Single Toggle Jaw Crusher Manufacturers,Single Toggle Jaw Crusher for Sale

R J-1170AS JAW CRUSHER - vanlaeckegroup.com · The NEW J-1170AS jaw crusher provides the...

Transcript of R J-1170AS JAW CRUSHER - vanlaeckegroup.com · The NEW J-1170AS jaw crusher provides the...

Transport Dimensions

Working Dimensions

R

The NEW J-1170AS jaw crusher provides the flexibility of a crushing

and screening plant on one machine. This aggressive machine

features a detachable on-board sizing screen that gives operators

the capability of producing two spec sized products. The heartbeat

of the machine is a robust hydrostatically driven Terex jaw chamber

which provides high capacity with large reduction ratios. The jaw

chamber configuration can be set up specifically for quarrying

applications or processing construction demolition debris using

the hydraulic release chamber option. The J-1170AS features a

heavy duty variable speed VGF and integrated prescreen giving

excellent production throughput in quarrying, mining, demolition

and recycling applications.

J-1170AS

TM

On board After Screen delivering a single sized product removing the need for a second machine.

After Screen system can be removed quickly allowing the operator to use as a standard unit, giving the operator versatility depending on the application.

Automatic variable speed VGF ensures continuous choke feeding of the crushing chamber for optimal productivity.

High powered hydrostatic drive ensures precise chamber control and reverse functionality for clearing blockages and assisting in demolition and recycling applications.

Hydraulic assisted closed side setting adjustment minimises downtime and offers quick adjustment.

u

u

u

u

Features:

u

STANDARD FEATURESEngine:Tier 3 / Stage IIIA : Caterpillar C9 Tier 3 ACERT. 261kW (350hp)

Tier 4F/ Stage IV: Scania DC9 257 kW (350 hp) Stage IIIa (Tier 3): Constant Speed Scania DC9 273kW (365hp)

(EU ONLY)

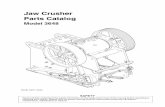

Jaw Chamber:Terex 1100 x 700mm (43” x 27”) Single toggle jaw crusherCSS range from 50mm (2”) to 150mm (6”)

75mm pre-set closed side setting for quarry applications

40mm (1.5”) thick wear resistant cheek plates

Hydrostatic drive and advanced electronic control system

Reversible operation for clearing blockagesS’ Tooth Liners - 18% Manganese as standardHydraulic assist closed side settingAvailable in either hydraulic assist or hydraulic release

Hopper / Feeder:Hopper Capacity: 9.66m3 (12.5yd3)

Belt width: 2.4m (7’ 10”)

10mm thick hopper walls fabricated from wear resistant steelHydraulically foldable sides and rear on hopper

Heavy duty vibrating feeder

Selectable discharge to by-pass conveyor or main conveyor

Integrated pan and feeder - cassette is 75mm spacing as standard

Mesh aperture on grizzly feeder: 38mm

Main Conveyor:Belt width: 1000mm (40”)

Discharge height: 3.1m (10’ – 2”) if afterscreen section is detached

Impact bars & wear resistant liners at crusher discharge point

Hydraulic Raise/Lower of the conveyor as standard

Afterscreenu Screenbox: 2.5m x 1.52m (8’ x 5’)

u Oversize Conveyor: 650mm wide belt; 2.8m discharge height

u Fines Conveyor: 1400mm wide belt; 2.8m discharge height

u Both conveyors are hydraulically folding, requiring no manual intervention with cranes, etc

Chassisu Heavy duty fabricated ‘I-Section’ Construction

u Increased service access with large open sections

Catwalksu Catwalk access to left hand side and rear of jaw

chamber and also to both sides of the engine enclosure

u Catwalks are fully galvanised

By-Pass Conveyor (Optional)u Wide plain belt: 650mm (26”)

u Discharge height: 2.9m (9’ 6”)

u Stockpile Capacity: 36.3m3 (47.5yd3) @ 40°

u Hydraulically foldable for transport

Hopper/Feederu Standard hopper capacity: 9.66m3 (12.5yd3)

u 2.4m (7’ 10”) across the width of the hopper

u 11m3 (14.4yd3) hopper capacity with optional hopper extensions

u 10mm thick hopper walls fabricated from wear resistant steel

u Hydraulically foldable sides and rear on hopper

Chamberu Terex Jaw Chamber

u Jaw inlet opening: 1100mm x 700mm (44” x 28”)

u CSS range from 50mm (2”) to 150mm (6”)

u 40mm (1.5”) thick wear resistant cheek plates

u Hydraulic assist closed side setting

u Available in either hydraulic assist or hydraulic release

Powerunitu Tier 3 / Stage IIIA : Caterpillar C9 Tier 3 ACERT. 261kW (350 hp)

u Tier 4F/ Stage IV: Scania DC9 257 kW (350 hp)

u Stage IIIa (Tier 3): Constant Speed Scania DC9 273kW (365hp) (EU ONLY)

Machine weight: 55,000kg (121,254lbs) (without by-pass conveyor and magnet options)

3.4m

(11’

)

16m (52’ 8”) 2.95m (9’ 8” )

4.01

m (1

3’ 2

”)

6.04m (19’ 10”)17.16m (56’ 3”)

AFTERSCREEN:Screenbox: 2.44m X 1.52m (8’X5’) Single deck screen

Oversize Conveyor: 650mm wide belt;

Discharge height: 2.8m

Fines Conveyor: 1.4m wide belt;

Discharge height: 2.8m

Both conveyors are hydraulically folding, requiring no manual intervention with cranes, etc.

Rapid detach after screen system for flexability.

R

www.terexfinlay.com

Effective June 2014. Product specifications and prices are subject to change without notice or obligation. The photographs and/or drawings in this document are for illustrative purposes only. Refer to the appropriate Operator’s Manual for instructions on the proper use of this equipment. Failure to follow the appropriate Operator’s Manual when using our equipment or to otherwise act irresponsibly may result in serious injury or death. The only warranty applicable to our equipment is the standard written warranty applicable to the particular product and sale and Terex GB Ltd. makes no other warranty, express or implied. Products and services listed may be trademarks, service marks or trade-names of Terex Corporation and/or its subsidiaries in the USA and other countries. All rights are reserved. Terex® is a registered trademark of Terex Corporation in the USA and many other countries. Copyright 2010 Terex GB Ltd.

Follow us on: