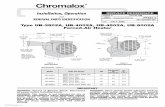

Quick Lift UB Series Product Manual - LECTURA Specsa… · Quick Lift UB Series Product Manual - 1...

Transcript of Quick Lift UB Series Product Manual - LECTURA Specsa… · Quick Lift UB Series Product Manual - 1...

Quick Lift UB Series Product Manual

- 0 -

Quick Lift UB Series Product Manual

- 1 -

Congratulations on your purchase of this

quality Quick Lift Product!

Before operating, please read this manual

thoroughly and follow the safety rules closely.

CONTENTS

1. Product Schematic Diagram..................................................................... 2

2. Product Introduction……………………………………………………. 3

3. Technical Specifications…………………………………………….….. 4

4. Operating Instructions…………………………………………….……. 5

5. Hydraulic System………………………………………………………. 11

6. Electrical System………………………………………………………. 12

7. Machine Maintenance………………………………………………….. 13

8. Safety Rules……………………………………………………………...16

9. Transport Instructions……………………………………………………17

10. Maintenance & Repair Record………………………………………… 18

11. Charger Operating Instructions…………………………………… .…. 19

Quick Lift UB Series Product Manual

2

1. Product Schematic Diagram

1. Work Platform

1a. Guard Rails

1b. Entry Gate

1c. Hand held controls

1d. Document Box

2. Scissor mechanism assembly

3. Actuating cylinder

4. Chassis (inside)

4a. Battery

4b. Tilt Sensor

4c. Emergency Down

4d. Pump assy

4e. Battery charger

4f. Hydraulic oil reservoir

5. Tool box

6. Forklift pocket

7. Level indicator

8. Brake wheels

9. Main Control Panel (for detailed view

refer to page 6)

9a. Change-Over selector

9b. Key Switch

9c. Emergency Stop

9d. Hour meter

9e. External Battery Connector

9f. Button Battery Charge Indicator

9g. Low Voltage Alarm

Quick Lift UB Series Product Manual

3

2. Product Introduction

QUICK LIFT is a small scissor type single person work platform, which can be manually

moved into work positions. The platform changes elevation using an electro-hydraulic control

system.

This handbook describes dangerous situations which should be avoided due to high risk of

serious human injury or death , as well as damage to the machine or property.

All personnel should read carefully every warning sign in this instruction manual and follow

the operating rules. Operators of this equipment should be given adequate training. The onus is

on the owner of the equipment to ensure that this training is carried out.

QUICK LIFT small scissors are suitable for low level access such as in cleaning, painting,

decorating and general maintenance type work of less than 5 meters height. Quick Lift series

models are designed to pass through standard doorways and are well suited for small/confined

work spaces. Applications include warehouses, supermarkets, department stores, shopping

malls, offices, commercial premises, hotels, restaurants, construction fields, railway stations,

subways, hospitals, universities and schools.

Key Features:

Quick ascend and descend.

Rechargeable battery powered for easy mobility.

Descend alarm.

Castor wheels equipped with braking mechanism.

Self-closing platform access door.

Emergency down valve.

Forklift pocket provision.

Platform safety bars.

Easy hand-held controls with spiral cord.

Anti-slip platform floor.

Motor overheat protection.

1 year standard warranty on parts & labor.

Quick Lift UB Series Product Manual

4

3. Technical Specifications

Model UB 6 UB 8 UB 10

Working Height (m) 3.8 4.5 5.0

Platform Height (m) 1.8 2.5 3.0

Rated Capacity (kg) 240 240 200

Machine Weight (kg) 270 315 515

Platform Size (m) 1.04x0.57 1.04x0.57 1.4x0.65

Stored Dimensions (m) 1.2x0.7x1.70 1.2x0.7x1.74 1.5x0.75x1.8

Time to reach max. height

(sec) 11/13 19/21 21/25

Time to return to min. height

(sec) 14/7 22/10 25/16

Foot print (m) 0.6x0.95 0.6x0.95 0.65x1.19

Initial Platform Height (m) 0.57 (1 step to reach) 0.65 (1 step to reach) 0.65 (1 step to reach)

Travel (m) 1.23 1.85 2.35

Battery (V/Ah) 12 DC / 80 12 DC / 100 12 DC / 100

Motor (kW) 0.8 1.2 1.2

Battery charger Input Voltage

(V) 230 (or 110) 230 (or 110) 230 (or 110)

Max. Allowable manual force

(N) 200 200 200

Max Allowable wind speed

(m/s) 0 0 0

Max Allowable inclination

(degrees) 1.5 1.5 1.5

Quick Lift UB Series Product Manual

5

4. Operating Instructions:

Setting up the Machine:

1. Ensure that the floor on which the QUICK LIFT is to operate is capable of supporting the weight of

the machine carrying the operator and tools. Beware of false floors or coverings (e.g. manhole

covers) that may not withstand sharp loadings exerted by the wheels.

2. QUICK LIFT should only be operated on flat level surfaces. The allowable chassis inclination is

shown by the spirit level bubble falling within the red circle marked. Castor wheels must be in full

contact with the ground and brakes engaged.

3. Ensure that there are no overhead obstructions and adequate clearance is available above and

around the platform before elevating the platform.

4. Move the machine to the location where aerial working is required. Check if centre bubble level is

achieved and adjust position slightly if required. Lock brakes on wheels.

Operation:

1. On the main control panel, set the Change-Over-Switch to "ON" position. Battery indicator light will

lite up. Turn the key-switch to the "ON" position.

2. Enter the platform through the access gate. Make sure that the gate closes after entry.

3. Release the emergency stop switch button on the platform hand held controls.

4. Depress the "UP" button to raise the platform. When the required height is reached, releasing

pressure on the button will stop the platform. Commence aerial work.

5. Check that the area beneath the platform is clear before depressing the "DOWN" button to lower the

platform. Releasing pressure on the button will stop the platform.

6. Lower the platform fully using the “DOWN” button.

7. Depress the platform control’s emergency stop button.

8. Set the Change-Over-Switch to the "OFF" position.

9. Turn the key-switch to the “OFF” position. Remove key.

Closing up the machine:

1. Store the machine in a clean dry environment. Never move the machine unless the platform has

descended to the lowest position.

2. Lock the brakes on the wheels to prevent any inadvertent movement.

Quick Lift UB Series Product Manual

6

Note: If during the execution of the above procedure, malfunctions or damage on the machine were

discovered. In this event, the machine must not be used until the problem is rectified. If in

doubt, seek assistance from the manufacturer.

How to charge the battery after use:

A battery indicator meter is fitted to the QUICK LIFT as shown in the photograph below. When all segments

of the display are illuminated the battery is fully charged. When 2 or more segments are not illuminated then

the battery should be recharged.

To charge the battery, follow these steps.

1. Connect the female plug of the battery charger’s power cord

to the power socket situated below the main control panel’s

change over switch, then connect the male plug to a 230VAC

power supply.

2. Set the Change-Over-Switch to "CHARGE" position.

3. The battery is now under charging.

4. Charging is complete when charger indicator light turns green.

Red light appears on charger when power is connected.

Red light appears on charger during charging

Green light appears on charger when charging is complete.

Operation of Change-Over-Switch

QUICK LIFT is provided with a key operated switch which isolates the electrical system, preventing

unauthorized use. To enable the electrical system, set the Change-Over-Switch to the “ON” position. Then

insert the key into the Key switch and turn the key clockwise to “on”. Release the emergency stop button

When the machine is not in use, the Emergency Stop Button should be depressed and the key on the key

switch removed. Turn the Change - Over Switch to the “OFF” position.

External Battery Connector

In the event of too low battery to raise the platform, the back-up

power connector can be used to connect to an external 12V battery.

Remove the connector cover (held by two screws) and connect the

external battery using the cable stored inside the tool box (Refer

photo).

Quick Lift UB Series Product Manual

7

Level Indicator:

Always ensure that the bubble is kept within the red circle

mark before operation

Document Box:

The box is located on the machine’s platform and contains

the following:

Product Manual- Including:

- Warranty Certificate.

- Quality Control pass certificate..

- Customer satisfaction survey.

AHI brochure.

Customer Satisfaction Survey.

Hour meter:

This meter registers the accumulated operation hours of of the machine.

It commences registering when the Change- Over Switch and the Key-

Switch are set to their “ON” positions and stops registering when the

Key-Switch is set to its “OFF” position.

The Hour meter provides important information with regard to the

machine’s servicing requirements.

Low voltage alarm:

This feature awares the user of battery low voltage. When the battery’s

voltage falls bellow 11 volts the alarm will be activated (audible and

visual) and the battery should be recharged immediately.

Engaging the brakes:

Always ensure that both castor wheel brakes are engaged before entering the work platform to prevent any

inadvertent movement. This is done by pushing down the lever marked “ON” (the narrower lever). Pushing

down on the wider lever (marked “OFF”) releases the brakes. (pictures below.)

Engaging the brakes Releasing the brakes

Quick Lift UB Series Product Manual

8

Entering and leaving the work platform:

Always use the three-point-contact rule when entering or exiting the platform. Use two hands to hold securely

the handrails and place your foot on the step provided on the chassis before accessing the platform (pictures

below).

After entering the platform, ensure that the gate is closed behind you.

Hand Held Control Box

The control box houses “Up” , “Down” and “Emergency Stop”controls.

Pressing the ‘UP’ button raises the platform.

Pressing the ‘DOWN’ button lowers the platform.

Pressing Emergency Stop Switch isolates power to the platform raising

and lowering functions.

To restore functionality, turn the emergency stop button clockwise to release

the button, as shown below.

While on the platform, keep loading well balanced and move as steadily

as possible.

Quick Lift UB Series Product Manual

9

Tilt Sensor (OPTIONAL EXTRA)

The tilt sensor is set to trigger an alarm if the lateral or longitudinal tilt angle of the chassis exceeds 1.5o.

Depressing the emergency stop button will stop the tilt alarm.

Note: To return the machine to normal operation, place the machine on a level condition, and release the

emergency stop button.

WARNING:

Failure to correctly calibrate the tilt sensor will result in the tilt sensor failing to operate normally and could

result in serious injury or death .

The tilt sensor is not intended to replace the spirit level indicator functionality. Spirit level must show

correct before any operation.

NB. The sensitivity of the tilt sensor may cause alarm to sound when pushing the machine too quickly. This

should cease once the machine is stationary.

Moving the platform:

Move the platform into position using both hands on the platform railings as shown below.

Caution: Release brakes first. Keep hands and feet clear whilst attempting to move the platform.

Never move the QUICK LIFT whilst it is elevated or carrying personnel, tools or materials on the

platform.

Quick Lift UB Series Product Manual

10

Tool Box:

At one end of the chassis beneath the step is a tool storage drawer held in position with a retainer pin.

Pull the pin to unlock the drawer. Release the pin to lock it.

The drawer is used to store the battery charger’s power cord and back up emergency power

connector.

Quick Lift UB Series Product Manual

11

5. Hydraulic System:

(A) Operating Principle

The pump delivers high pressure hydraulic oil

as the electric motor is switched on. This

pressurised oil flows through the unidirectional

valve into the hydraulic cylinder. This in turn

pushes the platform up gradually. The relief

valve adjusts the working pressure delivered to

the cylinder in accordance to the loading on the

platform. This mechanism prevents overloading

or excessive pressure. When descending is

called for, the electric solenoid valve is

activated. The platform weight pushes the oil

back hydraulic cylinder through the valve block

on the pump. Due to the presence of the unidirectional valve, this oil can only flow through the double

acting valve and through the flow restrictor into the oil reservoir. As a result, the platform lowers gradually.

As the valve block is designed to achieve pressure equilibrium, platform action is only controlled by the

electric solenoid valve and hence the stability of the ascending and descending speed can be maintained.

(B) Hydraulic System Maintenance

1. The specification of the hydraulic oil used is ISO32.

The oil requires a complete change once a year.

Mixing of oil with other fluid and introduction of

any other fluid into the oil tank are strictly forbidden.

Should the oil level fall below normal operating

level, the platform will not reach its maximum

height. In addition, the noise coming from the

hydraulic system during lifting of the platform will

increase and may sound abnormal. If this happens,

top up the oil tank with ISO32 hydraulic oil.

2. If the manual lowering valve is used during an

emergency to lower the platform to its stored position, please remember to return the valve spindle to its

original closed position. The platform cannot be raised normally unless this is carried out to close the

valve.

3. Do not adjust the hydraulic pressure setting and change any original hydraulic system parts without the

approval of the supplier of the machine.

Recommended Hydraulic Oil based on ambient temperature

Normal above 32oF (0

o C) - ISO32 or ISO46

Low Temp 32oF (0

o C) - ISO32

Below 0oF (-17

o C) - ISO15

Quick Lift UB Series Product Manual

12

6. Electrical System

Quick Lift UB Series Product Manual

13

7. Machine Maintenance

WARNING:

When performing maintenance on the QUICK LIFT with the platform elevated, always ensure that the

safety bars are engaged as shown in the illustration below. failure to engage the safety bars during

maintenance may result in the platform lowering without warning and causing serious injury or death.

1. Remove all tools and material from the platform.

2. Use the platform control box while on the ground and press on the “UP” button to raise the platform.

Check that this is high enough to applysafety bars.

3. Swing the safety bars from storage position to the support position as shown in the picture above.

4. Keep hands and all body parts clear from the scissors arms area.

5. Lower the platform slowly until the scissor platform is supported by the safety bars.

To return the Safety Bars to Stowed Position:

1. Use the platform control box while on the ground and press the “UP” button to raise the platform

slowly. Check that it is sufficiently high to swing the safety bar back into its stowed position.

2. Carefully swing the safety bar back into its stowed position.

Regular Maintenance & Checks

The electrical components included with the QUICK LIFT are not protected from adverse outdoor weather

conditions. At all times, the machine should be used indoors and stored indoors in a clean, dry environment.

Regular checks on the machine should be conducted to ensure its safe operation.

The following points should be noted:

1. Conduct a quick check on the Quick Lift everytime before use.

2. If the machine has not been used for some time, a more thorough check is required to cover the

mechanical, hydraulic and electrical systems.

3. The lifting mechanism should be checked every six months.

4. Complete test on the functionality and operation of the machine should be done after each round of

maintenance on the machine.

Quick Lift UB Series Product Manual

14

5. Only qualified technicians should be allowed to conduct maintenance on the machine. In addition,

only approved parts can be used to replace any damaged parts on the machine during maintenance or

service. Deviation from this rule may result in the machine becoming unserviceable.

6. It is recommended that checks be carried out on the parts at the indicated intervals as below

Daily/Pre-use Monthly 6 Monthly 12 Monthly

Structural Parts Y Y Y Y

Platform, Gate and Handrails Y Y Y Y

Brakes & Wheels Y Y Y Y

Linkages & Connectors Y Y Y Y

Hydraulic Oil - Check level & any leaks Y Y Y Y

Battery Condition Y Y Y Y

“Up” & “Down” Functions Y Y Y Y

Warning Signs Y Y Y Y

Electrical Wiring Y Y Y

Electrical Contacts Y Y Y

Lubrication - (guides pivot pins) Y Y Y

Replace Hydraulic Oil Y

Hydraulic oil:

The oil level in the reservoir tank should be checked regularly. This can be done by removing the dip stick on

the oil reservoir and checking that the hydraulic fluid remains on the tip of the dipstick. The platform should

be in the stored position to conduct this check.

To top up the hydraulic oil, add oil carefully to the oil refill point as shown.

To Drain hydraulic oil, disconnect the hydraulic pump and remove the bolts connecting the oil reservoir tank

to the pump. Dispose the hydraulic oil properly. Re-assemble the reservoir back to the pump body after filling

with fresh oil.

Quick Lift UB Series Product Manual

15

Trouble shooting

PROBLEM CAUSE REPAIR

Platform does not raise

( motor is not running)

1. Incorrect Operating Method

1. Rotate CHANGE-OVER-Switch

to the “ON” position and the Key

switch to “ON”

2. Wiring connection wrong. 2. Refer to the electrical schematic

and check wiring.

3. Battery charge is low 3. Re-charge the battery.

Platform does not raise

(with motor running)

1. Hydraulic oil is low. 1. To up with hydraulic oil.

2. Hydraulic pump is faulty. 2. Replace hydraulic system

3. Relief valve out of adjustment. 3. Check & adjust relief valve.

Platform raises slowly and

does not remain in elevated

position

1. Leakage in hydraulic oil system 1. Replace descend valve.

2. Hydraulic conduit leaking likely

through joints.

2. Check where leakage originated

and refit the joint.

Oil leakage from hydraulic

cylinder or conduits

Faulty seals or joint requires

tightening

Change seals or tighten affected

connections

Oil leakage from conduits

or near reservoir

Joint seals faulty.

Oil filled excessively during top up.

Change seals and check no leakage.

Drain excess oil.

Quick Lift UB Series Product Manual

16

8. Safety Rules

1. CRUSHING RISK: Always keep body parts away from scissor arms

before operating the machine.

2. NEVER operate at close proximity of live conductors.

Electricity Kills!

3. NEVER undertake any repair or maintenance under the platform

without blocking scissor arms using bars provided.

4. NEVER operate the platform if the level indicator shows the machine

is not on level ground.

5. NEVER raise platform without locking brakes.

6. NEVER enter or exit the platform unless it is at the lowest position.

7. NEVER use machine as a goods lift or a people mover. Never use the

platform to pull or apply an external load.

8.NEVER use ladders or other devices to increase the height of the

platfor

Caution:

NEVER raise platform while machine is on truck or a loading

platform.

NEVER sit-on, stand on or climb over the platform guard-rails or

mid-rail to conduct aerial work.

Please note that the battery forms part of the counterweight

system in the design of the machine and should not be changed to

a different weight or size without checking with the supplier

Quick Lift UB Series Product Manual

17

9. Transport Instructions

Loading and Unloading

When loading or unloading the QUICK LIFT, use one of the methods shown below.

The QUICK LIFT can be lifted into positions using a forklift. During lifting, make sure that the forks are

inserted into the forklift pockets above the castor wheels. These forklift positions are shown by the safety

stickers above the four castor wheels. Apply brakes before lifting.

WARNING

NEVER attempt to Load or Unload the QUICK LIFT manually without proper equipment or assistance.

As no lifting lugs are provided on the QUICK LIFT, extreme care should be taken to lift the machine using

lifting straps. Failure to do so may result in serious Injury to the Operator and/or damage to the machine or

property.

Preparation for transport

Normal due care and precautions should be taken prior to transporting the QUICK LIFT on a vehicle.

Failure to do so may result in serious injury to the operator and/or damage to the machine or the

transport vehicle or property.

Only transport machines in the stored position with brakes applied and with the machine securely tied down

to the transporting vehicle.

Quick Lift UB Series Product Manual

18

10. Maintenance & Repair Record

WARNING: Regular checks should be undertaken by qualified and trained technician for early and prompt

detection of any faults or unsafe condition in the machine. Failure to do so may result in serious

injury to the operator and/or damage to the machine or property.

Daily Checks

a) Prior to operating the platform, make sure that the following items are checked and confirmed as in

proper order. A similar format as below can be used to record the checks carried out and the record book

kept with the machine.

Date:

Operator:

Machine Serial Number:

Tick Item after checking Tick Item after checking

Structural Parts Emergency Stop

Platform, Gate &

Handrails Brakes & wheels

“Up” & “Down”

Functions

Emergency

Down Valve

Oil Leaks Warning Signs

Battery charge Hydraulic Oil

b) Make sure that the “Up”, “Down” & “Emergency Stop” functions are all operating correctly.

Report any faults immediately to your supervisor.

c) Repairs should only be carried by qualified and trained technicians who are authorized to do so.

If necessary, seek assistance from the manufacturer or supplier.

d) Any repairs carried out by authorized technicians should be entered in the Record Book.

Quick Lift UB Series Product Manual

19

11. Charger Operating Manual 1. Description:

The charger selected is a compact type battery charger, using the latest PWM switching technology to

charge a battery. It is a light weight, compact and high efficiency charger with a wide range of input

voltage. The steady current and voltage output prevents overcharging and prolongs battery life. The

automatic gradual adjustment in charging time, current and voltage according to the battery condition

extended battery life.

2. Charging Procedure:

1) First connect the Positive (Red) wire from the charger to the Positive terminal of the battery. Connect

the Negative (Black) wire from the charger to the Negative terminal of the battery.

CAUTION: Wrong connection could damage the battery.

2) Using the charging cord provided, connect the socket end to the charger and then the plug end into a

power supply socket. The power supply indicator light (RED) will appear. At the same time, the

charging light (YELLOW) will also light up, indicating normal charging has commenced. After 6-10

hours of charging, the Yellow light will be off and the floating charge light (GREEN) will light up.

This means that charging is complete and the charger is at a floating or buffer state.

3) Once charging is complete, disconnect the plug from the power socket.

3. Trouble Shooting:

1) If the RED power supply indicator light does not light up when charging starts or during charging,

check if the supply is available or if the fuse is burnt.

2) If at the commencement of charging, the green indicator light is on. Check that the plug or the power

socket connection is faulty. Alternatively, the battery itself is already fully charged indicating a state of

floating charge.

4. Caution:

1) The charger terminal should be connected to the correct terminal (Positive to Positive, Negative to

Negative), otherwise damage to the charger will occur.

2) Charger is suitable for charging the 12V battery and should not be used for any other purposes.

3) Protect the charger from exposure to moisture.

4) When the Yellow indicator light is on, charging is going on, fan will operate. When the Green indicator

light is on, charging is complete, fan will stop. If the fan is not operating during charging when the

Yellow indicator light is on, stop using the charger.

5) If the Power supply light (Red) light is not on check the fuse to see if this needs replacement (see

picture). Use only the correct fuse rating.

5. Charger Output Wiring:

1) The Red cable from the charger is POSITIVE

2) The Black cable from the charger is NEGATIVE

3) Use 8A power socket to connect to charger

6. Technical Specifications:

Model Input (V) Input (A) Rated Output

(A)

Battery

Voltage (V)

Capacity

(AH)

External Dimensions

(mm)

1215A 200-240 ≤14.8 15A 12V 80~120 170*120*50

Quick Lift UB Series Product Manual

20

UB Series Elevated Work Platform

ISO9001 Quality Management System Certification.

CE & AS1418.10 Compliance

The product is insured by CPPIC

The Company reserves the right to alter its design & specification

without prior notification.

Version: Dec 2014