RECEIVED : November 01 , 2016signature date€09/25/2016€ email€[email protected]€ api...

Transcript of RECEIVED : November 01 , 2016signature date€09/25/2016€ email€[email protected]€ api...

RECEIVED: November 01, 2016

STATE OF UTAHDEPARTMENT OF NATURAL RESOURCES

DIVISION OF OIL, GAS AND MINING

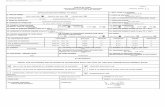

APPLICATION FOR PERMIT TO DRILL 1. WELL NAME and NUMBER

IDRAS 2

2. TYPE OF WORK

DRILL NEW WELL REENTER P&A WELL DEEPEN WELL 3. FIELD OR WILDCAT

WILDCAT

4. TYPE OF WELLTest Well Coalbed Methane Well: NO

5. UNIT or COMMUNITIZATION AGREEMENT NAME

6. NAME OF OPERATORDOSECC EXPLORATION SERVICES, LLC

7. OPERATOR PHONE801 538-2150

8. ADDRESS OF OPERATOR2075 S. Pioneer Rd., Salt Lake City, UT, 84104

9. OPERATOR [email protected]

10. MINERAL LEASE NUMBER(FEDERAL, INDIAN, OR STATE)

private

11. MINERAL OWNERSHIP

FEDERAL INDIAN STATE FEE 12. SURFACE OWNERSHIP

FEDERAL INDIAN STATE FEE

13. NAME OF SURFACE OWNER (if box 12 = 'fee')Salt Lake City Corporation

14. SURFACE OWNER PHONE (if box 12 = 'fee')801-535-6308

15. ADDRESS OF SURFACE OWNER (if box 12 = 'fee')451 South State Street, Suite 505A, ,

16. SURFACE OWNER E-MAIL (if box 12 = 'fee')[email protected]

17. INDIAN ALLOTTEE OR TRIBE NAME(if box 12 = 'INDIAN')

18. INTEND TO COMMINGLE PRODUCTION FROMMULTIPLE FORMATIONS

YES (Submit Commingling Application) NO

19. SLANT

VERTICAL DIRECTIONAL HORIZONTAL

20. LOCATION OF WELL FOOTAGES QTR-QTR SECTION TOWNSHIP RANGE MERIDIAN

LOCATION AT SURFACE 2350 FSL 800 FEL SWNE 35 1.0 N 2.0 W S

Top of Uppermost Producing Zone 2350 FSL 800 FEL SWNE 35 1.0 N 2.0 W S

At Total Depth 2350 FSL 800 FEL SWNE 35 1.0 N 2.0 W S

21. COUNTYSALT LAKE

22. DISTANCE TO NEAREST LEASE LINE (Feet)0

23. NUMBER OF ACRES IN DRILLING UNIT0

25. DISTANCE TO NEAREST WELL IN SAME POOL(Applied For Drilling or Completed)

0

26. PROPOSED DEPTHMD: 590 TVD: 590

27. ELEVATION - GROUND LEVEL

4223

28. BOND NUMBER

4741a

29. SOURCE OF DRILLING WATER /WATER RIGHTS APPROVAL NUMBER IF APPLICABLE

municipal

Hole, Casing, and Cement Information

String Hole Size Casing Size Length Weight Grade & Thread Max Mud Wt. Cement Sacks Yield Weight

Cond 8 6.625 0 - 60 75.0 J-55 Buttress 0.0 Class A 5 0.27 15.4

L1 5.5 2.375 0 - 590 0.0 J-55 Casing/Tubing 0.0 No Used 0 0.0 0.0

ATTACHMENTS

VERIFY THE FOLLOWING ARE ATTACHED IN ACCORDANCE WITH THE UTAH OIL AND GAS CONSERVATION GENERAL RULES

WELL PLAT OR MAP PREPARED BY LICENSED SURVEYOR OR ENGINEER COMPLETE DRILLING PLAN

AFFIDAVIT OF STATUS OF SURFACE OWNER AGREEMENT (IF FEE SURFACE) FORM 5. IF OPERATOR IS OTHER THAN THE LEASE OWNER

DIRECTIONAL SURVEY PLAN (IF DIRECTIONALLY OR HORIZONTALLY DRILLED) TOPOGRAPHICAL MAP

NAME Dennis L. Nielson TITLE President PHONE 801 538-2150

SIGNATURE DATE 09/25/2016 EMAIL [email protected]

API NUMBER ASSIGNED

43035000040000

Permit Manager

APPROVAL

FORM 3

AMENDED REPORT

API Well Number: 43035000040000API Well Number: 43035000040000

FORM 3STATE OF UTAH

DEPARTMENTOF NATURALRESOURCES AMENDEDREPORTDIVISION OF OIL, GAS AND MINING

APPLICATION FOR PERMIT TO DRILL 1. WELL NAME and NUMBRAS2

2. TYPE OF WORK 3. FIELD OR WILDCATDRILLNEWWELL REENTERP&AWELL DEEPENWELLI WLDCAT

4. TYPE OF WELL 5. UNIT or COMMUNITIZATION AGREEMENT NAMETest Well Coalbed Methane Well: NO

6. NAME OF OPERATOR 7. OPERATOR PHONEDOSECC EXPLORATIONSERVICES, LLC 801 538-2150

8. ADDRESS OF OPERATOR 9. OPERATOR E-MAIL2075 S. Pioneer Rd., Salt Lake City, UT, 84104 [email protected]

10. MINERAL LEASE NUMBER 11. MINERAL OWNERSHIP 12. SURFACE OWNERSHIP(FEDERAL,INDIAN,ORSTA)vate FEDERAL INDIANISTATE FEE FEDERAL INDIAN STATE FEEI

13. NAME OF SURFACE OWNER (if box 12 = 'fee') 14. SURFACE OWNER PHONE (if box 12 = 'fee')Salt Lake City Corporation 801-535-6308

15. ADDRESS OF SURFACE OWNER (if box 12 = 'fee') 16. SURFACE OWNER E-MAIL (if box 12 = 'fee')451 South State Street, Suite 505A, , [email protected]

17. INDIAN ALLOTTEE OR TRIBE NAME 18. INTEND TO COMMINGLE PRODUCTION FROM 19. SLANT

(if box 12 = 'INDIAN')MULTIPLE FORMATIONS

YES (Submit Commingling Application) NO VERTICAL DIRECTIONAL HORIZONTAL

20. LOCATION OF WELL FOOTAGES QTR-QTR SECTION TOWNSHIP RANGE MERIDIAN

LOCATION AT SURFACE 2350 FSL 800 FEL SWNE 35 1.0 N 2.0 W S

Top of Uppermost Producing Zone 2350 FSL 800 FEL SWNE 35 1.0 N 2.0 W S

At Total Depth 2350 FSL 800 FEL SWNE 35 1.0 N 2.0 W S

21. COUNTY 22. DISTANCE TO NEAREST LEASE LINE (Feet) 23. NUMBER OF ACRES IN DRILLING UNITSALT LAKE 0 0

25. DISTANCE TO NEAREST WELL IN SAME POOL 26. PROPOSED DEPTH(Applied For Drilling or Completed) MD: 590 TVD: 590

0

27. ELEVATION - GROUND LEVEL 28. BOND NUMBER 29. SOURCE OF DRILLING WATERIWATER RIGHTS APPROVAL NUMBER IF APPLICABLE

4223 4741a municipal

Hole, Casing, and Cement Information

String Hole Size Casing Size Length Weight Grade & Thread Max Mud Wt. Cement Sacks Yield Weight

Cond 8 6.625 0 - 60 75.0 J-55 Buttress 0.0 ClassA 5 0.27 15.4

L1 5.5 2.375 0 - 590 0.0 J-55 Casing/Tubing 0.0 No Used 0 0.0 0.0

ATTACHMENTS

VERIFY THE FOLLOWING ARE ATTACHED IN ACCORDANCE WITH THE UTAH OIL AND GAS CONSERVATION GENERAL RULES

WELL PLATOR MAP PREPARED BY LICENSED SURVEYOR OR ENGINEER COMPLETE DRILLING PLAN

AFFIDAVIT OF STATUS OF SURFACE OWNER AGREEMENT(IF FEE SURFACE) FORM 5. IF OPERATOR IS OTHER THAN THE LEASE OWNER

DIRECTIONAL SURVEY PLAN (IF DIRECTIONALLYOR HORIZONTALLY DRILLED) TOPOGRAPHICAL MAP

NAME Dennis L. Nielson TITLE President PHONE 801 538-2150

SIGNATURE DATE 09/25/2016 EMAIL [email protected]

API NUMBER ASSIGNED APPROVAL43035000040000

Permit Manager

RECEIVED: November 01,

API Well Number: 43035000040000

FORM 3STATE OF UTAH

DEPARTMENTOF NATURALRESOURCES AMENDEDREPORTDIVISION OF OIL, GAS AND MINING

APPLICATION FOR PERMIT TO DRILL 1. WELL NAME and NUMBRAS2

2. TYPE OF WORK 3. FIELD OR WILDCATDRILLNEWWELL REENTERP&AWELL DEEPENWELLI WLDCAT

4. TYPE OF WELL 5. UNIT or COMMUNITIZATION AGREEMENT NAMETest Well Coalbed Methane Well: NO

6. NAME OF OPERATOR 7. OPERATOR PHONEDOSECC EXPLORATIONSERVICES, LLC 801 538-2150

8. ADDRESS OF OPERATOR 9. OPERATOR E-MAIL2075 S. Pioneer Rd., Salt Lake City, UT, 84104 [email protected]

10. MINERAL LEASE NUMBER 11. MINERAL OWNERSHIP 12. SURFACE OWNERSHIP(FEDERAL,INDIAN,ORSTA)vate FEDERAL INDIANISTATE FEE FEDERAL INDIAN STATE FEEI

13. NAME OF SURFACE OWNER (if box 12 = 'fee') 14. SURFACE OWNER PHONE (if box 12 = 'fee')Salt Lake City Corporation 801-535-6308

15. ADDRESS OF SURFACE OWNER (if box 12 = 'fee') 16. SURFACE OWNER E-MAIL (if box 12 = 'fee')451 South State Street, Suite 505A, , [email protected]

17. INDIAN ALLOTTEE OR TRIBE NAME 18. INTEND TO COMMINGLE PRODUCTION FROM 19. SLANT

(if box 12 = 'INDIAN')MULTIPLE FORMATIONS

YES (Submit Commingling Application) NO VERTICAL DIRECTIONAL HORIZONTAL

20. LOCATION OF WELL FOOTAGES QTR-QTR SECTION TOWNSHIP RANGE MERIDIAN

LOCATION AT SURFACE 2350 FSL 800 FEL SWNE 35 1.0 N 2.0 W S

Top of Uppermost Producing Zone 2350 FSL 800 FEL SWNE 35 1.0 N 2.0 W S

At Total Depth 2350 FSL 800 FEL SWNE 35 1.0 N 2.0 W S

21. COUNTY 22. DISTANCE TO NEAREST LEASE LINE (Feet) 23. NUMBER OF ACRES IN DRILLING UNITSALT LAKE 0 0

25. DISTANCE TO NEAREST WELL IN SAME POOL 26. PROPOSED DEPTH(Applied For Drilling or Completed) MD: 590 TVD: 590

0

27. ELEVATION - GROUND LEVEL 28. BOND NUMBER 29. SOURCE OF DRILLING WATERIWATER RIGHTS APPROVAL NUMBER IF APPLICABLE

4223 4741a municipal

Hole, Casing, and Cement Information

String Hole Size Casing Size Length Weight Grade & Thread Max Mud Wt. Cement Sacks Yield Weight

Cond 8 6.625 0 - 60 75.0 J-55 Buttress 0.0 ClassA 5 0.27 15.4

L1 5.5 2.375 0 - 590 0.0 J-55 Casing/Tubing 0.0 No Used 0 0.0 0.0

ATTACHMENTS

VERIFY THE FOLLOWING ARE ATTACHED IN ACCORDANCE WITH THE UTAH OIL AND GAS CONSERVATION GENERAL RULES

WELL PLATOR MAP PREPARED BY LICENSED SURVEYOR OR ENGINEER COMPLETE DRILLING PLAN

AFFIDAVIT OF STATUS OF SURFACE OWNER AGREEMENT(IF FEE SURFACE) FORM 5. IF OPERATOR IS OTHER THAN THE LEASE OWNER

DIRECTIONAL SURVEY PLAN (IF DIRECTIONALLYOR HORIZONTALLY DRILLED) TOPOGRAPHICAL MAP

NAME Dennis L. Nielson TITLE President PHONE 801 538-2150

SIGNATURE DATE 09/25/2016 EMAIL [email protected]

API NUMBER ASSIGNED APPROVAL43035000040000

Permit Manager

RECEIVED: November 01,

RECEIVED: September 16, 2016

DRILLING PLAN – IDRAS 2 HOLE 09/05/2016

Page 1 of 10

DOSECC Exploration Services, LLC Drilling Plan

IDRAS 2 Test Hole Salt Lake County, Utah

DOSECC Exploration Services, LLC 2075 South Pioneer Road, Suite B

Salt Lake City, UT 84104

Presented to:

Utah Division of Oil, Gas, and Mining 1594 N Temple, #1210

Salt Lake City, UT 84116

September 16, 2016

API Well Number: 43035000040000API Well Number: 43035000040000

DRILLING PLAN - IDRAS 2 HOLE 09/05/201€OSECCxploraiion

Services

DOSECC Exploration Services, LLCDrilling Plan

IDRAS 2 Test HoleSalt Lake County, Utah

DOSECC Exploration Services, LLC2075 South Pioneer Road, Suite B

Salt Lake City, UT 84104

Presented to:

Utah Division of Oil, Gas, and Mining1594 N Temple, #1210

Salt Lake City, UT 84116

September 16, 2016

RECEIVED: September 16,

API Well Number: 43035000040000

DRILLING PLAN - IDRAS 2 HOLE 09/05/201€OSECCxploraiion

Services

DOSECC Exploration Services, LLCDrilling Plan

IDRAS 2 Test HoleSalt Lake County, Utah

DOSECC Exploration Services, LLC2075 South Pioneer Road, Suite B

Salt Lake City, UT 84104

Presented to:

Utah Division of Oil, Gas, and Mining1594 N Temple, #1210

Salt Lake City, UT 84116

September 16, 2016

RECEIVED: September 16,

RECEIVED: September 16, 2016

DRILLING PLAN – IDRAS 2 HOLE 09/05/2016

Page 2 of 10

Table of Contents General Information ..................................................................................................................................... 3

Well Objectives ......................................................................................................................................... 3

General Procedure .................................................................................................................................... 4

Hole Survey Procedures ............................................................................................................................ 4

Development Tooling Test Plan ................................................................................................................ 5

Estimated Geologic Markers and Zones ....................................................................................................... 6

Water Rights Approval .................................................................................................................................. 6

Pressure Control Equipment ......................................................................................................................... 7

BOPE configuration ................................................................................................................................... 7

Choke Manifold Equipment ...................................................................................................................... 7

Accumulator .............................................................................................................................................. 7

Well Control Drills ..................................................................................................................................... 7

Monitoring Equipment .............................................................................................................................. 7

Miscellaneous Information ....................................................................................................................... 7

Casing Program ............................................................................................................................................. 7

Cementing Program .................................................................................................................................. 7

Surface Casing ........................................................................................................................................... 8

Intermediate Casing .................................................................................................................................. 8

Mud Program ................................................................................................................................................ 8

Evaluation Program ....................................................................................................................................... 9

Abnormal Conditions .................................................................................................................................... 9

Wellbore Diagram ......................................................................................................................................... 9

Bond .............................................................................................................................................................. 9

Affidavit of Surface Agreement .................................................................................................................... 9

Exception Location Application ..................................................................................................................... 9

Anticipated Starting Dates and Notification of Operations .......................................................................... 9

API Well Number: 43035000040000API Well Number: 43035000040000

DRILLING PLAN - IDRAS 2 HOLE 09/05/201€OSECCxploraiion

Services

Table of ContentsGeneral Information ......................... ..........................3

Well Objectives .......................... .......................... 3

Gener a I Procedure .......................... .......................... 4

Hole Survey Procedures.......................... ..........................4

Development Tooling Test Plan.......................... ..........................5

Estimated Geologic Markers and Zones......................... ..........................6

Water Rights Approval.......................... .......................... 6

Pres sure Co ntrolEqu ipme nt .......................... .......................... 7

BOPE configuration.......................... ..........................7

Choke Ma nifold Equipment .......................... .......................... 7

Accumulator.......................... ..........................7

We Il Co ntrolDr iIls .......................... .......................... 7

Monitoring Equipment.......................... ..........................7

Miscellaneous Information.......................... ..........................7

Casing Program.......................... ..........................7

Cementing Program.......................... ..........................7

Surface Casing.......................... ..........................8

Intermediate Casing.......................... ..........................8

Mud Program.......................... ..........................8

Evaluation Program.......................... ..........................9

Abnorm a I Co nd itions .......................... .......................... 9

We Ilbo re Diagra m .......................... .......................... 9

Bond .......................... .......................... 9

Affidavit of Surface Agreement ......................... ..........................9

Exception Location Application.......................... ..........................9

Anticipated Starting Dates and Notification of Operations.......................... ..........................9

RECEI ED: September 16,

API Well Number: 43035000040000

DRILLING PLAN - IDRAS 2 HOLE 09/05/201€OSECCxploraiion

Services

Table of ContentsGeneral Information ......................... ..........................3

Well Objectives .......................... .......................... 3

Gener a I Procedure .......................... .......................... 4

Hole Survey Procedures.......................... ..........................4

Development Tooling Test Plan.......................... ..........................5

Estimated Geologic Markers and Zones......................... ..........................6

Water Rights Approval.......................... .......................... 6

Pres sure Co ntrolEqu ipme nt .......................... .......................... 7

BOPE configuration.......................... ..........................7

Choke Ma nifold Equipment .......................... .......................... 7

Accumulator.......................... ..........................7

We Il Co ntrolDr iIls .......................... .......................... 7

Monitoring Equipment.......................... ..........................7

Miscellaneous Information.......................... ..........................7

Casing Program.......................... ..........................7

Cementing Program.......................... ..........................7

Surface Casing.......................... ..........................8

Intermediate Casing.......................... ..........................8

Mud Program.......................... ..........................8

Evaluation Program.......................... ..........................9

Abnorm a I Co nd itions .......................... .......................... 9

We Ilbo re Diagra m .......................... .......................... 9

Bond .......................... .......................... 9

Affidavit of Surface Agreement ......................... ..........................9

Exception Location Application.......................... ..........................9

Anticipated Starting Dates and Notification of Operations.......................... ..........................9

RECEI ED: September 16,

RECEIVED: September 16, 2016

DRILLING PLAN – IDRAS 2 HOLE 09/05/2016

Page 3 of 10

General Information

Surface Owner Information Salt Lake City Corporation

City and County Building

P.O. Box 145478

451 South State Street, Suite 505A

Salt Lake City, Utah 84114-5478

Attn: Daniel Rip 801-535-6308

Location Plat See Exhibit A. The drill site is located on a legal parcel at 5812 Amelia Erhart Drive, Salt Lake City, Utah

Drilling Pad Layout No new road or pad construction is anticipated. Please see Exhibit B for site details.

Well Objectives IDRAS 2 is intended to function as a test hole to operate and evaluate the performance of tooling developed for application in conjunction with the IDRAS project. IDRAS is an acronym that stands for International Drilling to Recover Aquifer Sands. The International Continental Scientific Drilling Program (ICDP) defines the purpose of the IDRAS project as follows:

“IDRAS seeks to identify the limited set of parameters that need to be considered in order to make meaningful predictions about the vulnerability of a low-As aquifer. Elevated groundwater arsenic (As) concentrations impact the health of over 100 million villagers across Pakistan, Nepal, India, Bangladesh, Myanmar, Cambodia, Vietnam, and China who rely on tube wells as their main source of drinking water.”

As a first step, two new tool configurations were tested in March 2016 to recover uncompromised core samples (freeze-shoe sampler). The first configuration tested was the Hydraulic Piston Core Freeze Shoe sampler (HPC FS), which will be able to sample at depths of up to 100 m (328 ft.). The other configuration tested was the Alien Freeze Shoe sampler (ALN FS) which can sample at depths from the surface to about 300 meters. With the IDRAS 1 test hole, DOSECC collected core samples at three depths with the HPC FS, and three depths with the ALN FS.

For the IDRAS 2 test hole, DOSECC plans to test a newly developed third tool configuration, the HPC 1.5 M FS. The IDRAS 2 field testing will test the new HPC 1.5 M FS and the ALN FS samplers between the surface and 180 meters. DOSECC will collect core samples for the entire depth of the bore hole from the surface to the total depth drilled using a combination of the newly developed tools, and a set of standard coring tools. A liner will be grouted in place in the hole to enable short term temperature data collection. The test well will be plugged and abandoned after a period of approximately 9 months.

API Well Number: 43035000040000API Well Number: 43035000040000

DRILLING PLAN - IDRAS 2 HOLE 09/05/201€OSECCxplorgion

Services

General InformationSurface Owner Information

Salt Lake City Corporation

City and County Building

P.O. Box 145478

451 South State Street, Suite 505A

Salt Lake City, Utah 84114-5478

Attn: Daniel Rip 801-535-6308

Location PlatSee Exhibit A. The drill site is located on a legal parcel at 5812 Amelia Erhart Drive, Salt Lake City, Utah

Drilling Pad LayoutNo new road or pad construction is anticipated. Please see Exhibit B for site details.

Well ObjectivesIDRAS 2 is intended to function as a test hole to operate and evaluate the performance of toolingdeveloped for application in conjunction with the IDRAS project. IDRAS is an acronym that stands forInternational Drilling to Recover Aquifer Sands. The International Continental Scientific DrillingProgram (ICDP) defines the purpose of the IDRAS project as follows:

"IDRAS seeks to identify the limited set of parameters that need to be considered in order to makemeaningful predictions about the vulnerability of a low-As aquifer. Elevated groundwater arsenic (As)concentrations impact the health of over 100 million villagers across Pakistan, Nepal, India, Bangladesh,Myanmar, Cambodia, Vietnam, and China who rely on tube wells as their main source of drinking water."

As a first step, two new tool configurations were tested in March 2016 to recoveruncompromised coresamples (freeze-shoe sampler). The first configuration tested was the Hydraulic Piston Core Freeze Shoesampler (HPC FS), which will be able to sample at depths of up to 100 m (328 ft.). The otherconfiguration tested was the Alien Freeze Shoe sampler (ALN FS) which can sample at depths from thesurface to about 300 meters. With the IDRAS 1 test hole, DOSECC collected core samples at three depthswith the HPC FS, and three depths with the ALN FS.

For the IDRAS 2 test hole, DOSECC plans to test a newly developed third tool configuration, the HPC1.5 M FS. The IDRAS 2 field testing will test the new HPC 1.5 M FS and the ALN FS samplers betweenthe surface and 180 meters. DOSECC will collect core samples for the entire depth of the bore hole fromthe surface to the total depth drilled using a combination of the newly developed tools, and a set ofstandard coring tools. A liner will be grouted in place in the hole to enable short term temperature datacollection. The test well will be plugged and abandoned after a period of approximately 9 months.

RECEIVED: September 16,

API Well Number: 43035000040000

DRILLING PLAN - IDRAS 2 HOLE 09/05/201€OSECCxplorgion

Services

General InformationSurface Owner Information

Salt Lake City Corporation

City and County Building

P.O. Box 145478

451 South State Street, Suite 505A

Salt Lake City, Utah 84114-5478

Attn: Daniel Rip 801-535-6308

Location PlatSee Exhibit A. The drill site is located on a legal parcel at 5812 Amelia Erhart Drive, Salt Lake City, Utah

Drilling Pad LayoutNo new road or pad construction is anticipated. Please see Exhibit B for site details.

Well ObjectivesIDRAS 2 is intended to function as a test hole to operate and evaluate the performance of toolingdeveloped for application in conjunction with the IDRAS project. IDRAS is an acronym that stands forInternational Drilling to Recover Aquifer Sands. The International Continental Scientific DrillingProgram (ICDP) defines the purpose of the IDRAS project as follows:

"IDRAS seeks to identify the limited set of parameters that need to be considered in order to makemeaningful predictions about the vulnerability of a low-As aquifer. Elevated groundwater arsenic (As)concentrations impact the health of over 100 million villagers across Pakistan, Nepal, India, Bangladesh,Myanmar, Cambodia, Vietnam, and China who rely on tube wells as their main source of drinking water."

As a first step, two new tool configurations were tested in March 2016 to recoveruncompromised coresamples (freeze-shoe sampler). The first configuration tested was the Hydraulic Piston Core Freeze Shoesampler (HPC FS), which will be able to sample at depths of up to 100 m (328 ft.). The otherconfiguration tested was the Alien Freeze Shoe sampler (ALN FS) which can sample at depths from thesurface to about 300 meters. With the IDRAS 1 test hole, DOSECC collected core samples at three depthswith the HPC FS, and three depths with the ALN FS.

For the IDRAS 2 test hole, DOSECC plans to test a newly developed third tool configuration, the HPC1.5 M FS. The IDRAS 2 field testing will test the new HPC 1.5 M FS and the ALN FS samplers betweenthe surface and 180 meters. DOSECC will collect core samples for the entire depth of the bore hole fromthe surface to the total depth drilled using a combination of the newly developed tools, and a set ofstandard coring tools. A liner will be grouted in place in the hole to enable short term temperature datacollection. The test well will be plugged and abandoned after a period of approximately 9 months.

RECEIVED: September 16,

RECEIVED: September 16, 2016

DRILLING PLAN – IDRAS 2 HOLE 09/05/2016

Page 4 of 10

General Procedure The drilling system will be a standard diamond core drilling system with wireline core sampling capability. DOSECC will drill near the center of the city lot, to enable all drilling equipment to be located within the drilling site land plat boundaries.

To provide a core sample for the Utah Geological Survey (UGS), DOSECC will drill an initial 5.5” diameter pilot hole with a face centered Non-Coring Assembly (NCA) bit. This hole will be approximately two to three feet below the ground surface, to attain enough depth to clear any existing site-fill material. DOSECC will collect core samples of undisturbed material with a standard ALN coring tool to a depth of 20 feet below the surface. The maximum length of the ALN coring cycle will be approximately 10 feet. DOSECC will deploy an HPC standard coring tool to collect core from 20 feet to 30 feet for UGS.

After collecting the initial core samples for the UGS in the 0 to 30 foot depth range, DOSECC will begin drilling the test hole. The test hole will be rotary drilled at an 8 inch diameter, to a depth of 20 feet below the surface. After reaching a depth of 20 feet, a 6-5/8” steel casing will be placed in the hole, and the base of the casing may be cemented. The annular space between the steel casing and the wall of the drilled hole will be filled with Bentonite granules. After setting the casing in the initial 20 feet of the hole, the drilling will proceed with a 5.5” face centered drill bit or coring bit, depending on the coring system used on the drill wireline, and the final depth that can be reached for the test hole. The planned maximum depth for the test hole is 180 meters (590 ft.) +/- 3 m (10 ft.).

Drilling with the face centered 5.5” diameter bit will halt whenever a sample is to be collected with the HPC 1.5 M FS core sampling system. The HPC 1.5 M FS system will be exchanged for the face centered bit by wireline. The HPC 1.5 M FS system will collect a core sample following a hybrid process that combines a thoroughly established process for deployment, actuation, and retrieval of the HPC 1.5 M FS tooling, with a new method for core capture. The HPC 1.5 M FS will freeze the fluids entrained in the base of the core sample, and leave the fluids in the portion of the core above the base of the core sample undisturbed. This will preserve the fluids in the core in-situ with the solids.

When the hole reaches a depth at which the HPC 1.5 M FS is determined to be ineffective due to the type of sediments encountered, the team will test the ALN FS. The ALN FS has a different type of coring functionality than the HPC 1.5 M FS. The ALN FS collects a core sample while the driller is drilling to advance the hole depth. The ALN FS will also collect a core sample following a hybrid process that combines a thoroughly established process for deployment, and retrieval of the ALN FS tooling, with a new method for core capture. The ALN FS will freeze the fluids in the base of the core sample.

Hole Survey Procedures The IDRAS 2 test hole will collect cuttings every 1.5 m (5 feet). The drill cuttings will help the tool development team determine the time at which the sediment type of the test hole may be conducive to the successful deployment of the new tooling to collect a core sample. The primary zones of interest for the HPC 1.5 M FS are zones of saturated sands. The well log for the nearby water well 59-2378 will also be used as a guide for determining zones containing sand.

After the completion of the hole to the planned maximum depth of 180 meters (590 ft.), or the depth allowed by drilling conditions if the planned maximum depth cannot be attained, a second team is expected to support the drilling crew and tooling test team with collecting additional information on the drilled hole. The logging tools will be provided by the UGS, or a third party logging company. The

API Well Number: 43035000040000API Well Number: 43035000040000

DRILLING PLAN - IDRAS 2 HOLE 09/05/201€OTECCaplomiinn

Services

General ProcedureThe drilling system will be a standard diamond core drilling system with wireline core samplingcapability. DOSECC will drill near the center of the city lot, to enable all drilling equipment to be locatedwithin the drilling site land plat boundaries.

To provide a core sample for the Utah Geological Survey (UGS), DOSECC will drill an initial 5.5"diameter pilot hole with a face centered Non-Coring Assembly (NCA) bit. This hole will beapproximately two to three feet below the ground surface, to attain enough depth to clear any existingsite-fill material. DOSECC will collect core samples of undisturbed material with a standard ALN coringtool to a depth of 20 feet below the surface. The maximum length of the ALN coring cycle will beapproximately 10 feet. DOSECC will deploy an HPC standard coring tool to collect core from 20 feet to30 feet for UGS.

After collecting the initial core samples for the UGS in the 0 to 30 foot depth range, DOSECC will begindrilling the test hole. The test hole will be rotary drilled at an 8 inch diameter, to a depth of 20 feet belowthe surface. After reaching a depth of 20 feet, a 6-5/8" steel casing will be placed in the hole, and the baseof the casing may be cemented. The annular space between the steel casing and the wall of the drilledhole will be filled with Bentonite granules. After setting the casing in the initial 20 feet of the hole, thedrilling will proceed with a 5.5" face centered drill bit or coring bit, depending on the coring system usedon the drill wireline, and the final depth that can be reached for the test hole. The planned maximumdepth for the test hole is 180 meters (590 ft.) +/- 3 m (10 ft.).

Drilling with the face centered 5.5" diameter bit will halt whenever a sample is to be collected with theHPC 1.5 M FS core sampling system. The HPC 1.5 M FS system will be exchanged for the face centeredbit by wireline. The HPC 1.5 M FS system will collect a core sample following a hybrid process thatcombines a thoroughly established process for deployment, actuation, and retrieval of the HPC 1.5 M FStooling, with a new method for core capture. The HPC 1.5 M FS will freeze the fluids entrained in thebase of the core sample, and leave the fluids in the portion of the core above the base of the core sampleundisturbed. This will preserve the fluids in the core in-situ with the solids.

When the hole reaches a depth at which the HPC 1.5 M FS is determined to be ineffective due to the typeof sediments encountered, the team will test the ALN FS. The ALN FS has a different type of coringfunctionality than the HPC 1.5 M FS. The ALN FS collects a core sample while the driller is drilling toadvance the hole depth. The ALN FS will also collect a core sample following a hybrid process thatcombines a thoroughly established process for deployment, and retrieval of the ALN FS tooling, with anew method for core capture. The ALN FS will freeze the fluids in the base of the core sample.

Hole Survey ProceduresThe IDRAS 2 test hole will collect cuttings every 1.5 m (5 feet). The drill cuttings will help the tooldevelopment team determine the time at which the sediment type of the test hole may be conducive to thesuccessful deployment of the new tooling to collect a core sample. The primary zones of interest for theHPC 1.5 M FS are zones of saturated sands. The well log for the nearby water well 59-2378 will also beused as a guide for determining zones containing sand.

After the completion of the hole to the planned maximum depth of 180 meters (590 ft.), or the depthallowed by drilling conditions if the planned maximum depth cannot be attained, a second team isexpected to support the drilling crew and tooling test team with collecting additional information on thedrilled hole. The logging tools will be provided by the UGS, or a third party logging company. The

RECEIVED: September 16,

API Well Number: 43035000040000

DRILLING PLAN - IDRAS 2 HOLE 09/05/201€OTECCaplomiinn

Services

General ProcedureThe drilling system will be a standard diamond core drilling system with wireline core samplingcapability. DOSECC will drill near the center of the city lot, to enable all drilling equipment to be locatedwithin the drilling site land plat boundaries.

To provide a core sample for the Utah Geological Survey (UGS), DOSECC will drill an initial 5.5"diameter pilot hole with a face centered Non-Coring Assembly (NCA) bit. This hole will beapproximately two to three feet below the ground surface, to attain enough depth to clear any existingsite-fill material. DOSECC will collect core samples of undisturbed material with a standard ALN coringtool to a depth of 20 feet below the surface. The maximum length of the ALN coring cycle will beapproximately 10 feet. DOSECC will deploy an HPC standard coring tool to collect core from 20 feet to30 feet for UGS.

After collecting the initial core samples for the UGS in the 0 to 30 foot depth range, DOSECC will begindrilling the test hole. The test hole will be rotary drilled at an 8 inch diameter, to a depth of 20 feet belowthe surface. After reaching a depth of 20 feet, a 6-5/8" steel casing will be placed in the hole, and the baseof the casing may be cemented. The annular space between the steel casing and the wall of the drilledhole will be filled with Bentonite granules. After setting the casing in the initial 20 feet of the hole, thedrilling will proceed with a 5.5" face centered drill bit or coring bit, depending on the coring system usedon the drill wireline, and the final depth that can be reached for the test hole. The planned maximumdepth for the test hole is 180 meters (590 ft.) +/- 3 m (10 ft.).

Drilling with the face centered 5.5" diameter bit will halt whenever a sample is to be collected with theHPC 1.5 M FS core sampling system. The HPC 1.5 M FS system will be exchanged for the face centeredbit by wireline. The HPC 1.5 M FS system will collect a core sample following a hybrid process thatcombines a thoroughly established process for deployment, actuation, and retrieval of the HPC 1.5 M FStooling, with a new method for core capture. The HPC 1.5 M FS will freeze the fluids entrained in thebase of the core sample, and leave the fluids in the portion of the core above the base of the core sampleundisturbed. This will preserve the fluids in the core in-situ with the solids.

When the hole reaches a depth at which the HPC 1.5 M FS is determined to be ineffective due to the typeof sediments encountered, the team will test the ALN FS. The ALN FS has a different type of coringfunctionality than the HPC 1.5 M FS. The ALN FS collects a core sample while the driller is drilling toadvance the hole depth. The ALN FS will also collect a core sample following a hybrid process thatcombines a thoroughly established process for deployment, and retrieval of the ALN FS tooling, with anew method for core capture. The ALN FS will freeze the fluids in the base of the core sample.

Hole Survey ProceduresThe IDRAS 2 test hole will collect cuttings every 1.5 m (5 feet). The drill cuttings will help the tooldevelopment team determine the time at which the sediment type of the test hole may be conducive to thesuccessful deployment of the new tooling to collect a core sample. The primary zones of interest for theHPC 1.5 M FS are zones of saturated sands. The well log for the nearby water well 59-2378 will also beused as a guide for determining zones containing sand.

After the completion of the hole to the planned maximum depth of 180 meters (590 ft.), or the depthallowed by drilling conditions if the planned maximum depth cannot be attained, a second team isexpected to support the drilling crew and tooling test team with collecting additional information on thedrilled hole. The logging tools will be provided by the UGS, or a third party logging company. The

RECEIVED: September 16,

RECEIVED: September 16, 2016

DRILLING PLAN – IDRAS 2 HOLE 09/05/2016

Page 5 of 10

logging process will include geophysical data logs and consist of caliper, sonic with gamma, SP with resistivity, and magnetic susceptibility measurements.

Development Tooling Test Plan The extent of these tests on the IDRAS 2 hole at the Salt Lake City site will be to evaluate the functionality of tools that are developed to support the IDRAS project. The two tools are the HPC 1.5 M FS (Hydraulic Piston Core 1.5 Meter Freeze Shoe) and ALN FS (Alien Freeze Shoe). These tools are newly developed core collection tools that extend the capabilities of the standard HPC and standard ALN tools that were designed for collecting geologic core samples in modern lake beds.

A generalized test plan has the goal of testing the HPC FS at a minimum of six depths between 10.0 meters (32.8 ft.), and 100.0 m (328 ft.). Each test will consist of these steps:

1. Stop the face centered bit drilling process or HPC standard core collection process to test the HPC 1.5 M FS.

2. Retract the drill string to the closest tubular joint. Separate the drill pipe at the joint. 3. Retrieve the Non-Coring Assembly (NCA) bit using wireline. 4. Install the sampling tool (HPC 1.5 M FS) in the center of the drill tubular with the wireline

system. Rejoin the drill pipe tubular at the joint. Pump the sampling tool to the bottom of the hole.

5. Apply hydraulic pressure on the fluid in the drill tubular above the HPC 1.5 FS to actuate the coring tool.

6. Apply additional pressure until the hydraulic pressure on the fluid in the drill tubular has reached the limit available based on the capacity of the fluid circulation pump (1000 psi +/- 100 psi).

7. Wait for the HPC 1.5 M FS to freeze the tip of the core sample. 8. Retract the HPC 1.5 M FS from the hole using the drill and wireline system. 9. Remove the HPC 1.5 M FS from the drilling tubular when it has reached the surface to process

the core and evaluate the tool function in collecting a core. 10. Remake the drilling tubulars on the drill string. 11. Lower the NCA bit to the bottom of the hole and resume drilling and coring with the standard

HPC coring tool. 12. Repackage the HPC 1.5 M FS as needed to prepare for the next sampling test interval.

The ALN FS relies on an inner coring bit that operates at the same time as the 5.5” diameter outer drill bit. Due to how the ALN FS functions from a drilling perspective, it can be deployed at any depth between the surface and the maximum depth reached for the test hole. The new feature of the ALN FS that requires freezing the base of the core sample, will vary in performance as a function of the hole depth. As the depth of the hole increases, and the amount of drilling fluid within the hole increases the back pressure on the ALN FS system fluid vent, the efficacy of the tool may degrade. DOSECC has completed some theoretical calculations to predict the range of the ALN FS and estimate the maximum depth for freezing capability. The complexity of the downhole conditions of temperature, pressure, and other variables prevents predicting the exact range of the tool with a high degree of accuracy. Field testing in the IDRAS 2 test hole to a depth of 180 m will allow DOSECC to validate some of the tool performance models and collect field data on the tool function in certain temperature and pressure combinations.

When drilling with the face centered bit has reached a zone where the team determines that the ALN FS should be tested, the following steps will take place:

API Well Number: 43035000040000API Well Number: 43035000040000

DRILLING PLAN - IDRAS 2 HOLE 09/05/201€OTECCaplomiinn

Services

logging process will include geophysical data logs and consist of caliper, sonic with gamma, SP withresistivity, and magnetic susceptibility measurements.

Development Tooling Test PlanThe extent of these tests on the IDRAS 2 hole at the Salt Lake City site will be to evaluate thefunctionality of tools that are developed to support the IDRAS project. The two tools are the HPC 1.5 MFS (Hydraulic Piston Core 1.5 Meter Freeze Shoe) and ALN FS (Alien Freeze Shoe). These tools arenewly developed core collection tools that extend the capabilities of the standard HPC and standard ALNtools that were designed for collecting geologic core samples in modern lake beds.

A generalized test plan has the goal of testing the HPC FS at a minimum of six depths between 10.0meters (32.8 ft.), and 100.0 m (328 ft.). Each test will consist of these steps:

1. Stop the face centered bit drilling process or HPC standard core collection process to test the HPC1.5 M FS.

2. Retract the drill string to the closest tubular joint. Separate the drill pipe at the joint.3. Retrieve the Non-Coring Assembly (NCA) bit using wireline.4. Install the sampling tool (HPC 1.5 M FS) in the center of the drill tubular with the wireline

system. Rejoin the drill pipe tubular at the joint. Pump the sampling tool to the bottom of thehole.

5. Apply hydraulic pressure on the fluid in the drill tubular above the HPC 1.5 FS to actuate thecoring tool.

6. Apply additional pressure until the hydraulic pressure on the fluid in the drill tubular has reachedthe limit available based on the capacity of the fluid circulation pump (1000 psi +/- 100 psi).

7. Wait for the HPC 1.5 M FS to freeze the tip of the core sample.8. Retract the HPC 1.5 M FS from the hole using the drill and wireline system.9. Remove the HPC 1.5 M FS from the drilling tubular when it has reached the surface to process

the core and evaluate the tool function in collecting a core.10. Remake the drilling tubulars on the drill string.11. Lower the NCA bit to the bottom of the hole and resume drilling and coring with the standard

HPC coring tool.12. Repackage the HPC 1.5 M FS as needed to prepare for the next sampling test interval.

The ALN FS relies on an inner coring bit that operates at the same time as the 5.5" diameter outer drillbit. Due to how the ALN FS functions from a drilling perspective, it can be deployed at any depthbetween the surface and the maximum depth reached for the test hole. The new feature of the ALN FSthat requires freezing the base of the core sample, will vary in performance as a function of the holedepth. As the depth of the hole increases, and the amount of drilling fluid within the hole increases theback pressure on the ALN FS system fluid vent, the efficacy of the tool may degrade. DOSECC hascompleted some theoretical calculations to predict the range of the ALN FS and estimate the maximumdepth for freezing capability. The complexity of the downhole conditions of temperature, pressure, andother variables prevents predicting the exact range of the tool with a high degree of accuracy. Field testingin the IDRAS 2 test hole to a depth of 180 m will allow DOSECC to validate some of the toolperformance models and collect field data on the tool function in certain temperature and pressurecombinations.

When drilling with the face centered bit has reached a zone where the team determines that the ALN FSshould be tested, the following steps will take place:

RECEIVED: September 16,

API Well Number: 43035000040000

DRILLING PLAN - IDRAS 2 HOLE 09/05/201€OTECCaplomiinn

Services

logging process will include geophysical data logs and consist of caliper, sonic with gamma, SP withresistivity, and magnetic susceptibility measurements.

Development Tooling Test PlanThe extent of these tests on the IDRAS 2 hole at the Salt Lake City site will be to evaluate thefunctionality of tools that are developed to support the IDRAS project. The two tools are the HPC 1.5 MFS (Hydraulic Piston Core 1.5 Meter Freeze Shoe) and ALN FS (Alien Freeze Shoe). These tools arenewly developed core collection tools that extend the capabilities of the standard HPC and standard ALNtools that were designed for collecting geologic core samples in modern lake beds.

A generalized test plan has the goal of testing the HPC FS at a minimum of six depths between 10.0meters (32.8 ft.), and 100.0 m (328 ft.). Each test will consist of these steps:

1. Stop the face centered bit drilling process or HPC standard core collection process to test the HPC1.5 M FS.

2. Retract the drill string to the closest tubular joint. Separate the drill pipe at the joint.3. Retrieve the Non-Coring Assembly (NCA) bit using wireline.4. Install the sampling tool (HPC 1.5 M FS) in the center of the drill tubular with the wireline

system. Rejoin the drill pipe tubular at the joint. Pump the sampling tool to the bottom of thehole.

5. Apply hydraulic pressure on the fluid in the drill tubular above the HPC 1.5 FS to actuate thecoring tool.

6. Apply additional pressure until the hydraulic pressure on the fluid in the drill tubular has reachedthe limit available based on the capacity of the fluid circulation pump (1000 psi +/- 100 psi).

7. Wait for the HPC 1.5 M FS to freeze the tip of the core sample.8. Retract the HPC 1.5 M FS from the hole using the drill and wireline system.9. Remove the HPC 1.5 M FS from the drilling tubular when it has reached the surface to process

the core and evaluate the tool function in collecting a core.10. Remake the drilling tubulars on the drill string.11. Lower the NCA bit to the bottom of the hole and resume drilling and coring with the standard

HPC coring tool.12. Repackage the HPC 1.5 M FS as needed to prepare for the next sampling test interval.

The ALN FS relies on an inner coring bit that operates at the same time as the 5.5" diameter outer drillbit. Due to how the ALN FS functions from a drilling perspective, it can be deployed at any depthbetween the surface and the maximum depth reached for the test hole. The new feature of the ALN FSthat requires freezing the base of the core sample, will vary in performance as a function of the holedepth. As the depth of the hole increases, and the amount of drilling fluid within the hole increases theback pressure on the ALN FS system fluid vent, the efficacy of the tool may degrade. DOSECC hascompleted some theoretical calculations to predict the range of the ALN FS and estimate the maximumdepth for freezing capability. The complexity of the downhole conditions of temperature, pressure, andother variables prevents predicting the exact range of the tool with a high degree of accuracy. Field testingin the IDRAS 2 test hole to a depth of 180 m will allow DOSECC to validate some of the toolperformance models and collect field data on the tool function in certain temperature and pressurecombinations.

When drilling with the face centered bit has reached a zone where the team determines that the ALN FSshould be tested, the following steps will take place:

RECEIVED: September 16,

RECEIVED: September 16, 2016

DRILLING PLAN – IDRAS 2 HOLE 09/05/2016

Page 6 of 10

1. Stop the face centered bit drilling process and ALN coring process. 2. Retract the drill string to the closest tubular joint. 3. Retrieve the Non-Coring Assembly (NCA) bit using wireline. 4. Assemble and deploy the ALN FS down the drilling string using the wireline coring system. 5. The drill crew will resume drilling with the face centered drill bit and the coring drill operating

simultaneously. The 5.5” diameter outer drill bit will advance and open the outer diameter of the hole to allow the drilling bottom hole assembly and drill string tools to advance the hole depth. The 3.8” diameter diamond coring tool will extend slightly beyond the face of the 5.5” diameter outer bit, and collect the core sample from the center of the hole as the bottom hole assembly advances the hole depth.

6. A preset control timer on the ALN FS will determine when the drilling with the two drill bits should pause. At the expiration of the timer, the rotation of the drill bits, and the circulation of the drilling fluid will pause. The ALN FS will actuate the system designed to freeze the material at the tip of the core sample.

7. At the completion of the time necessary to ensure the core tip is frozen, the ALN FS sample assembly will be retracted using the wireline coring system.

8. Lower the NCA face-centered bit to the bottom of the hole and resume drilling. 9. The drilling process with the 5.5” diameter drill and ALN coring assembly will continue to

advance the hole depth. 10. The ALN FS sampler and coring tool will be disassembled to process the core sample and prepare

the tool for the next sampling test.

Estimated Geologic Markers and Zones The total depth drilled is expected to be in the Holocene/Pleistocene-aged valley-fill deposits. Based on evaluation of nearby oil and gas tests the top of the Tertiary (Salt Lake Formation) is at least 1,100 feet deep. The total planned depth of this well is above the depth of the top of the Tertiary (Salt Lake Formation).

Mixed briny and fresh ground water is likely to be encountered in the first approximately 121.9 m (400 feet) of drilling. From nearby shallow ground water drilling, these zones should present no major problems in drilling the test hole. Ground water drilling in the last 15 years has encountered small artesian flows of water. Similar zones may be encountered in the test hole. Since these flows are above hydrostatic pressure, there is no potential for damage from co-mingled waters entering these aquifers.

Minor gas shows have been encountered by oil and gas drilling in the township, but most occurred below about 1,500 feet. An early oil and gas test (API 4303516540) in Section 30, T1N, R1W, records several oil and gas shows in the section drilled from 192 feet to 542 feet. There is doubt expressed by an entry into the well file as to the authenticity of these shows. The shallow total depth proposed for IDRAS 2 should not encounter these deeper, bonafide gas zones. Numerous shallow water wells have been drilled within a 3 mile radius of the proposed location, with no notes on the well logs of encountering oil or gas in the section between the surface and 600 feet.

Water Rights Approval No water rights approval plan is required. DOSECC will purchase water from Salt Lake City and haul the water required for the project to the site by truck.

API Well Number: 43035000040000API Well Number: 43035000040000

DRILLING PLAN - IDRAS 2 HOLE 09/05/201€OSECCxplorgion

Services

1. Stop the face centered bit drilling process and ALN coring process.2. Retract the drill string to the closest tubular joint.3. Retrieve the Non-Coring Assembly (NCA) bit using wireline.4- Assemble and deploy the ALN FS down the drilling string using the wireline coring system.5. The drill crew will resume drilling with the face centered drill bit and the coring drill operating

simultaneously. The 5.5" diameter outer drill bit will advance and open the outer diameter of thehole to allow the drilling bottom hole assembly and drill string tools to advance the hole depth.The 3.8" diameter diamond coring tool will extend slightly beyond the face of the 5.5" diameterouter bit, and collect the core sample from the center of the hole as the bottom hole assemblyadvances the hole depth.

6. A preset control timer on the ALN FS will determine when the drilling with the two drill bitsshould pause. At the expiration of the timer, the rotation of the drill bits, and the circulation of thedrilling fluid will pause. The ALN FS will actuate the system designed to freeze the material atthe tip of the core sample.

7. At the completion of the time necessary to ensure the core tip is frozen, the ALN FS sampleassembly will be retracted using the wireline coring system.

8. Lower the NCA face-centered bit to the bottom of the hole and resume drilling.9. The drilling process with the 5.5" diameter drill and ALN coring assembly will continue to

advance the hole depth.10. The ALN FS sampler and coring tool will be disassembled to process the core sample and prepare

the tool for the next sampling test.

Estimated Geologic Markers and ZonesThe total depth drilled is expected to be in the Holocene/Pleistocene-aged valley-fill deposits. Based onevaluation of nearby oil and gas tests the top of the Tertiary (Salt Lake Formation) is at least 1,100 feetdeep. The total planned depth of this well is above the depth of the top of the Tertiary (Salt LakeFormation).

Mixed briny and fresh ground water is likely to be encountered in the first approximately 121.9 m (400feet) of drilling. From nearby shallow ground water drilling, these zones should present no majorproblems in drilling the test hole. Ground water drilling in the last 15 years has encountered small artesianflows of water. Similar zones may be encountered in the test hole. Since these flows are abovehydrostatic pressure, there is no potential for damage from co-mingled waters entering these aquifers.

Minor gas shows have been encountered by oil and gas drilling in the township, but most occurred belowabout 1,500 feet. An early oil and gas test (API 4303516540) in Section 30, TlN, RlW, records severaloil and gas shows in the section drilled from 192 feet to 542 feet. There is doubt expressed by an entryinto the well file as to the authenticity of these shows. The shallow total depth proposed for IDRAS 2should not encounter these deeper, bonafide gas zones. Numerous shallow water wells have been drilledwithin a 3 mile radius of the proposed location, with no notes on the well logs of encountering oil or gasin the section between the surface and 600 feet.

Water Rights ApprovalNo water rights approval plan is required. DOSECC will purchase water from Salt Lake City and haul thewater required for the project to the site by truck.

RECEIVED: September 16,

API Well Number: 43035000040000

DRILLING PLAN - IDRAS 2 HOLE 09/05/201€OSECCxplorgion

Services

1. Stop the face centered bit drilling process and ALN coring process.2. Retract the drill string to the closest tubular joint.3. Retrieve the Non-Coring Assembly (NCA) bit using wireline.4- Assemble and deploy the ALN FS down the drilling string using the wireline coring system.5. The drill crew will resume drilling with the face centered drill bit and the coring drill operating

simultaneously. The 5.5" diameter outer drill bit will advance and open the outer diameter of thehole to allow the drilling bottom hole assembly and drill string tools to advance the hole depth.The 3.8" diameter diamond coring tool will extend slightly beyond the face of the 5.5" diameterouter bit, and collect the core sample from the center of the hole as the bottom hole assemblyadvances the hole depth.

6. A preset control timer on the ALN FS will determine when the drilling with the two drill bitsshould pause. At the expiration of the timer, the rotation of the drill bits, and the circulation of thedrilling fluid will pause. The ALN FS will actuate the system designed to freeze the material atthe tip of the core sample.

7. At the completion of the time necessary to ensure the core tip is frozen, the ALN FS sampleassembly will be retracted using the wireline coring system.

8. Lower the NCA face-centered bit to the bottom of the hole and resume drilling.9. The drilling process with the 5.5" diameter drill and ALN coring assembly will continue to

advance the hole depth.10. The ALN FS sampler and coring tool will be disassembled to process the core sample and prepare

the tool for the next sampling test.

Estimated Geologic Markers and ZonesThe total depth drilled is expected to be in the Holocene/Pleistocene-aged valley-fill deposits. Based onevaluation of nearby oil and gas tests the top of the Tertiary (Salt Lake Formation) is at least 1,100 feetdeep. The total planned depth of this well is above the depth of the top of the Tertiary (Salt LakeFormation).

Mixed briny and fresh ground water is likely to be encountered in the first approximately 121.9 m (400feet) of drilling. From nearby shallow ground water drilling, these zones should present no majorproblems in drilling the test hole. Ground water drilling in the last 15 years has encountered small artesianflows of water. Similar zones may be encountered in the test hole. Since these flows are abovehydrostatic pressure, there is no potential for damage from co-mingled waters entering these aquifers.

Minor gas shows have been encountered by oil and gas drilling in the township, but most occurred belowabout 1,500 feet. An early oil and gas test (API 4303516540) in Section 30, TlN, RlW, records severaloil and gas shows in the section drilled from 192 feet to 542 feet. There is doubt expressed by an entryinto the well file as to the authenticity of these shows. The shallow total depth proposed for IDRAS 2should not encounter these deeper, bonafide gas zones. Numerous shallow water wells have been drilledwithin a 3 mile radius of the proposed location, with no notes on the well logs of encountering oil or gasin the section between the surface and 600 feet.

Water Rights ApprovalNo water rights approval plan is required. DOSECC will purchase water from Salt Lake City and haul thewater required for the project to the site by truck.

RECEIVED: September 16,

RECEIVED: September 16, 2016

DRILLING PLAN – IDRAS 2 HOLE 09/05/2016

Page 7 of 10

Pressure Control Equipment

BOPE configuration No oil and gas is anticipated in the zone drilled. The drilling site and drilling plan have been reviewed by a professional geologist. Due to a site review for the location of the planned test hole, the review of the planned drilling efforts, and review of the drilling results for holes in the vicinity of this test hole, Blow Out Prevention Equipment (BOPE) is not necessary. No BOP is planned for use on the hole, to support the process of drilling this hole, testing the downhole core sampling tools, or to support the general plug and abandonment efforts when the drilling is completed.

Choke Manifold Equipment This equipment is only required if a BOP is required.

Accumulator This equipment is only required if a BOP is required.

Well Control Drills The operations for drilling the IDRAS 2 test hole will be conducted using two shifts of drill operating crews. This will allow DOSECC to drill the test hole continuously, minimize trip times of tooling up and down the hole incurred by idling the drill for more than several hours, and minimize the time to complete the hole. No well control drills are planned at this time, as the drilling effort is not expected to exceed several days in duration.

Monitoring Equipment No monitoring equipment is applied to this drilling effort. The standard process for monitoring the drilling fluid circulation used in diamond core drilling and sampling will be employed. The driller will monitor the volume of mud in the mud mixing tank by observing the tank level. The rate of drilling mud consumption will be determined based on the amount premixed in the tank, the tank level, and the speed of the circulation pump. The approximate speed in revolutions per minute of the circulation pump, and the pump’s standard operating characteristics, will enable the driller to approximate the gallon per minute rate of drilling fluid consumption.

Mud weight and mud viscosity will be measured and recorded at intervals determined by the driller.

Miscellaneous Information No miscellaneous information pertains to this hole drilling plan.

Casing Program

Cementing Program This is a short term hole and DOSECC Exploration Services does not anticipate it being open for more than a few days, which will be long enough to complete the objectives associated with validating functionality of the new core sampling tools, and to complete the logging surveys.

A 6-5/8” casing will be cemented in place for the first 60 feet of the hole. After the 5.5” diameter hole is logged, a 2-3/8” diameter liner will be grouted in place within the 5.5” diameter bore hole and surface casing. The annular space will be filled with a thermal grout by pumping the grout down the liner, through a float plug with a ball-check valve. When the annular space is filled between the 2-3/8” liner and the bore hole, a wiper plug will be pumped down the liner to seal the ball-check valve. The liner will be

API Well Number: 43035000040000API Well Number: 43035000040000

DRILLING PLAN - IDRAS 2 HOLE 09/05/201€OSECCaplomiion

Services

Pressure Control EquipmentBOPE configurationNo oil and gas is anticipated in the zone drilled. The drilling site and drilling plan have been reviewed bya professional geologist. Due to a site review for the location of the planned test hole, the review of theplanned drilling efforts, and review of the drilling results for holes in the vicinity of this test hole, BlowOut Prevention Equipment (BOPE) is not necessary. No BOP is planned for use on the hole, to supportthe process of drilling this hole, testing the downhole core sampling tools, or to support the general plugand abandonment efforts when the drilling is completed.

Choke Manifold EquipmentThis equipment is only required if a BOP is required.

Accu mu latorThis equipment is only required if a BOP is required.

Well Control DrillsThe operations for drilling the IDRAS 2 test hole will be conducted using two shifts of drill operatingcrews. This will allow DOSECC to drill the test hole continuously, minimize trip times of tooling up anddown the hole incurred by idling the drill for more than several hours, and minimize the time to completethe hole. No well control drills are planned at this time, as the drilling effort is not expected to exceedseveral days in duration.

Monitoring EquipmentNo monitoring equipment is applied to this drilling effort. The standard process for monitoring thedrilling fluid circulation used in diamond core drilling and sampling will be employed. The driller willmonitor the volume of mud in the mud mixing tank by observing the tank level. The rate of drilling mudconsumption will be determined based on the amount premixed in the tank, the tank level, and the speedof the circulation pump. The approximate speed in revolutions per minute of the circulation pump, and thepump's standard operating characteristics, will enable the driller to approximate the gallon per minute rateof drilling fluid consumption.

Mud weight and mud viscosity will be measured and recorded at intervals determined by the driller.

Miscellaneous InformationNo miscellaneous information pertains to this hole drilling plan.

Casing ProgramCementing ProgramThis is a short term hole and DOSECC Exploration Services does not anticipate it being open for morethan a few days, which will be long enough to complete the objectives associated with validatingfunctionality of the new core sampling tools, and to complete the logging surveys.

A 6-5/8" casing will be cemented in place for the first 60 feet of the hole. After the 5.5" diameter hole islogged, a 2-3/8" diameter liner will be grouted in place within the 5.5" diameter bore hole and surfacecasing. The annular space will be filled with a thermal grout by pumping the grout down the liner,through a float plug with a ball-check valve. When the annular space is filled between the 2-3/8" liner andthe bore hole, a wiper plug will be pumped down the liner to seal the ball-check valve. The liner will be

RECEIVED: September 16,

API Well Number: 43035000040000

DRILLING PLAN - IDRAS 2 HOLE 09/05/201€OSECCaplomiion

Services

Pressure Control EquipmentBOPE configurationNo oil and gas is anticipated in the zone drilled. The drilling site and drilling plan have been reviewed bya professional geologist. Due to a site review for the location of the planned test hole, the review of theplanned drilling efforts, and review of the drilling results for holes in the vicinity of this test hole, BlowOut Prevention Equipment (BOPE) is not necessary. No BOP is planned for use on the hole, to supportthe process of drilling this hole, testing the downhole core sampling tools, or to support the general plugand abandonment efforts when the drilling is completed.

Choke Manifold EquipmentThis equipment is only required if a BOP is required.

Accu mu latorThis equipment is only required if a BOP is required.

Well Control DrillsThe operations for drilling the IDRAS 2 test hole will be conducted using two shifts of drill operatingcrews. This will allow DOSECC to drill the test hole continuously, minimize trip times of tooling up anddown the hole incurred by idling the drill for more than several hours, and minimize the time to completethe hole. No well control drills are planned at this time, as the drilling effort is not expected to exceedseveral days in duration.

Monitoring EquipmentNo monitoring equipment is applied to this drilling effort. The standard process for monitoring thedrilling fluid circulation used in diamond core drilling and sampling will be employed. The driller willmonitor the volume of mud in the mud mixing tank by observing the tank level. The rate of drilling mudconsumption will be determined based on the amount premixed in the tank, the tank level, and the speedof the circulation pump. The approximate speed in revolutions per minute of the circulation pump, and thepump's standard operating characteristics, will enable the driller to approximate the gallon per minute rateof drilling fluid consumption.

Mud weight and mud viscosity will be measured and recorded at intervals determined by the driller.

Miscellaneous InformationNo miscellaneous information pertains to this hole drilling plan.

Casing ProgramCementing ProgramThis is a short term hole and DOSECC Exploration Services does not anticipate it being open for morethan a few days, which will be long enough to complete the objectives associated with validatingfunctionality of the new core sampling tools, and to complete the logging surveys.

A 6-5/8" casing will be cemented in place for the first 60 feet of the hole. After the 5.5" diameter hole islogged, a 2-3/8" diameter liner will be grouted in place within the 5.5" diameter bore hole and surfacecasing. The annular space will be filled with a thermal grout by pumping the grout down the liner,through a float plug with a ball-check valve. When the annular space is filled between the 2-3/8" liner andthe bore hole, a wiper plug will be pumped down the liner to seal the ball-check valve. The liner will be

RECEIVED: September 16,

RECEIVED: September 16, 2016

DRILLING PLAN – IDRAS 2 HOLE 09/05/2016

Page 8 of 10

filled with water, and a cap with lock will be installed on the top of the liner. Test hole data will be collected for a period of approximately 9 months.

After monitoring data has been collected, the test hole will be plugged and abandoned. A sand fill will be used to displace the water from the liner in the lower portion of the hole. The top 100 feet of the liner will be filled with a neat cement plug. The liner will be cut so that it is level with the top of the surface casing. A ground cap of neat cement will be installed over the well, and a surface marker attached for identification purposes.

The 6-5/8” casing will be cemented in place with a cement cap at the bottom. A Portland cement, ASTM Type 1 or API Class A & B – Portland cement, that is a mixture of lime, alumina, magnesia, and sulfur trioxide will be used to cement the casing. The cement forms a hard rock-like seal around the casing which will not wash out from ground water flow in the formation. A curing time of 24 hours is required before resuming drilling if a neat cement plug is used to set casing. As the water to cement ratio increases, the compressive strength of the cement will decrease and shrinkage during curing and permeability of the cement will increase. When the cement is mixed with water, a number of chemical reactions take place. As the mixture cures and changes from a liquid mixture to a solid, heat is given off. The exothermic reaction is referred to as the “heat of hydration” and will result in an increase of the temperature of the casing and the surrounding soil. The amount of heat given off is dependent upon several factors, such as cement composition, use of additives, and the thickness of the grouting envelope. The American Petroleum Institute (API) recommends a water to cement ratio of 0.46 by weight of 5.2 gallons of water per 94 lb. sack of cement (5.2 gal of water x 8.33 lb./gal =43.3 lbs. water / 94 lbs. of cement = 0.46).

Surface Casing A surface casing / conductor that is a 6-5/8” buttress or SWT will be used in the first 60 feet of the hole to stabilize the surface sediments. The casing will be cemented in place to stabilize the top 10% of the total drilled depth of the hole.

Intermediate Casing No intermediate casing is planned for this test hole. The core samples and downhole tests are intended to be completed while the drill string is down hole. The drill string will be removed from the hole when the hole reaches planned maximum depth and the logging / survey team is ready to proceed with surveying and logging the hole.

Mud Program This is a shallow test well that will use bentonite mud with a water (H2O) solution, soda ash for pH balance, and possibly some food grade polymer if needed. The system will consist of an above ground tank and mixing hopper that will deliver a 7.6 lb./gal mud to a W-1122 Bean pump circulating in the range of 20-30 gpm for flow rate in the 5.5” diameter hole with 4.5” diameter rods. A series of settling tanks will be employed to use gravity settling of the drilling fluid cuttings and fines. The mud and cuttings will debut into a concrete box sump and be lifted to another tank outfitted with a shaker and de-silter. A dynamic gravity separation unit (centrifuge) may be employed near the end of the drilling program to improve the condition of the drilling fluid by removing excessive fines. The mud will be allowed to settle in the system of settling tanks, and then be used as makeup fluid that is circulated back to the mixing tank.

API Well Number: 43035000040000API Well Number: 43035000040000

DRILLING PLAN - IDRAS 2 HOLE 09/05/201€OTECCaplomiinn

Services

filled with water, and a cap with lock will be installed on the top of the liner. Test hole data will becollected for a period of approximately 9 months.

After monitoring data has been collected, the test hole will be plugged and abandoned. A sand fill will beused to displace the water from the liner in the lower portion of the hole. The top 100 feet of the liner willbe filled with a neat cement plug. The liner will be cut so that it is level with the top of the surface casing.A ground cap of neat cement will be installed over the well, and a surface marker attached foridentification purposes.

The 6-5/8" casing will be cemented in place with a cement cap at the bottom. A Portland cement, ASTMType 1 or API Class A & B - Portland cement, that is a mixture of lime, alumina, magnesia, and sulfurtrioxide will be used to cement the casing. The cement forms a hard rock-like seal around the casingwhich will not wash out from ground water flow in the formation. A curing time of 24 hours is requiredbefore resuming drilling if a neat cement plug is used to set casing. As the water to cement ratio increases,the compressive strength of the cement will decrease and shrinkage during curing and permeability of thecement will increase. When the cement is mixed with water, a number of chemical reactions take place.As the mixture cures and changes from a liquid mixture to a solid, heat is given off. The exothermicreaction is referred to as the "heat of hydration" and will result in an increase of the temperature of thecasing and the surrounding soil. The amount of heat given off is dependent upon several factors, such ascement composition, use of additives, and the thickness of the grouting envelope. The AmericanPetroleum Institute (API) recommends a water to cement ratio of 0.46 by weight of 5.2 gallons of waterper 94 lb. sack of cement (5.2 gal of water x 8.33 lb./gal =43.3 lbs. water / 94 lbs. of cement = 0.46).

Surface CasingA surface casing / conductor that is a 6-5/8" buttress or SWT will be used in the first 60 feet of the hole tostabilize the surface sediments. The casing will be cemented in place to stabilize the top 10% of the totaldrilled depth of the hole.

Intermediate CasingNo intermediate casing is planned for this test hole. The core samples and downhole tests are intended tobe completed while the drill string is down hole. The drill string will be removed from the hole when thehole reaches planned maximum depth and the logging / survey team is ready to proceed with surveyingand logging the hole.

Mud ProgramThis is a shallow test well that will use bentonite mud with a water (H2O)solution, soda ash for pHbalance, and possibly some food grade polymer if needed. The system will consist of an above groundtank and mixing hopper that will deliver a 7.6 lb./gal mud to a W-1122 Bean pump circulating in therange of 20-30 gpm for flow rate in the 5.5" diameter hole with 4.5" diameter rods. A series of settlingtanks will be employed to use gravity settling of the drilling fluid cuttings and fines. The mud andcuttings will debut into a concrete box sump and be lifted to another tank outfitted with a shaker and de-silter. A dynamic gravity separation unit (centrifuge) may be employed near the end of the drillingprogram to improve the condition of the drilling fluid by removing excessive fines. The mud will beallowed to settle in the system of settling tanks, and then be used as makeup fluid that is circulated backto the mixing tank.

RECEIVED: September 16,

API Well Number: 43035000040000

DRILLING PLAN - IDRAS 2 HOLE 09/05/201€OTECCaplomiinn

Services

filled with water, and a cap with lock will be installed on the top of the liner. Test hole data will becollected for a period of approximately 9 months.

After monitoring data has been collected, the test hole will be plugged and abandoned. A sand fill will beused to displace the water from the liner in the lower portion of the hole. The top 100 feet of the liner willbe filled with a neat cement plug. The liner will be cut so that it is level with the top of the surface casing.A ground cap of neat cement will be installed over the well, and a surface marker attached foridentification purposes.

The 6-5/8" casing will be cemented in place with a cement cap at the bottom. A Portland cement, ASTMType 1 or API Class A & B - Portland cement, that is a mixture of lime, alumina, magnesia, and sulfurtrioxide will be used to cement the casing. The cement forms a hard rock-like seal around the casingwhich will not wash out from ground water flow in the formation. A curing time of 24 hours is requiredbefore resuming drilling if a neat cement plug is used to set casing. As the water to cement ratio increases,the compressive strength of the cement will decrease and shrinkage during curing and permeability of thecement will increase. When the cement is mixed with water, a number of chemical reactions take place.As the mixture cures and changes from a liquid mixture to a solid, heat is given off. The exothermicreaction is referred to as the "heat of hydration" and will result in an increase of the temperature of thecasing and the surrounding soil. The amount of heat given off is dependent upon several factors, such ascement composition, use of additives, and the thickness of the grouting envelope. The AmericanPetroleum Institute (API) recommends a water to cement ratio of 0.46 by weight of 5.2 gallons of waterper 94 lb. sack of cement (5.2 gal of water x 8.33 lb./gal =43.3 lbs. water / 94 lbs. of cement = 0.46).

Surface CasingA surface casing / conductor that is a 6-5/8" buttress or SWT will be used in the first 60 feet of the hole tostabilize the surface sediments. The casing will be cemented in place to stabilize the top 10% of the totaldrilled depth of the hole.