Railway Strategies Issue 115 Final Edition

-

Upload

schofield-publishing-ltd -

Category

Documents

-

view

233 -

download

4

description

Transcript of Railway Strategies Issue 115 Final Edition

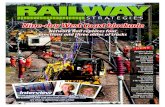

RAILWAYS T R A T E G I E Szzzzzzzzzzzzzzzzzzzzz

Issue 115 FINALF o r S E N I o r r A I L M A N A G E M E N T

New art commissioned for Tottenham Court

Road station extension

Winner of RICS Infrastructure

Photography competition announced

Battery powered train carries first passengers

Resilience planning

FOCUS ONInfrastructure

FOCUS ONPermanent Way

FOCUS ONStations

NEWS

Interview: FutureRailway’s

Marcus Mayers – building a strong innovation base P6

www.railwaystrategies.co.uk 1

ChairmanAndrew Schofield

Managing DirectorMike Tulloch

Editor Gay Sutton

Managing EditorLibbie Hammond

Editorial Designer

Jon Mee

Advertisement Designer

David Howard

Profile EditorLibbie Hammond

Advertisement SalesDave King

Head of Research

Philip Monument

Editorial ResearchersKeith Hope

Gavin WatsonTarj Kaur-D’Silva

Mark Cowles

AdministrationTracy Chynoweth

No part of this publication can be reproduced, stored in a retrieval system or transmitted in any form or by any means

(electronic, mechanical, photocopying, recording or other) without prior written permission being obtained from the publisher.

While every care has been taken to ensure the accuracy of the editorial content, the publishers cannot be held responsible for

any errors or omissions. Views expressed by the contributors are not necessarily those of the editor or the publisher.

Published by

Schofield Publishing Cringleford Business Centre,

Intwood Road, Cringleford, Norwich NR4 6AU

Email: [email protected]

Tel: 01603 274 130Fax: 01603 274 131

Much has been written, over the Christmas and New Year period,

about the chaos of engineering overruns, line closures and what

the media has dubbed the lack of effective contingency planning.

Engineering has always been a profession of problem solving, and there

are times when with the best will in the world engineers will be unable to

achieve the expected result in the timescale expected. How to deal with the

consequences, however, can make a huge difference to the outcome, and to

public opinion. It’s good to see that the industry is to formally review the timing

of engineering works, to reduce the impact of overruns.

While the options for managing overruns may be limited, good

communication and customer care are absolutely essential. In this issue, we

look at customer relationships from several perspectives. Turn to

page 27 for a fascinating opinion piece from Amanda Clack of the Royal

Institute of Chartered Surveyors. She talks about the surprising but basic lack

of understanding of the term infrastructure among the general public.

How can rail improvements gain public support if their significance is not

fully understood?

Meanwhile, Sam Russell describes some of the ground breaking work

London Overground Rail Operations is doing with its local communities, and

the impact this is having on passengers and staff. Finally, Richard Parsons

explores some of the latest tools for engaging and communicating with the

passenger across a wide range of channels.

If you have any comments or opinions on this or any of the topics we cover

in the magazine, please do get in touch: [email protected]

From the Editorzzzzzzzzzzzzzzz zzHave your details changed? Are you reading someone else’s copy of Railway Strategies?Please email: [email protected] to amend your details or request a regular copy

Issue 115 ISSN 1467-0395

Railway Strategies by emailRailway Strategies is also now available by email as a digital magazine. This exciting development is intended to complement the printed magazine, which we will continue to publish and distribute to qualifying individuals, whilst also giving added value to our advertisers through a more widespread circulation. To secure your continued supply of Railway Strategies in either digital or hard copy format, please contact our subscriptions manager Iain Kidd ([email protected]).

Public opinion

Features

Profiles

Interview - Marcus Mayers 6A radical new freight bogie is being funded by FutureRailways. We hear how it could form the basis of an exciting new rail innovation hub Gay Sutton

The art of communicating 12How communicating through multiple channels can improve the efficiency and quality of rail servicesRichaRd PaRSonS

Challenging traditional thinking 13Three important changes that could fundamentally improve safety on the railwaysJaSon PeaRce

Giving safety the green light 14The role research, training and best practice can play in improving safetyMaRy claRke

Learning from the airlines 16Tempting the passenger with offerings in comfort and service they simply can’t refuseniGel lawSon

zzzzzzzzzzzzzzzzzzzzzzzzzContents

7798

6

16

vonRoll casting 38 Craig & Derricott 40 Semmco 43 Taylor Woodrow 46 Nexus 49 IDOM 55 ADComms 58 B&M McHugh 62 Stadler Rail 66 GB Railfreight (GBRf) 70 Keyline 73 Cubic Transportation Systems (CTS) 77 Transport for London 81 FP McCann 86 Arriva TrainCare 92Bourne Steel 98

News

Focus on Stations Working with local communities 18

How London Overground Rail Operations works to be a good neighbour to the community – Sam RuSSell

Improving station accessibility 22Improving disabled access at railway stations, and the types

of handrail that are most cost effective – VeRnon BaRRy

Entering the jet age 24 The first station installation of a new jet thrust fan system

takes place at Birmingham New Street

Focus on InfrastructurePublic opinion is crucial 27

Resistance to infrastructure development was a problem even for Brunel. How we can we improve public opinion of

infrastructure investment? – amanda ClaCk

Configuring the future 28The mysteries behind the design, integration and

optimisation of modern mass transit networks – SiemenS

Sound: an infrastructure blind spot? 32Using sound creatively to improve comfort and behaviour on

the railways – GRaeme HaRRiSon

Mobility = greater resilience 34Mobile apps – a crucial tool for reducing the risk of

disruption this winter – CatHal mCGloin

Focus on Permanent way Gearing up for improvement 36

Intelligent electrical switchgear – delivering superior safety, reliability and performance – maRk BeSwiCk

Industry 4Infrastructure 10

Stations 21Rail Alliance 26

Appointments 31Conferences & Exhibitions 104

24

36

zzzzzzzzzzzzzzzzzzzzzzzzzContents www.railwaystrategies.co.uk

28

11 Cover story

24

zzzzzzzzzzzzzzzzzzzzz NEWS I Opinion

l From Lord Berkeley, chairman of

the Rail Freight Group and a board

member of the European Rail Freight

Association. The opinions expressed

here are his own.

The latest draft of the 4th Railway

Package (RP) from the Latvian Presidency

makes depressing reading. It is a pale

version of what the Commission started

with, a blueprint to revitalise Europe’s

railways, to introduce competition and

efficiencies, better customer choice and

private investment.

Since then, Angela Merkel summoned

the then Commission President Barroso

to Berlin and told him to alter the 4th

RP to allow the German structure, full

of allegations of unfair subsidies and

competition issue, to continue. He capitulated and introduced

a second best solution of a ‘Chinese wall’ to prevent such

abuses. Now France, losing passenger and freight traffic at

an alarming rate because of poor service quality and higher

charges, is reintegrating track and train to further obstruct the

Commission, and is joining Germany in opposing any attempt

to introduce competition and bring some efficiencies into

Europe’s creaking railway system. According to a recent article

in les Echos, there will soon be little of a rail network left in

France apart from regional services around major cities and the

still loss making TGV lines.

Both DB and SNCF are also suffering from competition from

new long distance coach services, whose staff do not get

the benefits of SNCF drivers who retire at the age of 50 on a

pension of their final salary. France’s solution to Europe’s rail

problems is to try to get all rail workers across Europe to have

the same benefits as its own featherbedded ‘cheminots’; this

is indeed an odd way of beating the road or air competition.

Germany does not want competition for passenger services,

and refused to allow competitors to sell tickets in DB booking

offices or machines, and neither operator will consider selling

or leasing unused passenger trains to competitors.

Italy, in urgent need to finance its inefficient rail system, may

float part of it on the stock exchange but will this inefficient

monopoly provide the low risk dividends that investors will

expect without falling foul of state aid or competition law?

Does all this matter? Is it important for Europe to have a

thriving rail network capable of delivering faster, more reliable

and cheaper services to customers?

The Commission thought it did; that is why it developed the

4th Railway Package to try to break the monopolies of

the incumbents as well as introducing common standards

and interoperability. Germany and France are killing it, by

Is obstruction by Germany and France forcing a 5th Railway Package on Europe to bring its railways rather belatedly into the 21st Century?

4 www.railwaystrategies.co.uk

requiring the dilution of legislation on fair

competition, so that their monopolies can

be preserved in perpetuity. No sensible

investor will risk putting money into

services in competition with these and

other incumbents who obstruct, obfuscate,

deny fair access to the network, and try to

hide the unfair and secret subsidies that

they arrange with their paymasters

or owners.

Why don’t other member states object?

One might expect the UK to lead this, but

the UK Government’s uncertain approach

to Europe does not add to its credibility.

How many other member states are free

from German pressure on their budgets, or

French pressure on social issue?

So I fear that the Latvian Presidency will

be browbeaten into accepting whatever Germany and France

dictate, and the next Presidency, Luxembourg, sandwiched

geographically between Germany and France, is rather unlikely to

lead the campaign for liberalisation.

Will the European Parliament save the 4th RP? It is new, and

there are some strong supporters of liberalisation there. However,

it can be much easier to accept the story that all is fine with the

railway – and one can always go by road or air. MEPs should

remember that monopolies are self-perpetuating, provide bad

service and high costs to their governments, and lose more

and more money, but have unlimited resources for fighting off or

buying up any competition whilst at the same time having their

begging bowl out for more and more state subsidy.

Nobody gains from this, neither the passenger or freight

customer, not in the end the featherbedded workers who, in the

end, will lose their jobs, as the more efficient road or air transport

takes the business. It does not have to be like this but, at the

present rate of progress, it will be, to the serious detriment of

Europe’s’ business and quality of life.

If you don’t want such monopolies, then you need fair

and open competition, separation of infrastructure from train

operation, strong and comprehensive regulation, and the will

to make it all work fairly; that is the only way to encourage

investment that Europe’s railway so desperately needs.

With an increasing number of press articles predicting the

slow death of many railways, is the 4th Railway Package the last

train to a competitive market, now departing almost empty of

passengers, freight – and hope for the future!

Roll on the 5th Railway Package, supported by a strong

political will to bring the single market, competition and

investment to this rail sector which, with few exceptions, instead

of looking forward, clings to a starry-eyed version

of history!

zzzzzzzzzzzzzzzzzzz zzNEWS I Industry

IN FACTh 5.8% The latest Passenger Rail Service

Satisfaction data to be published

by the ORR show that the rail

passenger complaint rate has

risen by 5.8% in comparison

with the same quarter last year.

Train service performance, which

includes punctuality, was the

leading cause of complaint.

28.3m record In the run up to Christmas, the

London Underground carried

over 28.346 million people in one

week. This broke the previous

record set during the 2012

London Olympic Games when

28.235m journeys were made.

Passenger numbers have risen

by a third in the last ten years.

38% at risk More than a third (38%) of travel

and transportation workers put

their health at risk by putting off

visiting the doctor, according to

a survey from the British Heart

Foundation.

39% said they had too much

work to do to take time off.

96.6% on time National Express train operator

c2c has been named the most

punctual train operator during

2014, according to Network Rail.

Across the year, 96.6% of c2c

trains arrived on time.

Meanwhile, the national average

was 89.6% punctuality.

Prototype battery-powered train carries its first passengers l The first battery-powered train to run on Britain’s rail network in more than half a century

has carried its first passengers. This marks an important milestone in the FutureRailway

project to demonstrate the viability of an eco-friendly Independently Powered Electric Multiple

Unit (IPEMU) for bridging the gaps between electrified parts of the network, and also running

on branch lines where it would be too expensive to install overhead electrification.

Successful retrofitting and trials were undertaken last year by Bombardier at test tracks in

Derby and Leicestershire. The modified Class 379 Electrostar battery-powered train is now

scheduled to run in weekday timetable service for five weeks between Harwich International

and Manningtree stations in Essex, operating as part of Abellio Greater Anglia’s fleet.

Network Rail Principal Engineer James Ambrose said: “After months of engineering and

testing, the train is running just as we would like it. We’ll be using this five-week period to

gather data on how it handles during passenger service – most travellers will recognise how

quiet and smooth the ride is compared to a diesel-powered train.”

Any future IPEMU would most likely be designed as a new train and not an adapted

unit, to minimise energy consumption, but this project will also provide useful

information for retrofit.

Partners working on the IPEMU project are: Network Rail, The Rail Executive arm of the

Department for Transport, FutureRailway, Abellio Greater Anglia and Bombardier.

Batteries Included - the

modified Class 379 Electrostar

carrying its first passengers

Hitachi training carriage arrives in the UK

Hitachi training carriage arrives in UK via the Port of Tynel A training carriage for the Hitachi Rail Europe plant in Newton Aycliffe, County Durham, has arrived in the Port of Tyne where it will be

stored before being delivered to the plant.

The part assembled train carriage, which was built at Hitachi’s factory in Kasado, Japan, will become the plant’s training unit. Hitachi Rail Europe’s

manufacturing plant manager Darren Cumner said: “The arrival of the training carriage is a significant step for Hitachi Rail Europe’s plans to train our

manufacturing staff. Apprentices, technicians and engineers will use this train carriage to gain in-depth knowledge of how to build trains. Shipping this

carriage via the Port of Tyne is testament to our commitment to working with local partners and promoting a strong local supply chain.”

www.railwaystrategies.co.uk 5

6 www.railwaystrategies.co.uk

zzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzz

T he UK rail industry has a proud history of innovation.

Although this has been through a period of stagnation, that

trend is being reversed. An essential element in this is the

FutureRailway initiative, a collaboration between Network

Rail and RSSB working with the rail industry and the supply chain to

accelerate research and development.

While it has been many years since bogie design and development

has flourished in the UK, a new knowledge-base of engineers and

facilities is being drawn together to test and develop a radical new

concept in bogie design – currently known as the radial freight bogie.

In the beginning.... Like so many radical new concepts, the radial bogie began life as an

idea that was batted around among engineers – people whose lives

revolve around problem solving. In many such situations, the enormous

costs and risks of developing an untried idea means it has very little

chance of progressing into a concept stage let alone through the

INTERVIEW I Marcus Mayers

A radical step?Marcus Mayers talks to

Gay sutton about progress in developing an innovative

new radial freight bogie, and the prospects for

building a strong bogie innovation hub in the uK

demonstration stage to a fully fledged marketable product. And this is

where FutureRailway plays a significant part in bridging this gap.

In February 2013, FutureRailway launched a new initiative called

the Radical Train Competition. “The idea behind this competition,”

explained Marcus Mayers, programme & portfolio manager,

FutureRailway, “was to ask suppliers to bring us any ideas that could

improve the quality of rolling stock or enhance the UK’s capability in

rolling stock.”

The radial freight bogie, a new idea in track friendly bogies, was just

one of 57 concepts to be proposed.

Moving forward

To progress these ideas to the point where winners could be chosen for

funding, FutureRailway organised a collaboration day, bringing together

those who would like to enter the competition with a wide range of

universities, entrepreneurs, SMEs and large companies who could

potentially partner with them to support and part finance that aim.

www.railwaystrategies.co.uk 7

zzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzz

Innovations are being sought to improve ticketing and gatelines

It was at the Leicester Space Centre that the freight bogie’s designers

linked up with Huddersfield University which has expertise in vehicle

dynamics and the wheel rail interface, and a forward thinking export,

sales and marketing organisation, Holdtrade UK.

“And this is where the radial freight bogie is distinct. Holdtrade UK

had a number of customers including South Africa’s Transnet who had

expressed a pain,” he continued. They were all experiencing similar

capacity and track damage issues, but there were no solutions for it in

the marketplace. “Holdtrade UK’s thinking was that if they could support

the development of a new solution to deliver more profitable freight

movement then they could sell it into the market.”

The radial freight bogie had the potential to fulfil that need, by reducing

damage to the track when carrying freight, and increasing the capacity

that could be carried per wagon. Not only could this work very well on the

lower quality heavy haul freight track in South Africa, it could have other

applications such as super heavy haul in Australia.

As a result of that event, the original design team formed a partnership

with Holdtrade UK and Transnet, along with Huddersfield University and

the project went on to became one of six to win funding and support

from FutureRailway. By the end of 2013, following a technical review that

indicated that the proposal could work, the complex contracts between

the partners had been thrashed out and signed.

Building the knowledge base

The first three months of 2014 were spent recruiting a full complement

of skills to build a strong design team based in Wales, a team that could

form the foundation for a bogie design hub for future innovation in the UK.

That time seems to have been well spent. The bogie design is currently at

Huddersfield University being iteratively modelled, tested and refined.

“A key lesson we’ve learned from this,” Marcus said, “is that innovation

projects can take longer to set up than traditional projects, due to the

risks and level of understanding.” The next step is to manufacture the

bogies here in the UK and begin non-destructive testing on them. Once

all parties are happy with the results, the bogies will be sent to South

Africa where they’ll be fitted to wagons built specifically for the project

by Transnet, and then tested on a 1067mm narrow gauge manganese

freight line, to an extent we simply could not achieve here in the UK.

“South Africa has the largest narrow gauge freight railway in the

world, stretching some 27,000 km,” Marcus said. “They have huge

manufacturing capability, and an approvals process that is simpler than

anything in Europe. The question they will be asking is: does the radial

freight bogie move more freight more efficiently than current bogies and

will it be financially worth buying?”

If the testing is successful, there will be a significant market for the

product in South Africa with Transnet, but there have already been some

tentative approaches from other African countries.

A radical idea?

So is the new freight bogie really a radical idea? For obvious reason,

Marcus could not describe the bogie in any great detail. It is still going

through the patent protection process. However he was able to say:

“We believe it’s a really excellent idea, one that is likely make a significant

difference in the world of freight. And if it’s successful in South Africa, then

the second or third iteration will be for standard gauge, and could make a

significant impact here in the UK. It’s a concept that could also be applied

to passenger vehicles in due course, but of course that market is very

different to the freight bogie market.”

Marcus Mayers, programme & portfolio

manager, FutureRailway

8 www.railwaystrategies.co.uk

zzzzzzzzzzzzzzzz

Why promoting innovation is important

“This entire project will cost upwards of £1 million,” Marcus explained.

“If the original design team had had to finance this, the project would

never have got off the ground. Demonstrators are expensive, and there

are always significant risks involved.” However by sharing the costs

and risks, and ultimately sharing the benefits and rewards, there is a

much higher likelihood that innovation can be followed through

to market.

In this instance, FutureRailway is contributing 45 per cent towards

the total cost. Transnet will fund around 25 per cent of the cost, the

majority of which will go into constructing the wagon that will be fitted

with the new bogie and then testing it extensively on South Africa’s

heavy railways. The remaining contributions to the project will be made

by the design team and Holdtrade UK. Meanwhile, in line with EU

regulations, Huddersfield University will be able to recoup some

80 per cent of their expenses from partnership and fund the remaining

20 per cent of their costs themselves.

Benefits to each partner

Each of the project partners has signed up to an agreement that

defines the terms and conditions, deliverables and benefits. One of the

conditions is that the innovation must be delivered to the market. “So

we’re tying them to the yoke of commerciality,” Marcus said. Holdtrade

is currently building its business model for marketing the end product.

And as a company with no manufacturing base, it has two options

for marketing the product: selling the third party manufactured

bogies around the world, or selling interested companies the unique

constituent components and the licence to manufacture the bogies.

INTERVIEW I Marcus Mayers

“That’s where the money will be,” Marcus said. “And then the profits will

feed back into what will become a new bogie R&D business based

here in the UK.”

From FutureRailway’s perspective, the aim is to bring innovative

products to market. “We take IP very seriously, but we don’t want

to own it.” The ownership of the IP is defined in the initial contract,

and FutureRailway merely asks for a percentage royalty which is then

reinvested into further projects. The aim ultimately is to build a strong

R&D base here in the UK which can continue to innovate, delivering new

and exciting products to the rail network, and bringing financial rewards

to the economy. The bogie design team is just one element of that. “We

want to see innovators succeed as individuals and organisations, and go

on to spread their wings and do great things.”

Revelations...the innovation DNA

As an enabler to innovation, Marcus had some interesting observations

to make, and a plea for everyone to start questioning. “Innovation in the

rail market is only as good as the ideas people come to us with, and

ideas that people are willing to buy,” he commented. “We exist by the

good grace of the supply chain and the people who operate railways.

Without their engagement and involvement there is no place for a

FutureRailway in the railway industry.”

Looking at this project individually, it’s all too easy to think of innovation

as a one off idea. It’s not. “Innovation is about DNA. It’s about waking

up in the morning and thinking about what you do, asking is this really

the right way to do it, or is there a better way? Very often it’s identifying a

pain people don’t realise they have. That’s where this radial freight bogie

is a very good example. It’s a different type of thinking which I would

encourage people in the railway industry to adopt.” zz

A Transnet freight train in South Africa

zzzzzzzzzzzzzzzzzz NEWS I Infrastructure

10 www.railwaystrategies.co.uk

l A stunning photograph of rail tracks, taken from The Shard, has won The Royal Institution

of Chartered Surveyors’ inaugural RICS Infrastructure Photography Competition. Launched to

champion the importance of major infrastructure projects to British society, the competition was won

by Rita Tesa with her photograph, Double Travel. The photo beat nearly 300 other submissions.

Of the winning image, associate director at WSP and chair of the judging panel, Roma Agrawal

FRICS, commented: “This photo is what infrastructure is all about - providing transport on top of a

busy city. We just loved the dynamic nature of this image, captured at the perfect time as the trains

pass each other.” See page 27 for comment on the competition.

The winning photograph, Double Travel

Rail image chosen to improve public perception of infrastructure

l Product Innovation Ltd has developed a

product that measures the movement of a

rail or sleeper in real time.

Network Rail were looking for a Void

Meter to fit in with their new Intelligent

Infrastructure system and approached

Product Innovation having seen an old

design on the company’s website. Once

alerted to this interest Product Innovation

reviewed the design and decided to

produce a completely new one using the

latest technology.

The new Void Meter was developed and

a prototype built before the first meeting

with Network Rail. They were impressed by

the design and ordered prototype samples,

the first of which was installed at Witham

in July 2014. Since then six more samples

have been supplied.

Peter Frank, the CEO of Product

Innovation says: “The new concept is

beautifully simple and uses modern

electronics in a way that was not possible

in the past. The sensing of position uses a

Hall Effect microchip that allows us to totally

encapsulate the electronics. We believe this

is a significant technological development

and have applied for patents.”

Smart sensor

Phase completel At 07:16 on Monday 15 December, Siemens

Rail Automation successfully completed Phase

Two of the Great Northern Great Eastern (GNGE)

programme, with the Auckley and Beech level

crossings being signed into use. This work

represented the final delivery stage of the GNGE

project for Siemens and the conclusion of the two

year programme.

Bringing a significant upgrade to this double-

tracked line, the GNGE programme is an integral

part of the East Coast Main Line (ECML) Capacity

Relief Project. The programme enables freight

trains to achieve the equivalent average journey

times using GNGE rather than the ECML, such

that it will become the primary daytime route for

freight traffic. By diverting traffic from the ECML

to GNGE, a significant number of paths can be

released for additional passenger services.

Rob Cairns, Siemens’ Delivery Director for the

Central East region, noted: “With 37 new level

crossings, the demolition of 25 signal boxes and

the renewal of seven interlockings, this has been

a technically complex and logistically challenging

programme.”

Twitter reveals the ‘most hated’ train providers l Railway companies have received hundreds of thousands of complaints for poor services

from long-suffering commuters, according to a new report developed by Commute London,

a group of data scientists.

The new report entitled Twitter Trains of Thought analysed 1,778,090 Twitter interactions

with 14 leading railway Twitter feeds throughout 2014.

The most talked about was First Great Western which received 265,201 tweets closely

followed by Virgin Trains at 257,254 and Greater Anglia with 241,038.

l There were 70,969 tweets directed at the 14 rail feeds using cancellation language,

an average of 5,069 per handle including words like ‘cancel’ ‘replacement’ and ‘bus

replacement’.

l 280,960 tweets used delay language including words like ‘delay’ ‘late’ ‘stuck’

l 62,352 tweets captured included overcrowding language such as ‘crowd’ ‘sardine’ and

‘no seat’

“Our analysis shows that the train companies need to make much better use of their Twitter

feeds if they wish to keep customers happy by listening and learning from criticism,”

said Daren Wood, director, Commute London.

Hong Kong’s new metro extension goes into operation l The extension to the MTR Island Line in Hong Kong was officially opened on 28 December

2014. Running for 3.3km westwards, the West Island

Line connects Sheung Wan station to the three newly-built stations of Sai Ying Pun, Hong Kong

University (HKU) and Kennedy Town. It now takes only about seven minutes to travel the length of

the extension compared with the 30 minutes it used to take by bus.

www.railwaystrategies.co.uk 11

Netw

ork

Rail

zzzzzzzzzzzzzzzz zzNEWS I Infrastructure

l In December the Rail Delivery Group (RDG)

published a 10 point plan setting out how the

industry would make track and trains more

resilient to adverse weather conditions this

winter, and ensure passengers are better

informed during disruption.

Operators and Network Rail have learned a

considerable amount from the extreme weather

of last few years, and used this knowledge to

develop measures to improve the network’s

resilience to snow, ice and flooding, and to

improve customer care.

Trains:

l Fitting some trains with snow ploughs,

hot-air blowers, steam jets, brushes, scrapers

and jets for heated anti-freeze and compressed

air to de-ice tracks. Heated skirts for trains

running in colder parts of the country

l Thorough checks of standard train features,

including coupler heaters, door seal grease, fuel

tank heaters and horn heaters

Tracks:

l Empty trains will run through the night in

key areas as temperatures fall, to help keep

tracks clear. Freight proving trains will run in

the mornings following adverse conditions to

ensure routes are clear

l Network Rail has expanded its winter fleet

to include 14 snow ploughs, 10 snow and ice

treatment trains, two snow blowers,

25 locomotives fitted with mini snow ploughs

(10 more than last year) and 24 multi-purpose

vehicles (14 more than last year) with

de-icing capability

Winter weather on the railway

How the industry has increased resilience to bad weather this winter

l Anti-icing fluid and heating strips are used

on live conductor rails to stop ice building up.

Heating strips in key locations have reduced

ice-related incidents by up to 80 per cent

l Flood defence systems are on standby,

including inflatable barriers to protect tracks

and vital equipment from flood water

l Heaters and NASA grade insulation have

been attached to critical points to prevent ice

l Protective covers have been added to

4,000 points and 2,500 points motors, to

keep snow out and prevent damage by ice

falling from trains

l Remote temperature monitoring is in place,

and a helicopter fitted with thermal imaging

cameras is on standby to identify points

heaters that are not working effectively

Stations and depots:

l Ensuring depots and stations have enough

salt, shovels and de-icer supplies

l Preparing specialist equipment such as hot

air blowers and steam jets at depots

Staff:

l In times of severe disruption, staff will be

based at strategic places to provide rail users

with information and advice, and ensure full

depot staffing, even where some staff are

unable to get to work

l Thousands of staff will patrol the network

round the clock in times of extreme weather,

clearing snow and ice from junctions

and tunnels

l When flood warnings are received from the

Environment Agency, staff and equipment will

be sent to at risk areas so preventative and

mitigation measures can be put in place

Information at stations:

l A multimillion pound project is underway to

display consistent information at stations, on

websites and on apps. Around a third of the

country’s stations are now connected to the

same single real time information feed

Early information about changes:

l Revised timetable information can now be

fed into customer information systems more

quickly. New timetables can be in place the

evening before enabling passengers to plan

their journeys for the following day

Utilising social media:

l Operators, Network Rail and NRE are

increasingly using social media to keep

passengers informed, including answering

real-time queries, publicising updated travel

plans and travel information, sharing images

of what has caused a delay, and showing

progress in efforts to get people moving again

Explaining delays:

l The industry has developed explanations

of common causes of delays, which are now

publicised at stations, on websites and social

media, especially during times of disruption

Information on compensation:

l Train companies are doing more to

remind delayed passengers how to

claim compensation including: more train

announcements; posters at stations with

smartphone barcodes; information on

platform screens; handing out claim forms

on delayed trains; tweeting links to claim

forms; making information more prominent on

websites during disruption; and sending email

reminders to passengers.

A spokesperson for the Rail Delivery Group, representing operators and Network Rail, said: “While most parts of the country have not seen particularly severe weather this winter, there have been localised events such as freezing conditions in Scotland and issues with ice affecting the conductor rail in coastal areas. The preventative measures the industry had in place meant that disruption to passengers was minimised on the vast majority of these occasions. But we will continue to assess each weather related incident to look at how we can further improve our mitigation plans and actions. Providing passengers with accurate and timely information, particularly during disruption, remains a key focus for Network Rail and operators. More than half of all stations are now connected to the same single real time information feed, and in the coming months train companies will be publishing individual plans to improve customer communications.”

According to the Association of Train Operating

Companies (ATOC), there are a million more

trains and half a billion more passengers each

year compared to a decade ago. The ATOC’s

most recent data report from its LENNON database

showed over 140,000 more journeys were made in

the six months to September this year than during the

same period in 2013. The company forecasts that

by 2020, an additional 400 million journeys will be

made by rail.

And it’s not just the growth of passenger numbers

that has seen the railway industry experience such

consistent and significant growth – the freight industry

contributes £870 million to the UK economy alone and

supports an output of £5.9 billion.

Responding to growing demand is an exciting

challenge for the rail industry, but innovation is key.

Punctuality, performance, efficiency and safety – all

crucial deliverables – have to be reviewed alongside

capacity levels. A process that worked a year ago may

no longer be the most effective way to maintain quality

of service.

Making those vital improvements

Improving infrastructure is an important step – for

example Network Rail is spending an average of

£27 million a day on improving services to create

increased capacity to carry extra passengers. It hopes

that by 2018, 2,000 more carriages will be available,

generating almost a third more peak time places

into major cities and 20 per cent more commutes in

and out of London by the end of the decade. These

changes will allow passengers more flexibility with

travel times and reduce crowding in carriages, allowing

Network Rail to improve service levels.

Providing a good experience is crucial alongside

comfortable and convenient travel, but there are also

other elements to consider when reviewing ways to

engage and retain customers.

Whether it’s providing offers, live service information

or online surveys, drawing in passengers through

digital platforms can help to engage customers

and generate increased revenue. For instance, the

convenience of being able to book advanced train

tickets through online booking apps and websites

is an attractive prospect for passengers who may

be time poor. KPMG found discounted fares now

account for almost half of consumer sales, an

increase of 36 per cent since 2004.

Driving customers to websites is beneficial for

rail companies who use customer relationship

management (CRM) systems. This tool allows

companies to glean data from customers at every

stage of connection – from areas of the website they

have visited, to previous telephone conversations

with business representatives. For rail businesses,

this includes promoting offers – such as discounted

tickets – to regular customers to encourage further

travel and loyalty.

Where information gathering already works well The use of CRM systems can also improve safety

and efficiency for both staff and customers in the rail

industry. For example, there are some 6,500 level

crossings across Britain – many in rural areas on

private land where users must operate the

crossings themselves.

As a key safety measure, users must register

with Network Rail and contact them before using

crossings for the first time. The company has a vital

database of authorised users and must regularly

communicate with them by SMS, phone and email

in order to keep registered users informed of safety

issues, maintenance work and much more.

To manage this, developers at Experience Assist

have configured a sophisticated new CRM system

for Network Rail, allowing the company to keep

track of all of its outbound communications.

Similarly, Cross Country Trains has improved

business performance through the use of CRM.

Introducing new platforms such as the use of

tailored screens and automation for telephone

inbound enquiries has reduced staff overheads

by 25 per cent and helped to deliver a more

personalised service whilst increasing

capacity levels.

As the industry continues to develop and grow, it

is vital rail companies sustain customer engagement

and continue to improve health and safety efficiency

levels through the use of the most efficient and

collaborative tools available. zz

The art of communicating

12 www.railwaystrategies.co.uk

Richard Parsons is commercial director at

Experience Assist

RICHARD PARSONS discusses how the efficiency and quality of rail services can be improved, and customer demand further increased, by communicating through multiple channels

Customer Relationship Management zzzzzzzzzzz

www.railwaystrategies.co.uk 13

Since Mark Carne took over as Network Rail’s

CEO in February 2014, he’s not pulled any

punches where safety is concerned. Describing

the level of health and safety incidents among

staff and contractors over the last five years as

‘unacceptable’, he has sent a very clear message to

everyone within the rail sector.

The Government’s commitment to funding £38 billion

in rail over the next five years will bring inevitable health

and safety risks. While this is one of the most exciting

periods of growth in the UK’s rail infrastructure, the

industry needs a properly educated and disciplined

workforce to cope with the unprecedented demands

and pressures to deliver projects on time and

within budget.

Putting safety firstThe statistics do not make good reading: rail workforce

fatalities have risen consistently since 2010/11. Mark

Carne must be supported for his radical plans to ban

staff who aren’t directly employed by Network Rail from

holding safety managerial roles. It’s a strategy more

of the industry needs to follow and one we are driving

within our business.

Building strong relationships with our supply chain

and avoiding transient subcontractors, minimises

delivery and safety risk. Within our business model we

seek to ensure teams work closely together and build

a level of trust with one another. We have a very high

proportion of directly employed staff who in my view are

more engaged within the company culture and values.

That’s not to say there isn’t a significant challenge with

a policy like this: the industry is increasingly people

challenged, and typically has long gestation periods

between orders when it may be carrying a heavier

fixed employment cost.

Fundamental changes to the way the controller

of site safety (COSS) role will operate, supported by

massive training commitments from Network Rail must

be actively supported by everyone. 30,000 days of

delegate training completed this autumn by Network

Rail and briefings for 200 contractors, are a major step

in the right direction.

Network Rail has set a clear direction for safety on

the railways. The challenge facing contractors is how to

respond and act accordingly. Alongside Network Rail’s

initiatives, I believe there are three other areas where

rail contractors can focus efforts to actively support our

industry to achieve world-class levels of safety.

Challenging traditional thinking

The important trioFirstly, we need to recognise the impact that mental

health can have on people’s performance. Secondly,

we need to build more collaboration amongst

contractors to ensure that best safety practice is always

shared. Lastly, we need to embrace technology even

more to keep our people safe, especially lone workers.

In June 2014 the ORR published a paper on stress

in the rail industry, and this recognised that one in four

people in the UK are now affected by mental health

problems. The risks associated with unwell individuals

working in a high safety risk environment are significant.

The ORR’s proposed management approach is to be

applauded. The very fact that the problem has been

openly recognised marks a watershed in the industry.

Mental health issues in the workplace are real. As

all industries seek more businesses, we need to work

smarter and introduce the environment, systems

and methodologies that actively support individuals.

Culture within organisations usually cascades from the

boardroom, and contractors of every size must ensure

that occupational safety, including mental health safety,

is part of their DNA.

Sharing best practice is another big challenge for an

industry that has tended to operate in silos. That mind-

set simply has to change. Sectors such as the airlines

and defence have shown that collaboration delivers

significant benefit, including driving improved safety.

Network Rail are leading on collaboration, but the rest

of us must now adopt more open dialogue, sharing

health and safety best practice.

Finally, technology has a huge role to play in

making trackside working safer, dramatically cutting

down on paperwork and manual errors that can

lead to incidents.

IPS has adopted the use of iPads when working

on London Underground projects, streamlining safety

procedures and making arduous paper exercises far

more efficient. The use of this popular technology

means worker adoption has been high, which is

especially useful for lone workers operating

out of hours.

The ORR has taken a firm stance on recent health

and safety failures among contractors. And this robust

approach will quite rightly remain in place for some time

to come. We all have an important job to do to bring

the UK Rail industry to best in class, but putting

safety anywhere else but the top of the agenda just

won’t work. zz

JASON PEARCE, managing director of rail telecoms specialist Alan Dick Communications, believes contractors need to challenge their thinking

as part of the key role they have in improving rail safety

Jason Pearce

Health & Safetyzzzzzzzzzzzzzzzzzzzz zz

14 www.railwaystrategies.co.uk

Britain’s railways are among the safest in the world.

Indeed, last month it was reported that a British

team will help China to develop a health and

safety culture after a series of fatal accidents.

However, a series of impending challenges look likely to

test our ability to maintain that enviable reputation.

The rise in passengers is putting huge pressure on

the network. Overall numbers rose by 5.7 per cent to

more than 1.5 billion passenger journeys in 2013-14.

Meanwhile, the Office of Rail Regulation’s (ORR) latest

safety report highlighted the challenges of managing

record passenger levels and called for better

infrastructure management. While Britain’s railways

continue to have one of the best safety records in Europe,

the report showed that workforce safety remains a

significant challenge.

The report outlined the growing trend in track workers

being injured. It reached its highest level in seven years,

with 79 workers suffering serious injuries and 1,641

reporting minor injuries. There were also three rail workers

deaths in the past year. An increase in the number of

signals passed at danger (SPADs) is another worry

for the industry.

A recent report by the Rail Standards and Safety Board

(RSSB) found that the number of SPADs rose by

17 per cent during 2013-14, with 293 reported incidents,

compared with 250 in 2012-13. At the end of the 2013-14

the estimated level of risk from SPADs was 73 per cent of

the September 2006 baseline, compared with 60 per cent

at the end of 2012-13.

The Office of Rail Regulation has approved more than

£250 million in funding to improve protection and warning

systems for track workers. But what can rail companies do

to improve health and safety?

Improving standards as rail travel risesLook into the future and Britain’s railways will become

busier and busier, with unprecedented growth expected in

both passenger numbers and freight. Network Rail plans to

spend £37.5 billion on running and expanding the railways

over the five years to 2019. If approved, this investment in

new infrastructure will make a real difference by boosting

capacity at pinch points on the network and providing

170,000 extra commuter seats at peak times by 2019.

Statistically, the risk of having more accidents is likely to

increase. Rail companies need to do more now to ensure

they can maintain and improve their health and safety

record to cope with this growth. One accident is one too

many, and one signal passed at danger is another disaster

waiting to happen. And incidents like this have the potential

MARY CLARKE examines how research, training and best practice can help rail companies keep their employees and customers safe in the face of growing

pressures on the network

Mary Clarke, CEO, Cognisco

Giving safety the green light

zzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzz Health & Safety

www.railwaystrategies.co.uk 15

to cause crashes and derailments that could lead to

serious injuries and deaths. Human error is most

often the cause.

Helping change behaviour One of the things rail companies can do is spend more

on research into why human error occurs and adopt a

safety culture that minimises these risks. They should also

improve employee competency and ensure staff comply

with regulations at all times. It’s not as simple as just

holding a record of employee certificates and licences.

Managers need to be confident that their staff fully

understand their role and the latest safety procedures and

work within the expected safety guidelines.

Passing a red light is likely to be down to human error.

Rail companies need to understand why a driver made

the wrong decision – what made the driver make this

decision. It could be an error of judgement, a lack of

knowledge or a lapse in concentration. There is also the

chance that it was intentional – as can happen on the

roads when a driver takes a risk when the traffic lights are

changing. Maintaining a consistently competent workforce

is crucial to reducing exposure to risk.

All rail companies must have formal competency

management systems in place to maintain and assess

their workers’ skills. Such systems identify currently

qualified staff regardless of location and can rapidly build

and deploy new teams with the right skills and experience.

These systems also flag up forthcoming assessments

or licensing requirements. That is essential to ensure the

organisation is compliant with industry regulations.

Developing a health and safety cultureRail companies can also develop a health and

safety culture that all employees follow and respect.

Organisational culture not only drives how people behave,

but also their attitude towards taking risks. A driver

who thinks they have just enough time to get through

a red signal may reconsider if they understand the

consequences.

Companies must first identify why drivers may be taking

dangerous risks and then provide tailored training and

targeted intervention to educate drivers, and discourage

risky behaviour. Leaving things like this unchecked and

not clearly understanding the human behaviour behind the

statistics is unlikely to help reverse the trend of passing

signals at danger.

A critical part of creating the right culture at work lies in

being able to identify and document how people behave

in their roles, and their engagement and understanding of

the embedded processes. Managers need to understand

employees’ likely behaviour, current knowledge and

competence, understanding and confidence.

Every employee must be clear about what the company

expects from them – how they should behave at work,

how they should treat customers and the kind of actions

that are acceptable. Companies need to measure this

regularly to understand what employees are thinking and

how they are acting at work. By measuring people’s level of

understanding of their jobs, their likely behaviour in different

work scenarios and how confident they are in making

decisions, it will soon be clear if there are any gaps.

Using this knowledge, companies can offer more

targeted interventions to close the skills gaps and

help people to change for the better. It’s about offering

encouragement, setting out the right way to do things at

work and taking steps to ensure it happens.

New processes alone aren’t enough to improve safety,

however. Rail companies also need to know how well

employees understand the processes and if they will follow

them. Companies must have tools that will measure and

assess employee behaviour and risk. Without these tools,

it’s difficult to make lasting health and safety improvements.

The only way rail companies can improve their safety

record is to adopt a best practice approach to employee

assessment, invest in tools which provide transparency

and visibility around what individuals know and understand,

therefore ensuring staff are competent and unlikely to take

unnecessary health and safety risks. Taking these steps

will help Britain to meet the safety challenges posed by

the increasing popularity of its railways and pre-empt any

arising safety issues. zz

Safe practice in action

Historic light on go. Some of these lights are still operational on the network

Track workers 2013/14 l 3 rail fatalities l 79 major injuries – a seven year highl 1,641 minor injuriesl 17 per cent increase in SPADsl Risk of SPADs 73 per cent

zzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzz

16 www.railwaystrategies.co.uk

In October 2014, staff of airline Flybe were questioned

by police for leafleting at Exeter St David’s train station

in the South West. The airline had recently launched

a route to London City airport from Exeter and staff

were promoting this at the railway station. This small

scale spat exemplifies a wider issue. Where once air and

train travel were seen as complementary, they are now

also competitive. And shortly, with the development of

Crossrail, HS2 and the announcement of HS3, alongside

the growth in regional airports across the UK, this trend is

likely to continue.

The Airlines’ strength: monetising passengersAirlines have traditionally been very strong at monetising

the space in an aircraft. While the majority of the space is

allocated to economy travellers, airlines have been very

successful at upselling passengers, using the benefit of

extra space and enhanced facilities to significantly increase

the revenue that they can command from a customer.

Airlines have traditionally offered at least three classes of

travel – effectively branding the same product (travel from

A to B) with different values to attract different groups of

people. More recently many airlines have also bridged the

gap between economy class and business with Premium

or upgraded economy, offering additional choice to

customers and upselling the proposition.

This is something that the rail industry is poor at. Despite

the fact that airlines and railways are competing head

to head on an increasing number of journeys, railway

Learning from the airlines

operators have simply not embraced the concept of

offering incremental benefits for additional services on the

same journey.

First class: limited interestIn the rail industry the choice for passengers is first class or

standard class. Unsurprisingly, most passengers choose

the standard option. In a survey conducted by The Daily

Telegraph in 2013, only East Coast railways were prepared

to disclose the proportion of first class seats sold: an

average of 40 per cent.

This suggests that not only is the railway industry going

about the way in which it offers different seats ineffectively,

but that resources are being wasted at exactly the same

time as overcrowding is blighting standard class carriages.

To resolve this, railway operators need to rethink the

experiences that they are offering passengers.

A pathway to upgradeOne thing that the airline industry has done effectively

is to offer passengers simple ways to spend more. Very

broadly a premium economy flight costs around double an

economy flight. This, combined with loyalty points that can

be used for upgrades, enables airlines to make upgrading

to the next class affordable and a treat. Whilst train travel

takes a similar approach to the differential in cost, the

difference in experience is nothing like as marked as within

an airline.

If the railway industry is serious about improving its ability

to offer different experiences within the same journey it

The railways have a way to go if they are truly to compete with the air travel. NIGEL LAWSON reveals how the airlines have perfected the art of tempting the

passenger with offerings in comfort and service they can’t refuse

Nigel Lawson, director, Acumen Design Associate

Service zzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzz

The Etihad Business Studio – with paired reclining seats and flexible privacy screens

www.railwaystrategies.co.uk 17

would do well to consider how the airline industry

has achieved this.

First, by providing multiple classes, the airline industry

is able to encourage almost any passenger to look at the

next most expensive experience. Additionally, the airlines

make these experiences desirable. The airlines have taken

on board new developments in air travel experience. For

example, Acumen worked with BA in the mid-1990s on

the development of fully flat beds. Since then these have

been rolled out to more and more classes over time.

Thus an experience that used to be exclusive to first class

passengers is now commonly incorporated into business

class, driving achievable aspiration for passengers.

The challenge for rail operators is to achieve a similar

environment: one where there is a genuine reason to

upgrade and one that encourages people to take the

next step.

The next development for rail operators is to provide

modular carriage layouts for different classes of travel.

For example, there may be a first class layout for high net

worth individuals, a business class layout for those that

wish to get work done. Because, particularly in school

holidays, so many families travel, it makes sense to develop

family friendly carriages.

The key to this approach is flexibility. Airlines can add

additional business class rows in certain aircraft and the rail

industry needs to think along the same lines – having the

flexibility to change the configuration of a train quickly and

easily to suit different times of day and different audiences.

Smart use of spaceAirlines are incredibly savvy at using space in the most

efficient and effective way. They recognise that providing

people with more personal space and privacy on a journey

has value that can be monetised. Rail operators need to

become much more focused on this area. Simple changes,

such as clustering two reclining chairs together enable

passengers travelling together to enjoy a more private and

personal journey.

Flexible privacy screens enable passengers to control

their intimacy with others when the suites are shared by

strangers. By using techniques common in the airline

industry it is possible to generate more paying spaces on a

train yet also provide more personal space to

each passenger.

Creating an experienceAirlines recognise that, while their job is to safely transport

their passengers from one place to another, a large

number of small but important non essentials make up the

customer experience – from the quality of the coffee to

the ease of booking. Airlines work incredibly hard on these

experiences to build brand loyalty.

Despite an increasing number of long journeys taken

on railways, facilities are still generally quite limited in

advance of the journey and on-board. Staples of the airline

experience (such as reclining seating, at seat refreshments,

dedicated lounges, luggage storage and dining options) are

all limited, and more recent developments in air travel such

as dedicated check in and complimentary travel to and

from departure are non-existent. Rail operators are missing

opportunities to engage with their customers and deliver an

experience rather than a mundane journey.

Even supermarkets are embracing complimentary hot

drinks for loyalty programme customers – recognising that

anything that makes the experience of shopping more

pleasant will drive loyalty and engagement. Rail operators

need to be thinking in the same way – is there less value in

selling someone a £1.95 cup of coffee rather than giving it

away as part of the experience.

ConclusionRail operators could monetise their space far more

effectively by learning the lessons from the airline industry’s

cut throat competitive space. Rail operators need to give

passengers more choice – from family friendly carriages

to luxurious first class suites, through business lounges

and beyond. Designing carriages so that they can quickly

transform from one need to another is critical here. Details

matter: from the complimentary newspaper or coffee to fully

reclining seats, the airline industry knows the importance

of the experiential journey. Finally never forget the critical

non essentials: whilst an airline knows that success

constitutes everyone arriving in one piece, it never forgets

the importance of the experience in the sky. zz

zzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzz

Below: Delta’s Cirrus on the 747 – illustrating how angled layout can provide both inherent privacy for outboard passengers and a social-yet-flexible arrangement across centre seats

18 www.railwaystrategies.co.uk

T he London Overground links 21 of London’s

33 boroughs and provides an orbital service

around the capital, carrying over 455,000

passengers on a typical week day. However it is

the reach and variety of these community stakeholders that

makes engagement with them not only rewarding but also

particularly challenging.

LOROL’s response to this challenge has been to create a

community focused strategy that links up staff-led initiatives

and existing methods of engagement with our wider

corporate social responsibility agenda. This means that as an

organisation we have been able to make significant progress

in establishing long-term links with the communities that are

linked to and interested in the Overground.

Within LOROL, the overall responsibility for external

stakeholder engagement sits with the concession director.

But within this directorate, the specific role of stakeholder

& community manager enables the business to lead on

promoting and developing engagement with our community,

Working with local communities

something that includes LOROL’s direct neighbours, the

communities that use or live alongside railway operations,

and key groups in the communities we serve such as

schools and local societies.

A strategic view of community engagement As an organisation, we are moving towards creating a

strategic view of our impact on society and attempting

to define the benefit that we bring to our community

stakeholders.

Under our Concession Agreement with Transport for

London, we are contractually obligated to engage with our

community via a Passenger Group – with which we meet

every three or four months. Our Passenger Group brings

together individuals and rail user groups from across the

network to discuss the latest news about LOROL, with a

particular emphasis on forthcoming project work and

an acknowledgement and discussion about

performance issues.

Sam RuSSell, stakeholder & community manager at london Overground Rail Operations talks about the challenges, rewards and importance of

working closely with the railway’s local communities

zzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzz Stations

Acton Central, Overground in Bloom

The station garden at Norwood Junction

www.railwaystrategies.co.uk 19

has certainly added value to the community. Whenever

we are working either on the platform planters or in the

forecourt, people stop to compliment us and say what a

difference it makes to their experience of the train station

and their journey, being greeted by such a cheery scene

as they pass through.”

And at Acton Central, the station team has partnered

with passengers and members of the community to

develop a lending library, a book swap system where

passengers can borrow books. This scheme has really

helped to strengthen links with passengers and is

complemented by other initiatives, such as the station

Christmas tree which local passengers have helped to

decorate, and this includes using their own decorations.

Our staff reaching out to communitiesAnother way that LOROL has been able to actively

develop its support for its community is through the

creation of the LOROL Charitable Donations Fund. This

initiative enables LOROL’s 1100 plus employees to apply

for a share of a fund that has recently been extended to

£10,000 to support their chosen cause or charity.

To receive a LOROL award from this fund, it is vital that

charities and good causes are nominated by employees

to demonstrate their personal connection or involvement.

Many of the awards over the last year have gone to local

groups and organisations, including hospices, theatre

groups, sports teams and children’s clubs with whom

staff have developed personal links. A key measure of

success for LOROL is the added value that our staff

bring to their community.

zzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzHowever, as a business we have always striven to

do more. LOROL’s company vision is ‘Developing our

railway together, proudly connecting communities around

London’, and we are constantly seeking to identify, map

and engage with community and rail user groups, as well

establishing a pathway to other groups and individuals

who also have an interest in the work that we do.

We often identify these other groups through our

existing stakeholders, or through events at which LOROL

is represented. Once these links are established, we

provide these new groups with the opportunity to speak

to us about their needs, both informally and through

attendance at formal meetings.

A particularly successful approach is to then ask

these groups ‘who next?’. Asking this question helps to

achieve our ambition of widening our service by using

the expertise of these groups to engage at the next level

– that includes potential service users who would not

otherwise have considered travelling on our services and

who will not have heard from us before.

By increasing our body of stakeholders in this way, we

are able to gather even more enhanced and accurate

information via annual surveying, as well as valuable

informal feedback as we speak to people on a day to

day basis.

Establishing community linksThere are a number of specific initiatives across the

Overground network where LOROL has established

strong community links.

At Forest Hill, the Forest Hill Society has been

established by local residents to work in partnership with

the station on its garden and to organise a monthly food

market. Once every month the station car park is closed

and it becomes a produce market.

Here, a key driver has been to position the station

firmly at the heart of the community and, according to

Quetta Kaye, chair of the Forest Hill Society’s environment

committee, it’s certainly achieving this objective: “The

gardening project at Forest Hill

A cheque for the Railway Children charity

Another Forest Hill initiative has been a music festival

The womens project at City Gateway

Furthermore, as part of our developing strategy, we are

looking to support local community schemes and events by

organising opportunities for staff, particularly those based at

Head Office, to spend some time assisting in

the community.

LOROL is also very supportive of staff who volunteer

outside of work, and policies are currently under

development to allow for some time to be set aside to allow

this volunteering to take place.

Creating a positive station environmentOf course, a key way that LOROL has been able to make a

positive impact on the communities it serves is by creating

a positive, safe, secure and welcoming station environment.

There is a rolling programme of works across the network to

improve and enhance stations. And according to the results

from Transport for London’s latest Customer Satisfaction

Survey – where LOROL scored 84 per cent – passengers

seem to agree.

A key initiative that ensures LOROL creates and maintains

a positive station environment is the annual Overground

in Bloom competition which encourages station teams to

develop floral displays and gardens, and helps to enhance

and showcase station environments.

At Norwood Junction, the station team, in partnership

with passengers and local residents, has created a garden

at the station. Funding for the project has been secured from

a number of sources including LOROL, Network Rail, the

British Transport Police and the local council and schools,

and groups take part in weekly gardening and planting

activities. In fact, the project has grown to become an

extremely positive link between a broad range of

community groups.

Norwood Junction resident, Alan Oakley, who designs

and manages the gardens at this station in partnership

with British Transport Police officers, said: “The garden

has clearly improved links between the BTP and the

local community. Primary school children have met the

police and learned about their role. It’s also been a great

opportunity to educate them about railway safety while

at the same time giving them the chance to sow seeds,

cultivate plants and study the various wildlife habitats

found in the garden, as well as paint murals for display on

the garden wall.”

Assessing the impact of our workAs our community work becomes more established,

it is important that we are able to demonstrate a clear

methodology behind the work that we do, and show a

measurable impact.

To achieve this, the LOROL Executive has developed a

very clear view on how society is defined within the context

of the service we provide. All community engagement

within LOROL is now expected to contribute to the

improvement of society through five key outcomes:

l Empowering our staff to benefit the wider community

l Encouraging economic growth

l Behaving and procuring in an ethical and

environmentally sound way

l Being a good neighbour to our local residents

l And working with industry colleagues to deliver a

popular, reliable and accessible train service

Each of these outcomes has a range of measures

attached, and individual directors within LOROL are

responsible for their success. This approach will enable

us to demonstrate our commitments and priorities now,

while also allowing us to review our progress against clear

criteria in the future.

The future for community engagement at LOROLLOROL has undergone a huge journey in the past seven

years. As passenger numbers and the Overground

network continue to grow, it is important we continue

to establish and formalise our community links. With a

framework in which to do this and a dedicated internal

resource to ensure that stakeholders and the wider

community can be reached, this is sure to continue and

drive levels of partnership and engagement. zz

Illustrating Ground Model prior to over water Ground Investigation

20 www.railwaystrategies.co.uk

London Overground Rail Operations Limitedl In November 2007 LOROL was awarded a seven year concession to operate the London Overground networkl Today over 455,000 people travel on the Overground daily - a five-fold increase from November 2007l The concession has since been extended for another two-years to 2016l More recently LOROL was selected to operate the West Anglia inner suburban network operating out of Liverpool Street station from May 2015

Stations zzzzzzzzzzzzzzzzzzzzzzzzzz

The station garden at Norwood Junction

www.railwaystrategies.co.uk 21

Exciting new art is commissioned for the Tottenham Court Road station extension l Turner Prize-winning artists Douglas Gordon and Richard Wright have been

commissioned to create large-scale artworks in the new Tottenham Court

Road Crossrail station.

Douglas Gordon’s commission will be installed in the station’s western ticket

hall in Dean Street, Soho. A series of three video screens will display images

of people to evoke the history, culture and character of Soho. These images

collectively form human compositions in a concept known as

Exquisite Corpse.

Richard Wright’s commission will see gold-leaf hand-gilded on the vast

ceiling above the eastern ticket hall, next to the existing Tottenham Court Road

London Underground station. It draws on the lightness and colour of the ticket

hall architecture and the rapidly improving public areas around the station. The

pattern, which echoes the tile patterns of historic underground stations, will

appear to change, fading in and out, depending on the light and viewpoint.

The commissions are lead-funded by Almacantar and the City of London

Corporation and co-funded by Derwent London. Both artists are from

Glasgow and their proposals were selected by the Crossrail Art Advisory

Board in consultation with Gagosian Gallery, station architects Hawkins/Brown

and the funders.