PUB07-392-MMC-PPA-055

-

Upload

sharanya-vaidyanath -

Category

Documents

-

view

213 -

download

0

Transcript of PUB07-392-MMC-PPA-055

-

7/28/2019 PUB07-392-MMC-PPA-055

1/8

Copyright 2009 Year IEEE. Reprinted from IEEE TRANSACTIONS ON COMPONENTS

AND PACKAGING TECHNOLOGIES. Such permission of the IEEE does not in any way imply

IEEE endorsement of any of Institute of Microelectronics products or services. Internal ofpersonal use of this material is permitted. However, permission to reprint/republish this

material for advertising or promotional purposes or for creating new collective works forresale or redistribution must be obtained from the IEEE by writing to pubs-

-

7/28/2019 PUB07-392-MMC-PPA-055

2/8

IEEE TRANSACTIONS ON COMPONENTS AND PACKAGING TECHNOLOGIES, VOL. 32, NO. 3, SEPTEMBER 2009 593

Optical Coupling Methods for Cost-EffectivePolymer Optical Fiber Communication

Jayakrishnan Chandrappan, Member, IEEE, Zhang Jing, Ramkumar Veppathur Mohan, Philbert Oliver Gomez,Than Aye Aung, Xiao Yongfei, Pamidighantam V. Ramana, John H. Lau, Fellow, IEEE, and

Dim Lee Kwong, Fellow, IEEE

AbstractIn this paper, we report cost-effective light couplingmethods for polymer optical fiber (POF) communication. Here, wecompare the various optical coupling schemes in detail. By opticalsimulations, we analyze the conventional light coupling schemes,namely the direct coupling, lens coupling, and lensed fiber cou-pling. The simulation studies reveal that a lensed fiber tip partic-ularly at the receiver side improves the light coupling efficiency toa great extent. The optimized lensed POF design confers an 85%coupling efficiency. Lensed POFs are realized with two low-costfabrication methods. The characterization of the lensed POF arecarried out to evaluate the lensing properties and hence to opti-mize the fabrication process.

Index TermsCharacterization, detector, fabrication, lensedfiber, optical coupling, polymer optical fiber, simulation.

I. INTRODUCTION

IN the recent past, polymer optical fibers POFs found

exciting applications as a low-cost alternative in home

network, automotive, and short reach applications [1], [2].

The lower connection costs and other low cost factors made

large-core multimode POFs attractive over single-mode fibers

for short-distance communications [4]. POFs are large-coremultimode optical fibers with very high numerical apertures.

They have the advantages of optical fibers while maintaining

the flexibility of copper cables in installation [3]. The major

challenges for POF networks are low-cost components, their

packaging, and the interfacing with the existing networks [5].

At present, both light emitting diodes (LEDs) and vertical

cavity surface emitting lasers (VCSEL) are being used as the

light source. They give the cost advantage over laser diode as

Manuscript received March 19, 2008; revised August 25, 2008 and October08, 2008. First published March 16, 2009; current version published August26, 2009. This work was supported by the Science and Engineering Research

Council (SERC) of Agency for Science, Technology, and Research (A*STAR),Singapore. This work was recommended for publication by Associate Editor F.Shi upon evaluation of the reviewers comments.

J. Chandrappan, Z. Jing, P. V. Ramana, J. H, Lau, and D. L. Kwong arewith the Institute of Microelectronics, A*STAR, Singapore 117685 (e-mail:

[email protected]).R. V. Mohanis with theDepartment of Electrical andComputer Engineering,

National University of Singapore, Singapore 119077.P. O. Gomez is with the School of Electrical and Electronics Engineering,

Nanyang Technological University, Singapore 639798.T. A. Aung is with the School of Engineering, Ngee Ann Polytechnic, Sin-

gapore S599489.X. Yongfei is with the School of Electrical Engineering, National University

of Singapore, Singapore 119077.Color versions of one or more of the figures in this paper are available online

at http://ieeexplore.ieee.org.

Digital Object Identifier 10.1109/TCAPT.2008.2011559

the light source. Availability of high speed, high-performance

VCSELs, and resonant cavity LEDs (RCLED) at a reasonable

cost keep POF networks attractive for gigabit applications.

Since POFs have a large core diameter, the coupling with the

transmitter does not raise any serious light coupling issues.

However, the large core diameters always results in severe

power coupling losses at the receiver side. This in turn re-

duces the maximum communication link distance achievable.

Realization of additional coupling elements brings in process

complexities at an added cost. All these factors necessitate acost effective coupling method along with ease of installation,

fiber plug-in modules, to keep POFs attractive in the market [6].

II. COUPLING METHODS

The conventional connector-less transceiver packages for

POF communication use an aspherical lens or ball lens as an

additional coupling element between the light source and POF

or POF and detector [7]. The drawbacks of an external passive

coupling element like a ball lens or an aspherical lens is that

it requires additional structures in the package to house the

coupling elements. Again, the integration of these componentsrequires precision assembly which comes at an additional cost

of manpower and time. Moreover, it becomes necessary to

study the alignment requirements of the stand-alone optical

coupling elements at the transmitter and receiver side in great

detail. Hence, the total cost of the system will be increased by

the cost of additional coupling components, the cost necessary

to model and fabricate the substrate to assemble these com-

ponents. At the receiver side of the POF, coupling takes place

from a large core diameter to a small area photo detector. If

precision subassemblies and precise component placements are

not employed, optical coupling with an external element at this

point becomes a tedious task.

Plastic fiber with a lensed tip is a cost-effective couplingmethod for coupling light from the transmitter to the POF and

from POF to the receiver [8], [9]. In this coupling scheme, the

hemispherical lens fabricated at the tip of the fiber makes the

system simple and efficient [10]. This eliminates precision sub-

assembly and alignment, thereby lowering the manufacturing

cost. In addition to this, it is seen that reflections and scattering

are greatly reduced at transition surfaces in this hemispherical

model since the lens and the fiber are of precisely the same

material. Since POF has a large core radius, the hemispherical

addendum will also have greater dimensions which will help to

collect and focus light effectively at the ease of manufactura-

bility. Besides, the device will be more mechanically stable and

1521-3331/$26.00 2009 IEEE

Authorized licensed use limited to: ASTAR. Downloaded on September 6, 2009 at 00:10 from IEEE Xplore. Restrictions apply.

-

7/28/2019 PUB07-392-MMC-PPA-055

3/8

594 IEEE TRANSACTIONS ON COMPONENTS AND PACKAGING TECHNOLOGIES, VOL. 32, NO. 3, SEPTEMBER 2009

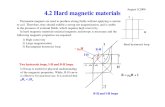

Fig. 1. Direct coupling of POF with source and detector.

less prone to shock and vibrations as external components are

minimized.

The conventional lensed fiber fabrication methods include

fiber grinding, wet etching, hot melting, etc. [11][13]. Since

the core diameter of the plastic fiber is very high compared to

its counterparts, it is easier to fabricate the hemispherical lenses

at the tip. The manufacturing cost is lower since the fabrication

is simple and does not require highly sophisticated equipment.

This also gives the freedom to re-engineer the lens formed as

and when it is required. The fabrication methods adopted are

discussed in detail in the following sections.

III. POF MODELING, SIMULATION, AND ANALYSIS

Geometrical image analysis in ZEMAX software is an effec-

tive tool for computing the multimode fiber coupling efficiency.

This analysis can generate the irradiance at any surface from an

extended source with specific size and shape at the object sur-

face. We have simulated the parameters of MH4001 Esaka fiber

from Mitsubishi Rayon. The POF we modeled has a core diam-

eter of 980 m, cladding diameter of 1000 m, and numerical

aperture of 0.3. The core material is poly methyl methacrylate

(PMMA) with an index of refraction 1.49. Simulations are done

for direct coupling, fiber bends, light coupling with an external

lens, and lensed fiber.The direct coupling model, as shown in Fig. 1, involves a light

source of 850-nm wavelength coupled to the input end of bare

POF with flat ends, and the output of fiber is coupled to a de-

tector of 50- m radius. The simulations show a coupling effi-

ciency of only 9.38%, which reflects the need for an additional

coupling optics for the fiber. At this juncture, the two possible

ways of improving the coupling efficiency is to use either an ex-

ternal discrete lens attached to the fiber or by making lens at the

tip of the fiber.

To enhance the coupling efficiency, we amended the model

by placing an external spherical ball lens between POF and de-

tector. Since the diameter of the POF is large, a large ball lens

is required for better light coupling to the detector, but as thesize of the coupling lens increases the package dimensions also

becomes larger. Various dimensions of ball lenses are evaluated

and a tradeoff between the package size and coupling efficien-

cies are arrived at. Based on these studies, an optimum value

of 2-mm radius lens is simulated and it yielded a power output

coupling efficiency of 37.45%. Fig. 2 shows that a discrete large

ball lens would achieve good coupling efficiency in comparison

to the bare fiber, but this coupling scheme will increase the di-

mensions of the transceiver module since the ball lens radius is

large compared to the dimensions of the fiber, which is undesir-

able.

On the other hand, a discrete ball lens of radius 0.48 mm, as

shown in Fig. 3, would be a better fit since it will not increase

the housing size required to hold the fiber-lens system. How-ever, the difficulty is that the lenses of small radii have a shorter

focal distance. A small radius lens can focus the beam to a nearer

point at the expense of power output, while a large radius lens

will focus at a longer distance from the lens, but maintain the

power output to a high value. This can be observed with the fall

in power to 18.81% in comparison to the larger lens radius cou-

pling efficiency of 37.45%. Furthermore, using an aspherical

lens to improve the coupling efficiency instead of a large ball

lens, it becomes necessary to concentrate on the alignment and

orientation of the lens in the module, which would require ad-

ditional cost and effort, for the sake of increasing power output.

The following analysis discusses the proposed coupling

method, namely the hemispherical structures integrated to both

side of the fiber, as shown in Fig. 4. Here, a plastic fiber of 0.49

mm radius is modeled with hemispherical ball lenses attached

to both end of the fiber. The refractive indices of the fiber

core and the hemispheres are made identical. Simulations are

carried out to optimize the distance between the lensed fiber

and detector, which would maximize the power output. The

beam focusing distance from the lens at the receiver side is

found to be 0.7 mm. A dummy surface with a circular aperture

of 50- m radius is inserted just before the image surface to

simulate the power incident on the surface of the photo detector

of radius 50 m.

The simulations yielded a higher power coupling efficiencyof 85%. The power is concentrated in the 20- m radius, and

Authorized licensed use limited to: ASTAR. Downloaded on September 6, 2009 at 00:10 from IEEE Xplore. Restrictions apply.

-

7/28/2019 PUB07-392-MMC-PPA-055

4/8

CHANDRAPPAN et al.: OPTICAL COUPLING METHODS FOR COST-EFFECTIVE POLYMER OPTICAL FIBER COMMUNICATION 595

Fig. 2. POF coupling using an external ball lens of radius 2 mm.

Fig. 3. POF coupling using an external ball lens of radius 0.48 mm.

Fig. 4. POF coupling using hemispherical lenses formed at the tip.

Authorized licensed use limited to: ASTAR. Downloaded on September 6, 2009 at 00:10 from IEEE Xplore. Restrictions apply.

-

7/28/2019 PUB07-392-MMC-PPA-055

5/8

596 IEEE TRANSACTIONS ON COMPONENTS AND PACKAGING TECHNOLOGIES, VOL. 32, NO. 3, SEPTEMBER 2009

Fig. 5. Coupled power versus radius for hemispherical lensed fiber.

hence shifting of the fiber by 20 m on either side of the de-

tector will not affect the coupling efficiency of the system. Sincethe POF diameter is inherently large, the hemispheres radius is

also large, thereby improving the spatial resolution of the image.

Besides this, the whole system is spherically symmetric. This

eliminates the need for orientation, unlike in the case of an as-

pherical lens.

An optimization algorithm is run for optimizing the radius of

curvature of the lens. The radius of the integrated hemispherical

lens is varied from 0.40 to 0.55 mm, to identify the optimum

radius of the lens for the maximum output power coupling. A

graph plotted with radius of lens curvature versus coupled power

is shown in Fig. 5.

The results shown here reveal that the best case scenario formaximizing the power output is when the radius of the half lens

at both ends is equal to the radius of the fiber. On either side of

the radius, the output power drops sharply.

In the second optimization step, we analyzed whether the

power output can be improved with a change in the refractive

index of the hemispherical lens. It is observed that when the

hemispherical lens is of the same material as that of the fiber,

output power coupling is 85.445%. By increasing the refractive

index 20% higher than that of the fiber, the power output can be

increased to 88.67%.

IV. FABRICATION METHODS

Various methods have been reported in the literature for the

fabrication of light coupling elements for POFs [14]. We have

selected two fabrication methods based on the ease of fabrica-

tion and lower manufacturing cost.

The first method involves formation of the lens at the fiber

edge by pressing the end face on a hot lens forming mold. The

second method involves dipping the polished fiber tip in an op-

tically transparent organic liquid [15]. The process of fabrica-

tion of a lens by hot melting method onto a fiber of plastic or

glass origins would include the mechanical process of injection

molding or compression [16]. The physical property of either a

PMMA or perfluorinated polymer fiber and their lower fabrica-

tion temperatures have made the fabrication of lenses onto thefiber much easier. PMMA material is less dense with density

Fig. 6. Steel cylinder with mechanical mold.

Fig. 7. Lensed tip POF with unpolished edges.

range from 11501190 kg/m . This is less than half the den-sity of glass which ranges 2400 to 2800 kg/m . More impor-

tantly, PMMA has higher impact strength than glass and does

not shatter but instead breaks into large, dull pieces.

The hot plate method requires melting the fiber tip at its ma-

terial melting point temperature and molding it with suitable

cavity to form thelens. Based on the simulation results, we fabri-

cated a die in steel material by precisely machining the required

geometries, as shown in Fig. 6. Apart from this, the setup re-

quires a hot plate to heat the mold and an arrangement to hold the

POF vertically to the cavity. This simple fabrication setup and

highly repeatable process makes the fabrication method cheap

and attractive.The steel mold is heated to the required temperature initially.

The temperature of the mold is cross checked with the help of a

thermocouple to reaffirm the required temperature level. Once

the temperature reaches an approximate levelof 150 C160 C,

the fiber is lowered towards the mold and allowed to take the

shape of the mold. The fiber is subsequently allowed to cool to

normal room temperature for 34 min. The fiber under micro-

scopic view clearly shows the formation of a lens at the fiber tip,

as shown in Fig. 7.

However, due to the small geometry of the mold cavity and

the large diameter of the POF, the POF comes in contact not

only with the semispherical cavity of the mold but also with the

entire top surface of the steel structure. This makes the edgesof the POF melt outwards, and it requires additional polishing.

Authorized licensed use limited to: ASTAR. Downloaded on September 6, 2009 at 00:10 from IEEE Xplore. Restrictions apply.

-

7/28/2019 PUB07-392-MMC-PPA-055

6/8

CHANDRAPPAN et al.: OPTICAL COUPLING METHODS FOR COST-EFFECTIVE POLYMER OPTICAL FIBER COMMUNICATION 597

Fig. 8. Lensed tip POF with polished edges.

Fig. 9. Hemispherical lens formed by polymer dipping.

Fig. 10. From flat polished POF.

Fig. 8 shows the fiber tip after polishing. Another phenomenon

of the plastics behavior towards the heating and cooling processis the shrinkage of the fiber. Due to the lack of a surmountable

pressure on the POF, the fiber warps and shrinks, this prevents

the fiber in assuming the exact shape of the mold.

The second method describes a way of forming a spherical

convex contour at the tip of POF by immersing the fiber in an

optically transparent organic liquid and bonding this properly to

the end face soon after the optical fiber is lifted from the liquid.

The refractive index of the polymer material is matched to the

refractive index of the POF core. In this process, the fiber tip is

polished initially by mechanical polishing. Once the polishing

is done, the fiber ends are cleaned and dipped to the polymer

liquid. Now the fiber is taken out from the liquid and allowed

to form the lens shape under surface tension. The shape of thelens depends on the viscosity of the liquid and the time given to

settle down. Once the required shape is reached, the fiber tip is

irradiated with UV light to make a proper adhesion. Many ex-

periments have been carried out to optimize the required profile

by using various viscous liquids and variable time for settling.

The lens formed is as shown in the Fig. 9.

V. RESULTS AND DISCUSSIONS

The lenses formed by various methods are being character-

ized to evaluate its performance. The evaluation is done based

on their effectiveness to converge the large spot size of POF

output to a considerably smaller spot size and hence to improve

the coupling efficiency. Initially, the POF with lensed tip is illu-

minated with the light at the 850-nm wavelength. The distance

from the beam profiler is adjusted in such a way that the output

beam spot is reduced to the minimum size possible. Now the

lensed POF is replaced with a flat polished POF, and the output

spot is captured at the same distance using beam profiler. The

output spot size profile for a flat polished POF and lensed POF

formed by polymer dip method are as shown in Figs. 10 and 11.

The captured spot sizes at 1.6-mm distance from the profiler

are compared, and it clearly shows a reduction in the spot size of

the order of one-fourth of the original dimension. The coupling

efficiency has improved by 27% with the lensed fiber fabricated.

The experimental result shows that there is a major varia-

tion from the output spot size predicted by simulation. The light

beam is not converging to the smaller dimension, and hence the

coupling efficiency is much below the expected value. As per

our understanding, the minor variations in the lens parameters

cannot be responsible for such a larger deviation in the coupling

efficiency.

Closely analyzing the results, it is realized that the initial sim-ulations are done assuming that the fiber is straight, an ideal

state. It did not include any fiber bends, but in the real case,

the fiber has random bends. In addition, the lens structure at the

input side generates a restricted mode launch situation under

center launch conditions. Due to these factors, straight fiber

status and restricted mode launch conditions, light is confined

to the lower order modes lying at the center of the core which

results in a lower divergence beam exit [17]. Under the random

bends, all possible fiber modes are excited, and this leads to

larger divergence and hence a larger beam size at the exit.

In order to verify this fact, we modeled the same lens under

bend fiber conditions. This resulted in a lower coupling effi-

ciency of 34%, which very agrees well with the experimental

results under the fabrication limitations.

The lenses fabricated with the hot melting method did not

show a better convergence, as the lens curvatures could not be

controlled since the whole fiber tip was getting deformed during

the fabrication process. A new mold with wider aperture is being

considered to avoid these problems. Another concern is that, if

the molded portions are not allowed to cool down properly, in-

stead of a perfect smooth spherical surface, a lot of fiber hairs

will be formed. This reduces the lensing effect and further pol-

ishing is required to make the surface perfect. In this case, the

polymer dip method seems to be much better for the fabrica-

tion of lensed POFs. The variables for optimization vary withthe liquid properties and the final lens shape to be fabricated.

Authorized licensed use limited to: ASTAR. Downloaded on September 6, 2009 at 00:10 from IEEE Xplore. Restrictions apply.

-

7/28/2019 PUB07-392-MMC-PPA-055

7/8

598 IEEE TRANSACTIONS ON COMPONENTS AND PACKAGING TECHNOLOGIES, VOL. 32, NO. 3, SEPTEMBER 2009

Fig. 11. From the lensed tip.

VI. CONCLUSION

We have analyzed various cost-effective coupling methodsfor POF communication by optical simulations. The simulations

showed an improved light coupling efficiency with the lensed

POF. The lensedtips arerealized using hot blowing and polymer

dip fabrication techniques. The experimental evaluation of op-

timized lens structures resulted in an improved coupling effi-

ciency of 27%. It is also eminent that the fiber bends play an

important role in deciding the actual divergence of the beam at

the exit end. The variation of light coupling efficiency from the

simulation results are attributed to the higher order mode excita-

tion and divergence associated with the fiber bends. Therefore,

it is advised to take care of this fact while designing the coupling

optics. Comparing the two fabrication methods, the polymer dipmethod is preferred over the hot blowing technique. Another

added advantage of this method is that it can be used to fabri-

cate lenses of any refractive index.

In general, the use of lensed POF improves the coupling ef-

ficiency, reduces assembly costs, and also helps to maintain the

package dimensions to minimum. They also offer ease of instal-

lation and altogether become a cost-effective solution for POF

communications

REFERENCES

[1] A. Polley and S. E. Ralph, 100 m, 40 Gb/s plastic optical fiber link,in Proc. Opt. Fiber Commun. Conf. Expo., National Fiber Opt. Eng.Conf., OSA Tech. Dig. (CD) (Opt. Soc. Amer., 2008), 2008, paperOWB2.

[2] S. Junger, W. Tschekalinskij, and N. Weber,Multimedia and multiser-vice systems for home, office and industrial networks, in Asia-PacificOpt. Wireless Commun. Conf., Wuhan, China, 2003, 4.11.2003.

[3] C. Koeppen, R. F. Shi, W. D. Chen, and A. F. Garito, Properties ofplastic optical fibers,J. Opt. Soc. Amer. B, vol. 15, pp. 727739, 1998.

[4] G. Giaretta, W. White, M. Wegmuller, and T. Onishi, High-speed (11Gbit/s) data transmission using perfluorinated graded-index polymeroptical fibersfor short interconnects,IEEE Photon. Technol. Lett., vol.12, no. 3, pp. 347349, Mar. 2000.

[5] D. Hanson, Wiring with plastic optical fibre, IEEE LTS, vol. 3, no. 1,pp. 3439, Feb. 1992.

[6] N. Fujimoto, H. Rokugawa, H. Watanabe, A. Ishizuka, and T.

Sukegawa, Photonic access connector: A compact, gigabit opticallink for plastic optical fiber, in Proc. ECOC, Sep. 1519, 1996, vol.2, pp. 5962.

[7] Y.-K. Lu, Y.-C. Tsai, Y.-D. Liu, S.-M. Yeh, C.-C. Lin, and W.-H.Cheng, Asymmetric elliptic-cone-shaped micro lens for efficient cou-pling to high-power laser diodes, Opt. Express, vol. 15, no. 4, pp.14341442.

[8] J. K. Kim, D. U. Kim, B. H. Lee, and K. Oh, Arrayed multimodefiber to VCSEL coupling for short reach communications using hybridpolymer-fiber lens, IEEE Photon. Technol. Lett., vol. 19, no. 13, pp.951953, Jul. 2007.

[9] G. Shu, M. P. Bozeman, R. S. Hays, D. P. Robinson, W. K. Wright,and A. D. Kuan, Design and evaluation of fiber tip lenses for fiberoptic transmitter and receiver applications, in Proc. IEEE Avionics,Fiber-Opt. Photon. Technol. Conf., Oct. 25, 2007, pp. 4647.

[10] G. D. Khoe, J. Poulissen, and H. M. de Vrieze, Efficient coupling oflaser diodes to tapered monomode fibers with high-index end, Elec-tron. Lett., vol. 19, pp. 205207, 1983.

[11] Y. Ohtsuka and Y. Hatanaka, Preparation of light focusing plasticfiber by heat drawing process, Appl. Phys. Lett., vol. 29, no. 11, pp.735737, Dec. 1976.

[12] D. F. Merchant, P. J. Scully, and N. F. Schmitt, Chemical tapering ofpolymer optical fiber, Sens. Actuators A, vol. 76, pp. 365371, 1999.

[13] L. C. Ozcan,V. Treanton, F. Guay, andR. Kashyap,Highlysymmetricoptical fiber tapersfabricated with a CO laser,IEEE Photon. Technol.

Lett., vol. 19, no. 9, pp. 656658, May 2007.[14] K. L. Mittal and K.-W. Lee, Polymer Surfaces and Interfaces: Charac-

terization, Modification and Application. Utrecht, The Netherlands:

VSP, Jul. 1997.[15] K.-R. Kim, S. Chang, and K. Oh, Refractive micro lens on fiber using

UV-curable fluorinated acrylate polymer by surface-tension, IEEEPhoton. Technol. Lett., vol. 15, no. 8, pp. 11001102, Aug. 2003.

[16] H. Sakata and A. Imada, Lensed plastic optical fiber employing con-cave end filled with high-index resin, J. Lightw. Technol., vol. 20, no.4, pp. 638642, Apr. 2002.

[17] C. K. Asawa and H. F. Taylor, Propagation of light trapped within aset of lowest-order modes of graded-index multimode fiber undergoingbending, Appl. Opt., vol. 39, pp. 20292037, 2000.

Jayakrishnan Chandrappan (M07) received theM.Tech. degree in optoelectronics and laser tech-nology from the International School of Photonics,

Cochin University of Science and Technology,Cochin, India, in 1999 and the M.Sc degree inphysics from Cochin University of Science andTechnology in 1997.

He has been with the Micro Module Components(MMC) Laboratory, Institute of Microelectronics(IME), Singapore, since January 2007. Prior to that,he was with SAMEER, R&D Lab, Government of

India, Indian Institute of Technology (I.I.T), Mumbai.

Zhang Jing, photograph and biography not available at the time of publication.

Ramkumar Veppathur Mohan completed sixmonth internship during his undergraduate studies atthe Institute of Microelectronics in 20072008.

He graduated with Honors in Bachelor of Elec-trical Engineering from the National University ofSingapore in 2008 with Optoelectronics Specializa-tion. He is currently employed with Credit Suisse.

Philbert Oliver Gomez graduated in 2008 from School of Electrical and Elec-tronics Engineering, Nanyang Technological University, Singapore.

He completed a six-month internship during his undergraduate studies at theInstitute of Microelectronics in 20072008. Currently, he is working with Eco-nomic Development Board, Government of Singapore.

Authorized licensed use limited to: ASTAR. Downloaded on September 6, 2009 at 00:10 from IEEE Xplore. Restrictions apply.

-

7/28/2019 PUB07-392-MMC-PPA-055

8/8

CHANDRAPPAN et al.: OPTICAL COUPLING METHODS FOR COST-EFFECTIVE POLYMER OPTICAL FIBER COMMUNICATION 599

Than Aye Aung, photograph and biography not available at the time ofpublication.

Xiao Yongfei, photograph and biography not available at the time ofpublication.

Pamidighantam V. Ramana, photograph and biography not available at thetime of publication.

John H. Lau (F94) received three M.S. degreesin structural engineering, engineering physics, andmanagement science and the Ph.D. degree in theo-retical and applied mechanics from the University ofIllinois, Urbana Champaign.

He has been the Director of the MMC Laboratoryof the Institute of Microelectronics (IME), A*STAR,Singapore, since January 2007, and prior to that hewas with HP and Agilent. With more than 30 years of

R&D and manufacturing experience, he has authoredor coauthored more than 300 peer-reviewedtechnical

publications and more than 100 book chapters, and given more than 250 presen-tations. He has authored and coauthored 16 textbooks on advanced packagingsolder joint reliability and lead-free soldering and manufacturing.

He is an elected ASME Fellow.

Dim Lee Kwong (F09) is the Executive Directorof Institute of Microelectronics (IME), Agencyfor Science, Technology and Research (A*STAR),Singapore, a Professor of Electrical and ComputerEngineering at National University of Singapore,an Adjunct Professor of Electrical and ComputerEngineering at the University of Texas at Austin,and Distinguished Scientist at Republic Polytechnic,

Singapore. He was Earl N. and Margaret BransfieldEndowed Professor at The University of Texasat Austin from 1990 to 2007, and the Temasek

Professor of the National University of Singapore from 2001 to 2004. Heis the author of more than 900 referred archival publications (500 journaland 400 conference proceedings), has presented more than 70 invited talksat international conferences, and has been awarded with more than 23 U.S.patents. He has been a consultant to government research labs, semiconductorIC manufacturers, and materials and equipment suppliers in U.S. and overseas.More than 55 students received their Ph.D. degrees under his supervision. Hisareas of current research interest include CMOS-compatible Si/Ge nanowiredevices and circuits for future CMOS technology and applications, siliconelectronicphotonic integrated circuit technology and applications, Si-basedbiosensors and integrated lab-on-chip, and sensors, actuators, and integratedmicrosystems.

Prof. Kwong received the IBM Faculty Award in 1984 to 1986, the Semi-conductor Research Corporation (SRC) Inventor Award in 1993 and 1994, the

General Motors Foundation Fellowship in 1992 to 1995, the Halliburton Foun-dation Excellent Teaching Award in 1994, the Engineering Foundation Awardin 1995, and IEEE George Smith Award in 2007.