redPOWER 300W to 2.0kW Module Fiber Lasers Instructions ... · 7.8 Connecting the PIPA-Q Optical...

Transcript of redPOWER 300W to 2.0kW Module Fiber Lasers Instructions ... · 7.8 Connecting the PIPA-Q Optical...

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

2

Safety Notes These safety notes indicate potential hazards associated with this PRISM Fiber Laser and the

probable consequences of not avoiding them. Directions on the safe use of this Laser are

provided in the remainder of these instructions for use, particularly Sections 3 Health and

Safety, 7 Installation, and 8 Operating Instructions.

Throughout these Instructions for Use warning messages are given in contexts in which a

hazard may occur.

General Hazard Information

WARNING: Ensure that all Users are fully aware of all safety

implications identified in these Instructions for Use before

attempting to install, operate or maintain this Laser.

WARNING: Attempts to modify or alter this PRISM Fiber Laser or

the use of controls or adjustments or performance of procedures

other than those specified in these Instructions for Use may render

this Laser unsafe.

Attempts to modify or alter this Laser or the use of controls or adjustments or performance of

procedures other than those specified in these Instructions for Use additionally will invalidate

the warranty and may result in patent infringement.

Laser Integrators are not authorised to modify this Laser.

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

3

Laser Hazard Information

WARNING: The output aperture of this PRISM Fiber Laser may

emit both invisible and visible laser radiation.

The invisible laser radiation will be Class 4 laser radiation. The

invisible radiation can be up to approximately 115% of rated power

CW in normal operation and 150% with a single fault. The

wavelength of this invisible radiation is in the range 1050-1250nm.

Additionally, this Laser contains embedded lasers that emit invisible

laser radiation up to approximately 170% of rated power CW in

normal operation and 250% CW with a single fault. The wavelength

of this invisible radiation is in the range 900-1000nm.

AVOID EYE OR SKIN EXPOSURE TO DIRECT OR SCATTERED

RADIATION.

Contact with direct or scattered laser radiation can cause damage

to the eyes, burn human tissue and start fires.

The optical connector shall be mounted in a protective housing

which prevents human access to laser radiation (including errant

radiation) in excess of the AEL for class 1, for example a housing

meeting the requirements of EN 60825-4.

WARNING: The output aperture of this PRISM Fiber Laser may

emit both invisible and visible laser radiation.

The visible laser radiation is below the Accessible Emission Limit

(AEL) for a Class 2 laser. The wavelength of the visible laser

radiation is in the range 630 – 680nm.

DO NOT STARE INTO BEAM.

WARNING: This PRISM Fiber Laser must only be operated when

the optical connector is mounted in an appropriate receiver.

Care must be taken to prevent the electrical contacts on the optical

connector being accidentally connected. Do not place the optical

connector on a metal surface.

The protective cap must be placed over the connector whenever

the connector is not in a receiver.

WARNING: Before carrying out any maintenance task detailed in

these Instructions for Use ensure that power to the Laser is

disconnected. Failure to do so may lead to serious personal injury.

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

4

WARNING: This PRISM Fiber Laser does not control the pump

power supply and has no safety function to de-energise or control

the pump diodes or the output power.

Failure to provide external safety systems may result in exposure to

harmful levels of radiation.

Electrical Hazard Information

CAUTION: This PRISM Fiber Laser must be grounded for safety

and to comply with regional electrical codes.

Failure to do so may result in electric shock and incorrect operation

of the Laser.

Weight Hazard Information

CAUTION: This PRISM Fiber Laser is heavy and so precautions

must be taken when lifting and moving.

Failure to do so may cause serious injury.

Pressure Hazard Information

CAUTION: Ensure an approved overpressure safety device

compliant with ISO4126-1 (or equivalent) is installed when

connecting the PRISM Fiber Laser to an external chiller or factory

water supply.

Failure to do so may result in water leaks and damage to the Laser

and auxiliary equipment.

Laser for Incorporation

CAUTION: This PRISM Fiber Laser is specifically designed to be a

laser for incorporation or integration into other equipment. As such,

it is not required to, and does not, meet the requirements for a

stand-alone laser system as defined by IEC/EN 60825-1.

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

5

CONTENTS 1 Structure and Scope of these Instructions for Use 9

2 Definition of Symbols and Terms 10

3 Health and Safety 12

3.1 General 12 3.2 Intended Use of the PRISM Fiber Laser 12 3.3 Hazards 13 3.4 Compliance 14 3.5 Labelling 17

4 Document References 19

5 redPOWER PRISM Tour 20

5.1 Key Parts 21 5.2 Key Features 21 5.3 Auxiliary Equipment 25 5.4 Software Tools 26 5.5 Explanation of Order Codes 27

6 Getting Started 29

6.1 Receiving and Inspection 29 6.2 Unpacking and Handling 29 6.3 Unpacking the Beam Delivery Optic 33

7 Installation 34

7.1 Safety and Compliance During Installation 34 7.2 Location and Environment 34 7.3 Mounting 35 7.4 PRISM Fiber Lasers with Bare Fiber Output 35 7.5 Cooling Water Connections 35 7.6 Electrical Connections 39 7.7 Routing the Beam Delivery Optic 49 7.8 Connecting the PIPA-Q Optical Connector to the Process Head 51 7.9 Removing PIPA-Q Optical Connector from the Process Head 54

8 Operating Instructions 55

8.1 Before Operation 55 8.2 Modes of Operation 56 8.3 Turning the Laser On and Off 58 8.4 Turning the Alignment Laser On and Off 62 8.5 Monitoring, Alarms and Diagnostics 62 8.6 Laser Control Using PrismView 65 8.7 Serial Control of the Laser 65

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

6

9 Maintenance 66

9.1 Periodic Inspection 66 9.2 General Cleaning 66 9.3 Maintenance of Optics 67

10 Disposal 72

11 Specifications 73

11.1 Operating Conditions 73 11.2 Non-Operating Conditions 75 11.3 Utility Requirements 75 11.4 Optical Specifications 80 11.5 Mechanical Specifications 83

12 General Information 91

12.1 Trade Marks 91 12.2 Licensing 91 12.3 Software 91 12.4 Warranties 91 12.5 Copyright 91 12.6 Changes 92

13 Contact Information 93

14 Customer Service 94

FIGURES Figure 1 WEEE Symbol ........................................................................................................................... 14

Figure 2 PRISM Fiber Laser with Optical Connector Key Parts .............................................................. 21

Figure 3 PRISM Fiber Laser Key Features ............................................................................................. 22

Figure 4 PIPA-Q Optical Connector with Protection Against Back-Reflection ........................................ 24

Figure 5 PRISM Fiber Laser with Auxiliary Equipment ........................................................................... 26

Figure 6 Laser in Crate as Received ....................................................................................................... 29

Figure 7 Removing Fastener ................................................................................................................... 30

Figure 8 Crate without Lid and Top Layer of Foam Packaging ............................................................... 31

Figure 9 Lift BDO to Enable the Next Layer of Packaging to be Removed ............................................ 31

Figure 10 BDO Replaced ........................................................................................................................ 32

Figure 11 Lifting Laser from Crate ........................................................................................................... 33

Figure 12 Cooling Water Connections .................................................................................................... 36

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

7

Figure 13 Electrical Connections and Status Indicators .......................................................................... 40

Figure 14 Star Earthing Configuration ..................................................................................................... 41

Figure 15 Bus Bar Connection ................................................................................................................ 42

Figure 16 User Interface Connector ........................................................................................................ 43

Figure 17 PLC Logic Levels .................................................................................................................... 44

Figure 18 TTL Logic Levels ..................................................................................................................... 44

Figure 19 RS-232 and RS-485 Connector .............................................................................................. 48

Figure 20 PIPA-Q with Protective Cap .................................................................................................... 52

Figure 21 Connector Before Removal of Protective Tape ...................................................................... 52

Figure 22 Red Dots Aligned .................................................................................................................... 53

Figure 23 Connector Inserted into Receiver ............................................................................................ 53

Figure 24 Timing Diagram for CW Operation .......................................................................................... 59

Figure 25 Timing Diagram for Operation in Analogue Modulation Mode ................................................ 60

Figure 26 Timing Diagram for Operation in Digital Modulation Mode ..................................................... 61

Figure 27 PIPA-Q Window Assembly ...................................................................................................... 68

Figure 28 Removing Sleeve .................................................................................................................... 69

Figure 29 Placing Lens Cleaning Paper on top of the Window ............................................................... 69

Figure 30 Wetting the Lens Paper ........................................................................................................... 70

Figure 31 Cleaning the Window .............................................................................................................. 70

Figure 32 Removing Window .................................................................................................................. 71

Figure 33 Environmental Conditions for Non-Condensing Operation ..................................................... 74

Figure 34 Minimum Flow Rate against Inlet Water Temperature ............................................................ 79

Figure 35 Modulation Bandwidth as a Function of Set Power ................................................................ 81

Figure 36 Outline Drawing – Short Module ............................................................................................. 84

Figure 37 Mounting Locations – Short Module ........................................................................................ 85

Figure 38 Outline Drawing – Long Module .............................................................................................. 86

Figure 39 Mounting Locations – Long Module ........................................................................................ 87

Figure 40 PIPA-Q Optical connector ....................................................................................................... 87

Figure 41 Outline Drawing – PIPA-Q Beam Delivery Optic .................................................................... 88

Figure 42 Outline Drawing – Bare Fiber Output ...................................................................................... 89

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

8

TABLES Table 1 Safety, Explanatory and Compliance Labels ............................................................................. 17

Table 2 Information Labels ...................................................................................................................... 18

Table 3 Explanation of Order Code ......................................................................................................... 27

Table 4 Water Tubing and Fittings .......................................................................................................... 37

Table 5 Electrical Interface Connections ................................................................................................. 40

Table 6 Pinout of User Interface Connector ............................................................................................ 45

Table 7 RS-232 and RS-485 Control ...................................................................................................... 48

Table 8 Meaning of Status Words ........................................................................................................... 62

Table 9 Replacement Window Kit and Replacement Window ................................................................ 67

Table 10 Environmental Operating Conditions........................................................................................ 73

Table 11 Non-Operating Conditions ........................................................................................................ 75

Table 12 Electrical Requirements ........................................................................................................... 75

Table 13 Power Supply Output Capability Requirements ....................................................................... 76

Table 14 Cooling Water Requirements ................................................................................................... 77

Table 15 Cooling Requirements (Base Plate) ......................................................................................... 78

Table 16 Required Chiller Capacity ......................................................................................................... 79

Table 17 Cooling Requirements (PIPA-Q Optical Connector) ................................................................ 79

Table 18 General Laser Optical Specifications ....................................................................................... 80

Table 19 Maximum Modulation Bandwidth ............................................................................................. 81

Table 20 Single Mode Optical Specification ............................................................................................ 82

Table 21 Multimode Optical Specifications: 50µm Fiber ......................................................................... 82

Table 22 Multimode Optical Specifications: 100µm Fiber ....................................................................... 82

Table 23 Multimode Optical Specifications: 300µm Fiber ....................................................................... 82

Table 24 Mechanical Specifications – Short Modules ............................................................................. 83

Table 25 Mechanical Specification – Long Modules ............................................................................... 85

Table 26 Mechanical Specifications – PIPA-Q Optical Connector .......................................................... 87

Table 27 Bare Fiber Output Interface ...................................................................................................... 89

Table 28 Contact Information .................................................................................................................. 93

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

9

1 Structure and Scope of these Instructions for Use

These Instructions for Use for SPI Lasers’ redPOWER® PRISM Fiber Lasers contain all the

information that Users need to know for their safe and efficient use. This information is

important. These Instructions for Use must be read before installing and using the Laser and

made available for reference at the location where the Laser is being used. Additional or

replacement copies are available from SPI Lasers.

These Instructions for Use are divided into the sections below which provide Users with health

and safety information before introducing the Laser and then guiding them through its

installation, operation, maintenance and disposal. Lastly they provide other useful information

and the Lasers’ specifications.

2 Definition of Symbols and Terms

3 Health and Safety

4 Document References

5 redPOWER PRISM Tour

6 Getting Started

7 Installation

8 Operating Instructions

9 Maintenance

10 Disposal

11 Specifications

12 General Information

13 Contact Information

14 Customer Service

The PRISM Fiber Laser variants covered by these Instructions for Use have order codes:

SP -

0300

0500

0750

1000

1500

2000

- M - W -

014

020

050

100

300

-

02

05

10

15

20

30

- FBR

PIQ - 0

0

1 0 - 00

0

1 - 0

1 0 0

2

The order code can be found on a label on the rear panel of the Laser.

Details of the options shown in bold are expanded in Section 5.5 below.

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

10

2 Definition of Symbols and Terms

This symbol alerts the user to the hazard of exposure to laser

radiation.

This symbol alerts the user to the hazard of exposure to electricity.

This symbol alerts the user to the hazard caused by the weight of

this Laser.

This general warning symbol emphasises important information

needed during installation and operation.

This symbol identifies the protective conductor terminal (ground

point).

WARNING: Indicates a hazard with a medium level of risk which, if not avoided,

could result in death or serious injury.

Warnings must be observed to prevent personal injury to yourself

and others.

CAUTION: Indicates a hazard with a low level of risk which, if not avoided,

could result in minor or moderate injury.

Cautions must be observed to prevent personal injury and damage

to or destruction of equipment or loss of operational effectiveness.

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

11

PRISM Fiber

Laser and

Laser:

PRISM Fiber Laser and Laser as used herein means the item that

was procured from SPI Lasers.

The PRISM Fiber Laser is a complete fiber laser system. By

‘complete’ it is meant a laser system as sold and ready for use for

its intended purpose without modifications to the specification of

the product.

The PRISM Fiber Laser is specifically designed to be a laser for

incorporation or integration into other equipment. As such, it does

not meet the full requirements for a stand-alone laser system as

defined by 21 CFR 1040.10 and IEC/EN 60825-1.

The PRISM Fiber Laser is not a consumer product and is not to be

sold on or made available as such.

Laser

Integrator:

Any person who integrates the Laser into equipment, or any person

who uses the Laser in the form as supplied by SPI Lasers.

User: Individuals or organizations that use the Laser. User includes the

Laser Integrator and the end user.

Authorised

Personnel:

Those who have attended official Training Courses and have been

certified as competent.

OEM: Original Equipment Manufacturer. A company or organisation

which is skilled in and understands the integration issues

surrounding the use, design and supply of laser products to end

users in the end markets which it supplies.

SPI Lasers: SPI Lasers UK Ltd.

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

12

3 Health and Safety

3.1 General

This section gives information on the hazards which may be encountered during installation,

operation and maintenance of this PRISM Fiber Laser and steps to reduce the risk. Also

included is information on laser and electrical safety compliance. All safety instructions

including the instructions mentioned in other sections of these Instructions for Use must be

followed. Not following safety instructions may constitute a hazard to Users and third parties or

cause damage to property and the Laser.

Only Authorised Personnel who have been instructed in, and fully understand, the necessary

safety procedures should use this laser. Access to the laser must be restricted to Authorised

Personnel.

Any local safety requirements for the operation of this equipment must be complied with.

Throughout the documentation, ‘WARNING’, and ‘CAUTION’ paragraphs appear. It is the

responsibility and duty of all Users who operate and maintain this equipment to fully

understand the WARNING and CAUTION and act in order to reduce or eliminate hazards.

3.2 Intended Use of the PRISM Fiber Laser

This Laser has been designed exclusively for incorporation or integration into other equipment

for processing:

solid metals, including metal alloys and metal powders

ceramics in both solid and powder form

composite materials

Operating the device within the limits of its designated use requires the user to:

observe the instructions set out in these Instructions for Use

install and use this Laser in compliance with international, national and local

regulations regarding laser safety, for example IEC/EN 60825-1 and 21 CFR 1040.10.

install and use this Laser in compliance with international, national and local

regulations regarding the safety of electrical equipment, for example BS EN 60204

wire and connect the electrical lines to this Laser in compliance with international,

national and local regulations regarding electromagnetic compatibility (EMC), for

example the relevant sections of IEC/EN 61000 and FCC CFR47

not move this Laser when it is switched on (except that the optical connector may be

moved provided that the bending limits of the conduit are observed)

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

13

carry out necessary inspection and maintenance work

This Laser is not intended:

for processing in connection with flammable or explosive materials

for use in an explosion prone environment

SPI Lasers cannot be held liable for any damage resulting from such use. The risk lies entirely

with the User.

3.3 Hazards 3.3.1 Laser Hazards

All Warnings, including those in the Safety Notes and those in other sections of these

Instructions for Use, must be heeded.

Laser emissions from the housing of the Laser and the conduit of the beam delivery optic are

less than the AEL for Class 1 of IEC/EN 60825-1 with a single fault providing that the Fiber

Continuity Monitoring System (FCMS) is correctly implemented by the Laser Integrator.

WARNING: Care must be taken especially when controlling this

PRISM Fiber Laser remotely across a network.

Failure to do so could result in another User being exposed to

hazardous levels of radiation.

It is the responsibility of the Laser Integrator to ensure that when

controlled remotely no hazardous levels of radiation are emitted

when unsafe to do so.

3.3.2 Thermal Hazard

This Laser is designed to be used in a 19” rack cabinet or other housing which prevents

access to surfaces which may get hot during operation.

3.3.3 Materials Processing Hazards

Materials processing can generate vapour, fumes, solid particulates and other air

contaminants that may irritate, be toxic, or even fatal. It is the responsibility of the user to

ensure that all relevant safety precautions are followed and that any legal requirements are

adhered to in accordance with local legislation. It is advised that Material Safety Data Sheets

(MSDS) for any material to be processed are evaluated and that adequate measures for fume

extraction and venting are considered. Interaction of the beam with certain materials can

cause potentially harmful levels of visible radiation to be emitted. Appropriate protective

measures must be taken.

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

14

CAUTION: It is essential that any debris associated with laser

processing is removed and cleaned away on a regular basis.

Failure to do so may result in fire.

3.3.4 Other Hazards

While most of the hazard comes from laser radiation, there are certain non-beam hazards that

are often associated with use of laser systems. The Laser requires an electrical supply and is

water-cooled. Electricity and water, individually or in combination, may create hazards.

It is recommended that the Laser should be installed sufficiently far above the floor to reduce

the risk from electricity in the case of flooding: at least 250mm is recommended.

Mechanical hazards may include moving parts in cutting, welding and material handling

systems.

High temperatures and fire hazards may also result from the operation of Class 4 lasers.

3.4 Compliance

Within the EU, the Laser is CE marked and is supplied with a Declaration of Conformity. The

standards which SPI Lasers declares that the Laser is in conformity with, and the directives

which SPI Lasers declares that the Laser complies with the requirements of are listed in the

Declaration of Conformity.

Within the USA, the Laser is shipped with an appropriately completed FDA 2877 form.

It is the responsibility of the Laser Integrator to ensure that the integrated laser system

conforms with the appropriate standards and complies with the appropriate directives.

Nonetheless, many of the electronic and labelling requirements have been incorporated into

the Laser to facilitate compliance.

3.4.1 Europe: WEEE Directive

Figure 1 WEEE Symbol

This symbol indicates that, at end of life, this Laser should be separately collected from

unsorted waste.

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

15

3.4.2 Europe: RoHS Directive

This Laser is in conformity with European RoHS Directive. Compliance is demonstrated

through conformance with this standard which is harmonised to the RoHS directive:

BS EN 50581:2012

3.4.3 Europe: Machinery Directive

This Laser does not fall within the meaning of ‘machinery’ given in the Machinery Directive,

2006/42/EC, and therefore SPI Lasers cannot declare conformity with the Directive. However

SPI Lasers recognises that Laser Integrators may require the integrated laser system to

comply with the Directive. SPI Lasers has therefore designed for compliance to parts of the

standards listed below which are harmonised to the Machinery Directive:

EN11252:2013

EN13849-1:2015

EN13849-2:2012

EN11554:2008

EN12100:2010

EN12198-1:2000+A1:2008, EN12198-2:2002+A1:2008, EN12198-3:2002+A1:2008

3.4.4 Europe: Low Voltage Directive

This Laser falls outside the scope of the Low Voltage Directive as the Directive applies to

electrical equipment designed for use with a voltage rating of between 75V and 1500V for

direct current. However SPI Lasers recognises that Laser Integrators may require the

integrated laser system to comply with the Directive. SPI Lasers has therefore demonstrated

compliance to parts of the standard given below which is harmonised to the Low Voltage

Directive:

IEC/EN 60825-1

This Laser is specifically designed to be a laser for incorporation or integration into other

equipment. As such, it is not required to, and does not, meet the requirements for a stand-

alone laser system as defined by IEC/EN 60825-1.

During installation it is vital that the laser hazard is fully managed. In particular, the Laser

Integrator is required to provision the engineering requirements detailed in IEC/EN 60825-1.

These include, but are not limited to:

Provision of an additional protective housing which prevents human access or

exposure to laser radiation in excess of the AEL for Class 1 laser systems from the

output aperture. (IEC/EN 60825-1 section 4.2).

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

16

Provision of a remote interlock connector which when open-circuit prevents access to

laser radiation in excess of Class 1M (IEC/EN 60825-1 section 4.4).

Provision of a manual reset to enable resumption of accessible Class 4 laser radiation

emission after interruption of emission caused by use of the remote interlock connector

or an interruption of longer than 5s of electrical mains power (IEC/EN 60825-1 section

4.5).

Provision of a key-operated master control. The key must be removable and the laser

radiation shall not be accessible when the key is removed (IEC/EN 60825-1 section

4.6).

Provision of a fail-safe or redundant audible or visible emission indicator. This must be

repeated at the laser aperture if it is located more than 2m from the original emission

indicator (IEC/EN 60825-1 section 4.7).

Provision of one or more permanently attached means of attenuation (eg beam stop,

attenuator or switch). The beam stop, attenuator or switch shall prevent access to laser

radiation in excess of Class 1M (IEC/EN 60825-1 section 4.8)

Note that the visible alignment laser (if fitted) carries a Class 2 laser rating as defined by

IEC/EN 60825-1.

3.4.5 Europe: EMC Directive

This Laser falls outside the scope of the EMC Directive as it is intended exclusively for an

industrial assembly operation for incorporation into other apparatus. However SPI Lasers

recognises that Laser Integrators may require the integrated laser system to comply with the

directive. SPI Lasers has therefore designed for compliance to parts of the standards listed

below which are harmonised to the EMC Directive:

BS EN 50370-1:2005

BS EN 55011:2009+A1:2010.

3.4.6 USA: CFR Title 21 Part 1040, Food And Drug Administration

This Laser falls outside the scope of 21 CFR part 1040 as 21 CFR part 1040 does not apply to

laser products which are sold to a manufacturer for use as components. However SPI Lasers

recognises that Laser Integrators may require the integrated laser system to comply with the

regulation. SPI Lasers has therefore demonstrated compliance to parts of the European

standard:

IEC/EN 60825-1

Under Laser Notice 50, CDRH will not object to conformance with many sections of IEC

60825-1, as amended, as alternatives to comparable sections of 21 CFR §1040.10.

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

17

3.4.7 USA: CFR Title 47, Federal Communications Commission

This Laser is designed for compliance with:

FCC CFR47: §15.109 Radiated emission limits.

3.5 Labelling

Labels are placed on the top and rear panels of the Laser to warn of potential hazards and to

provide other useful information.

Table 1 and Table 2 below show the labels and give their locations.

Table 1 Safety, Explanatory and Compliance Labels

Rating plate label (example) (rear panel)

Different Laser variants have different voltage and current ratings. Refer to the label on

the Laser

Laser label (example) (rear panel)

Cautions label (top panel)

Laser emission, pipes and cautions label (top panel)

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

18

Laser aperture warning

(Optical connector)

Protective conductor terminal indicator

(rear panel adjacent to protective conductor

terminal)

Table 2 Information Labels

Laser identification (example) (rear panel)

Address, Patents, WEEE and CE label (rear panel)

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

19

4 Document References

Document

number

Description

SM-S00482 redPOWER PRISM Module Fiber Laser Command Reference

SM-S00483 redPOWER PRISM Fiber Laser GUI Manual

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

20

5 redPOWER PRISM Tour

The range of redPOWER PRISM Fiber Lasers builds on many years of experience of SPI

Lasers in designing, developing and supplying fiber lasers into a wide range of industrial laser

processing applications. It gives laser integrators the capability to manufacture industrial laser

machines with maximum output power levels from 300W to 1.5kW. They can be operated in

continuous wave (CW) or modulated (CWM) modes for applications enabled by fiber lasers

and applications traditionally serviced by lamp pumped and diode pumped solid-state lasers.

A flexible control architecture has been implemented using a combination of analogue, serial

and logic user interfaces.

The optical power is generated by SPI Lasers’ proprietary1 GTWave® active fiber technology

and reliable pump diodes to produce a high power, high brightness output. The output is

guided to the Laser Integrator’s optics by single mode (SM) or multimode (MM) delivery fibers.

The delivery fiber is usually supplied with a PIPA-Q optical connector, which is compatible with

industry standards, and a ruggedized conduit including SPI Lasers’ Fiber Continuity

Monitoring System (FCMS) to protect it.

To give Laser Integrators a flexible approach to multi-kW fiber lasers, PRISM Fiber Lasers

may be supplied without an optical connector to allow a spliced connection to a High Power

Combiner (HPC) supplied by SPI Lasers.

1 US 6,826,335, US 7,221,822, US 7,660,034, US 8,270,070, US 8,743,454 and granted patents in other territories

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

21

5.1 Key Parts

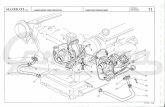

Figure 2 PRISM Fiber Laser with Optical Connector Key Parts

The Laser has many key parts. These are indentified in Figure 2. The names given in Figure 2

are used throughout these Instructions for Use.

PRISM Fiber Lasers are available with different rated output powers. Lasers with rated powers

of 1kW or less are shorter than those with higher rated powers. The dimensions are given in

section 11.5.1. The key parts and key features are the same for all rated powers.

5.2 Key Features

A schematic block diagram of the Laser is shown in Figure 3, which also indicates the main

User interfaces. In Figure 3 the Laser is represented by the red rectangle and the cooling

water circuit is indicated schematically in blue.

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

22

Key features of the Laser are given below.

Figure 3 PRISM Fiber Laser Key Features

Optical Engine

The heart of the Laser is the optical engine based on SPI Lasers’ proprietary

GTWave® active fiber technology. GTWave takes the optical power of the pump diodes

to generate the high beam quality output of the Laser. It requires no optical or

mechanical adjustments.

Pump Diodes

The pump diodes provide the power to the optical engine. Their high reliability means

that they will last for the life of the Laser.

Pump Drivers

The pump drivers control the current to the pump diodes allowing the CW power level

of the Laser to be adjusted and the Laser to be modulated over the specified power

and frequency ranges.

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

23

Beam Delivery

The delivery fiber guides the laser power from the optical engine into the Laser

Integrator’s optics. Options are available for the delivery fiber type and output

connector. Types include single mode and multimode, with different multimode core

diameters available. The delivery fiber is usually supplied with an industry standard

PIPA-Q optical connector. In this case a ruggedized conduit including SPI Lasers’

Fiber Continuity Monitoring System (FCMS) protects the delivery fiber. The optical

connector and ruggedized conduit with FCMS are referred to as the beam delivery

optic (BDO). When supplied without an optical connector mechanical protection is

provided by polymer jacket and Kevlar® reinforcement within a conduit, but there is no

FCMS.

Fiber Continuity Monitoring System (FCMS)

The FCMS is a thin copper wire wound around the delivery fiber. Should the delivery

fiber fail, the escaping laser power fuses the FCMS wire. The Laser Integrator must

monitor the continuity of the FCMS as described in Section 7.6.5 and shut the Laser

down to prevent the beam burning through the conduit and so prevent exposure of

Users to laser radiation.

Back Reflection Monitoring and Protection

In some laser processes the laser power couples poorly into the work piece causing

some of the power to be reflected back into the optical connector and coupled into the

delivery fiber. This back reflection is most likely to occur

o when setting focus at high power

o when processing highly reflective materials such as brass, copper and

aluminium, especially at normal incidence

o when operating away from the focal point of the process head

o during the piercing phase of laser cutting

This back reflected power has the potential to cause damage to the optical connector

and delivery fiber due to overheating. It may also to produce power instabilities due to

interaction with the optical engine.

The Laser is protected against back reflected power with active and passive measures.

Thus there is no need to employ additional optical components (such as optical

isolators), as is common with other fiber lasers, bringing cost and processing

disadvantages. The protection offered by the Laser comes from the design of the

optical connector and optical engine, and the use of sensors to monitor the back-

reflected power. In extreme cases, the Laser shuts itself down before damage occurs.

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

24

The optical connector incorporates the SPI Lasers patented2 technology, which

channels back-reflected laser light away from the delivery fiber via a capillary tube into

a water cooled beam dump, as shown in Figure 4, preventing damage to the delivery

fiber or its mechanical fixings.

Figure 4 PIPA-Q Optical Connector with Protection Against Back-Reflection

Thermal monitoring is also used within the optical connector and optical engine to

protect the Laser against back reflected power. If a temperature threshold is exceeded

a warning is generated. When the temperature falls below the threshold the warning

will clear. If higher temperature threshold is exceeded an alarm is generated and the

laser will shut down. The laser can be restarted when the temperature falls below the

threshold after the alarm has been cleared.

When processing highly reflective materials such as brass, copper and aluminium, or if

in doubt, contact SPI Lasers for applications advice.

Alignment Laser

An alignment laser provides a visible guide for the alignment of process heads. The

alignment laser is a Class 2 laser, meaning that it is safe to view the beam on a diffuse

work piece, although it is not safe to stare into the beam. (As an option, the alignment

laser may not be fitted.)

Low Power Mode

Low power mode allows the Laser to operate stably at lower powers so that, for

example, marking and cutting can be carried out consecutively on the same work

piece. Low power mode is not available in 300W Lasers.

2US6347178, JP3520044, GB1096285, DE60037091

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

25

Control and Monitoring Electronics

The control and monitoring electronics provide basic control and monitoring of the

Laser. Logic and analogue interfaces give Laser Integrators basic set point control and

status monitoring.

o Logic controls include Enable and Modulate, and monitors include Ready and

Emitting as well as alarms and warnings.

o Analogue controls include Power Set, and monitors include Output Power

Monitor and Back Reflected Power Monitor.

The Output Power Monitor may be used to improve power stability during changes in

ambient conditions as it allows Laser Integrators to provide closed loop control.

However the monitor may not accurately represent the output power when the output

is modulated or when processing highly reflective materials. Under such conditions,

SPI Lasers does not recommend using closed loop control.

To facilitate integration of multiple Lasers, all control and monitoring functions are

available using RS-232 and RS-485 serial interfaces. CAN bus is also available using

SPI Lasers’ proprietary protocol.

Mounting

The Laser can be fitted into a standard 19” rack cabinet. The front panel has the

conventional 2U dimensions.

5.3 Auxiliary Equipment

Installation of the Laser within an integrated laser system requires the provision of auxiliary

equipment for power and control as shown in Figure 5. A low noise DC power supply is

required to power the pump diodes. A temperature controlled supply of water is required for

cooling. A low noise 24V DC power supply is required for the monitoring circuits.

Requirements for the auxiliary equipment are given in the sections indicated below.

Pump power supply – Section 11.3.1

Auxiliary power supply – Section 11.3.1

Chiller – Section 11.3.2

It is the responsibility of the Laser Integrator to provide an integrator safety circuit which can

enable the Laser when the process cabinet doors are shut and disable it to make the process

cabinet safe both as required in normal operation and after activation of the emergency stop.

The Laser has no internal safety circuits.

SPI Lasers does not assume responsibility for specific integration decisions affecting the

safety and compliance to international standards of the Laser Integrator’s final laser product or

system.

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

26

Figure 5 PRISM Fiber Laser with Auxiliary Equipment

5.4 Software Tools

SPI Lasers’ Graphical User Interface for PRISM Module Fiber Lasers, PrismView, allows

Users to control the Laser over a serial interface. Operation of the Laser using PrismView is

described in the redPOWER PRISM Fiber Laser GUI Manual SM-S00483.

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

27

5.5 Explanation of Order Codes

The PRISM Fiber Laser variants covered by these Instructions for Use have order codes:

SP -

0300

0500

0750

1000

1500

2000

- M - W -

014

020

050

100

300

-

02

05

06

10

15

20

30

- FBR

PIQ - 0

0

1 0 - 00

0

1 -

0

1 0

0

2

Pow

er

Fib

er

BD

O le

ng

th

Co

nn

ecto

r

Alig

nm

ent la

ser

Win

dow

Be

am

qua

lity

Ba

se le

ng

th

Details of the options shown in bold are expanded in Table 3 below with reference to the

categories indicated above.

Table 3 Explanation of Order Code

Category Option Description Reference

Power Rated output power

0300 300W Rated power

0500 500W Rated power

0750 7500W Rated power

1000 1000W Rated power

1500 1500W Rated power

2000 2000W Rated Power

Fiber Core diameter of delivery fiber

014 14µm Table 27

020 20µm Table 20

050 50µm Table 21

100 100µm Table 22

300 300µm Table 23

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

28

Category Option Description Reference

BDO length

02 2m

05 5m

10 10m

15 15m

20 20m

30 30m

Connector Optical connector type

FBR Bare fiber Section 11.5.3

PIQ PIPA-Q Section 11.5.2

Alignment laser

0 Not fitted

1 Fitted

Window

0 Not fitted Bare fiber

1 Fitted PIPA-Q

Beam quality

0 Standard Table 22

1 Enhanced Table 22

Base length

0 Standard Table 24 and Table 25

2

Medium power Lasers built on

long base plate Table 25

Not all combinations of options are available. Further information can be provided by request

from SPI Lasers

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

29

6 Getting Started

6.1 Receiving and Inspection

Figure 6 Laser in Crate as Received

Before installing or operating the PRISM Fiber Laser, you should:

Inspect the shipping container for damage

Inspect the Laser for signs of damage

Inspect the optical connector and conduit for any signs of damage

Confirm that the shipping carton contains all items on the shipping inventory list

including any accessories ordered as separate line items

Retain all packaging materials until the Laser has been commissioned. If anything is missing

or defective contact SPI Lasers. See Section 13 for contact details.

6.2 Unpacking and Handling

CAUTION: This PRISM Fiber Laser is heavy and so precautions

must be taken when lifting and moving.

Failure to do so may cause serious injury.

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

30

This Laser is heavy. Two people are required to unpack it. To avoid the risk of personal injury

or damage to the Laser when lifting or moving, lift with two people and use a trolley or similar

mechanical assistance when moving over distance.

Figure 7 Removing Fastener

1. Undo all the fasteners which secure the lid (Figure 7).

2. Lift off the lid.

3. Remove the top layer of foam packaging. The Laser will appear as shown in Figure 8.

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

31

Figure 8 Crate without Lid and Top Layer of Foam Packaging

4. Remove the documentation.

5. Free the foam block containing the optical connector.

6. Lift and hold the BDO away from the packaging (Figure 9) while a second person

removes the next layer of foam packaging.

Figure 9 Lift BDO to Enable the Next Layer of Packaging to be Removed

7. Replace the BDO (Figure 10).

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

32

Figure 10 BDO Replaced

8. Remove the foam inserts, if any (Figure 10).

9. Lift the Laser from the crate (Figure 11). Do NOT use the BDO termination block on

front panel as a lifting handle.

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

33

Figure 11 Lifting Laser from Crate

6.3 Unpacking the Beam Delivery Optic

Take care not to twist the conduit when uncoiling the BDO. Always unroll the conduit from the

free end, compensating for any twist that might occur. The conduit is very flexible and easily

bent when uncoiling. Ensure that is never bent to less than the minimum bend radius. Never

pull on the optical connector to untangle the conduit.

Particular care should be taken with regard to possible damage to the optical connector when

uncoiling the bean delivery optic as there is a tendency for the coil to spring apart, which may

cause the optical connector to collide with other objects. Do not drop the optical connector or

allow it to hit surfaces or other objects.

Finally remove the optical connector from the foam block by pushing the connector out of the

block. Use a finger inserted in the top of the block to push against the protective cap on the

optical connector.

Do not pull the block off as the protective cap may be inadvertently removed from the optical

connector exposing the window to contamination.

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

34

7 Installation

7.1 Safety and Compliance During Installation

CAUTION: This PRISM Fiber Laser is heavy and so precautions

must be taken when lifting and moving.

Failure to do so may cause serious injury.

The Laser is heavy. To avoid the risk of personal injury or damage to the Laser when lifting or

moving, lift with two people and use a trolley or similar mechanical assistance when moving

over distance.

Before installation reference must be made to Section 3 regarding laser safety, electrical

safety, EMC and compliance. When installed, the laser and the additional equipment required

to operate it must not obstruct access to safety devices or impair their operation.

It is recommended that installation is done in the sequence of the following sections, with

water connections made and checked before electrical connections are made.

7.2 Location and Environment

This Laser is designed to be used in a 19” rack cabinet or other housing.

This Laser is designed for operation within the environment specified in Table 10. Operating

the Laser beyond the limits of the environmental specification may lead to accelerated

component ageing and performance degradation. As the Laser is water-cooled care must be

taken to ensure that it is always operated above the dew point so that internal condensation is

avoided. Refer to Figure 33 for a chart showing the relationship between relative humidity,

ambient air temperature and cooling water temperature for non-condensing operation.

This Laser must not be installed in a corrosive atmosphere.

This Laser must not be exposed to high levels of optical radiation, for instance laser radiation

from materials processing.

This Laser is sealed against dust and water ingress to IP52 to BS EN 60529:1992+A2:2013

with the exception of the electrical connectors which are rated IP50. The laser integrator must

ensure that when installed the Laser is not likely to be exposed to water, for instance from

coolant leaks.

At least 100mm clear space must be provided around the Laser to allow the BDO to be routed

correctly.

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

35

The optical connector shall be mounted in a protective housing which prevents human access

to laser radiation (including errant radiation) in excess of the AEL for class 1, for example a

housing meeting the requirements of EN 60825-4. The protective housing shall withstand

exposures under reasonably foreseeable single fault conditions without human intervention.

7.3 Mounting

The total weight of the Laser is approximately 38kg for the long version and 26kg for the short

version. The front panel has the conventional 2U dimensions enabling the Laser to be fitted

into a standard 19” rack cabinet with its weight supported on runners. If mounted using the

mechanical mounting points specified in Section 11.5.1, all 8 (short modules) or all12 (long

modules) must be used to support its weight. The recommended torque for the M5 bolts is

3.5Nm. This value should be confirmed by the Laser Integrator. Alternatively, the Laser can be

placed on a clean, stable surface that will support its weight.

Ensure that the conduit carrying the delivery fiber is not kinked or snagged. Follow the

guidance given in Section 0 and allow sufficient space for correct routing of the conduit so that

all bends have radii greater than minimum bend radius. Failure to do so may result in

permanent damage to the delivery fiber.

7.4 PRISM Fiber Lasers with Bare Fiber Output

WARNING: PRISM Fiber Lasers with bare fiber output must be

spliced to an SPI Lasers High Power Combiner.

Failure to do so will result in catastrophic damage to the Laser and

may result in exposure to hazardous laser radiation.

If the Laser is powered up without proper termination of the delivery fiber, the delivery fiber

and Laser may be catastrophically damaged. Laser Integrators must ensure that the delivery

fiber is properly terminated, for example by splicing to an SPI Lasers HPC, prior to turning on

the Laser. Failure to do so may invalidate the warranty.

Further information on terminating the delivery fiber and HPCs can be provided by request

from SPI Lasers.

7.5 Cooling Water Connections

CAUTION: Ensure an approved overpressure safety device is

installed when connecting this Laser to an external chiller or factory

water supply. This should comply with ISO4126-1 (or equivalent)

and be rated to protect the Laser against a flow or differential water

pressure in excess of that specified.

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

36

CAUTION: If coolant is allowed to enter this Laser enclosure, do

not use the Laser and contact SPI Lasers immediately.

Failure to do so may result in electrical shock and damage to the

Laser.

7.5.1 Base plate

The Laser must be operated with a source of chilled water as specified in Section 11.3. The

base plate has two cooling circuits. They are terminated with approximately 30mm of 10mm

diameter copper pipe protruding from four positions on the front panel. The two circuits must

be connected in parallel, with flows in directions as shown in Figure 12. Hoses must be routed,

observing the specified bend radius, so that any leaking cooling water will be kept away from

the Laser, and provision must be made to shut down the Laser and shut off the cooling water

flow when a leak is detected.

De-ionized water is not permitted in the cooling circuit to prevent corrosion.

Cooling water connections must be made and checked for leaks before making electrical

connections and powering up the Laser. To avoid potential water ingress the electrical

connectors should be capped while checking for leaks.

If an external coolant leak occurs and water comes into contact with any of the electrical

connectors, allow the Laser to dry completely before operating. If coolant is allowed to enter

the Laser enclosure, do not use the Laser and contact SPI Lasers immediately.

Figure 12 Cooling Water Connections

7.5.2 PIPA-Q Optical Connector

It is essential that the PIPA-Q optical connector is adequately cooled with a source of clean,

chilled water in accordance with the specifications listed in Section 11.3.2. Operating the

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

37

PIPA-Q optical connector without an adequate flow of cooling water may result in catastrophic

damage.

The inlet and outlet water connections are SMC MS-5HLH-6 type miniature hose elbows

suitable for 6mm LLDPE or polyurethane tubing.

7.5.3 Cooling Water Fittings

The Laser is not supplied with water fittings. SPI Lasers recommends that the widely available

push-on John Guest ‘Speedfit’ water connections are used to connect the cooling circuit to the

chilled water supply. Ensure that the pipes are clean before adding the connections and that

the correct locking clips are used. John Guest part numbers are given in Table 4.

Table 4 Water Tubing and Fittings

Description John Guest Part Number Illustration

10mm Equal Elbow PM0310E

10mm Equal Straight

Connector PM0410E

10mm Locking Clip PM1810R

10mm Plug PM0810R

10mm LLDPE Tubing (for

base plate) PE-1007-100M-*

6mm LLDPE Tubing (for

optical connector) PE-0604-0100M-*

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

38

Description John Guest Part Number Illustration

10mm Equal Elbow PEM0310W

Description SMC Part Number Illustration

10mm polyurethane tubing

(for base plate) TU1065**-**

6mm polyurethane tubing

(for optical connector) TU0604**-**

Description Essentra Item Code Illustration

End Cap FCWA-0095-013

When using ‘Speedfit’ the water connection should be made as follows:

Cut the tube square and remove burrs and sharp edges. Ensure the outside diameter

is free of score marks. Push the tube into the fitting, to the tube stop.

Push the locking clip onto the fitting behind the collet.

Pull on the tube to check it is secure. Test the system before use.

To disconnect the water connection:

Ensure the system is depressurised and drained.

Remove the locking clip.

Push the collet square against the fitting. With the collet held in this position the tube

can be removed.

If this Laser is to be transported to a new location, returned to SPI Lasers or placed in storage

the PSU must be turned off and disconnected first, and then once the chiller has been

disconnected both the Laser and the optical connector must be drained of all coolant and

blown through with compressed air.

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

39

7.6 Electrical Connections

CAUTION: This PRISM Fiber Laser must be grounded for safety

and to comply with regional electrical codes.

Failure to do so may result in electric shock and incorrect operation

of the Laser.

For safe operation of this Laser the electrical connections given in the following sections need

to be made. All electrical connections should use cables of the shortest practical length.

Before making electrical connections and powering up the Laser, the cooling water

connections must be made and checked for leaks with the electrical connectors protected

from water splashes. For safety, the Laser must be connected to an external protective

earthing system before any other electrical connections are made. The Laser is not ‘hot

pluggable’: all electrical connectors must be mated and secured in place before power is

applied.

All figures in this section indicate the pin positions when looking at the connector on the rear

panel of the Laser.

To operate this Laser two power connections and a control connection, which can be serial

(RS-232, RS-485 or CAN bus) or analogue and logic, must be made.

The connectors, mounted on the rear panel of the Laser as shown in Figure 13, are:

Bus bars – DC Pump Diode Supply

This is the DC power input to the pump diodes. Further details of the power supply

requirements are given in Section 11.3.1.

37-way D-type male connector – User Interface

This connector carries the main analogue and logic connections to the laser, and the

CAN bus serial interface.

It is used to enable, control and monitor the laser.

The FCMS circuit in the BDO is made available this connector. It must be monitored by

an external safety rated circuit provided by the Laser Integrator.

9-way D-Type male connector – serial interfaces

RS-232 and RS-485 serial interfaces.

The connector positions on the rear panel are shown in Figure 13, in which the head of the

arrow indicates pin 1. Table 5 give references to the sections in which the pinout and details of

the signals on each connector are given.

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

40

Figure 13 Electrical Connections and Status Indicators

Table 5 Electrical Interface Connections

№ Function Connector Description Reference

Section

1 Protective Conductor (Earth)

Terminal

M5 female thread 7.6.1

2 Pump Diode PSU +V Bus Bar with two eyes for M8 bolts 7.6.2

3 Pump Diode PSU -V Bus Bar with two eyes for M8 bolts 7.6.2

4 User Interface 37-way D-type male connector 7.6.3

5 RS-232 and RS-485 9-way D-Type male connector 7.6.4

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

41

7.6.1 Protective Conductor (Earth) Terminal

Figure 14 Star Earthing Configuration

For safe operation of the Laser, to comply with regional electrical codes, and to reduce the

possibility of interference in the control and monitoring electronics the Laser, 24V DC Auxiliary

PSU, laser integrator digital and analogue control circuits and pump diode PSU must be

correctly grounded.

A star arrangement, as shown in Figure 14, is essential. The star is connected to the negative

terminals of the 24V DC Auxiliary PSU, the pump diode PSU and to the protective conductor

terminal of the Laser. The Laser’s protective conductor terminal is an M5 threaded hole and

requires a fixing torque of 4Nm. The Pump Diode PSU and 24V DC Auxiliary PSU must be

sited as close as possible to the Fiber Laser to minimise the connecting cable lengths. The

connections to the 24V DC Auxiliary PSU and the pump diode PSU should be made as close

to the PSUs as possible.

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

42

The protective conductor shall support the maximum short-circuit current of the pump diode

PSU.

7.6.2 Pump Diode PSU

The principal power source for the Laser is the pump diode PSU. Connection to the Laser is

made using the two bus bars on the back panel of the Laser. The positive bus bar is on the left

and the negative bus bar is on the right when looking at the back panel, and they are identified

+V and –V as shown in Figure 13.

Connection to the bus bars is made as shown in Figure 15 using an M8x16 screw, two flat

washers, a spring washer and a nut for each bus bar. The nut should be tightened to a torque

of 12Nm to 13Nm.

Figure 15 Bus Bar Connection

The remote sense connections of the PSU should also be connected to the bus bars.

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

43

7.6.3 User Interface

Figure 16 User Interface Connector

The connector is a 37-way D-type male connector and has

connections for the auxiliary power supply

connections for the alignment laser power supply (if alignment laser fitted)

logic inputs and outputs

analogue inputs and outputs

FCMS connections

The pinout and functions of the connections are given in Table 6. A fully screened, high quality

cable should be used. SPI Lasers recommends a cable from the L-com series CSMN37.

Most of the logic connections are set up for operation with 24V PLC controllers. Logic lines are

set HIGH by applying a voltage in the range 5.0 to 24.0V and set LOW by applying a voltage

in the range 0.0 to 4.0V. These logic levels are illustrated in Figure 17. Logic outputs have the

voltage level of the auxiliary power supply.

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

44

Figure 17 PLC Logic Levels

An alternative Modulate input is set up for TTL logic levels to allow faster modulation. This

input is set HIGH by applying a voltage in the range 2.0 to 5.0V and set LOW by applying a

voltage in the range 0.0 to 0.8V, as illustrated in Figure 18. The two Modulate inputs are OR’d

internally.

Figure 18 TTL Logic Levels

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

45

Table 6 Pinout of User Interface Connector

Pin

№

Connection

Name Type Function Level/Tolerance

1 Alignment

Laser

Power The alignment laser (if fitted) is

powered from this connection, not

from the auxiliary power supply. It is

turned on by applying 24V and turned

off by removing 24V.

24V ±10%, 50mA

2 Enable Input When Enable is set HIGH the Laser

goes into the Ready state if there are

no alarms.

PLC (Figure 17)

3 Modulate

TTL

Input When Enable is set HIGH, Modulate

switches the laser power between the

powers set by Power Set (Modulate

HIGH) and Simmer Set3 (Modulate

LOW).

TTL (Figure 18)

4 Modulate

PLC

Input When Enable is set HIGH, Modulate

switches the laser power between the

powers set by Power Set (Modulate

HIGH) and Simmer Set3 (Modulate

LOW).

PLC (Figure 17)

5 Low Power

Mode

Enable

Input Set HIGH to enable low power mode PLC (Figure 17)

6 Alarm Reset Input Set HIGH to clear alarms that do not

require a service engineer. Alarms will

only reset if the fault condition is no

longer present.

PLC (Figure 17).

Alarms are reset

on a rising edge.

7 Reserved Input Do not connect -

8 Reserved Input Do not connect -

9 Alarm

Indicator

Output HIGH if an alarm is present. Auxiliary power

supply level.

10 Warning

Indicator

Output HIGH if a warning is present. Auxiliary power

supply level.

3 Simmer Set can only be adjusted through the serial interface.

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

46

Pin

№

Connection

Name Type Function Level/Tolerance

11 Ready Output HIGH indicates that the laser is ready

to emit.

Auxiliary power

supply level.

12 Emitting Output HIGH indicates that the laser is

emitting. Note that if Power Set is

small or zero, power may not be

emitted.

Auxiliary power

supply level.

13 Status 1 Output Status bit. LSB Auxiliary power

supply level.

14 Status 2 Output Status bit Auxiliary power

supply level.

15 Status 3 Output Status bit Auxiliary power

supply level.

16 Status 4 Output Status bit Auxiliary power

supply level.

17 Status 5 Output Status bit. MSB Auxiliary power

supply level.

18 Auxiliary

Power

Supply +ve

Power +24V to power control and monitoring

electronics

24V ±5%, 500mA

19 Auxiliary

Power

Supply +ve

Power +24V to power control and monitoring

electronics

24V ±5%, 500mA

20 Reserved Output Do not connect -

21 Reserved Output Do not connect -

22 Reserved I/O Do not connect -

23 Reserved I/O Do not connect -

24 Ground Ground - -

25 Power Set Input -

Analogue

0-10V differential analogue input to

set the power level.

0-10V with

respect to pin 26.

26 Analogue

Input Ground

Ground - -

27 Reserved Output Do not connect -

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

47

Pin

№

Connection

Name Type Function Level/Tolerance

28 Output

Power

Monitor

Output -

Analogue

A voltage proportional to the output

power of the Laser. Nominally 10V at

rated power.

0-15V

29 Back

Reflected

Power

Monitor

Output -

Analogue

A voltage indicative of the back

reflected power of the Laser.

Nominally 10V at rated power in the

absence of back reflection. Not

present on bare fiber units

0-15V

30 Ground Ground - -

31 FCMS

Monitoring

Pin 1

Analogue Connection to the BDO fiber continuity

monitoring system (FCMS)

-

32 Ground Ground - -

33 FCMS

Monitoring

Pin 2

Analogue Connection to the BDO fiber continuity

monitoring system (FCMS)

-

34 Ground Ground - -

35 FCMS

Monitoring

Pin 3

Analogue Not used -

36 Auxiliary

Power

Supply -ve

Power 0V -

37 Auxiliary

Power

Supply -ve

Power 0V -

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

48

7.6.4 RS-232 and RS-485

Figure 19 RS-232 and RS-485 Connector

Pin 1 of the RS-232 and RS-485 connector is indicated in Figure 19 and the connections are

given in Table 7. When connecting using RS-232 a three wire cable must be used. When

connecting to a standard computer serial port with RS-232, pins 2 and 3 must be crossed over

at the computer end. Note that no connection should be made to pins 6 to 9 when using RS-

232 and no connection should be made to pins 2 and 3 when using RS-485.

For operation of the RS-232 and RS-485 interfaces refer to the redPOWER PRISM Fiber

Laser Serial interface Manual SM-S00482 or redPOWER PRISM Fiber Laser GUI Manual

SM-S00483.

Table 7 RS-232 and RS-485 Control

Pin № Connection Name I/O Description

1 Ground - Ground

2 RS-232 Rx I RS-232 receive

3 RS-232 Tx O RS-232 transmit

4 Not connected - -

5 Ground - Ground

6 RS-485 Rx + I RS-485 receive (differential)

7 RS-485 Rx - I

8 RS-485 Tx - O RS-485 transmit (differential)

9 RS-485 Tx + O

The RS-485 interface may be used in differential mode or, by connecting pin 6 to pin 9 and pin

7 to pin 8 it can be configured as a two-wire bus, but in this case care must be taken to ensure

that the Laser’s responses are allowed to complete before a new command is transmitted

from the controlling device, as the transmit and receive data will use the same connections.

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00481 Revision F 02 August 2017

redPOWER 300W to 2.0kW Module Fiber Lasers

Instructions for Use

49

7.6.5 Connection to Interlock and Emergency Stop System

WARNING: The PRISM Fiber Laser does not control the pump

power supply and has no safety function to de-energise or control

the pump diodes or the output power.

Failure to provide external safety systems may result in exposure to

harmful levels of radiation.

It is the responsibility of the Laser Integrator to provide an integrator safety circuit, constructed

from components approved to the relevant standards, to make certain that electrical power is

removed to ensure laser safety. It is understood that this will be done in a manner certified to

the required national and international laws, rules, statutes and standards. This safety circuit

must only allow the Laser to be enabled when the industrial laser machine into which the

Laser is incorporated is in a state safe for laser emission. It must disable the Laser to make

the industrial laser machine safe both as required in normal operation and after activation of

the emergency stop system.

With appropriate monitoring of the FCMS, a fiber break or cable severance, an unmated

connector or optical connector over temperature condition can be detected and used to shut