Raimondi Cranes

-

Upload

metamorfosi -

Category

Documents

-

view

268 -

download

6

description

Transcript of Raimondi Cranes

2

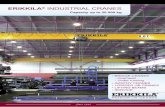

Raimondi CRanes was founded and established

in 1863 during the first industrialisation year in italy.

during the second half of the 19th century the

textile business was the most rapidly growing

industry in the region and Rodolfo Raimondi began

the first production of transmission equipment

utilised in a cotton manufacturing plant in Legnano,

where our headquarters are still located today.

during the following century and two World Wars,

Raimondi CRanes was devoted to the country’s

reconstruction needs, focusing on manufacturing

of building equipment from concrete mixers to

winches and tower cranes.

since 1946, Raimondi CRanes has devoted all

its resources to producing state of the art tower

cranes.

Raimondi HisToRY

Building a future through out the years

3Raimondi HisToRY

CoRPoRaTe PRoFiLe4

Raimondi CRanes was purchased in 2009 by

a conglomerate of Qatari investors, who saw the

business potential in the quality of Raimondi

CRanes.

The Qatar economy has been one of the most

dynamic in the world. This growth is due in part

to the rising energy prices and high exports of

liquefied natural gas (LnG). Qatar has huge gas

reserves as much as one third of the worlds total

gas reserves lies within its territory, making it the

largest exporter of LnG in the world.

Qatar’s economic growth has been further

strengthened by open & competitive economic

conditions of private enterprise & the promotion

of investments abroad, such as this one.

Under the new Qatari management, Raimondi

CRanes will continue to expand its production in

italy by investing, developing and managing the

business in order to satisfy its increase demand

and its aggressive expansion into new global

markets.

7oUR Vision

Today Raimondi CRanes is a modern company,

utilising the latest production technologies and

holds a prominent position in the global market

as a leading tower crane manufacturer.

Raimondi CRanes remains focused on delivering

exceptional quality and unparalleled customer

service with competitive pricing. The philosophy

of the company has always prioritised product

care, technological development and satisfying

market needs. Raimondi CRanes has so far

manufactured and distributed more than 15,000

cranes throughout the world and it is our goal to

double that figure in the next 7 years.

a R

an

Ge

WiT

Ho

UT

FR

on

Tie

Rs

9

at Raimondi CRanes, we pride ourselves on the

best of italian talent and european technology.

We have changed the building sites aesthetics,

improving performance, safety and functionality.

Raimondi tower crane’s have a well designed

harmonic line made to improve performance.

Beauty and simplicity, coupled with the latest

technology are fundamental characteristics of

Raimondi CRanes.

Raimondi tower cranes are conceived and

manufactured in italy to meet global market needs,

while maintaining its italian characteristics; style

combined with maximum functionality.

PURsUiT oF PeRFeCTion

Technological improvement,

our constant challenge

LR 165 - FinaL HeiGHT 200 mnURoL LLC, aBU dHaBi - Uae

LR 165 - FinaL HeiGHT 270 mJV – nPC - aRaBTeC, aBU dHaBi – Uae

2,0

m60,9 m 14,2 m

4,25

m

41,4

m

H =

43,

7 m

H

= 4

3,2

m

H =

47,

8 m

H

= 4

3,0

m

1,7 m

0,9 m

4,5 x 4,5 m 8,0 T/8,80 T - UL

7,65 T/8,30 T - UL

5,95 T / 6,55 T - UL

4,85 T / 5,35 T - UL

3,85 T / 4,25 T - UL

3,10 T / 3,40 T - UL

2,80 T / 3,05 T - UL

2,50 T / 2,75 T - UL

2,00 T / 2,20 T - UL

19,0 m

25,0 m

31,0 m

36,5 m

42,5 m

48,0 m

50,0 m

54,0 m

60,0 m

4,5 x 4,5 m

4,5 x 4,5 m

A

B

D

E

1,7 m

1,7

m

A E B D

BUiLdinG oF THe exHiBiTion CenTRe in miLan

PoWeRs THaT oPenNEW FRONTIERS

14

eR models are the traditional tower cranes which

are specifically designed for large construction

sites. it can carry a maximum load of 16 tons for

cranes of 75 and 80 meter jib, with modular towers

able to achieve maximum height of 400 meters

and maximum free stand height of 91 meters.

eR Line

eR 240 - HeiGHT 200 mimPReGiLo, CiTY disTRiCT’s PaLaCe – miLan

eR 291maLPensa aiRPoRT – miLan

16

Raimondi CRanes was one of the first companies

to introduce topless cranes: the classic “quick

assembling” cranes which are very popular because

of their reliability.

a crane with no a-frame and tie rods makes it easy

to assemble and subsequently easier to maintain,

allowing for faster modification of the jib length

to cater for the challenging needs of a job site.

devised to satisfy the ever-changing requirements

of building sites, the mRT has changed the concept

of lifting equipment. With its maximum loading

capacity of 16 ton and 76 meter jib length, the mRT

models are fast replacing the traditional cranes as

the preferred choice.

mRT Line

mRT 180exPo aRea – miLan

18

Luffing jib cranes are designed to operate in the

most difficult and restricted spaces within the

constraints of densely populated and congested

urban development sites.

With its unique and flexible design it can be used in

larger scale, ultra high types of construction sites.

With a maximum loading capacity of 16 ton and

55 meter jib, the LR range can easily satisfy the

needs of all job sites in the most challenging of

environments.

LR Line

LR 165 JUmeiRaH - dUBai

20

Raimondi CRanes offers a complete range of

self erecting Cranes, designed for small to medium

size projects.

self erecting Cranes (HR) are becoming increas-

ingly popular due to their simplicity of operation,

reduction of onsite vehicle movements, improving

productivity and reducing costs.

our self erecting Cranes (available in single and

three phase power supply options) with its inverter

devices can lift a maximum load of 4 tons, ideal

for quick constructions in the medium range

operations. The galvanisation of the steel ensures

for longer life.

HR Line

TH

e B

iRT

H o

F a

CR

an

e

24 deLUx CaBin

The delux cabin is an exclusive Raimondi CRanes

design, through extensive research and strict

international safety and quality regulation, the

delux cabin ensures the operator is in the best

visual position to perform his duties effectively

and safely.

Riamondi CRanes unique round cabin allows

for 180 degree wide visual access with tinted

heat reflecting glass on both sides, as well as an

ergonomic chair for comfort and easy access to

the commands via joy sticks, another example of

Raimondi CRanes creative initiative.

Raimondi CRanes understands the success of

a project site depends on its people, and they in

turn depend on proper working conditions, this is

why Raimondi CRanes has produced a superior

state of the art cabin.

28

The electrical system utilises components from

leading european suppliers, prominent in the

international market.

Raimondi CRanes uses leading edge technology

via the use of PLC and frequency variation con-

figurations, which drives the sensors integrated on

the crane through a Control area network (Can).

each PLC is designed with proprietary software

and controls each single drive: hoisting, trolley and

travelling for greater crane reliability and easier

repair operations.

Frequency inverters (variable speed drives) which

are set with our own parameters, provide soft-start

capabilities and have the advantage of productivity

improvement and reducing energy consumption.

assembly of all the electrical components is done

in-house and based on Raimondi’s proprietary

drawings which are the result of years of experience

gained from construction sites, worldwide.

eLeCTRiCaL PoWeR

de

Ta

iLe

d C

aR

e

31

each single manufacturing phase is carefully carried

out with focus on attention to detail of the steel

works as it is the core of the crane.

The material selection is based on quality and

resistance criteria with a further process dedicated

to certification and traceability. The welding of the

frames is made by highly qualified professionals

who are continuously trained with the newest

technology.

a final test on the quality of welding is completed

by a third party inspection company utilising

penetrating ink and magnetoscopes.

additional final dimensional and visual controls

eliminate even the smallest of imperfections.

CoRe oF sTeeL

Raimondi cranes are produced using the best steel and workmanship

CR

aF

Ts

ma

ns

HiP

& T

eC

Hn

oLo

GY

33

The best technicians in the field consider Raimondi

CRanes tubular structure more solid and stable

than the more commonly used angular structure.

due to its tubular design it provides more stability

with less wind resistance, resulting in greater work

safety on the job site, a characteristic which is not

always noticeable in other tower cranes.

The hoisting winches frequency variation in line

with manoeuvring is designed to avoid structural

over loads and to reduce load oscillation. The

‘Lebus’ drum ensures a correct wrapping of each

rope’s layer, allowing for greater quantity of rope

and reducing deteriation.

Raimondi CRanes design engineers and techni-

cians never compromise on service quality or safety

and for this reason have put in place further safety

measures on the brake system. The Raimondi

CRanes brake system is equipped with wear

sensors, which over-rides the control of the air gap,

in the event maintenance has not been done or

properly completed, the brakes will automatically

stop the crane.

a further indicator to alert the user of the problems

is the sLF, a red light located on the hoisting

electrical box, which will provide the details for

the shut down of the sensor lock, allowing the

end user to immediately identify the problem and

address it.

PReCision as KeY ComPonenT

differences that makea difference

eF

FiC

ien

CY

35oUR PHiLosoPHY

The best performancesfor an efficient service

increasing the performance level by reducing

the erection time will provide our customers with

considerable cost savings and efficiency. our

productive philosophy is inspired by this strate-

gic objective. on the erection side, Raimondi

CRanes have few rivals: the secret is the design

and production method.

a typical example of Raimondi CRanes designs

are not only based on technical criteria but driven

by practical and safety factors is the hydraulic

climbing cage. The cage is equipped with two

hydraulic pistons thus making it possible to cor-

rect any imbalances which may occur during the

raising phase.

Furthermore, a dual level walking platform allows

the erectors to work with maximum safety and ease.

an important point regarding practical efficiency

and safety is the position of the trolley. Raimondi

CRanes, counterjibs are delivered from the factory

with the trolley, the complete hook block and the

hoisting rope already arranged and fitted in each

trolley’s pulleys. This innovative system has a double

positive effect: to complete the assembling of the

rope on the jib with the maximum safety and to

reduce the time to assemble the jib because with

a single lift you have the counterjib, trolley, hook

block and hosting rope installed.

aF

Te

R s

aL

es

se

RV

iCe

37

The after sales department with its experienced

staff is in charge of maintaining customer loyalty

by providing reliable service from the factory

as well as training their local agents and the

customer’s crew.

Raimondi CRanes cabins are equipped with

a remote supervision application. This innova-

tive system allows for real time supervision of

the cranes operations, to perform updates or

modifications of parameters and to check the

maintenance, all factors designed to improve

productivity and safety.

Raimondi CRanes offers a 3d spare parts

manual for easier identification of items and

designed to help address customer needs faster.

Raimondi CRanes strives to provide their local

agents with all necessary spare parts for the

units sold in their region in order to minimise

customer down time and as a further assurance

Raimondi CRanes spare parts department is

only a phone call away.

onCe aT WoRK

38

Two crucial aspects need to be considered when

purchasing a crane: the maximum handling rates of

the crane and its total intended use, also referred

to as “service life”.

While great importance is placed on the maximum

handling rates in the decision to purchase, too little

focus is placed on the assessment of the crane’s

service life.

When a component or an entire unit is excessively

overloaded, it will fail at once.

However, by far the more relevant damage of the

crane is due to use beyond its service life.

at Raimondi CRanes, cranes are designed and

manufactured under Class a4 as per the european

standards F.e.m. 1,001.

This standard of classification for cranes, estab-

lished by the european Union, measures the com-

bination of two factors: how long & to which extent

(percentage of actual exploitation of maximum

nominal load) the crane works.

Raimondi CRanes, Class a4 cranes have an

operative life twice compared to cranes of Class

a3, which are the majority.

maximisinG YoUR inVesTmenT

A4 FEM 1, 001

every cycle of work affects the life cycle of the crane

Ra

imo

nd

i W

oR

Ld

click cRANE

www.raimondicranes.com

RAIMONDI CRANES s.p.a.sede legale:Piazza Filippo Meda, 3 - 20121 Milano MI - Italy

sede operativa:Corso Garibaldi, 253 - 20025 Legnano MI - ItalyT +39 0331 548061F +39 0331 450400www.raimondicranes.com

progetto grafico: Metamorfosi imola Bo

fotografie: Giorgio Tamagnini Reggio emilia

Ricci Photo imola Bo

stampa: Tipografia Valgimigli Faenza Ra

stampato nel mese di agosto del 2010