R35 CANTILEVER LARGE FORMAT PRECAST VERTICAL WALL …

Transcript of R35 CANTILEVER LARGE FORMAT PRECAST VERTICAL WALL …

ACP CONCRETE LTD We are Part of the Thomas Armstrong Group

www.thomasarmstrongacpconcrete.co.uk

• Low level Floor Retaining Walls – provide soil retaining inpermanent applications including bund walls, machineryinspection pits, car parks and landscaping projects.

• Attenuation Tanks up to 3m deep

• Ramp Walls

• Insulated Plant/Switch rooms

• Machinery Pits

• Small tanks up to 3m deep

• Agriculture – milking parlour pits, grain elevator ducts, slurrychannels and bund walls.

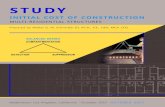

STANDARD WALL PANELS SIZES

R35 CANTILEVERLARGE FORMAT PRECAST VERTICAL WALL PANELSOur R35 precast concrete wall panels o�er a large format wall solution providing rapid, safe construction which minimises the number of panel joints with improved aesthetic bene�ts when compared to the prestressed panel system.

This system is designed for a wide range of applications including low-level retaining walls, attenuation tanks up to 3m deep, insulated plant/switch rooms, ramps walls and machinery pits.

The support depends on the wall height and anticipated loads but consists of protruding reinforcing bars cast into the �oor slab, typically 200mm thick.

Additionally, if the design requires, the precast wall panels can also be �xed via a structural connection between the top of the panel and a higher-level �oor slab

Manufactured o�site in controlled factory environment conditions from high grade 60 N/mm²engineering grade concrete to recognised industry standards i.e Eurocode 2, BS8110, BS5502 Part 22.

APPLICATIONS

Depth / Stem Thickness

Length

Width / Height

We are Part of the Thomas Armstrong Group

www.thomasarmstrongacpconcrete.co.uk

ACP R35CW 09.20

R35 CANTILEVER VERTICAL PRECAST CONCRETE WALL

CamberUnits will have little or no camber

Sound Attenuation

On request, please contact us.

Contact Us

For all Precast Wall Panels enquiries please contact us on 01889 598 660

DISCLAIMER: Please note that any information provided is to be used as a guide only. Any lifting/handling operations should be carried out by trained and competent personnel only. ACP (Concrete) Limited will not be held responsible for any damage or injuries in connection with handling or installation not carried out by ACP (Concrete) Limited.

MaterialsAll materials are sourced in accordance with the appropriate British Standard and in accordance with the ACP (Concrete) Ltd performance specifications.

• Concrete typical 28 days strengths are 60 N/mm²

• Concrete strength at transfer 30 N/mm²

• Water cement ratio 0.45 Maximum

• Reinforcement typically bent bar and mesh

DesignAll units are designed in accordance with BS8110 and BS 5502.

Unit design is typically to Class 3 with a limiting crack width of 0.1mm unless otherwise stated.

It is the client’s responsibility to provide loading data including bulk material density, angle of internal shear resistance and load condition. Any surcharge or impact loadings must be provided.

ManufactureThe large format precast wall panels are manufactured in tilting tables. Units are wet cast into steel moulds. Standard unit sizes are as follows:

TolerancesCross-sectional tolerances are within limits set out in clause 6.2.8.3 of BS8110:1997. ACP (Concrete) Ltd acceptable tolerances for standard precast units are as follows:

Special cast units will be to tolerances laid down in BS8110 where casting techniques permit.

Mould FinishesAll faces with the exception of the trowel face will be cast from steel shutter moulds. Surface �nish is listed in BS8110 6.2.7.3 and is to conform to Type A.

• Small blemishes caused by entrapped air,excess mould release agent, marks on thecasting surface and mould release agentstaining can be expected.

• The surface will be free from voids andhoneycombing.

• Surface marks from stacking timbers, strandruns and fork truck tine marks can be expected.

• Surface marks of stacking timber, strand runand mould release agent will fade out over timeand use.

• Where a blemish free surface is required,masonry paint application is recommended.

Trowel Finishes• The trowel face of units will comply with a U1

type finish.

• Finish will be uniform and provide full grout cover to aggregates.

• Some trowel marks will be visible.

• Some colour and texture variation may be expected.

• Stacking timber marks and cement blooming may be expected.

• Colour variation, trowel pattern and cement blooming will fade over time and weathering.

• Where uniform colour is required, masonry paint or mineral staining is recommended.