Remote detection of stage ii to stage iii cracking in steel bridge girder material

-

Upload

mozahid0104030 -

Category

Education

-

view

260 -

download

2

Transcript of Remote detection of stage ii to stage iii cracking in steel bridge girder material

M. Hossain

ASNT 20th Annual Research Symposium & Spring Conference

San Francisco, California

21-25 March, 2011

This project is sponsored by the U.S. Department of Commerce, NIST-TIP(Cooperative Agreement Number 70NANB9H9007)

Remote Detection of Stage II to Stage III Cracking in Steel Bridge Girder Material

Background

2

N

Safe area

S

da/dN

DK

stable cracking

unstable cracking

threshold

Paris Law:

da/dN=C(∆K)m

critical cracking level

Background

3

Acoustic emission (AE) techniques: High sensitivity and reliability Capability of locating and quantifying active cracks

Time, μS

Vol

tage

, mV

Objective

Bridge Prognostic System• Self-Powered • Wireless Sensor Network • Structural Bridge Health Prognosis

Current tasks• Understand mechanism of acoustic emission(AE) corresponding to

crack growth behavior in the steel bridge material• Data interpretation to identify structural damage and deterioration• Modeling to assess the remaining fatigue life

4

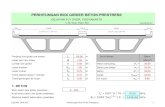

Experimental Procedure

5

AE-monitored fatigue tests:

Compact tension (CT) specimens, made of A572G50

MTS 810 hydraulic machine

Crack growth: clip gage, microscope and fiber light

AE sensors: R15I × 5, WDI × 3

Sensor Highway II-Remote Asset Integrity Monitor

12.0 in9.5 in

12.0 in

3.25 in

R15I WDI

Data Filtering and Reducing Procedures

6

Crack extension

Reversed yielding

Crack closure

Yielding

Crack opening

Stress-strain behavior at crack tip in a load cycle

Grating

Y-strain

Y-s

tres

s

loa

d

time

Pmin

Pmax

3

2 4

1 5

Pmean

1. Eliminate AE collected below 80% of peak load

Data Filtering and Reducing Procedures

7

Peak amplitude

Threshold

Rise time

Duration

Counts2. Friction emission tests to understand

characteristics of noise

3. Pencil lead break tests to understand characteristics of genuine hits

2 3

Data Filtering and Reducing Procedures

8

4. Swansong filter to minimize mechanical noise Ⅱ

Data Filtering and Reducing Procedures

9

5. Evaluate quality of filtered AE data

Results and Discussion

10

0 5,000 10,000 15,000 20,0000

0.5

1

1.5

2

2.5

3

3.5

4

Hit rate

Load cycles

Hit

rat

e

10% increase of cyclic loads

1. Sparse dataset

Results and Discussion

11

0 3,000 6,000 9,000 12,000 15,000 18,0000

2

4

6

8

10

12

0

50

100

150

200

250

300

350

Cumulative absolute energy

Maximum stress intensity

Load cycles

Cu

mu

lati

ve a

bso

lute

en

ergy

, aJ

Max

imu

m s

tres

s in

ten

sity

, MP

a√m

critical level

10% increase of cyclic loads

2. Determination of critical cracking level

Results and Discussion

12

2. Determination of critical cracking level

0 3,000 6,000 9,000 12,000 15,000 18,0000

2,000,000

4,000,000

6,000,000

8,000,000

10,000,000

12,000,000

14,000,000

16,000,000

0

50

100

150

200

250

300

350Cumulative signal strength

Maximum stress intensity

Load cycles

Cu

mu

lati

ve s

ign

al s

tren

gth

, V-T

Max

imu

m s

tres

s in

ten

sity

, Mp

a√m

critical level

10% increase of cyclic loads

Results and Discussion

13

2. Determination of critical cracking level

0 3,000 6,000 9,000 12,000 15,000 18,0000

5,000

10,000

15,000

20,000

25,000

30,000

35,000

Cumulative counts

Load cycles

Cu

mu

lati

ve c

oun

ts

critical level

10% increase of cyclic loads

Results and Discussion

14

2. Determination of critical cracking level

0 3000 6000 9000 12000 15000 180000

100

200

300

400

500

600

0

50

100

150

200

250

300

350Cumulative hits

Maximum stress in-tensity

Load cycles

Cu

mu

lati

ve h

its

Max

imu

m s

tres

s in

ten

sity

, MP

a√m

critical level

10% increase of cyclic loads

Results and Discussion

15

3. Prediction of fatigue life

Absolute energy of AE, U ∝ J(∆K), released energy due to crack growth

dU/dN=B(∆K)p

log(dU/dN)=plog(∆K)+log(B) Eq.(1)

Paris Law: da/dN=C(∆K)m; ∆K = ?

da/dN=D(dU/dN)q Eq.(2)

Applies to Stage crackingⅡ

Results and Discussion

16

3. Prediction of fatigue life

1.75 1.8 1.85 1.9 1.95 2 2.05-4

-3

-2

-1

0

1

2

f(x) = 5.74889754828652 x − 10.8645285573976

f(x) = 3.83380001661091 x − 9.95179643087376

crack growth rate, da/dNLinear (crack growth rate, da/dN)absolute energy rate, dU/dNLinear (absolute energy rate, dU/dN)

Stress intensity range, log(∆K)

Log

(da/

dN

), lo

g(d

U/d

N)

Results and Discussion

17

3. Prediction of fatigue life

0 10,000 20,000 30,000 40,0000

10

20

30

40

50

60

70

experimental crack

predicted crack

Load cycles

Cra

ck le

ngth

, mm

Results and Discussion

18

4. AE-detected cracking locations

crack path

Conclusions and Perspective

Summary:

AE absolute energy can provide warning signs for critical cracking in steel bridge material.

Absolute energy rate was found to most suitable feature.

Specific material constants in terms of both AE and crack growth behavior should be evaluated.

Robust data filtering techniques are required.

The combination of a Swansong II filter with a waveform-based approach was found to be appropriate.

Further work:

Mechanism of AE corresponding to crack growth in welded bridge elements

19

Acknowledgements

This work is performed under the support of the U.S. Department

of Commerce, National Institute of Standards and Technology,

Technology Innovation Program, Cooperative Agreement Number

70NANB9H9007. Special thanks to Jean-Louis Staudenmann.

South Carolina DOT for providing access to bridges and related

information for this project.

Valery Godinez, Adrian Pollock, Miguel Gonzalez (Mistras); Brian

Metrovich (Case Western Reserve Univ.); Fabio Matta (Univ. of

South Carolina).

20

Thanks for your time and attention

Annex1 Construction of a and dU/dN arrays for Fatigue Life Prediction

22

Array of a:

original a: ao

final a:

o generally, Kmax=F∙S∙(π∙afinal)1/2 = KIC ,

where F=f(geometry), S- applied stress, KIC – fracture toughness

o compact tension(CT) specimen-cantilever beam:

Kmax=Fp∙P/(t∙b1/2) = KIC ,

where Fp =fp (av/b), av=(afinal-1+ afinal)/2, P-applied load, t-thickness, b-width

o single edge(SE) specimen-freely supported beam:

Kmax=F∙Sg∙(π∙afinal)1/2 = KIC,

where F=f(av/b), Sg = 6M/(b2∙t), M-applied moment

a(i+1)=r∙ai , r ≈1.10,

Array of dU/dN:

original dU/dN: (du/dN)o

final dU/dN: (dU/dN)final=B(∆KIC )p , ∆K= KIC∙(1-R), where B, p-material constants, R-load ratio

(dU/dN)(i+1) / (dU/dN)i = B(∆K(i+1) / (∆K )i ) p = B(r) p/2 , r ≈1.10

CT SE