Real facts behind plastic injection molding process

-

Upload

lincy-thomas -

Category

Documents

-

view

222 -

download

2

description

Transcript of Real facts behind plastic injection molding process

By

Lincy Thomas

It is a manufacturing method to mass produce plastics.

Plastics and plastic related products as such play a very predominant role in our day to day lives.

Plastic in a way is one of the greatest inventions of mankind that has revolutionized his lifestyle.

Plastic Injection molding is one among such comprehensive processes that plays a very influential role in every plastic manufacturing company.

Plastics as we speak have several wonderful qualities that improve the overall quality of the end product wherein it is used.

For example, bulb switches, table fans, computer’s outer structures, and etc are all made from high end plastic as plastic is a better conductor of heat and electricity when compared to other materials.

It has revolutionized the art of manufacturing plastics and allowed us to manufacture all kinds of plastic components of various sizes and shapes as per our requirements.

Injection molding is a very complicated process. The final end product would be of high quality only when the molding machine is handled well.

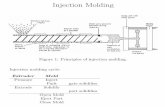

It mainly has two parts upon which the machines operates. On one end of the machine, the plastic is fed in the form of pellets or

granules which is then heated and melted at higher temperatures prevalent inside the first compartment.

The molten solution is the squeezed and collected at the other end in mold structure of a desired shape held by the clamping units.

The clamping unit is removed and the mold is opened after a while for the collected solution to cool.

Upon cooling down, the molten solution solidifies and takes the shape of the mold which collected it.

In this way highly quality molds are manufactured by various plastic injection molding companies.

Reliable Injection Molding, located Houston, Texas, is a family owned and operated plastic injection molding company that has been manufacturing quality injection molds and thermoplastics for customer plastic needs.

Our commitment to our customers is to provide our customers with the best possible service, support and quality. From design and development to final product and production runs Reliable Injection Molding is the best choice for your money.

Visit our site www.reliableinjectionmolding.com

Contact us:

Reliable Injection Molding,6302 W. little York ste 114,Houston, Texas 77091.

Email :[email protected]

Thanks for your patience