RACE TECH Issue 115

-

Upload

chris-pickering -

Category

Documents

-

view

250 -

download

6

description

Transcript of RACE TECH Issue 115

ww

w.r

acet

ech

mag

.co

m DRIVING TECHNOLOGY INTO POLE POSITION

I N T E R N A T I O N A L

MAY 2010 NO. 115 UK £4.95 USA $9.99 www.racetechmag.com

The quest to make Lotus a force in Formula One

LIVING UP TO A LEGEND

THE SECRETS OF INDY 500 SUCCESS

750FORMULA BUILDPROJECT UNDERWAY

WHY LOOSE WHEELSDRIVE US NUTS!DRIVE US NUTS!DRIVE US NUTS!

PAT SYMONDSSPECIAL REPORTON COATINGS

LPG’S BID FORBTCC HISTORY

+

ww

w.r

acet

ech

mag

.co

mw

ww

.rac

etec

hm

ag.c

om

Cover 115 v3.indd 1 30/4/10 18:34:59

Adverts 109 main section.qxd:Racetech.qxd 29/10/09 21:37 Page 1

6

16

34

40

46

52

54

62

64

74

80

May 2010 www.racetechmag.com 3

INDUSTRY NEWSRadical options discussed for next F1 tyre contract; DeltaWing wind tunnel testsreveal 50 per cent drag reduction over current Indycar; BTCC reprieve for rear-wheel drive; new NASCAR spoiler performs well

FORMULA ONEPat Symonds examines the generation of temperature in racing tyres and thedifferent strains the rubber endures

Why loose wheels drive us nuts! Pat Symonds sheds new light on a familiar problem

A frank account of the tempestuous infancy of Hispania Racing

ENGINE TECHNOLOGYThe LPG engine project that is ruffling feathers with its pace in the British Touring Car Championship

THE SECRETS OF SUCCESS IN THE INDY 500The Indy 500’s special place in the US racing industry

When everybody has the same technical package, what gives teams the extra edgeit takes to win the Indy 500? We find out

Why the future of the great race relies on technological innovation

MOTORSPORT’S GOLD RUSH: SPECIAL REPORT ON COATINGS Why an ever-increasing number of applications are being found for sophisticatedsurface coatings in motorsport

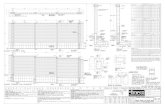

PRACTICAL RACERFront wishbones are on the agenda as Graham Templeman and Rod Hill embark ontheir T5 750Formula build programme

RACE EQUIPMENT DIGEST The latest products launched in the motorsport sector

COVER STORY - PAGE 28

LIVING UPTO A LEGENDTHE QUEST TO MAKE LOTUS A FORCE IN FORMULA ONE

Volume 17 Issue 7

Published May 2010

The next issue will be published

in early June 2010

ISSN 1356-2975

SUBSCRIPTIONS

Subscriptions from Racecar Graphic Ltd

841 High Road, Finchley, London N12 8PT

Tel +44 (0)20 8446 2100

Fax +44 (0)20 8446 2191

Overseas copies are sent via air mail

Special offer 12 issues for the price of 10

12 issue subscription UK: £45.00

Europe: € 97.50, US/Canada: US$127.40

Rest of World: £75.00

All major credit cards accepted. Cheques and

money orders only in Pounds Sterling payable to

Racecar Graphic.

BACK ISSUES AVAILABLE:

8,9,10,11,13,14,15,16,17,18,19,20,21,22,23,

24,25,26,27,28,29,30,31,32,33,35,36,37,38,

39,40,41,42,43,44,45,46,47,48,49,50,52,53,

54,55,56,57,58,59,60,61,62,66,67,68,69,70,

71,72,73,74,75,76,77,78,79,80,81,82,83,84,

85,86,87,88,89,90,91,92,93,94,95,96,97,98,

99,100,101,102,103,104,105,106,107,108,109,

110,111,112,113,114

Price including post & packing:

UK: £5.50, Europe: £6.50, Rest of World: £7.55

You can pay by cheque or credit card but please

note the minimum on Switch & Delta is £14

Race Tech (ISSN: 1356-2975) is published

monthly by Racecar Graphic Ltd.

Cover shot : Crashpa.net

Design & Repro by

Maluma Design Associates, [email protected]

Printed by Warners Midlands plc

© Racecar Graphic Ltd.

All rights reserved. Reproduction (in whole or in part) of

any article or illustration without the written permission of

the publisher is strictly prohibited. While care is taken to

ensure the accuracy of information, the publisher can

accept no liability for errors or omissions. Nor can

responsibility be accepted for the content of

any advertisement.

If you can’t always find a copy of thismagazine, help is at hand! Complete

this form and hand in atyour local store,they’ll arrange for a

copy of each issueto be reserved for

you. Some stores mayeven be able to arrange

for it to be delivered toyour home. Just ask!

Please reserve/deliver my copy of RACE TECHon a regular basis, starting with issue................................

Title...................................First name...................................................................

Surname.......................................................................................................................

Address..........................................................................................................................

....................................................................................................................................................

...................................................................................................................................................

...................................................................................................................................................

Postcode......................................................................................................................

Telephone number..........................................................................................

When you are sitting there with 15 people and sixmonths to do it, you have to make value judgementsof how to get the car to the race on time’

May 2010 CONTENTS ISSUE 115www.racetechmag.com

3

Contents 115.qxd:Section.qxd 30/4/10 21:19 Page 1

Adverts 114 main section.qxd:Racetech.qxd 27/3/10 13:23 Page 1

THE NEWS that Williams has increased its stake to 78% of Williams

Hybrid Power would seem to indicate that there are still great

opportunities to be had in developing hybrid technology. It also

vindicates the decision by the FIA to encourage Formula One teams to adopt

KERS (kinetic energy recovery systems). It is just a pity that it has been dropped

by the teams this season.

When I interviewed Hartmut Kristen, head of Porsche Motorsport, he was very

complimentary about Williams Hybrid Power, saying that when his company

was investigating hybrid technology that it was the British company that not

only had the right answers but also asked the best questions. The fact that

Porsche, of all companies, should be progressing this technology really is a sign

of the times. A class win in only its second race speaks volumes and makes one

wonder just what the future will hold once the Weissach carmaker really gets to

grip with this technology.

I remember a few years ago when Toyota and Honda were making hay with

their production hybrid models. Much to the surprise of the domestic and

European carmakers, these Japanese companies managed to ride the wave of

green motoring. While the German carmakers in particular were promoting

diesel technology as the sensible powertrain of the future, and were committing

vast resources to it, Toyota and Honda were winning the PR war in the ever-

important US market. I remember being briefed by senior executives from

virtually all the European car companies 10 years ago that hybrid technology

was just a flash in the pan and that once the benefits of the common-rail diesel

were explained that it would see the end of alternative powertrain technology.

That, of course, did not happen. While hybrids have not really caught on in a

big way in Europe due to the diesel stranglehold, the reality is that there is a

market for them and carmakers also need to be seen to be going that route. If

the carmakers go that route, then so should the sport’s governing bodies. They

should be encouraging different series to adopt hybrid technology, not at the

expense of petrol and diesel engines, but devising formulae so that no one

particular technology has a big advantage. In other words, not to follow the

Autombile Club de l’Ouest’s example whereby the petrol car is so heavily

disadvantaged to the diesel. That really does not do anyone any good at all.

We have entered a new world, one where energy conversation is very high on

the agenda and one to which motorsport must be responding to in a more

considered manner than it currently does.

William Kimberley EDITOR

PORSCHEPOINTSTHE WAY

EDITORWilliam Kimberley

EDITORIAL ASSISTANTChris Pickering

CONTRIBUTING EDITORS

Pat SymondsJohn CoxonSteve BridgesFrançois LassalleGraham TemplemanMatt Youson

CONSULTANT EDITORMark Skewis

CHIEF PHOTOGRAPHERBryn Williams

ART EDITORPaul Bullock (maluma.co.uk)

WEB MANAGEMENTCrash.Net ([email protected])

ADMINISTRATION/SUBSCRIPTIONSPhyllis Sofocleous

COMMERCIAL DIRECTORMaryam Lamond

PUBLISHERSoheila Kimberley

841 High Road, Finchley

London N12 8PT

Tel: +44 (0) 208 446 2100

Fax: +44 (0) 208 446 2191

www.racetechmag.com

May 2010 www.racetechmag.com 5

INTRODUCTION ISSUE 115www.racetechmag.com

5

Intro 115.qxd:Section.qxd 30/4/10 12:01 Page 1

MOTORSPORTS PROFESSIONALwww.racetechmag.com

May 20106 www.racetechmag.com

6

By Chris Pickering

MELKSHAM, UK – Michelin

may not be the only tyre

company contemplating a return

to Formula One. Cooper Tires is

also understood to be in

discussion with the relevant

parties over a plan to supply tyres

through its UK-based Avon Tyres

Motorsport operation, although

there has been speculation that

an F1 bid would use the Cooper

name as Avon is less well known

outside the UK. Either way the

company has refused to

comment at this stage.

Not only does this revive

competition to Michelin’s bid

after Bridgestone pulled out of

talks, but it is also understood to

be a rather different proposition.

Michelin stated several provisos

for its return to F1, including

that it wanted to be in

competition with another tyre

manufacturer, it wanted to be

paid for its involvement, and,

crucially, it wanted to switch

from the current 13 inch

diameter wheels to 18 inch rims,

making the technology more

relevant to road car tyres.

The principal objection to the

French firm’s bid so far is cost.

The projected bill is thought to

be around £45 million in total,

but the Cooper Tires bid is

rumoured to be far lower. Allied

to this, sources suggest that

Cooper would retain the 13 inch

wheel size, virtually eliminating

the need for a costly redesign.

Commenting on the switch to a

larger diameter, Race Tech

contributor Pat Symonds said: “If

you assume the tyres’ outside

diameter and width are to

remain roughly the same, then

the fronts will drop from an

aspect ratio of around 66%

down to around 40%, and the

rears from 50% to around 30%.

Those are pretty low profile tyres

and they’re likely to be pretty stiff

as a result, which could mean

some big changes.

“At present the suspension

geometry is very much dictated

by aerodynamics. The wishbones

are steeply inclined upwards

towards the inboard end on the

front of current Formula One cars

simply because the chassis has

been placed so high. That leads

to things like high roll centres

and poor camber compensation,

but to a certain extent you can

get away with that when you

have a nice big compliant tyre.

When you’re looking at a 30 or

40% aspect ratio, you’re going to

have to examine the geometry

far more carefully in order to get

the contact patch flat on the

ground though.”

Currently the tyre sidewalls also

account for something like 50%

of the wheel movement in an F1

suspension system, meaning that

significantly softer, longer travel

springs would be needed to

News 115.qxd:Racetech.qxd 30/4/10 18:10 Page 1

MOTORSPORTS PROFESSIONAL

www.racetechmag.com 7May 2010

www.racetechmag.com

7

compensate. The upside to this,

of course, is that more of it could

now be controlled and adjusted

with the dampers – and that is

not the only potential benefit.

Larger wheels are likely to give

more room to position the

outboard suspension pickups.

Likewise, it would provide more

room to package the brakes in,

and this may even mean it's

possible to make the brakes last

longer, reducing costs.

THE RACE IS ON

“A smaller volume would also

result in less gas in the tyres, so

they would be less pressure

sensitive, which could even raise

the possibility of abolishing

blankets,” Symonds noted. “This

would make the drivers fight to

warm the tyres up when they

come out of the pits in order to

retain track position, which

strikes me as a good thing.”

The potential change would be

a mixed blessing to the

aerodynamicists. Stiffer tyres with

less sidewall deflection are likely

to make the aerodynamics more

consistent and – sticking with

our assumption on overall size –

the basic frontal area would not

change much. The larger wheel

diameter would, however, clearly

put more aerodynamic emphasis

on wheel design. Finally, there is

also the safety implication. A

lower profile tyre with a smaller

gas volume would contain less

elastic energy than the current

tyres and would therefore

bounce around less if liberated

from the car in an accident.

The final agreement on next

year’s tyre suppliers is due to be

announced at the Spanish Grand

Prix this month. One thing is

certain – only one wheel

diameter will be allowed, so we

are highly unlikely to see

Michelin and Cooper fighting it

out on the track. Until the

decision is made, however, the

fight for Formula One is very

much still on.

BELOW The debate is on as to whichcompany will become the tyre supplierto Formula One in 2011

News 115.qxd:Racetech.qxd 30/4/10 18:11 Page 2

MOTORSPORTS PROFESSIONAL

May 20108 www.racetechmag.com

www.racetechmag.com

8

BATHURST, Australia – Aston Martin, Ferrari,Lamborghini, Mosler and Porsche could all beracing at the Bathurst 12 hour race next year asthe classic endurance race is opened up to otherbrands next year. However, the news has notbeen received with universal acclaim with someentrants stating that they will boycott the race.Some GT drivers have also expressed the viewthat a 12-hour race for their cars will make amassive dent in their race budgets.

“The momentum for this exciting initiative hascome from our drivers and entrants and it is a

natural progression for the expansion of the GTcategory and brand to compete in the 12 hour atthe iconic Bathurst circuit. A race of this nature iswhat GT cars are all about,” said a press releaseissued in the names of GT directors MartinWagg, Rachael Wagg and Terry Little.

“The GT Championship has growntremendously in recent years and thesevehicles will now join production cars in the12 Hour Race enabling the event to growfurther including the attraction of aninternational audience,” said, James O’Brien,

the Bathurst 12 Hour promoter.He added that when the 12 Hour was

reintroduced in 2007, it was always the intentionto incorporate GT vehicles but that the timinghad to be right. The introduction of GT vehicleswill assist in attracting more competitors, morespectators and a larger viewing audience viatelevision and the internet.

“The Armor All Bathurst 12 Hour has thecapacity for a 72 car grid, and with 42 carsentered for the 2010 event we are targeting a50 plus entry for 2011,” he said.

GT CARS TO RACE AT BATHURST 12 HOURS IN 2011

By Chris Pickering

INDIANAPOLIS, IN –

DeltaWing Racing Cars’ radical

concept for the 2012 Indy

Racing League, featured in our

March issue, has now

completed preliminary wind

tunnel testing at the Windshear

facility in North Carolina. Until

now the aerodynamic

development had been carried

out exclusively with CFD, and

DeltaWing LLC’s designer and

chief technical officer Ben

Bowlby was keen to stress that

the physical tests were largely

for the purpose of validation:

“The tests went extremely well.

I’ve never gone as far with the

development of any car using

only CFD, let alone one so

unusual, so we were

anticipating a few surprises, but

in reality the correlation was

extraordinarily close.”

The headline grabbing figures

produced by the 140mph full

size test were a drag reduction

of over 50% and a proportional

level of downforce to the

current car: “At Indy we race at

about 760lb of drag at

200mph in typical ambient

conditions. By comparison, the

DeltaWing is going to be

somewhere around 330 to

350lb of drag. Under the same

conditions, we generate around

the vehicle’s weight in

downforce – so around 1,800lb

– and the DeltaWing will also

pull its own weight, this time

around 1,000lb.”

The dramatically low drag

figures, allied to reduced

weight, would allow a modest

300 to 350 bhp engine –

around half the current figure –

to produce straightline

performance comparable to

today’s IndyCars. DeltaWing’s

simulations predict that overall

lap times on street courses

would be two to three seconds

a lap quicker than the current

cars, and fuel consumption

could be as low as half.

“The goal was to produce

something that was a

stepchange in efficiency –

something that could

demonstrate the performance

capability of modern

technology,” said Bowlby.

“We wanted something very

lightweight and very efficient

that’s still at least as fast and

as spectacular as a current

racecar.”

It was not just performance

that was under scrutiny, either.

According to Bowlby a wet

road simulation showed

minimal spray from the front

of the car hitting the cockpit

area and also significantly less

spray behind the car. The

design is also intended to

promote close racing.

Following cars are said to

only suffer half the loss in

downforce that those behind a

traditional open-wheeler

would. Likewise Bowlby said

the wind tunnel tests appear

to confirm the CFD predictions

of greatly improved yaw

stability over a conventional

machine. Current single-seater

designs tend to suffer a

dramatic fall in downforce at

relatively modest yaw angles,

but the DeltaWing’s yaw range

could allow the aerodynamics

to remain effective at far

greater slip angles. The idea is

this could see a return to the

more flamboyant driving style

of the pre-downforce era and

produce a more dramatic

spectacle as a result.

“We want to put the

Indianapolis 500 back at the

cutting edge of development,

with something truly relevant

to the auto industry,” Bowlby

summed up. “Wind tunnel

testing is a critical step for the

project and allows us to move

forward towards a final design

with growing confidence. We

are now more convinced than

ever that the DeltaWing

concept will meet or exceed

the parameters that the IZOD

IndyCar Series has established

for the 2012 chassis.”

GREAT EXPECTATIONS

RTRT

RTRT

News 115.qxd:Racetech.qxd 30/4/10 18:11 Page 3

The value of Xtrac’s competitive advantage is well recognised

by the champions and one make series who already rely on their

expertise, in addition to individual teams running on modest

budgets. Success is summarised by Xtrac’s watchwords:

QUALITY

To maintain their position as the leading supplier of high

performance transmissions, Xtrac operate a continuous re-

investment and improvement policy.

PERFORMANCE

Supplying championships such as IRL, BTCC, Grand-Am, FIA

Super2000, Formula Le Mans and most recently, Brazilian

Stockcar and Argentina’s TC2000, Xtrac’s track record speaks

for itself.

RELIABILITY

Xtrac’s advanced engineering solutions keep their customers

ahead of the competition in the most gruelling endurance

events - from Dakar to Daytona and from Monte Carlo to Le

Mans - all the way to the chequered flag.

www.xtrac.com

IMS

photo

by S

teve S

noddy

.xtrac.www

.com

Adverts 115 main section.qxd:Racetech.qxd 30/4/10 17:31 Page 1

BELOW BTCC series director Alan Gowhands rear-wheel drive a reprieve

MOTORSPORTS PROFESSIONAL

May 201010 www.racetechmag.com

www.racetechmag.com

10

BTCC REAR-WHEEL DRIVEREPRIEVE ANNOUNCED By Chris Pickering

LONDON, UK – TOCA, the

touring car association that

administers the British Touring

Car Championship, has

confirmed more details of the

forthcoming Next Generation

Touring Car rules and

announced its suppliers for

2011. Perhaps the biggest news

was the decision to include a

provision for rear-wheel drive

cars. Initially the NGTC formula

only covered front-wheel drive

machines, meaning that cars

such as the BMW 320si would

cease to be eligible when the

current Super 2000 based

regulations were phased out.

Although there are several

teams actively campaigning

rear-wheel drive machines in the

BTCC the last factory entry was

way back in 1996. When the

NGTC rules were previewed last

year it wasn’t thought there was

enough interest in rear-wheel

drive to justify it. At the time,

BTCC series director Alan Gow

argued that it did not make

sense to compromise the new

regulations and raise issues of

parity for the possibility of

including a single manufacturer,

but the option was left open.

“After we released details of

the NGTC programme last year,

I stated that we would revisit

the question of incorporating

rear-wheel drive in the

regulations if there was enough

interest or commitment from

teams and manufacturers of

rear-wheel drive cars to support

it,” he stated recently. “Having

now had those discussions, I’m

confident that there is and so

we have now included it.”

As expected, the rear-wheel

drive layout can only be used if it

is featured on the car’s standard

production equivalent and, like

the front-wheel drive cars, it

must also use standardised TOCA

front and rear subframe/

suspension assemblies. The units

will be produced by Berkshire-

based GPR Motorsport and

both layouts will feature

double wishbone suspension

with coil-over dampers.

Meanwhile AP Racing provides

the brake package and pedal

box, along with the clutch,

mated to an Xtrac 6-speed

sequential. Cosworth

Electronics has also been

confirmed as the electronics

supplier with a package that

includes the mandated ECU,

dashboard, data-logger and

scrutineering logger.

The NGTC package effectively

represents a kit of components

around which teams or

manufacturers can build their

own car. However GPR

Motorsport will also offer an

assembly service based around a

production car of the customer’s

choice. The bodyshell must be

based around a 2, 3, 4 or 5-

door car freely available in the

UK through the manufacturer’s

dealer network. An equalised

width of 1875mm and various

aerodynamic enhancements

such as a flat floor and a

standard rear wing profile will

be specified. The cars will also

feature stylised front and rear

wheelarch extensions which

are intended to give them a

more dramatic look, similar to

those of the old Super Touring

Cars. A rendering released by

the organisers points the way

to how a typical NGTC car

might look.

The main thinking behind the

NGTC rules remains cost

reduction. TOCA is aiming to

halve the budget needed to run

a current BTCC car, through

significantly lower parts and

maintenance costs. "At around

£100k, plus engine, they will

then have a better car - which is

easier to maintain and has

greater performance potential at

about half the cost of a current

one,” said Gow. “It's a win-win

situation for everyone.” RT

TOP & BELOW A rendering of the Next Generation Touring Carthat will be open to both front and rear-wheel driven cars

News 115.qxd:Racetech.qxd 30/4/10 18:11 Page 5

Sulzer Metco coats and enhances surfaces,

produces materials and equipment for these

purposes and develops machining processes

for special components. Our state of the art

products, solutions and services are delivered

through a global sales, customer support and

manufacturing network.

SUMEBore is a cylinder bore coating technology applied

in the Bugatti Veyron W16 engine and the Aston Martin

One-77 V12 engine. It is also used by teams in F1, GP2,

DTM and NASCAR, to name but a few.

The Leading Global SurfaceSolution Company

www.sulzermetco.com [email protected]

Sulzer Metco Plasma Ad RT115.qxd:Section.qxd 30/4/10 22:57 Page 1

MOTORSPORTS PROFESSIONAL

May 201012 www.racetechmag.com

www.racetechmag.com

12

By Andrew Charman

FORT WORTH, TX – Drivers in NASCAR’s

top level Sprint Cup series have reacted

positively to the first races with a new rear

spoiler on their cars, after NASCAR

abandoned the aerodynamic rear wing that

was such a signature feature of the Car of

Tomorrow introduced in 2007.

While the first races with the new spoiler

were at the short tracks of Martinsville on 28

March and Phoenix two weeks later, the

acid test of the changes was always

expected to be at Texas on 18 April. The

speedway is a 1.5-mile track like many of

the Sprint Cup schedule, and it is at these

tracks where the characteristics of the

spoiler are expected to be most keenly felt.

Despite rain washing out much of the vital

practice at Texas and delaying the race by 24

hours, drivers were very positive about the

spoiler when questioned after the race.

Drivers remarked that the cars had more

grip and were more drivable, particularly

when running side-by-side with rivals. This

had been a major criticism of the rear wing,

drivers complaining that the characteristics of

the aerofoil made it very difficult to run

alongside cars and pass them.

Denny Hamlin, who won the Samsung

Mobile 500 at Texas in his Joe Gibbs Racing

Toyota, said that the spoiler produced better

racing. “The car seemed to be planted to

the race track quite a bit more – you could

race around guys without the air being

taken off of you as much as it did.”

The spoiler is 64.5 inches wide and four

inches tall, placed at an angle of 70 degrees

to the car’s rear deck. It has been estimated

to add 20% downforce to the rear of the

car. For the Texas race a side fin was added

to the decklid with the aim of further

improving side forces on the car.

Some drivers have repeatedly commented

on the increase on drag caused by the spoiler.

Following tests at Charlotte Motor Speedway,

Penske Racing’s Kurt Busch said that the car

felt very stable but had a far more drag. “We

are going slower down the straightaways but

we can maintain that speed in the corners.

“We’re getting the difference we’ve

needed to help us run side by side better. It

has slowed us down by around 200rpm so

NASCAR will likely need to work on the

gearing. However, the car feels stable, that’s

the best thing, that’s a thumbs up.”

Four time champion Jeff Gordon suggested

that the spoiler would see an end to the

crab-like look of cars racing in the Sprint

Cup. “We learnt that with the wing if we ran

the car slightly sideways we could make up

for the loss of drag and downforce with

some side force. With the spoiler we don’t

have such an amount of side force but we

make up for it with overall downforce.”

Gordon added that the spoiler improved

the look of the car. “I like the way the cars

look with the spoiler, that’s a plus.”

NASCAR’s rear wing era lasted 93 races,

just under three seasons.

IN OTHER NEWS

In a move that sees it being gradually

phased in this year, all four Roush Fenway

Racing and four Richard Petty Motorsports

Ford Fusions ran the new-generation FR9

engine in a race. The new engine is said to

provide superior cooling and centre of

gravity as well as better handling.

“It’s really the first across-the-board running

for the FR9,” said Ford Racing engineer David

Simon. “We ran them at Daytona, of course,

in the (Budweiser) Shootout across-the-

board, but the Talladega race is the first full

one for it as the primary engine for us. The

reason it’s a milestone is that we’ve gone

through the validation process on the plate

package, so, at this point, we’re ready to race

the FR9 full-time in restrictor-plate form. In

the second half of the season, as the

validation process gets completed, the FR9

will become the primary race engine for us in

both the open and plate races.”

Uncertainty surrounds the future of Richard

Petty Motorsport after it was revealed that the

team had defaulted on a $90 million loan,

caused by car manufacturer Dodge ending its

financial support of the team – Petty has since

switched to racing Ford chassis.

Team owner George Gillett, who is

currently trying to sell his stake in Liverpool

Football Club in the UK, said that the loan

was not an issue, describing it as a

technical problem which would soon be

solved by a restructuring.

However, Petty was further troubled by the

news that its star driver Kasey Kahne will not

renew his contract at the end of the season,

heading instead to Hendrick Motorsports. The

team fears that lucrative sponsorship from the

Budweiser beer brand, which is built around

Kahne, could follow the driver to Hendrick.

In another move, Shell/Pennzoil is replacing

Mobil as the Penske Racing team’s official fuel

and motor oil supplier next year. It will also

sponsor the Kurt Busch No 22 car.

NO SPOILINGNASCAR’S PARTY

ABOVE The new Sprint Cup spoiler, seenhere on Juan-Pablo Montoya’s Chevrolet.(Photo: Rusty Jarrett for NASCAR).

ABOVE Team-mates Jimmie Johnson and JeffGordon battle at Texas in their now be-spoileredcars. (Photo: John Harrelson for NASCAR)

RT

News 115.qxd:Racetech.qxd 30/4/10 18:12 Page 7

Adverts 113 main section.qxd:Racetech.qxd 27/2/10 18:05 Page 2

BELOW John Watson's McLaren atthe Caesars Palace GP in 1982. Is areturn to Las Vegas on the cards?

MOTORSPORTS PROFESSIONAL

May 201014 www.racetechmag.com

www.racetechmag.com

14

F1 TO RETURN TO THE US?

GAS TURBINES BACKON THE AGENDA

SHANGHAI, China – Formula One could

be returning to the US following informal

talks between Bernie Ecclestone, the F1

commercial rights holder, and Tony George

the former Indianapolis Motor Speedway

and Indy Racing League chairman.

George attended the Chinese Grand Prix

in Shanghai at Ecclestone’s invitation to

examine how and where to get a Formula

One race back to the US. Despite George’s

links with Indianapolis, Ecclestone is known

to favour other venues, his first choice

being New York. However, he is also said to

be considering Las Vegas, Miami and San

Francisco and possibly even two races in

the country following strong support for

the idea from sponsors.

Although he retains a share in the

Speedway, where he spent around

$30 million of the Hulman-George

family fortune to build the 2.6-mile

road course needed for the US GP,

George is a free agent.

The US GP has struggled to find a home

in the US since leaving Watkins Glen in

1980. Long Beach in California was the

home to eight grands prix but the two

events in Detroit and Las Vegas, the single

event in Dallas and the three events in

Phoenix never caught on with the US

public. However, the event left after George

and Ecclestone could not come to an

agreement that made financial sense for

both sides. Reports from IMS management,

though, have stated that they would be

interested in bringing an F1 race back to

the Speedway under the right financial

circumstances, the stumbling block being

the high F1 sanctioning fee.

Athens, Greece: The turbine engine, last

seen in Formula One nearly 40 years ago,

could make a return. Project 1221, a

specialist company based in Athens that is

dedicated to creating and marketing gas

turbine vehicles, claims that it has

approached F1’s commercial boss Bernie

Ecclestone with a proposal. It says it could

have an engine ready to power a car by 2013.

The company claims it is working on

different turbine engines for land, sea and

air, working on new concepts to power

supercars, ‘superyachts’ and even

‘supersonic business jets’.

According to Andreas Andrianos, Project

1221’s CEO, gas turbine engines would be

cheaper to run than an internal combustion

unit. While fuel consumption would be higher

than with the current breed of petrol-fuelled

V8s, the inefficiency would be more than

offset by use of bio-diesel fuel, which would

make the engines more environmentally

friendly. With no traditional cooling required,

the engines present fewer packaging

problems, although the units could not be

used as stressed members of the car and

would also cause challenges with the gearbox.

Williams F1 recently acquired a majorityshareholding in Williams Hybrid Power(WHP), increasing its stake in thecomposite flywheel specialist to 78percent. It comes after WHP’stechnology made a successful racingdebut in the Porsche 911 GT 3 R Hybrid,which won its class at the second race ofthe VLN series last month.

PersonnelAnd finally...The recent spin-off of McLaren Automotive fromMcLaren Group has led to a fundamentalmanagement restructure with Ron Dennis willresuming his role of executive chairman ofMcLaren Group as Sir Richard Lapthorne resignsfrom being the non-executive chairman.However, he will continue is his role as aconsultant to McLaren Automotive.

Reporting to Dennis will be Tim Murnane, group

legal director and company secretary, and AndyMyers, financial officer, both of the McLaren Group.

Meanwhile Martin Whitmarsh has beenappointed to two new roles – chief executiveofficer of McLaren Group and deputy chairmanof McLaren Automotive. He will also continue inhis role of team principal of Vodafone McLarenMercedes. Antony Sheriff will continue in his roleof managing director of McLaren Automotive.

RT

RT

News 115.qxd:Racetech.qxd 30/4/10 18:12 Page 9

Adverts 113 main section.qxd:Racetech.qxd 27/2/10 18:05 Page 3

May 201016 www.racetechmag.com

www.racetechmag.com

16

Pat Symonds examines the generation of temperature in racing tyres and the different strains the rubber endures

track, there are three distinct areas of tyre

tread we should distinguish when we are

considering the thermal equilibrium.

Figure 1 shows a tyre running on the track

before it has reached thermal equilibrium.

The segment of the tyre that is marked (1)

is the part of the tyre that is adherent to

the road, the segment marked (2) is the

part of the tyre that is sliding and the

segment marked (3) is the large part that

is rotating in contact with the air.

In the adherent area (1) the thermal flow

is from the tyre to the road by means of

conduction (assuming that the tyre is at a

higher temperature than the road). In

segment (2) there is a lot of sliding

IN THE first part of this article, we

examined the peculiar properties of the

rubber mix used in tyres and identified

why temperature, amongst other things,

was fundamental to the grip that a tyre can

produce. We will now go on to look at the

generation of temperature in tyres and the

effect of the various strains that a tyre

undergoes in racing conditions.

TEMPERATURE EQUILIBRIUM

Before we look at the generation of the

temperature, we should first think about

the temperature equilibrium of the tyre.

If we consider a tyre running on the

A GRIPPING

FORMULA ONE PAT SYMONDS ON TYRE GRIP

FIGURE 1

Formula One-Pat Tyre Grip Part2.qxd:Racetech.qxd 30/4/10 13:52 Page 1

BELOW With each revolution theracing tyre gains and losestemperature in three distinct areas

FORMULA ONEwww.racetechmag.com

Subscribe +44 (0) 208 446 2100 www.racetechmag.com 17May 2010

17

energy and strain energy putting work into the tyre and hence

producing a large heat flow into the tyre. In the final segment

(3) the tyre is generally at a higher temperature than the

surrounding air and loses heat to the air by the mechanisms of

convection and radiation.

If we consider the temperature of the tyre surface as a function of

time through one revolution and if we assume that the tyre is

hotter than both the track surface and the air but not yet at

thermal equilibrium, we will see the conditions shown in Figure 2.

Area 1 shows the decrease in temperature as heat flows from

the tyre to the tarmac. Area 2 shows the very rapid increase in

temperature as the tyre does work through slippage and area 3

shows the loss of temperature of the tyre as it is cooled by the air.

This follows an approximate Newtonian cooling law.

It can be seen that in the cycle shown above the finishing

temperature of the tyre is higher than the starting temperature by

an amount . This implies that during this one revolution of the

tyre it is still increasing in temperature. Even with pre-heating in

tyre blankets, it still takes some time for the tyre to reach full

working temperature. True equilibrium can take six or seven laps

to be reached and, of course, this equilibrium temperature may

be above the ideal working temperature.

We achieve thermal equilibrium when

where Cp is the specific heat capacity of the tyre and Q is the heat

energy. The inflow of heat arises from the environmental conditions

and external heating discussed below. The outflow of heat is the

conduction to the road and the convection to the air while the

generated heat is the main source of heat energy that we will look

into in some detail.

At this point it is worth trying to decide what we mean by tyre

temperature. Rubber is a very good insulator. It has a coefficient

of thermal conductivity of only 0.16 Wm-1K-1. By way of

comparison, the Styrofoam used for insulated plastic cups is

about a fifth of this value and aluminium is over 1,500 times as

conductive. This means that the heat generated in any part of a

tyre moves very slowly through it. In Figure 2 we are considering

the tread temperature but this can be quite different to the bulk

temperature of the tyre.

Race teams tend to make three measurements of the temperature

of the tyres. When the car is running they can measure the tread

surface temperature. This is measured by remote infrared sensors.

They can also record the temperature as measured by the tyre

pressure measuring system (TPMS) which relates to the bulk

temperature. Both have drawbacks and need to be treated with

caution. The measurement of tread temperature is very sensitive to

the aim of the focal point of the sensor. Typically, a sensor will have

a viewing angle of around 15 degrees and will average the

temperature of all it sees in its viewing spot. This means that at a

distance of 250 mm it is averaging the temperature in a spot of

over 65 mm diameter. There is obviously a temperature gradient

across the width of a racing tyre that needs to be considered and if

the tyre has grooves or a tread pattern then large inaccuracies can

be present. TPMS systems tend to measure the temperature of

the gas in the tyre cavity. This is, in general, a reasonable

indicator of the tyre rubber bulk temperature. Unfortunately the

TALE

FIGURE 2

Formula One-Pat Tyre Grip Part2.qxd:Racetech.qxd 30/4/10 13:53 Page 2

ABOVE The flow of heat from thebrakes into the tyres can be avery significant factor

May 201018 www.racetechmag.com

FORMULA ONE PAT SYMONDS ON TYRE GRIPwww.racetechmag.com

18

sensors themselves are difficult to insulate

from the wheel and therefore can be

influenced by the fact that the wheel is

heated quite strongly by the brakes.

The final measurement used is that

made by the tyre technicians in the pits.

This is done with a needle thermocouple

that is stabbed into the tyre. It is essential

to use a thermocouple that has a depth

stop on it so that the temperature is

always measured at the same distance

into the rubber. The technician will

normally make three measurements across

the width of the tread and again it is

important that he makes the

measurements in the same place every

time as, particularly near the shoulders,

there can be large temperature gradients.

This method can be quite accurate as the

slow heat flow in the tyre actually helps

make this a stable measurement. It relies

more than anything on the driver driving

consistently hard on his in-lap – something

all drivers should be required to do

anyway. In absolute terms the conditions

on entry to the pit can make a difference.

For example at Spa, when using the F1

pit lane, the temperatures are highly

influenced by the high loadings at

Blanchimont but for comparative

purposes this does not matter.

SOURCES OF TYRE HEATING

There are three primary sources of heat

generation in racing tyres. The first of

these is the heating from what may be

termed the environmental conditions. In

a racing car, a large part of this will be

heating from the brakes. Secondly, there

is the heat generated by the strain energy

loss in the constantly deflecting tyre,

which occurs in the tread bulk and

carcass area, and finally there is heat

generated by the friction of the tyre on

the road or more specifically that caused

by tyre slip. This occurs largely in the

tread surface of the tyre.

Environmental conditions, particularly

track and air temperature, will play a part

in determining the running temperature of

the tyres but is not, at least in the first

order, a source of heating.

Although generally the environmental

conditions will dictate a net heat flow out

from the tyre into either the tarmac or the

surrounding air, there is a particular case

when there can be additional heat flow

The flow of heat from the brakes into thetyres is not something that is commonlylooked at outside the racing industry’

Formula One-Pat Tyre Grip Part2.qxd:Racetech.qxd 30/4/10 13:53 Page 3

Adverts 115 main section.qxd:Racetech.qxd 30/4/10 17:31 Page 2

into the rear tyres from the exhaust plume. This has been used as

a tuning aid by at least one Formula One team that had exhaust

tail pipes that were angled toward the rear tyres for use in cold

conditions and away from the rear tyres for use when the tyres

were easily able to achieve their operating temperature.

The flow of heat from the brakes into the tyres is not something

that is commonly looked at outside the racing industry. In a car

with carbon brakes it can be very significant. In racing there is

little that can be done to alter this effect other than to polish the

inside of the rims if it is desired to minimise this effect or to coat

them in a dark colour if it is desired to use this heat energy.

Thermal barriers on the brake cowlings can also have some

influence. This effect is not completely unique to motor racing,

however, as a paper was published in 1998 by authors from

Mercedes-Benz and Pirelli in Brazil that examined the effect of

brake heating on urban bus tyres after a number of tyre failures

on buses in Sao Paulo!

STRAIN ENERGY LOSS

The strain energy loss is a function of the tyre forces in X, Y and Z

directions as well as the camber angle, rotational speed and

inflation pressure. There are other factors, for example while the

slip angle is mainly thought of as a generator of frictional heating,

the deformation of the tyre carcass resulting from the slip angle

causes an additional source of strain energy loss. Strain energy

arises from the tread bulk area.

This strain energy loss contributes around 90% of what is termed

the rolling resistance of the tyre. It is largely generated by the

vertical deformation of the tyre as vertical load is applied to the

carcass as it enters the contact patch area and the relaxation of

that deformation as it leaves the contact patch area.

In Figure 3 we can see that as the tyre flattens in the contact

patch area there is a longitudinal deformation of the crown that

leads to bending as well as shearing and the compression that

arises from vertical force. The angle shown as α is known as the

“de-radialisation” angle which indicates the angular deflection

which leads to shearing in the sidewalls.

The distribution of energy dissipation is approximately 14% in the

bead area, 25% in the sidewalls, 27% in the shoulder and 34% in

the tread. Approximately 70% of the heat build up is therefore in

the tread and shoulder (edge of belt) area. Anyone who worked

with extremely soft qualifying tyres in the past will remember that

they often blistered on the straight. This is the reason why.

Let us look at the strains involved before reminding ourselves of

how these heat the tyre. Firstly we have the bending strain in the

rubber entering and leaving the contact patch. This strain depends

on the change from the initial curvature in the upper part of the

tyre, through its curvature in the transition zone at the leading

edge of the contact patch, and through and out of the contact

patch. In the contact patch itself the radius is of course infinite as

the tyre is flat on the track surface. A simple model known as the

Koutny model can be used to construct the geometry of curvature.

The maximum strain of the tread subject to bending is

where h is the tread thickness, Ri is the initial radius of curvature

and Rf is the final radius of curvature. Note that when an object is

flat its curvature radius is infinite and hence 1/R equals 0.

The second strain is the compression strain of the tread and is

defined as the ratio between its deformation (Δh) and the initial

height (hinitial) such that

The compression strain depends on the pressure (σ) exerted on

the tread and the modulus of rigidity of the material (M) but the

modulus of the material is also a function of the pressure exerted

on it. This is because rubber is in fact essentially incompressible.

If you apply a load to a block of rubber it will deform in the

direction of the load but at the same time it will bulge out

sideways if unconstrained. This bulging (known as dilation) is

not, however, infinite. Even when unconstrained, the more load

that is applied, the more the rigidity increases. To take this into

account the compression strain may be calculated by the

following formula:

where σ is the pressure, M10 is the modulus at 10% stretch or

compression and F is the aspect ratio of the tread footprint defined

as shown in Figure 4.

The final strain involved in the total strain energy loss is the shear

strain. If a block of rubber is placed in shear then it will take an

angular deformation. If the block has a height of h and is displaced

by a distance d then it will have an angular displacement of

May 201020 www.racetechmag.com

FORMULA ONE PAT SYMONDS ON TYRE GRIPwww.racetechmag.com

20

FIGURE 3 FIGURE 4

Formula One-Pat Tyre Grip Part2.qxd:Racetech.qxd 30/4/10 13:53 Page 5

Adverts 114 main section.qxd:Racetech.qxd 27/3/10 13:23 Page 3

This angle α is the so-called “de-radialisation” angle

shown in Figure 3. It can be shown geometrically that

If we consider these three strain energy losses for a typical rolling

tyre, we may see that the bending strain is around 3% and acts

through both transition areas as well as the footprint itself. The

compression strain will be around 5% (less for a slick tyre as F is

larger) and will act only in the footprint area. The shear strain will

peak at around 8% at the entry to the contact patch and 10% on

exit while reducing in the middle.

SLIPPAGE AND FRICTION ENERGY

In part 1 of this article we considered slippage and friction in some

detail as it is the most fundamental requirement of any tyre, let

alone a racing tyre. Fortunately, it is also much easier to determine

than the various types of strain energy loss. Friction energy arises

from the tread surface area. The total energy from slip is simply the

sum, in the X and Y directions, of the slip multiplied by the force.

May 201022 www.racetechmag.com

FORMULA ONE PAT SYMONDS ON TYRE GRIPwww.racetechmag.com

22

ABOVE Even after the use of tyre blanketsit can be half a dozen laps before a tyrereaches its full working temperature

The stress-strain curve has “memory” ’

Formula One-Pat Tyre Grip Part2.qxd:Racetech.qxd 30/4/10 13:53 Page 7

Adverts 101a.qxd:Racetech.qxd 2/3/09 15:02 Page 1

From Figure 5 we can determine the longitudinal slip speed (Slip X)

which can be approximated for small angles to

Similarly for the lateral slip speed (Slip Y)

The slip energies are therefore, from the X direction:

And from the Y direction:

ENERGY TO HEAT

So how do these energies relate to the heat generation? In part 1

of this article, we looked at the phase diagram for a visco-elastic

material. It is reproduced as Figure 6 in a slightly different form.

In this representation, we have applied a sinusoidal stress to the

material just as before and have a phase lag between that stress

and the subsequent strain. As the X axis is expressed as the angle

of the sinusoidal input we can now express the lag as an angle δ.

Engineers will often use this phase lag as a measure of hysteresis

by referring to the property of the polymer known as “Tan δ”.

This arises from the difficulty of determining a single value for

May 201024 www.racetechmag.com

FORMULA ONE PAT SYMONDS ON TYRE GRIPwww.racetechmag.com

24

70% of the heat build up is in thetread and shoulder, which is whyextremely soft qualifying tyresused to blister on the straight’ ABOVE Track and air temperature

both play a part in determining therunning temperature of the tyres(Photo: Bridgestone Corporation)

FIGURE 5 FIGURE 6

Formula One-Pat Tyre Grip Part2.qxd:Racetech.qxd 30/4/10 13:53 Page 9

Adverts 107 main section.qxd:Racetech.qxd 27/8/09 05:20 Page 3

May 201026 www.racetechmag.com

FORMULA ONE PAT SYMONDS ON TYRE GRIPwww.racetechmag.com

26

the modulus of rubber. The stress-strain

curve has ‘memory’ and does not follow

reversible stress-strain relations. For filled

rubber there is no valid constitutive law.

The higher the value of Tan δ, the more

inherent damping there is in the rubber.

This leads to higher heat dissipation but

also a higher potential for sliding friction.

In order to describe the modulus of

rubber engineers use a descriptor named

the dynamic modulus. In tension this is

referred to as E*. This value is the stress

amplitude divided by the strain amplitude

but, by means of the phase lag δ, allows

the modulus to be split into two parts.

The first is the storage modulus (E’) which

relates to the spring part of the

Kelvin–Voight model we introduced in part

1 and therefore converts kinetic energy

into potential energy. The second is the

loss modulus (E’’) which relates to the

damper element of the model and

therefore converts kinetic energy to heat.

These are related as follows:

So therefore the measure “Tan δ” is:

If we consider the two main sources of

heat generation, friction loss and strain

energy loss, then we find that typically,

even in a racing tyre, the strain energy loss

is the more significant. In general, between

55% and 65% of the total heat generated

by both friction loss and strain energy loss

will come from the strain energy loss.

A NOTE ON TYRE WEAR

It may not have escaped your notice that

the slippage and friction energy is the

energy that has the primary influence on

tyre wear. If we integrate this energy with

respect to time we can determine

and

By integrating the slip velocities with

respect to time, the wear is dependent on

the force and the slip distance. If the limits

of integration are zero and the lap time

then the relevant distance is the lap

distance. This integration shows that equal

wear could be obtained under conditions

of low load and high slip as may be

obtained under conditions of higher load

and reduced slip.

In generalisation, the wear rate will be a

function of the sum of these energies

multiplied by factors that pertain to the

track abrasion, the general compound

wear characteristics and a coefficient that

describes the change in wear rate with

temperature.

ABOVE The theory isn’t confined to the laboratory:tyre companies have worked hard to improve theteams’ assessment of grip and understanding ofthe way the car behaves over consecutive laps

Formula One-Pat Tyre Grip Part2.qxd:Racetech.qxd 30/4/10 13:54 Page 11

FORMULA ONEwww.racetechmag.com

Subscribe +44 (0) 208 446 2100 www.racetechmag.com 27May 2010

27

ABOVE Energy generated from slippage and friction isthe primary influence on tyre wear. This is RubensBarrichello’s Williams (Photo: Bridgestone Corporation)

RT

USING THIS INFORMATION

It may seem that this information is largely

academic. In fact, this is far from the case. In

Formula One the tyre companies have spent

considerable effort in the last few years to

develop thermal models that can be used to

supplement the general Pacejka model to

improve the teams’ understanding of the way

the car behaves over consecutive laps and

give a more accurate assessment of grip. The

ability to predict the bulk temperature of the

tyre, together with knowledge of the thermal

behaviour of a particular compound, can also

be used to determine if the compound may

be prone to blistering on a particular circuit

and, even if blistering is not a problem,

ensure that a compound with a suitable

working temperature range is chosen.

In the concluding article we will look at

how tyre companies may use this

knowledge to choose the correct tyre

compound for a given set of conditions and

how the competitor may use means at his

disposal to alter the characteristics of the

tyre that has been supplied to him.

Of the two main sources of heatgeneration – friction loss andstrain energy loss – the latter istypically the more significant’

Formula One-Pat Tyre Grip Part2.qxd:Racetech.qxd 30/4/10 13:54 Page 12

May 201028 www.racetechmag.com

COVER STORY LOTUS RACINGwww.racetechmag.com

28

Technical chief Mike Gascoyne tells William Kimberley that having won its race against timeto make the grid, Lotus Racing faces a tough choice: develop its car or focus on 2011

STICK OR

TWIST?

ABOVE The T127 has acquitted itself well in the early races, notablysurviving the punishing heat in Bahrain

When you are sitting there with 15people and six months to do it, youhave to make value judgements ofhow to get the car to the race on time’

Cover Story-Lotus.qxd:Racetech.qxd 30/4/10 01:33 Page 1

COVER STORYwww.racetechmag.com

Subscribe +44 (0) 208 446 2100 www.racetechmag.com 29May 2010

29

THIS YEAR has been a rather special

one for Mike Gascoyne. Not only is he

returning to the thick of the action on

the Formula One circuit after a short spell

away, but he is also heading up the technical

team of Lotus F1 Racing. As a Norfolk man

through and through, he is aware of the

responsibility that goes with the name, the

baggage of its history and heritage and the

level of expectation that goes with it.

Nothing can escape the fact, though, that

in reality it is still a start-up team, one that

technically did not even have any facilities to

its name on September 14, the day before

team principal Tony Fernandes, founder of

the AirAsia airline, learnt that it had been

awarded the 13th entry in the 2010 World

Championship. In other words, Gascoyne,

upon whom the weight of responsibility fell

as the chief technical officer, had just six

months and two days to get a car designed,

constructed, tested and onto the grid for

the first race of the season.

However, he had already taken the precaution

of doing some groundwork before receiving

the official green light from the FIA on the

offchance that the team was selected. Through

MGI Motorsport, his own Cologne-based

design consultancy, he had already initiated

design work and identified some suppliers.

“When we got the entry, the chassis and

primary crash structures such as the nose box,

side impact structures and sidepod inlets were

on critical paths which we had to fix before

we’d undertaken any wind tunnel testing

which only commenced in October,” he says.

“Then final design decisions were being made

after just a month or two of wind tunnel

testing. At the same time the fundamental

architecture had to be fixed without data

from the engine supplier. What this added

up to was that we had to be reasonably

ABOVE The dreams of relocation to Malaysiaare on hold for the short-term, with the teamoperating from a factory in Hingham, Norfolk

Cover Story-Lotus.qxd:Racetech.qxd 30/4/10 01:33 Page 2

local companies carrying out work for us.”

The Malaysian consortium has pledged to

commit 168m ringgits (£30m) to starting

up the team and set an annual racing

budget of 308m ringgits (£56m). “I think

the Malaysian government is also very

keen to sponsor Malaysian graduates in

the UK with internships and things like

that,” says Gascoyne.

LOTUS F1 COMES HOME

That the decision was made to go to

Norfolk in England, home of Lotus Cars and

the original Team Lotus when owned and

run by Colin Chapman, was met with

universal praise. However, it did set its own

challenges, as Gascoyne explains.

“Obviously location was a relevant thing

because we decided to locate the factory in

Norfolk at the former Intersport Racing

location in Hingham on which we have a

three-year lease. It is an asset for us because

it’s well-equipped and was originally designed

as a motorsport facility. We had all the plant

and machinery serviced and calibrated and

with an IT infrastructure, carbon clean rooms

and with all the facilities here, it was very easy

to get up and running. It’s very similar in size

to the old Jordan or Force India factory but in

some ways slightly better equipped – and it’s

on a site where there are other buildings

available for expansion purposes.”

No matter how romantic that the new team

has located in Norfolk, a more logical choice

would have been to move to a more

centralised region and not one on the edge,

but Gascoyne disagrees. “There are quite a

number of people in the industry who work

in Formula One teams that have families in

the county because they come from the

infrastructure that exists around here. So in

the event there have been quite a number of

people who have been willing to move back

to the county as they were originally Norfolk-

based and have family connections here.”

The proof of the pudding was that more

than 1,000 people applied for a job when

recruitment began in earnest last autumn.

The main problem, though, has been

getting people with Formula One

experience in quickly enough.

“The bigger problem has been in terms of

designers because while Formula One

experience is not necessary on the production

side – there are composites facilities in Norfolk

because of the junior formula infrastructure –

the main problem is attracting the design and

technical staff,” says Gascoyne. “Most people

in the industry can be on three or six months

conservative to produce a reliable car.”

Being up against it in terms of time and

with little more than a skeleton staff,

Gascoyne had to turn to help wherever it

was offered. “It wasn’t just about the best

supplier but the one that could do it in the

time available. It was quite different criteria

than usual for selecting suppliers,” he says.

“Our hands were very tied in some areas

because it was a case of who had the

short-term capability as opposed to where

the best place was in getting a job done.

For example, we had to use some suppliers

in Germany for the major composite and

suspension components.”

Apart from work on the car, the other

principal challenge was finding a factory

and then staffing it. At first, the talk was of

establishing a state-of-the-art facility in

Malaysia, home of the investors behind

this Formula One team, but a reality check

quickly established that this was impossible

in the circumstances. The immediate

problem was therefore finding somewhere

suitable in Europe.

“Initially it was odds-on that we would

move to Malaysia but there has been a

realisation from the owners that it’s not really

possible,” says Gascoyne. “For the

foreseeable future, Lotus F1 Racing is going

to be based in the UK, specifically Norfolk,

and we are looking at setting up research

centres and maybe a wind tunnel and calling

upon the expertise of such local companies

as Carbon Fibre Technologies, which works

closely with Airbus, and establishing a

partnership with them. During any car-build

period even the biggest teams look to get

help from high-quality sub-contracting

experts and we are very lucky in Norfolk to

have so many great companies on our

doorstep. We will also be using specialists

from Europe and beyond and, of course,

Malaysia but already we have a number of

May 201030 www.racetechmag.com

COVER STORY LOTUS RACINGwww.racetechmag.com

30

ABOVE & LEFT The evocative sightof Ayrton Senna at the wheel of theLotus 97T at Monza in 1985 (above).The team’s history has burdened itwith expectation. Left, in case ofvictory: Colin Chapman wouldcelebrate wins by throwing his capinto the air and the team is readyand waiting if a twist of fate offers itthe chance to emulate its founder

Cover Story-Lotus.qxd:Racetech.qxd 30/4/10 01:33 Page 3

NEWSFEATURESCREDIBLEORIGINALCONTENTINTERACTIVEUSER FRIENDLY

Coming Soon...the new-look RACE TECH website

It is one that is beingdeveloped specifically for theRace Tech reader, people whorequire topical in-depthinformation that is notavailable anywhere else. Therelaunched website will alsogive our advertisers theopportunity to have a directlink from it, thereby openingup huge opportunities forattracting new visitors.

RACE TECHGOES DIGITALRACE TECH is going digital. Thosewho cannot wait to receive theirprinted version can now subscribe to adigital edition. Get the creative designand relevant, focused content of print,the instant accessibility, searchability,and interactivity of the web while alsofeeling good about choosing anenvironmentally-friendly media option.

• Receive your issue much faster thanthe traditional print publication – insome cases, up to three weeks faster

• The digital edition provides for acompletely new experience that includesvideo, audio and animation possibilities

• Content becomes truly interactivewhere you can go directly from themagazine to related content on the Web

• Readers can search the articles usingthe keyword feature

• Issues will be archived allowingreaders to search multiple issuesconveniently for information

To subscribe e-mail:[email protected]

ADVERTISINGON THE RACE TECHWEBSITEAdvantages to Advertisers

• Direct links from your ad on the RaceTech website or the digital edition toyour website

• Link pictures of your equipment directlyto videos or other information givingreaders more information at the initialpoint of contact

• Allows readers to contact advertiserdirectly via e-mail link from the Race Techwebsite or within the digital edition

• Ability to imbed audio or video filesdirectly into your ad

• Detailed tracking information on theactivity connected to your ad

• Connect your ad with your onlinepromotion and market campaign. Drivetraffic directly to your site without having topay for referral clicks from search engines

• Faster delivery to the reader than traditionalpostal mail. Get your message out fast!

• Competitive pricing for print advertisers

For further information on placing abanner, logo or booking a space in theDirectory, contact:[email protected]

Watch out for the new-lookwww.racetechmag.comthe new online motorsportengineering resource

www.racetechmag.com

WEb ad.qxd:Racetech.qxd 30/4/10 16:39 Page 1

ABOVE Jarno Trulli in the thick of the action.The T127 will get an update package forrace five but resources could be switchedearly to focus on the 2011 challenger

However, we got it right because we ran and

finished at one of the hottest races of the year

in Bahrain at the start of the season without

any problems. This was the result of some

good engineering decisions being made.”

WEIGHT DISTRIBUTION

Asked whether the diminishing fuel might

upset the handling of the car as the 160 kg

payload at the start of the race disappeared,

Gascoyne responds: “In some respects some

of that worry passed us by because we didn’t

have time to think about it. We did some

modelling and were aware of where people

were going with weight distribution. There

were concerns in terms of tyre degradation,

especially at the rear with the extra weight,

but we knew where we wanted to aim at

following the modelling in terms of weight

distribution. We are a little limited compared

to some other cars because they have far

more freedom in terms of weight distribution

and can have far more ballast whereas we are

on the weight limit. We estimate that by race

five in Barcelona, though, we will be on our

optimum weight distribution.

“So we got the basic assumptions right but

May 201032 www.racetechmag.com

COVER STORY LOTUS RACINGwww.racetechmag.com

32

notice but if you have just half a year to do

the whole project it means they can’t

contribute very much.”

When it came to designing the car,

Gascoyne deliberately chose to follow

conventional lines as time and resource

meant that he could not take risks and look

for the 2010 equivalent of the double diffuser.

“Our aim was to develop a reliable

package that would cool and finish the first

four races because no matter how quick you

are, you still need to finish and then we’d

make it quicker,” says Gascoyne. “For

example, we always knew the amount of

time spent on aero would be very limited

which means that there are some pretty big

steps we can be making. We can take plenty

of weight out of the car because we weren’t

able to instigate some things like FE work

due to the lack of time and people to do it.

We can also lower the car or reduce the

unsprung masses and we don’t have carbon

suspension at the moment because it just

wasn’t possible to do the iterations and tests

and get it on the car in time, so there is a

project we can very quickly switch onto.

“It’s similar in other areas: we don’t have

any mass dampers because when you

struggle to design a car it’s left as a future

project once the decks are cleared. We can

run the car, get Penske to do the

adjustable lightweight dampers, all the

good things, but when you are sitting

there with 15 or so people and six months

to do it then you just have to make value

judgements of how to get the car to the

race on time. Likewise we knew we didn’t

have time to do a 7-post rig test so we had

to leave it and not worry about it.”

The relationship with Cosworth has worked

out very well, says Gascoyne. “The engine has

been very reliable – its fuel consumption is

good, as is its performance in terms of power.

There are some issues we are solving with

them in terms of general mapping and

driveability – things like fuel volumes because

they didn’t know what the fuel consumption

was going to be as they had never run an

engine to 18,000 rpm in a race. However, we

were making basic architecture decisions

before we even had the figures that were

predicting what was going to happen. This

meant that we were taking some pretty

rough guesses with cooling numbers based

on average face velocities and assumed heat

rejection figures without any definite data.

Cover Story-Lotus.qxd:Racetech.qxd 30/4/10 01:33 Page 5

didn’t have the time to do as much work as some

of the other teams. For example, you only get tyre

data from Bridgestone once you are a confirmed

entrant into the F1 championship. With things like

the revised front tyre for 2010 we didn’t have any

data and were doing the basic architecture for the

car without any. It was a challenge but in the end

we don’t have any compromises so I think we did

our job pretty well.”

However, Gascoyne has a conundrum. While he

knows that he can improve this year’s car, there is

only so much he can do to bring the car up the

grid whereas next year, with the change in the aero

regulations, it is much more of a level playing field.

“We are already looking at the 2011 aero

regulations and the banning of the double diffusers

and how we are going to cope with that and have

accordingly set up a separate design group to deal

with it. Against that, though, is the desire to catch

up this year. However, you don’t want to put too

much resource into trying to do so as it may never

happen anyway and consequently you miss out on

the opportunity of starting on a level playing field

next year. So we have to box clever as a new, small

team. I think that for us the priority of putting

people on next year’s car is very important.”

As with every team on the Formula One grid

this year, Lotus F1 Racing is racing under the

Restricted Resource Agreement, the Formula One

Teams Association’s (FOTA) response to the

proposed budget cap that was put forward by

the-then FIA president Max Mosley.

“I think that what Max was trying to do was

exactly right,” says Gascoyne. “Formula One and

the spending competition had become totally

unsustainable in today’s economy. When I was at

Force India spending €40-€50 million a year and

racing not that far off the pace, the argument was

always that if you had 26 Force Indias on the gird

painted in different colours, would the spectator

really notice the difference? And would anyone

notice the difference where the total cost of that

would be €50 million per team? Of course they

wouldn’t, so it can be done for that. The problem

was that there was a cartel of manufacturers that

didn’t want to give up any advantage.

“Formula One had got to the stage like the

Premier League in Britain where only four or five

teams can afford to spend enough money to be at

the top while the smaller teams can never

generate enough revenue from their results to join

the big group, and that was clearly unsustainable.

I still think a budget cap would have been a good

idea. We’ve got the Resource Restriction

Agreement and it’s not bad as a start but I hope it

becomes much tighter so that it really does limit

what people spend because I think that’s the only

way forward for Formula One.”

COVER STORYwww.racetechmag.com

Subscribe +44 (0) 208 446 2100 www.racetechmag.com 33May 2010

33

ABOVE The T127 noseconeundergoing crash testing. Nevermind race wins, just getting the carto the grid on time was a victory

RIGHT Chief technical officerMike Gascoyne oversaw afrantic dash to get a carready for pre-season testing

The spending had become totally unsustainable but a cartelof manufacturers didn’t want to give up any advantage’

RT

Cover Story-Lotus.qxd:Racetech.qxd 30/4/10 01:34 Page 6

May 201034 www.racetechmag.com

FORMULA ONE LOOSE WHEELSwww.racetechmag.com

34

WHY LOOSE WHEELSDRIVE US NUTS!With all the technology at our disposal in Formula One, it seems crazy that loose wheels are still the cause of retirements.Pat Symonds sheds new light on a familiar problem

A FORMULA ONE car is an incredibly sophisticated piece of

equipment designed by some of the best engineers on the planet and

maintained by technicians chosen for their understanding of

engineering and their attention to detail. How, therefore, can a

fundamental problem like a loose wheel cause a race retirement – a

situation we saw twice in the first three races of the season?

Losing wheels is certainly not a phenomenon exclusive to

motorsport. Reports can even be found in Horse and Hound magazine

about accidents caused by wheel nuts coming off horseboxes.[1] Prior

to EU rules on the subject, many heavy goods vehicles used left-hand

threads on the wheel nuts fitted on the left-hand side of the vehicle.

Recent research carried out in both the UK and Finland [2] showed

that there was a bias toward the problem occurring on the left-

hand side of vehicles. However, the bias was small for loose wheel

nuts but large for wheel detachment, suggesting that the thread