Hydraulicsemanuals.nordson.com/adhesives/English_Manuals/b10210.pdfpump, solenoid valve, air...

Transcript of Hydraulicsemanuals.nordson.com/adhesives/English_Manuals/b10210.pdfpump, solenoid valve, air...

� 2000 Nordson CorporationAll rights reserved

41-3000VIssued 5/00

B1EN-02-[3V-X-ADXX]-10

Part B, Section 1

Hydraulics

This section covers the following unit configurations.

Model 3500V3700V3860389039303960

Voltage All

Pump Piston (D)

Manifold 4-Port (A)6-Port (B or C)2-Port (S or T)

Control Vista Standard (V)Vista Pattern (PC)

HydraulicsB 1-0

� 2000 Nordson CorporationAll rights reserved

41-3000VIssued 5/00

B1EN-02-[3V-X-ADXX]-10

Hydraulics B 1-1

� 2000 Nordson CorporationAll rights reserved

41-3000VIssued 5/00

B1EN-02-[3V-X-ADXX]-10

Section B 1Hydraulics

WARNING: Allow only qualified personnel to perform thefollowing tasks. Follow the safety instructions in this documentand all other related documentation.

This section of the manual describes how to troubleshoot and repair thehydraulic system. It includes the following information:

� an overview of the unit’s hydraulic system

� troubleshooting guidelines and procedures

� pump, solenoid valve, and manifold repair procedures

� pump, solenoid valve, air pressure regulator, and manifold assemblyparts lists

Refer to the parts lists at the end of this section for the part numbers ofany components that need to be replaced.

If you try all the suggestions in this section and still need assistancesolving hydraulic system problems, call your Nordson representative.

Refer to the following sections of this manual for additional information onthe hydraulic system:

� Description includes pump specifications.

� Installation includes the procedures for connecting the air supply tothe pump and installing hoses.

To replace the tank and manifold, refer to the Tank section. The Tanksection also includes the frame and tank assembly parts lists.

1. Introduction

HydraulicsB 1-2

� 2000 Nordson CorporationAll rights reserved

41-3000VIssued 5/00

B1EN-02-[3V-X-ADXX]-10

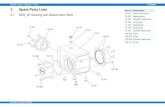

Two major assemblies make up the hydraulic system: an air-drivenpiston pump and a manifold. See Figure B 1-1. The pump assemblyincludes an air section, a hydraulic section, and a triggering solenoidvalve. There is also a pump solenoid valve inside the unit’s electricalenclosure. The manifold assembly, which is indirectly heated by the tank,includes an aluminum manifold with hose ports, a filter assembly, a drainvalve, and a pressure relief valve.

4130884A

1

2

3

4

Fig. B 1-1 Key Parts of the Hydraulic System (shown with a typical tank andmanifold)

1. Triggering solenoid valve2. Pump air section

3. Pump hydraulic section4. Manifold

2. Overview of theHydraulic System

Hydraulics B 1-3

� 2000 Nordson CorporationAll rights reserved

41-3000VIssued 5/00

B1EN-02-[3V-X-ADXX]-10

The following troubleshooting table describes the kinds of hydraulicsystem problems you may encounter and provides corrective actions forhandling those problems. When necessary, the table refers you to theTroubleshooting Procedures part of this section, which contains moredetailed procedures for diagnosing hydraulic system problems.

Problem Possible Cause Corrective Action

1. Pump not stroking (noadhesive output)

Pump not turned on Wait for the READY light to turn on.

NOTE: For some standard Vista andVista PC units, you may need to turnthe pump on manually after theREADY light turns on. If theauto-energize pump feature isenabled, the pump will turn onautomatically.

Triggering device not functioning Check the triggering device for thetriggering solenoid valve. Make sure thetriggering device is supplying 24 VDC tothe valve.

Air pressure too low Adjust the pump air pressure regulator.

Failed pump air pressure regulator Check the pump air regulator.

Failed solenoid valve (internal ortriggering)

Check the solenoid valve. Refer toInternal Solenoid Valve Check orTriggering Solenoid Valve Check inTroubleshooting Procedures.

Blockage in adhesive channelupstream of drain valve

Remove and clean the manifold filterscreen. Refer to Cleaning a StandardManifold Filter or Cleaning aReverse-Flush Manifold Filter in theMaintenance section.

Continued on next page

3. Troubleshooting

Troubleshooting Table

HydraulicsB 1-4

� 2000 Nordson CorporationAll rights reserved

41-3000VIssued 5/00

B1EN-02-[3V-X-ADXX]-10

Problem Possible Cause Corrective Action

2. Pump strokingerratically

Adhesive level too low Check the adhesive level. Add adhesiveif necessary. Refer to Checking theAdhesive Level and Filling the Tank inthe Operation section.

Adhesive too cold Check the temperature settings. Referto System Programming Procedures inthe Installation section.

Pump siphon ball not seating Check the siphon ball seat. Refer toPump Siphon Ball Seat Check inTroubleshooting Procedures.

Pump check valve ball not seating Replace the check valve ball and seat.Refer to Replacing the Check Valve Balland Seat in Pump Repair Procedures.

Pump leaking at crossover tube Replace the crossover tube O-ring andbackup ring. Refer to Replacing theCrossover Tube, O-Ring, or BackupRing in Pump Repair Procedures.

Pressure relief valve defective Replace the pressure relief valve. Referto Replacing the Pressure Relief Valvein Manifold Repair Procedures.

Use these procedures as directed in the Troubleshooting Table to furtherdiagnose hydraulic system problems.

Pump Siphon Ball Seat Check

1. Make sure the READY light is lit and the pump is turned on.

2. Place a container under the manifold drain valve and open the valve.

Filter Type Procedure for Opening Drain Valve

Standard Turn the drain valve counterclockwise.

Reverse-flush With the manifold filter in the RUN position, turnthe right-side drain valve counterclockwise.

Troubleshooting Table (contd)

Troubleshooting Procedures

Hydraulics B 1-5

� 2000 Nordson CorporationAll rights reserved

41-3000VIssued 5/00

B1EN-02-[3V-X-ADXX]-10

3. Apply a 24 VDC trigger to the triggering solenoid valve.

4. Turn the pump air pressure regulator alternately counterclockwiseand clockwise to increase and decrease pump air pressure. Thisshould remove any particles lodged between the siphon ball and itsseat.

5. Check to see if the pump is stroking normally or erratically.

Pump strokes… Action

Normally Resume operation.

Erratically Replace the siphon ball cage and seat assembly.Refer to Replacing the Siphon Ball Cage andSeat Assembly in Pump Repair Procedures.

Internal Solenoid Valve Check

The internal solenoid valve is located inside the unit’s electricalenclosure.

1. Reduce the pump air pressure to 0.

2. Remove the pump cover.

3. Disconnect the air input line from the elbow on the triggering solenoidvalve.

4. Make sure the READY light is lit and the pump is turned on.

5. Slowly increase pump air pressure.

6. Check the disconnected air input line for air flow.

Condition Action

Air flows The solenoid valve is functioning properly.Reduce the pump air pressure to 0, reconnectthe air input line, and return to theTroubleshooting Table.

Air does not flow Go to the next step.

HydraulicsB 1-6

� 2000 Nordson CorporationAll rights reserved

41-3000VIssued 5/00

B1EN-02-[3V-X-ADXX]-10

Internal Solenoid Valve Check (contd)

WARNING: Risk of electrical shock. Failure to observeelectrical safety procedures may result in personal injury ordeath. Allow only qualified personnel to perform the followingprocedures. Observe all high voltage indicators.

7. Open the electrical enclosure. Refer to Opening and Closing theElectrical Enclosure in the Control section.

8. Locate connector J9 on the power board and measure the voltage atpositions 1 and 2.

Voltage Action

22.8–25.2 VDC Replace the solenoid valve. Refer to SolenoidValve Repair Procedures.

Less than22.8 VDC

Replace the power board. Refer to Replacing aControl Assembly Board in the Control section.

Triggering Solenoid Valve Check

The triggering solenoid valve is connected to the pump and is locatedunder the pump cover.

1. Reduce the pump air pressure to 0.

2. Remove the pump cover.

3. Disconnect the triggering solenoid valve from the pump.

4. Apply a 24 VDC trigger to the solenoid valve.

5. Slowly increase pump air pressure.

Condition Action

Air flows from thesolenoid valve

The solenoid valve is functioning properly.Reduce the pump air pressure to 0,reconnect the solenoid valve to the pump,and return to the Troubleshooting Table.

Air does not flow fromthe solenoid valve

Defective solenoid valve. Replace thesolenoid valve. Refer to Solenoid ValveRepair Procedures.

Hydraulics B 1-7

� 2000 Nordson CorporationAll rights reserved

41-3000VIssued 5/00

B1EN-02-[3V-X-ADXX]-10

Use these procedures to replace the piston pump or to replace thecrossover tube O-ring and backup ring, the check valve ball and seat, orthe siphon ball assembly. Refer to the parts lists in the Parts section forthe part numbers of any components that need to be replaced.

NOTE: The air section of the 10:1 piston pump is not field-serviceable.For any pump air section repair needs, contact your Nordsonrepresentative.

Follow this procedure before removing the pump from the unit.

1. Make sure the unit is at operating temperature so the adhesivearound the pump body is molten.

2. Reduce the pump air pressure to 0.

WARNING: System or material pressurized. Relieve pressure.Failure to observe this warning may result in serious burns.

3. Relieve system pressure. Refer to Relieving System Pressure in theMaintenance section.

WARNING: Risk of equipment damage, personal injury, ordeath. Disconnect and lock out electrical power to the unit.

4. Place the unit’s POWER switch in the off position, disconnect andlock out electrical power to the unit at the branch circuit disconnectswitch, and disconnect and lock out electrical power supplied throughany I/O wiring.

5. Remove the pump cover.

6. Disconnect the triggering solenoid valve from the pump.

4. Pump Repair Procedures

Preparing for Pump Removal

HydraulicsB 1-8

� 2000 Nordson CorporationAll rights reserved

41-3000VIssued 5/00

B1EN-02-[3V-X-ADXX]-10

Follow this procedure to remove the pump from the unit.

1. Have a pan or rag ready to catch adhesive that will drip off the pumpwhen it is removed.

2. Remove the three bolts and washers that secure the pump to the tankand carefully lift the pump out of the tank.

NOTE: If you are replacing the pump with a new one, go to Installingthe Pump.

Follow this procedure to replace the crossover tube, O-ring, orbackup ring.

1. See Figure B 1-2. Remove the O-ring (5) and backup ring (4) fromthe crossover tube (3).

2. Unscrew the crossover tube from the pump body.

3. Screw the new crossover tube into the pump body.

4. Apply O-ring lubricant to the new O-ring.

5. Install a new O-ring and backup ring on the crossover tube.

Follow this procedure to replace the check valve ball or seat.

1. See Figure B 1-2. Remove the check valve ball (2) and ball seat (1)from the pump body.

2. Install a new check valve ball and ball seat.

Removing the Pump

Replacing the Crossover Tube,O-Ring, or Backup Ring

Replacing the Check Valve Balland Seat

Hydraulics B 1-9

� 2000 Nordson CorporationAll rights reserved

41-3000VIssued 5/00

B1EN-02-[3V-X-ADXX]-10

Follow this procedure to replace the siphon ball, siphon ball cage, orsiphon ball seat.

1. See Figure B 1-2. Remove the siphon ball seat (8), siphon ball (7),and siphon ball cage (6) from the bottom of the pump body.

2. Install a new siphon ball seat, siphon ball, and siphon ball cage.

4130880A

1

2

3

5

47

6

8

Fig. B 1-2 Pump Components

1. Check valve ball seat2. Check valve ball3. Crossover tube4. Backup ring

5. O-ring6. Siphon ball cage7. Siphon ball8. Siphon ball seat

Replacing the Siphon BallCage and Seat Assembly

HydraulicsB 1-10

� 2000 Nordson CorporationAll rights reserved

41-3000VIssued 5/00

B1EN-02-[3V-X-ADXX]-10

Follow this procedure to install a new pump or to reinstall a pump after ithas been serviced.

NOTE: If you are replacing an old pump with a new, complete pump andyour old pump has a pump cover bracket, remove the bracket and installit on the new pump.

1. Make sure the pump pan is positioned correctly.

2. Lower the pump into the unit until the crossover tube seats in themanifold.

3. Secure the pump to the unit with the screws and washers youremoved earlier. Tighten to 12.20–13.56 N�m (9–10 ft-lb).

4. Connect the triggering solenoid valve to the pump.

Follow this procedure to restore the unit to normal operation.

1. Reinstall the pump cover.

2. Remove the lockout and restore power to the unit, turn the unit on,and allow it to reach operating temperature.

3. See Figure B 1-3. Place a container under the manifold drain valveand open the valve.

Filter Type Procedure for Opening Drain Valve

Standard Turn the drain valve counterclockwise.

Reverse-flush With the manifold filter in the RUN position, openthe right-side drain valve.

Installing the Pump

Restoring the System toNormal Operation

Hydraulics B 1-11

� 2000 Nordson CorporationAll rights reserved

41-3000VIssued 5/00

B1EN-02-[3V-X-ADXX]-10

4130669A

2

3

1

Fig. B 1-3 Opening the Manifold Drain Valve

1. A manifold (standard filter)2. B or S manifold (standard filter)

3. C or T manifold(reverse-flush filter)

4. Increase pump air pressure and switch the 24 VDC signal to thetriggering solenoid valve on and off until clean adhesive flows fromthe drain valve. This will purge the system of trapped air.

5. Reduce the pump air pressure to 0.

6. Close the drain valve.

7. Return the air pressure to the normal operating setting and resumeoperation.

HydraulicsB 1-12

� 2000 Nordson CorporationAll rights reserved

41-3000VIssued 5/00

B1EN-02-[3V-X-ADXX]-10

Use these procedures to replace either the internal or triggering solenoidvalve. Refer to the parts lists at the end of this section for the partnumbers of any components that need to be replaced. You can use thesolenoid valve assembly parts list illustration as a guide if you need toreplace other solenoid valve assembly components.

Follow this procedure to replace the solenoid valve that is located insidethe electrical enclosure.

Solenoid Valve Removal

WARNING: Risk of equipment damage, personal injury, ordeath. Disconnect and lock out electrical power to the unit.

1. Place the unit’s POWER switch in the off position, disconnect andlock out electrical power to the unit at the branch circuit disconnectswitch, and disconnect and lock out electrical power supplied throughany I/O wiring.

2. Reduce the pump air pressure to 0.

WARNING: Risk of electrical shock. Failure to observeelectrical safety procedures may result in personal injury ordeath. Allow only qualified personnel to perform the followingprocedures. Observe all high voltage indicators.

3. Open the electrical enclosure. Refer to Opening and Closing theElectrical Enclosure in the Control section.

4. See Figure B 1-4. Unplug (1) the solenoid valve.

5. Disconnect the air lines (3) from the elbows (2) on the solenoid valve.

6. Remove the screws that secure the solenoid valve mountingbracket (4) to the unit; then remove the valve and bracket from theunit.

7. Remove the screws (5) that secure the mounting bracket to thesolenoid valve and disconnect the bracket from the valve.

8. Remove the elbows from the solenoid valve.

5. Pump Solenoid ValveReplacementProcedures

Replacing the InternalSolenoid Valve

Hydraulics B 1-13

� 2000 Nordson CorporationAll rights reserved

41-3000VIssued 5/00

B1EN-02-[3V-X-ADXX]-10

4130841A

4

2

2

1

3

5

Fig. B 1-4 Solenoid Valve Assembly Components

1. Plug2. Air lines3. Elbows

4. Mounting bracket5. Screws

Solenoid Valve Installation

1. See Figure B 1-4. Install the elbows on the new solenoid valve.

2. Install the mounting bracket on the new solenoid valve.

3. Install the mounting bracket and solenoid valve on the rear cover ofthe unit with the screws you removed earlier.

4. Connect the air lines to the solenoid valve elbows.

5. Connect the solenoid valve plug.

HydraulicsB 1-14

� 2000 Nordson CorporationAll rights reserved

41-3000VIssued 5/00

B1EN-02-[3V-X-ADXX]-10

Solenoid Valve Installation (contd)

6. Close the electrical enclosure, remove the lockout, and restore powerto the unit.

7. Return the pump air pressure to the normal operating setting.

8. Turn the unit on and listen for air leaks. If you hear air leaking, checkthe air line connections at the elbows.

Follow this procedure to replace the triggering solenoid valve that isconnected to the pump.

Solenoid Valve Removal

WARNING: Risk of equipment damage, personal injury, ordeath. Disconnect and lock out electrical power to the unit.

1. Place the unit’s POWER switch in the off position, disconnect andlock out electrical power to the unit at the branch circuit disconnectswitch, and disconnect and lock out electrical power supplied throughany I/O wiring.

2. Reduce the pump air pressure to 0.

3. Remove the electrical enclosure lid and the pump cover.

4. Disconnect the air line from the triggering solenoid valve elbow (1).

5. See Figure B 1-5. Disconnect the solenoid valve wires (2) fromterminals 3 and 4 on the center frame terminal block. Do notdisconnect the wires from your triggering device.

6. Disconnect the solenoid valve ground wire (3) from the ground studon the unit’s base.

7. Unscrew the solenoid valve (4) and bushing (5) from the pipenipple (6).

8. Remove the elbow and bushing from the solenoid valve.

Replacing the TriggeringSolenoid Valve

Hydraulics B 1-15

� 2000 Nordson CorporationAll rights reserved

41-3000VIssued 5/00

B1EN-02-[3V-X-ADXX]-10

4130883A

4

23

5

6

1

2

Fig. B 1-5 Triggering Solenoid Valve Components

1. Elbow2. Solenoid valve wires3. Ground wire

4. Solenoid valve5. Bushing6. Pipe nipple

Solenoid Valve Installation

1. See Figure B 1-5. Install the elbow and bushing on the new triggeringsolenoid valve.

2. Install the solenoid valve by screwing the bushing onto the pipenipple.

3. Connect the air line to the solenoid valve elbow.

4. Route the solenoid valve wires around the center frame and connectthem to terminals 3 and 4 on the center frame terminal block.

HydraulicsB 1-16

� 2000 Nordson CorporationAll rights reserved

41-3000VIssued 5/00

B1EN-02-[3V-X-ADXX]-10

Solenoid Valve Installation (contd)

5. Connect the solenoid valve ground wire to the ground stud on theunit’s base.

6. Install the pump cover and the electrical enclosure lid.

7. Return the pump air pressure to the normal operating setting.

8. Remove the lockout and restore power to the unit.

9. Turn the unit on and listen for air leaks. If you hear air leaking,retighten each air line elbow.

Use these procedures to replace the pressure relief valve or the manifolddrain valve. Refer to the parts lists at the end of this section for the partnumbers of any components that need to be replaced.

Use this procedure to replace the pressure relief valve. The pressurerelief valve is located in the bottom of the tank.

1. Drain as much adhesive from the tank as possible. Refer to Flushingthe System in the Maintenance section for different ways to drain thetank.

WARNING: System or material pressurized. Relieve pressure.Failure to observe this warning may result in serious burns.

2. Relieve system pressure. Refer to Relieving System Pressure in theMaintenance section.

6. Manifold RepairProcedures

Replacing the Pressure ReliefValve

Hydraulics B 1-17

� 2000 Nordson CorporationAll rights reserved

41-3000VIssued 5/00

B1EN-02-[3V-X-ADXX]-10

3. See Figure B 1-6. Use a socket wrench to loosen the pressure reliefvalve (1); then carefully unscrew the valve and remove it.

4130835

1

2

Fig. B 1-6 Replacing the Pressure Relief Valve

1. Pressure relief valve 2. Typical tank

4. Screw the new valve into the tank until it is finger-tight.

5. Use a socket wrench to tighten the valve. Tighten to 4–16 N�m (10–12 ft-lb).

6. Refill the tank with adhesive and resume operation.

HydraulicsB 1-18

� 2000 Nordson CorporationAll rights reserved

41-3000VIssued 5/00

B1EN-02-[3V-X-ADXX]-10

Use this procedure to replace the drain valve. The drain valve is locatedin the manifold near the manifold filter.

NOTE: Units with a reverse-flush filter have two manifold drain valves.

1. Make sure the unit is at operating temperature.

WARNING: System or material pressurized. Relieve pressure.Failure to observe this warning may result in serious burns.

2. Relieve system pressure. Refer to Relieving System Pressure in theMaintenance section.

3. See Figure B 1-7. Remove the drain valve alignment screw (1) andwasher (2); then remove the valve (3) from the unit. Some adhesivewill flow from the valve.

41308361 2

3

Fig. B 1-7 Replacing the Drain Valve

1. Alignment screw2. Washer

3. Drain valve

4. Screw the new drain valve into the manifold until it is secure; thenadjust it as necessary to install and tighten the alignment screw andwasher.

Because the manifold has no moving parts, you should not need toreplace it. However, if you need to remove the manifold for any reason,refer to Tank.

Replacing the Drain Valve

Replacing the Manifold