Purification of Japanese Vaccine by Centrifugation · Abbreviations: (ppt) precipitate; (sup.)...

Transcript of Purification of Japanese Vaccine by Centrifugation · Abbreviations: (ppt) precipitate; (sup.)...

JOURNAL OF CLINICAL MICROBIOLOGY, Jan. 1975, p. 96-101Copyright 0 1975 American Society for Microbiology

Vol. 1, No. 1Printed in U.S.A.

Purification of Japanese Encephalitis Virus Vaccine by ZonalCentrifugation

KOREMASA OKUDA, KOZO ITOH, KOICHI MIYAKE, MICHIO MORITA, MASAO OGONUKI, ANDSEIJI MATSUI

Chiba Serum Institute, Ichikawa, Chiba, Japan

Received for publication 1 November 1974

A large-scale procedure for purification and concentration of Japaneseencephalitis virus vaccine by a continuous-flow isopycnic banding technique in asucrose density gradient solution, using a K-III zonal centrifuge rotor, ispresented. The quality of zonal-purified vaccine was compared with commercialand Japanese National Institutes of Health reference vaccines for antigenicity,immunodiffusion, and allergic encephalitogenicity tests to show its high purity.

Both live and inactivated Japanese encepha-litis (JE) virus vaccines have been studied inthe United States and Japan. In spite of manystudies, a suitable strain of live vaccine that isacceptable for human use has not been found (8,9). Inactivated vaccine has been produced byseveral methods including tissue cultures (3, 15,16) of mouse or chicken embryo origin. JE viruspropagates well in mouse brain and this type ofvaccine has a high antigenic potential. In Ja-pan, this type of vaccine has been producedsince 1954.

Since 1954, the number of people vaccinatedhas increased yearly, and in recent years asmany as 24 x 106 doses have been produced andused every year. As people are injected manytimes in their lifespan, a vaccine that contains aminimum of impurities is required.The purity of the early vaccine was not high;

however, it has been increased by chemical andcentrifugation purification techniques (12, 17).It is known that experimental allergic encepha-litis is caused by injection of nervous systemtissue of various animal species with Freundadjuvant clinically or histologically (4, 5). Thetype of vaccine prepared from brains or spinalcords of infected animals is thus capable ofcausing allergic encephalitis. Although Okinakaand his associates have recorded very few casesof demyelination after repeated injection of thevaccine to many thousands of people (13), theJapanese National Institutes of Health (JNIH)restricts the protein-nitrogen (P-N) content ofJE vaccine to under 10 gg/ml (11) to avoidpossible hazardous side reactions. Althoughcurrent JE vaccine is highly purified, smallamounts of impurities originating from tissueprotein are still permitted. It is vital that apurification procedure minimize the amount ofhazardous allergic tissue protein present.

96

At present, vaccine production requires largequantities of crude viral material. In addition,the purification procedures are both laboriousand very complicated. The development of largecapacity continuous-flow zonal centrifugationby Anderson et al. has made possible theconcentration and purification of large volumesof crude viral materials (1, 7). This paper de-scribes the application of continuous-flow zonalcentrifugation for mass purification of JE virusvaccine.

MATERIALS AND METHODSVirus strain. Nakayama NIH virus strain supplied

by the JNIH was used. After one passage in sucklingmouse brain in our laboratory, the strain was frozenand stored at -80 C. At the time of thawing, the virustitered 10-80 mean lethal dose per 0.03 ml by in-tracerebral injection of adult mice. This virus wasused both for production of the vaccine and as achallenge virus in the antigenicity test.Vaccine preparation and purification. A stock

virus preparation was injected intracerebrally intoadult, 21- to 28-day-old mice. After full developmentof paralysis, moribund mice were killed, and theirbrains were harvested aseptically.A 20% suspension of brain tissue was prepared by

grinding in a homogenizer with sterile phos-phate-buffered saline (PBS) at pH 8.0. This suspen-sion was then continuously centrifuged at 14,000 x gwith a flow rate of 2 liters/h in a Kokusan centrifuge(Tokyo, Japan). The supernatant fluid collected fromthis centrifugation was then treated with protaminesulfate (Salmine, Nutritional Biochemical Corp.) ata final concentration of 1.5 mg/ml, permitted to standfor 2 h in a cold room to form floccules, and then cen-trifuged. The supernatant was removed after a sec-ond continuous centrifugation at 2,500 x g with aflow rate of 10 liters per h. This supernatant was thenintroduced into the zonal centrifuge as the crude viralmaterial for further purification.

Isopycnic separation by zonal centrifugation.The zonal centrifuge consisted of a K-Ill rotor driven

on August 28, 2019 by guest

http://jcm.asm

.org/D

ownloaded from

PURIFICATION BY ZONAL CENTRIFUGATION

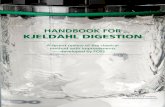

in a K-IIC zonal ultracentrifuge manufactured byElectro-Nucleonics, Inc., Fairfield, N.J. The sucrosegradient solution was formed by the reorienting,self-forming method by a static loading of 1,600 ml ofPBS and 1,600 ml of 60% (wt/wt) buffered sucrose.Then, the rotor was accelerated to an operationalspeed of 35,000 rpm. When operational speed wasattained, the sample of crude viral material wasintroduced into the rotor from the top for continuousflow isopycnic separation to purify the viral material.To increase the recovery of the viral material, theeffluent was recycled through the centrifuge once.Flow rate of the sample was kept at 6 liters per h.After recycling the effluent, the centrifuge was decel-erated to rest and the gradient solution was unloadedfrom the bottom by air pressure and distributed in 32fractions of 100 ml. The procedure for vaccine purifi-cation is schematically shown in Fig. 1.

Each fraction was immediately analyzed for su-crose concentration, ultraviolet absorbancy, and he-magglutination (HA) titer. The sucrose concentrationwas determined by using a Bausch and Lomb refrac-tometer and the ultraviolet absorbancy of each frac-tion was determined by a Hitachi 139 spectrophotom-eter at 280-nm wave length.

Inactivation of vaccine. The fractions with highHA titer, usually 10 or 11 fractions, were pooled andinactivated with 1:2,500 formalin for about 30 days ina cold room. After inactivation, sucrose was removedwith Sephadex G-75 (Pharmacia Fine Chemicals,Sweden). Thimerosal was added as a preservative(0.01% wt/vol). T'he final vaccine was prepared bydilution of the virus concentrate to the desired level ofantigenicity for use.P-N determination. The nitrogen content originat-

ing from the protein of the vaccine was measured asfollows. Trichloroacetic acid was added to the vaccinein a final concentration of 5% (wt/vol), and then themixture was heated to 100 C and kept at this temper-ature for 15 min. The resulting insoluble material was

20% brain homogenate

Centrifuge(14,000 x g, continuous)

Ppt Sup Add protamine sulfate

Ppt

(1.5 mg/ml, final)2hat4 C

CentrIifuge (2,500 x g, continuous)

ISup.

Zonal centrifugation

Distribute to 32 fractions

Pool high HA titer fractionsand inactivate with 1:2,500

formalin

FIG. 1. Procedure for purification of JE vaccine.Abbreviations: (ppt) precipitate; (sup.) supernatant.

then subjected to nitrogen content measurement bythe micro-Kjeldahl method (lOa).HA assays. A HA assay was performed according

to the method of Clark and Casals (2). Goose erythro-cytes were used and the reaction was allowed toproceed in a plastic tray at 37 C, pH 6.4. Then, viruspreparations were diluted in twofold steps, startingwith a dilution of 1:10. Titers were expressed as thereciprocal of the highest dilution with positive HAafter 1 h of incubation.

RESULTSTable 1 shows the results of five typical runs.

The effluent contained about 90% of the originalP-N content and the remaining 10% was re-tained in the sucrose gradient. The final gradi-ent characteristics of a typical run are shown inFig. 2. Most of the HA activity was banded infractions 4 to 22 between 25 and 52% (wt/wt)sucrose concentration. Maximal activity ofmore than 1:216 x 10/0.4 ml was obtainedbetween 42 and 47% (wt/wt) sucrose concentra-tion (1.19 and 1.22 g/ml in density). As shown inFig. 2 by the optical density absorbancy (280nm), the protein component was banded in aregion centering around 20% (wt/wt) sucroseconcentration (1.08 g/ml in density). It is shownthat by zonal centrifugation it is possible toseparate most of the nonspecific protein fromthe HA activity, which is essential in vaccineproduction. About 10 fractions with high HAactivity were collected as the purified-concen-trated vaccine.Electron microscopy. Electron microscopy

was performed with Hitachi model HU-11B.Test specimens were dialyzed through cellulosetubing (Visking Co., N.Y.) and sedimented byultracentrifugation (Hitachi, model 55P-2, To-kyo, Japan) at 106,000 x g for 5 h. The pelletswere immediately resuspended in a smallamount of PBS. Specimens were negativelystained with 1% phosphotungstic acid, pH 7.5.An electron micrograph of the purified-con-

centrated vaccine is shown in Fig. 3a. A similarelectron micrograph of a commercial vaccine isshown in Fig. 3b for comparison. In Fig. 3a,spheres, about 41 nm in diameter with thedense central 26-nm core, are presumed to beJE virus from their size and shape (6, 10). Thezonal-purified vaccine contained a small pro-portion of doughnut-shaped particles in addi-tion to predominant virus particles, whereas thecommercial vaccine contained many amor-phous particles. Thus, it appears that most ofthe impurities, contained in the viral materialwere removed by the zonal isopycnic separation.Comparative effectiveness with com-

mercial and reference vaccine. The effective-ness of the zonal purified-concentrated vaccine

97VOL. 1, 1975

on August 28, 2019 by guest

http://jcm.asm

.org/D

ownloaded from

OKUDA ET AL. J. CLIN. MICROBIOL.

TABLE 1. Recovery of HA and P-N after zonal centrifugation

ExptIAmtoffltid|Vol of LHA' P-N (ug/ml)Expt Amt of fluid Volloected_______no. processed (ml) fluid (ml) Original Effluent Flow-out Original Effluent Flow-out

fraction (% (%)

1 21,400 1,000 10 16 < 6 6 685 635 932 25,500 1,000 10 16 < 5 3 677 589 873 27,500 1,100 10 16 < 5 3 826 764 934 23,500 1,000 9 16 < 4 3 770 700 915 21,300 900 8 16 < 4 6 710 650 92

a HA is represented 2n x 10/0.4 ml.' Titer of the highest HA fraction.

H A

15-

13-

O.D. O. (28011- 3.01

9- 2.0]

7 1.01

25,,,,,, 0c5 O2 30TOP

FIG. 2. Profile of continuous flow isopycnic band-ing of JE virus in sucrose gradient. Symbol: (a) HAis represented 2n x 10/0.4 ml.

was tested against that of' commercial andJNIH reference vaccines. After the zonal-puri-fied vaccine was diluted to contain 3 ,g of'P-N/ml, an antigenicity test was performed.Three serial fourfold dilutions (1:4, 1:16, 1:64)

were made. Each dilution was inoculated intra-peritoneally into 10 mice, in a 0.5-ml dose.Inoculations were made four times every otherday. Seven days after the last injection, themice were challenged intracerebrally with 10 to50 mean lethal doses of Nakayama NIH strainand observed further for 21 days.The antigenicity of f'ive zonal-purified vac-

cines, a commercial vaccine, and a JNIH lot 168lyophilized reference vaccine is shown in Table2. All zonal-purified vaccines exhibited a higherlevel of antigenicity than either the reference or

commercial vaccines. Their relative potencieswere at least five times that of commercialvaccine (Table 2). Significant difference was

observed at P = 0.05. Calculations were per-formed by the Probit method (5a).Immunodiffusion test. Immunodiffusion

tests were performed in 1.0% special Noble agar(Difco) dissolved in PBS containing 0.01% (wt/vol) thimerosal.

Chickens were highly immunized by repeated

subcutaneous injections of normal mouse brainsupernatant and commercial vaccine withoutadjuvant. After confirming the production ofsufficient quantity of antibody by HA-inhibitiontests, animals were bled and sera were sepa-rated.

Antigens, commercial vaccine, and zonal-purified material were concentrated to 120times of the concentration of the final productsin collodion tubing (Sartorius MembranefilterGmbH, Germany) under reduced pressure. Thereaction was performed between these sera andthree kinds of antigens, 20% suspension ofnormal mouse brain supematant, concentratedcommercial, and zonal-purified vaccines. Theplate was kept at 31 C under high humidity andthe photograph was taken after 48 h.

Figure 4 shows precipitation lines producedby these reactions. Commercial vaccine showedtwo distinct immunoprecipitate lines againstantiserum to commercial vaccine; the one closerto the serum was associated with mouse braintissue whereas the other one was produced byJE particles. The zonal-purified vaccine had amuch fainter precipitate associated with mousebrain derivatives than the clear precipitate toJE particles. Thus, the purity of the viruspreparation was greatly improved by zonalcentrifugation. although a small amount ofimpurities originating from mouse brain stillexisted.

Allergic encephalitogenicity test. Commer-cial and zonal-purified material was concen-trated 350 and 700 times, respectively, com-pared with the final product, and each wasmixed with an equal volume of complete Freundadjuvant.A 0.1-ml dose of each sample was inoculated

intradermally at the pectoral region of five or six400- to 500-g Hartley strain guinea pigs.The animals were kept under observation for

40 days. Animals which died or survived wereexamined histopathologically. As a comparison,rabbit spinal cord and normal mouse brain werealso tested.

98

DENSITY1.30 (g/ml )

1.20-

1.10-POOL

1.00- +f#1

BOTTOM5 10 is 20FRACTION NO

c

on August 28, 2019 by guest

http://jcm.asm

.org/D

ownloaded from

PURIFICATION BY ZONAL CENTRIFUGATION

-I- :kr -ww_-: u..-Js. P- MM_Am I

FIG. 3. Electron micrograph of zonal-purified vaccine (3a) and commercial vaccine (3b). Scale: 100 nm.

TABLE 2. Antigenicity of zonal-purified vaccines

P-N Vaccine dilution EDO0a Relative potencies andVaccines (,gIml) 41 42 43 ED50 (gg of P-N) their fiducial limits0

Reference V. 7/10c 2/10 1/9 41.47Commercial V. 7 9/10 4/10 1/10 41290 0.2540 1Zonal-purified V-1 3 10/10 7/10 2/10 42.44 0.0515 4.93 (1.80, 15.5)Zonal-purified V-2 3 9/10 6/10 5/10 42.49 0.0481 dZonal-purified V-3 3 10/10 6/10 4/10 42.44 0.0515 4.93 (2.05, 14.6)Zonal-purified V-4 3 10/10 8/9 3/10 42.76 0.0332 7.65 (2.52, 29.6)Zonal-purified V-5 3 10/10 8/10 4/10 42.78 0.0323 7.86 (3.11, 29.8)

aMean effective dose.b Relative potency equals ED50/P-N of zonal-purified vaccine to ED.0/P-N of commercial vaccine. Fiducial

limits were calculated at P = 0.05.c Number of mice survived to number of mice challenged.dDosage response curve departed from parallelism in this case.

The results of allergic encephalitogenic testsare tabulated in Table 3. Zonal-purified andcommercial vaccines produced no symptom ofparalysis, clinically or histologically, 40 daysafter injection even when concentrated 700 and350 times (2,060 and 2,880 gg of P-N/ml,respectively) compared with the final product.On the other hand, mouse brain produced

histological symptoms at 910 ,g of P-N/ml.

DISCUSSIONThe effectiveness of the K-III rotor in JE virus

vaccine production has been demonstrated by

the high efficiency of isolation and purificationof JE virus from liter volumes of culture har-vests. This process combines the technique ofcontinuous flow centrifugation with isopycnicseparation and results in the separation ofvirus particles from the majority of cell debris.Purification of JE virus thus occurs simultane-ously with virus isolation and concentration. Bya single rapid technique, quantitative recoveryof JE virus particles can be achieved.

It should, however, be noted that zonal-puri-fied vaccine contained small doughnut-shapedparticles about 12 nm in diameter, which mor-

99VOL. 1, 1975

on August 28, 2019 by guest

http://jcm.asm

.org/D

ownloaded from

OKUDA ET AL. J. CLIN. MICROBIOL.

gation and H. W. Hsu of University of Tennessee, Knoxville,for his assistance and discussion in improvement of themanuscript.

FIG. 4. Immunodiffusion analysis of normal mousebrain supernatant, commercial and zonal-purified JEvaccine against highly immune chicken sera. Uppertrough: Chicken serum against commercial vaccine.Lower trough: Chicken serum against normal mousebrain. Left well: 20% mouse brain supernatant. Cen-ter well: Commercial vaccine. Right well: Zonal-puri-fied vaccine. Both commercial and zonal-purifiedvaccines were concentrated to 1/120 compared withthe final vaccine products.

TABLE 3. Incidence of allergic encephalomyelitis inguinea pigsa

Antigens (Pgm) Clinical Histo-(,ug/ml) ~logical

Concn zonal-purified V 2,060 0/6b 0/6

Concn commercial V 2,880 0/6 0/6

Mouse brain 9,100 2/5 4/4910 0/5 3/591 0/5 NTC

a Both zonal-purified and commercial vaccines (V)were concentrated to 1/700 or 1/350 compared withthe final vaccine products and each was mixed withequal volume of complete Freund adjuvant. (Injected0.1 ml intradermally).bThe numerator shows number of guinea pigs with

manifestation of allergic encephalomyelitis, the de-nominator number of inoculated animals.

c NT, Not tested.

phologically resemble Fukai's Ht substance (6)and the slowly sedimenting hemagglutinin de-scribed by Shapiro et al. (14). To confirmwhether they are identical, further studies arerequired. The allergic encephalitogenic test re-sults further confirm the field results of Oki-naka et al. (13).

ACKNOWLEDGMENTSWe wish to acknowledge N. G. Anderson of Oak Ridge

National Laboratory for his kind assistance in zonal centrifu-

LITERATURE CITED

1. Anderson, N. G., D. A. Waters. C. E. Nunley. R. F.Gibson, R. M. Schilling, E. C. Denny, G. B. Cline,E. F. Babslay, and T. E. Perardi. 1969. K-series cen-

trifuge. 1. Development of the K-II continuous sam-

ple-flow-with-banding centrifuge system for vaccinepurification. Anal. Biochem. 32:460-494.

2. Clark, D. H., and J. Casals. 1958. Techniques for hemag-glutination and hemagglutination-inhibition with ar-

thropod-borne viruses. Am. J. Trop. Med. Hyg.7:561-573.

3. Darwish, M. A., and W. McD. Hammon. 1966. Studies onJapanese B encephalitis virus vaccine from tissueculture. VI. Development of a hamster kidney tissueculture inactivated vaccine for man. (3). Potencytesting of an attenuated strain of OCT-541. J. Immu-nol. 96:878-884.

4. Eylar, E. H., and Y. Oshiro. 1970. Allergic encephalo-myelitis: a comparison of the encephalitogenic Al pro-tein from human and bovine brain. Arch. Biochem.Biophys. 138:606-613.

5. Eylar, E. H., J. Salk, G. C. Beveridge, and L. V. Brown.1969. Experimental allergic encephalomyelitis, an en-

cephalitogenic basic protein from bovine myelin. Arch.Biochem. Biophys. 132:34-48.

5a. Finney, D. J. 1952. Probit analysis. A static treatmentof the sigmoid response curve, 2nd ed. Cambridge Uni-versity Press, London.

6. Fukai, K., H. Kitano and T. Fukunaka. 1966. Morphol-ogy of Japanese encephalitis virus, p. 167-168. Maru-zen Co. Ltd., Tokyo.

7. Gerin, J. L., and N. G. Anderson. 1969. Purification ofinfluenza virus in the K-Il zonal centrifuge. Nature(London) 221:1255-1256.

8. Hammon, W. McD., M. A. Darwish, J. S. Rhim, G. E.Sather, D. S. Yohn, A. Mittelman, E. Deverson, and J.P. Soyka. 1966. Studies on Japanese B encephalitisvirus vaccines from tissue culture. V. Response of manto live, attenuated strain of OCT-541 virus vaccine, J.Immunol. 96:518-524.

9. Hammon, W. McD., M. A. Darwish, G. Sather. 1971.Results of human volunteer studies with live, at-tenuated strain of OCT-541, p. 237-238, In W. McD.Hammon, M. Kitaoka, and W. G. Downe (ed.), Im-munization for Japanese encephalitis. Igaku ShoinLtd., Tokyo.

10. Kitaoka, M., and C. Nishimura. 1963. Noninfectionshemagglutinin and complement fixing antigen of Japa-nese B. encephalitis. Virology 19:238-239.

10a. Kabat, E. A., and M. M. Meyer. 1961. Experimentalimmunachemistry, p. 476-48.3. Charles C Thomas,Springfield, Ill.

11. Minimum requirements of biological products. 1971.Ministry of Health Welfare Japanese Government,Tokyo.

12. Nakamura, H. 1971. The method of preparing the al-cohol-protamine purified, inactivated Japanese en-

cephalitis vaccine (AP vaccine), p. 55-56. In W. McD.Hammon, M. Kitaoka, and W. G. Downe (ed.), Im-munization for Japanese encephalitis, Igaku ShoinLtd., Tokyo.

13. Okinaka, S., Y. Toyokura, H. Tsukagoshi, Y. Kuroiwa, S.Araki, M. Arima, S. Otani, T. Tsubaki, H. Shiraki, T.Takatsu, H. Narabayashi, and S. Yoshimura. 1967.Physical reactions following vaccination against Japa-nese B encephalitis, with special reference to neurolog-ical complications. Adv. Neurolog. Sci. 11:410-424. (InJapanese).

100

on August 28, 2019 by guest

http://jcm.asm

.org/D

ownloaded from

PURIFICATION BY ZONAL CENTRIFUGATION

14. Shapiro, D., W. E. Brandt, R. D. Cardiff, and P. K.Russell. 1971. The proteins of Japanese encephalitisvirus. Virology 44:108-124.

15. Singh, B.. I. C. Chang, and W. McD. Hammon. 1973.Semi-commercial-scale production of Japanese B en-

cephalitis virus vaccine from tissue culture. Appl.Microbiol. 25:945-951.

16. Singh, B., M. A. Darwish, and W. McD. Hammon. 1971.Development of an inactivated vaccine from an at-tenuated strain of OCT-541, produced in primary

hamster kidney cells, p. 180-184. In Immunization forJapanese encephalitis. Igaku Shoin Ltd., Tokyo.

17. Takaku, K., T. Yamashita, T. Osanai, I. Yoshida, M.Kato, H. Goda, M. Takagi, T. Amano, K. Fukai, N.Kunita, K. Inoue, K. Shozi, A. Igarashi, and T. Ito.1971. Inactivated vaccine from Japanese encephalitisinfected mouse brains (ultracentrifuge-purified vac-

cine), p. 59-64. In Immunization for Japanese encepha-litis. Igaku Shoin Ltd., Tokyo.

VOL. 1, 1975 101

on August 28, 2019 by guest

http://jcm.asm

.org/D

ownloaded from