Reliability Assessment of a Solarpowered Center Pivot ... · 3 Figure 1. Simplified diagram for...

Transcript of Reliability Assessment of a Solarpowered Center Pivot ... · 3 Figure 1. Simplified diagram for...

Papers presented before CSBE/SCGAB meetings are considered the property of the Society. In general, the Society reserves the right of first publication of such papers, in complete form; however, CSBE/SCGAB has no objections to publication, in condensed form, with credit to the Society and the author, in other publications prior to use in Society publications. Permission to publish a paper in full may be requested from the CSBE/SCGAB Secretary, 2028 Calico Crescent, Orleans, ON, K4A 4L7 or contact [email protected]. The Society is not responsible for statements or opinions advanced in papers or discussions at its meetings.

The Canadian Society for Bioengineering The Canadian society for engineering in agricultural, food, environmental, and biological systems.

La Société Canadienne de Génie Agroalimentaire et de Bioingénierie La société canadienne de génie agroalimentaire, de la bioingénierie et de l’environnement

Paper No. CSBE13-61

Reliability Assessment of a Solar-powered Center Pivot Irrigation System

Hafiz Faizan Ahmed Department of Chemical and Biological Engineering, University of Saskatchewan, Saskatoon, SK, S7N 5A9 Canada. Email: [email protected]

Warren Helgason Department of Chemical and Biological Engineering, University of Saskatchewan, Saskatoon, SK, S7N 5A9 Canada. Email: [email protected]

Written for presentation at the CSBE/SCGAB 2013 Annual Conference

University of Saskatchewan, Saskatoon, Saskatchewan 7-10 July 2013

ABSTRACT Photovoltaic (PV) technology, used for generating power from solar, has a great potential for adoption in irrigated agriculture since both the energy production and requirement (load demand) strongly depends upon solar radiation. However, a reliable system design considering irrigation system specifications, climatic history, crop type, soil profile, and irrigation management strategy is of considerable importance for its successful adoption by the irrigation sector. The objective of this study is to develop a model for assessing the reliability of a PV powered center pivot irrigation system by combining power production, storage and requirement (load demands) sub-models considering variable operating and meteorological conditions. Given the required input variables, the developed model determines the reliability of the PV system by analyzing the time of irrigation for which both power produced by the generator and stored in the batteries are sufficient to fulfill the load demands. The model was validated by comparing the modeled results to the field measurements for a small (1.4 ha) solar powered center pivot irrigation system installed at Outlook, Saskatchewan, Canada. The results showed an excellent agreement (NRMSE, 0.031) of the modeled results with the actual field data. The model is intended to be applied as a design tool to determine the required size of the PV system to achieve the desired reliability.

Keywords: Center pivot irrigation system, PV sizing, Reliability model,

2

INTRODUCTION There has been a common reliance on fossil fuels for generating power to run irrigation systems in remote areas with restricted electrical supplies. Escalating prices of fossil fuels, as well as the associated environmental issues with their usage, have raised the importance of consuming renewable energy resources such as solar, wind, and bio-fuel for sustainable irrigated agriculture. The advantage of using solar energy in irrigation sector is that the energy requirement (derived from crop water use) as well as the energy production strongly depends upon the incoming solar irradiance. Photovoltaic (PV) technology is used for generating electricity from the incoming solar radiation. Several attempts have been made to evaluate, monitor and improve the performance of different components of a PV system: a PV module (Abdallah, 2004; Vick and Clark, 2004; Huang and Sun, 2007; Hansen et al., 2000; Lorenzo, 1994), a controller (Hohm and Ropp, 2003), a battery (Copetti et al., 1993; Gergaud et al., 2003; Achaibou et al., 2012), a pump (Vick and Clark, 2011), and a pump motor (Bhat et al., 1987). These, and similar studies have been effective for improving the efficiency of the PV system components. However, several factors need to be considered for an optimal PV system design to achieve the desired reliability of the system in a given environment. This involves a detailed investigation of all interacting physical (plant and soil type, irrigation system specifications, PV system sizing, site attributes), meteorological (solar radiation, air temperature, relative humidity, wind speed, precipitation) and managerial (irrigation scheduling) variables with the aim of achieving the desired reliability of the PV system. Ultimately, a technique that combines the center pivot irrigation system characteristics, daily crop water requirements, soil moisture status, irrigation applications, PV array output, load demands, and energy storage is required for evaluating a solar-powered center pivot irrigation system in terms of its reliability. This sort of holistic approach could be very beneficial for effective sizing of the system.

The purpose of this study is to develop a model for determining the reliability of the selected PV system under variable operating and meteorological conditions by combining interacting crop, soil, irrigation management, center pivot system, and climatic variables. In addition, the developed model application will be demonstrated by evaluating a pre-installed 1.4 ha solar powered pivot irrigation system in Outlook, Canada.

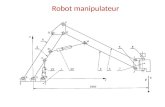

MATERIALS AND METHODS The reliability of a PV system providing power to a center pivot can be determined by a model developed on the basis of loss of power supply probability (LPSP) technique (Borowy and Salameh, 1996). The ratio of the energy deficit and demand, both with respect to the load, is termed as LPSP (Copetti et al., 1993). Its value ranges from zero to one where zero indicates a PV system (produced and stored energy) which always fulfills the load demands. Thus reliability could be estimated by the inverse of the LPSP where one (100% in terms of percentage) could be used to describe the same system. The deficit energy could be projected for the given time period by comparing the energy required by the load (irrigation system) against the total available energy (produced and consumable stored energy). Therefore, sub-models of energy production, storage and requirement incorporating all interacting variables for the most accurate predictions/calculations are required for reliability assessment of the PV system. The desired reliability of the PV system could be achieved by altering the PV panel sizing, the battery capacity, or the irrigation management strategy in the relevant sub-models of energy production, energy storage and energy requirement respectively. The reliability assessment model is presented with a simplified flow diagram in figure 1.

3

Figure 1. Simplified diagram for reliability assessment model for center pivot irrigation system

Produced Energy The power (P) produced by the PV module at any level of irradiance is the product of voltage (V) and current (I) of that module (Helikson, 1991). Voltage of the module remains practically constant and current varies directly with the ambient irradiation. Voltage and current of the PV system could be increased by wiring the PV modules in series and parallel respectively to achieve the desired output. The power production model (fig. 2) requires climatic variables which include ambient irradiation and temperature as well as PV panel properties/specifications usually given in the manufacturer’s data sheet such as open circuit voltage, short circuit current, cell temperature, maximum power produced, standard irradiation, and no of cells connected in series and parallel to be provided as an input. The model then predicts the current and voltage of the PV system (Lorenzo, 1994), which are modified for their optimum product considering the maximum power point tracking algorithm yielding the maximum average power produced at a given level of irradiation and ambient temperature. The energy produced for a given time interval was estimated by integrating the pre-determined maximum produced power for that time.

Figure 2. Simplified flow diagram for the power production model

Required/Load Energy A model considering irrigation system specifications, site attributes, irrigation management strategy (starting time, frequency, and depth of irrigation), crop characteristics and climatic variables was developed for estimating the required energy by the load for a given time (fig. 3). The total instantaneous power required by the center pivot irrigation system was estimated by combining the power required for pumping water and the power required for driving the pivot in the field. The power required for pumping was estimated from the irrigation system capacity and the total dynamic head, both were provided as inputs in the model. Pivot drive

4

power was also provided as an input in the model and the average energy required during the operation of the system was calculated by the pivot percent timer settings. This is the setting which regulates the pivot drive motor to be turned on and off during the system operation time with respect to desired amount of water to be applied. The irrigation management strategy which determines the frequency of irrigation, depth of water to be applied, and the starting time of irrigation was considered as the driving variable in distributing the required energy during the crop growing season . Soil moisture status at any time could be monitored / estimated by subtracting the crop evapotranspiration from the water supplied through net irrigation and effective precipitation in addition to previously stored soil moisture assuming the runoff and deep percolations negligible. Initial water content (IWC) was provided as input in the model to start the simulations. Crop water use was determined using the Penman-Monteith technique described in Allen et al. (2005). Thus a suitable irrigation depth could be selected and/or readjusted to maintain the soil moisture within the desired limits considering the predicted/recorded crop water use and precipitation. The duration of irrigation was determined from the selected depth of irrigation, irrigable area and irrigation system capacity. The load/power demand was then distributed in accordance with the pre-determined irrigation time duration and the selected starting time of irrigation.

Figure 3. Load energy estimation model considering center pivot specifications, irrigation management strategy, crop choice and climatic variables

5

Stored Energy Energy produced by the PV panels and required by the load was incorporated with the battery specifications such as no. of cells, base temperature, maximum and minimum state of charge, and the battery capacity along with the climatic variables (temperature) for developing a model for the estimation of stored energy in the battery bank at a given time (fig. 4). State of charge (SOC) of the battery was used to determine the energy stored in the battery bank at any time. The battery terminal voltage and SOC were determined from the battery current using the CIEMAT model (Copetti et al., 1993). Battery current, positive when going into the battery bank and negative when flowing away from it, was determined by dividing the battery power by its terminal voltage. Battery power was assumed to be zero when the power produced by the PV array was greater than the estimated load demand as well as the state of charge of the battery was higher than or equal to its maximum. Similarly, when SOC of the battery was below the lower limit and the power required by the load was greater than that produced, battery power was assumed to be zero in the model. In all other cases, battery power was estimated by subtracting the load power from the produced by the PV array. Initial battery terminal voltage was provided as input in the model and subsequent estimations for the given time steps were made with respect to pre-determined battery current using the CIEMAT model.

Figure 4. Stored energy estimation model for a PV powered center pivot irrigation system

6

Model Validation and Application Demonstration A small, 67 m long (1.4 ha) solar powered center pivot irrigation system installed at Outlook, Saskatchewan, Canada (51° 30’ N, 107° 03’ W) was selected for validating the model and demonstrating its application. The system capacity (discharge) was 113.5 L min-1 and was supplied by two Lorentz PS200 submersible solar pumps having their own parallel power production and storage systems. Each system was comprised of eight 200W @ 12V solar panels connected in series and an array of eight 240 Ah @ 6V batteries, which were connected with the panels through a controller to prevent the undesired operation of the battery banks and solar panels. The arrangement of the batteries yielded a total battery bank capacity of 480 Ah at 24V. The average power required for each solar pump was 280W. Since both the systems were identical, validation of the model was performed for one of the parallel systems for the average hourly battery current cycle.

The model application was demonstrated by evaluating the PV system performance for canola crop at the selected site using 2012 climatic data. The growing season of the canola crop was considered from May 16 to August 31. The required climatic variables for modeling of crop water requirement and the power production were taken from the nearby weather station site. Conventional irrigation management strategy was adopted, where 20-35 mm water was applied each time the soil moisture depletes to 60% of the filed capacity. Soil water holding capacity considering the root-zone depth and soil texture was estimated and found to be 220 mm. An hourly time step was used in the model for analyzing the energy produced and stored against the load demands.

RESULTS AND DISCUSSIONS A model combining all the components of a solar powered center pivot irrigation system for determining the reliability of the selected system capacity (PV array and batteries for power production and storage respectively) under given operating and meteorological condition was developed. For validation, the modeled battery current was compared with one of the installed parallel pumping systems from July 31 to August 02, 2012 (figure 5). Normalized root mean square error (NRMSE) was estimated and found to be 0.031, indicating an excellent agreement between the modeled results and the observed/recorded data. Battery current was chosen for validation because the battery model considers the power production, load requirement and controller models for estimating the battery power and ultimately the battery current. Thus validation of the battery model also endorses the accurate functioning of the other models. The model was also validated in terms of reliability estimation. It was observed that during the testing period of the model (July 31 – August 02, 2012), load demand was always fulfilled by the power production and storage systems. The model results also suggested that the installed system is 100 % reliable for the selected testing period verifying the accurate working of the model for reliability assessment.

Figure 5. Modeled Vs. actual battery current

-‐20

-‐15

-‐10

-‐5

0

5

10

15

20

12:00 PM

6:00 PM

12:00 AM

6:00 AM

12:00 PM

6:00 PM

12:00 AM

6:00 AM

12:00 PM

6:00 PM

12:00 AM

Curren

t (Am

p)

Time (hrs)

Irriga=ng hours

Actual Current

Modeled Current

July, 31 August, 01 August, 02

7

The usefulness of the developed model is demonstrated by evaluating a pre-installed PV powered center pivot irrigation system described in previous sections using 2012 climatic data. The variation of reliability with the PV panel sizing for the selected irrigation management strategy and chosen battery capacity is shown in figure 6. The traditional irrigation management strategy was adopted for evaluation of the PV system where 30 mm water was applied when soil moisture depletes to 60% field capacity. The reliability curves were generated for the two fixed combination of battery capacities (480 and 960 Ah). In traditional/conventional irrigation management strategy, PV systems may be designed at a moderate level of reliability (80-95%) to optimize the size of the PV system components. This is because of the fact that the deficit of water caused by the loss of power supply may be fulfilled by applying irrigation during the following days of PV system failure since irrigation system only operates for some days in the season under a conventional management strategy. It can be seen from the figure that an 80% reliable PV system can be designed for the selected irrigation management strategy either by employing 11 solar panels with 960 Ah batteries or 20 solar panels with 480 Ah battery capacity. After considering the economics of the PV system components, the appropriate system can be designed.

Figure 6. PV system performance for the selected site and irrigation management strategy It has been demonstrated that the model can be used to determine the different combinations of PV system sizing required to achieve the desired reliability for the selected irrigation management strategy and given operating conditions. A suitable PV system can then be selected considering the economics of its components. This kind of detailed investigation may be carried out for designing a reliable PV system either by providing the stochastically determined and/or predicted input climatic variables in the model or by analyzing the PV system performance using historic data.

CONCLUSION A reliability assessment model for a solar powered center pivot irrigation system considering climatic variations, crop water use, irrigation management strategy and site attributes has been developed. The modeled battery current was compared against the hourly recorded data and the normalized root mean square error was found to be 0.031. The model was also validated in terms of reliability and the results were in excellent agreement. The usefulness of the developed model was demonstrated by evaluating a 1.4 ha system installed in Outlook, Saskatchewan, Canada for the conventional irrigation management strategy (20-35 mm water application when soil moisture depletes to 60% field capacity) using 2012 climatic data. The results suggested that different combinations of PV panels and batteries can provide the same reliability, thus PV sizing should be based on best economic match of its components. The model can be used as a tool to develop a reliable PV system design with appropriate system sizing for a given environment and crop choice.

0

20

40

60

80

100

0 5 10 15 20 25

Reliability

No. of Panels

960 Ah

480 Ah

8

Acknowledgements. We are grateful for the financial support for the project that was provided by the Ministry of Agriculture, Government of Saskatchewan. The logistical and financial support from Agriculture and Agri-Food Canada and the Canada-Saskatchewan Irrigation Diversification Center (CSIDC) is also acknowledged and greatly appreciated.

REFERENCES Abdallah, S., 2004. The effect of using sun tracking systems on the voltage-current characteristics

and power generation of flat plate photovoltaics. Energy Conversion and Management 45: 1671-1979.

Allen R.G., I.A. Walter., R. Elliott., T. Howell., D. Itenfisu., and M. Jensen. 2005. ASCE Standardized Reference Evapotranspiration Equation. ASCE-EWRI Task Committee Report: American Society for Civil Engineers.

Achaibou, N., M. Haddadi., and A. Malek. 2012. Modeling of lead acid batteries in PV systems. Energy Procedia 18: 538-544.

Bhat, S.R., A. Pittet., and B. S. SONDE., 1987. Performance optimization of induction motor-pump system using photovoltaic energy source. IEEE Transactions on Industry Applications IA-23: 995-1001.

Boroway, B.S., Salameh, Z.M., 1996. Methodology for optimally sizing the combination of a battery bank and PV array in a wind/PV hybrid system. IEEE transactions on energy conversion 11: 367-375.

Copetti, J.B., E. Lorenzo., and F. Chenlo. 1993. A general battery model for PV system simulation. Progress in photovoltaic: Research and Applications 1: 283-292.

Gergaud, O., G. Robin., B. Multon., and H. B. Ahmed. 2003. Energy modeling of a lead acid battery within hybrid wind/photovoltaic systems. SATIE- Brittany branch, ENS de Cachen- Ker Lan Campus: ISBN 90-75815-07-7.

Hansen, A.D., P, Sorensen., L.H. Hansen., and H. Binder. 2000. Models for a standalone PV system. Riso-R-1219 (EN)/ SEC-R-12.

Hohm, D.P., and M.E. Ropp. 2003. Comparative study of maximum power point Tracking algorithms. Progress in Photovoltaics: Research and Applications 11: 47-62.

Huang, B.J. and F.S. Sun. 2007. Feasibility study of one axis three positions tracking solar PV with low concentration ratio reflector. Energy Conversion and Management 48: 1273-1280.

Lorenzo, E. 1994. Solar electricity engineering of photovoltaic systems. Artas Graficas Gala, Spain. Vick, B.D. and R.N. Clark. 2004 Effect of panel temperature on a solar-PV AC water pumping system. ASES Solar 2004: A Solar Harvest Growing Opportunities. July 11-14. Portland.

Vick, B.D. and R.N. Clark. 2011. Experimental investigation of solar powered diaphragm and helical pumps. Solar Energy 85: 945-954.