH was maintained at 50 by automaticallypumping 1mol Lminus1 NaOH and 1mol Lminus1 H

3

PO4

[19] Theinitial biomass was 02 gDCWLminus1 The carbon source in theSC plus CSM-LEU-URA medium was 20 g Lminus1 L-arabinose200120583gmLminus1 G418 was supplied in the fermentation of strainBSW3AG The dry cell weight of evolved strains and theunevolved strains were calculated according to the formulaof dry weight (mgmLminus1) = 0266 times OD

600

minus 00762 and dryweight (mgmLminus1) = 02365 times OD

600