PROJECT AND STUDY DRAWINGS & DIAGRAMS. DIAGRAMS AND DRAWINGS DIAGRAMS ARE TYPICALLY SCHEMATICS...

-

Upload

melina-webster -

Category

Documents

-

view

235 -

download

2

Transcript of PROJECT AND STUDY DRAWINGS & DIAGRAMS. DIAGRAMS AND DRAWINGS DIAGRAMS ARE TYPICALLY SCHEMATICS...

DIAGRAMS AND DRAWINGS

• DIAGRAMS ARE TYPICALLY SCHEMATICS

• DRAWINGS ARE PHYSICAL REPRESENTATIONS FOR CONSTRUCTION

• VARIOUS FORMS ARE COMPLETED DURING EACH PHASE OF THE PROJECT

• INITIAL PRODUCTS ARE CONCEPTUAL SCHEMATICS

• FINAL PRODUCTS ARE CONSTRUCTION DRAWINGS

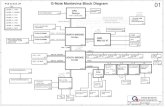

BLOCK FLOW DIAGRAMS (BFD)

• THESE INDICATE THE FUNCTION COMPLETED IN EACH AREA, NOT THE EQUIPMENT USED

• NORMALLY START WITH AN OVERALL BFD FOR THE PLANT

• AT LEAST ONE IS TO BE COMPLETED FOR EACH SECTION OF THE PLANT AND USED IN THE FINAL REPORT FOR THE AREA DESCRIPTIONS.

BFD PREPARATION

• SELECT PROCESS TECHNOLOGY• PREPARE DESIGN BASIS DOCUMENT

WITH ‘SCOPE OF WORK’• PREPARE A DOCUMENT PROCESS

DESCRIPTION• PREPARE ‘INPUT/OUTPUT’ DIAGRAM

(I/O)• PREPARE ‘BLOCK FLOW DIAGRAM’

(BFD)

BLOCK FLOW DIAGRAM

ALKYLATIONREACTION

BUTYLENE FEED

ISOBUTANE FEED

PROPANE RECOVERY

PROPANE

n-BUTANE RECOVERY

n-BUTANE

ALKYLATE

ISOBUTANERECYCLE

ALKYLATE PROCESS BLOCK FLOW DIAGRAM

PROCESS FLOW DIAGRAMS (PFD)

• SCHEMATIC SHOWING THE EQUIPMENT CONFIGURATION AND PROCESS STREAMS

• SYMBOLS - USE SIMSCI© AND SUPERPRO© STANDARDS

• EQUIPMENT NAMES AND NUMBERING - ALL ARE LOCATED ABOVE THE EQUIPMENT ON THE DIAGRAM. ALSO SEE CTA-04. DO NOT SHOW NAMES FOR PARALLEL EQUIPMENT, USE NUMBER DESIGNATIONS.

• FORMAT - ENTERING LINES LEFT, EXIT RIGHT. CAN MATCH UP BETWEEN AREAS IF PRACTICAL.

PROCESS FLOW DIAGRAMS (PFD)

• MASS & ENERGY BALANCE TABLE• STREAM LISTS

• SHOW PROPERTIES FOR EACH STREAM• CHANGE NUMBER EACH TIME PROCESS

CONDITIONS ARE CHANGED.• FLOWS ARE TYPICALLY BASED ON CONTINUOUS

AVERAGE OPERATION.• ADD A LINE FOR DESIGN FLOW IF THAT EXCEEDS

NORMAL OPERATING, FOR EXAMPLE WITH A BATCH PROCESS.

• SPREAD-OUT FIGURES – USE FOR P&IDs• MAJOR FLOW LINES ONLY - NO START-UP

OR COMMISSIONING LINES

PROCESS FLOW DIAGRAMS (PFD)

RX-101 VL-101RX-102

101

102

103

105

104

106

SHIFT REACTORMETHANATERSHIFT VAP/LIQ SEP

Stream NameStream Description

Phase

TemperaturePressure

Flowrate

Composition H2O CO H2 CO2 C1 N2 H2S

FPSIA

LB-MOL/HR

101

Vapor

600.000340.000

99.200

0.0000.5530.2910.0340.0720.0440.005

102

Vapor

435.000340.000

60.400

1.0000.0000.0000.0000.0000.0000.000

103

Vapor

918.393335.000

159.600

0.1660.1310.3940.2340.0440.0280.003

104

Mixed

240.000330.000

63.662

0.4110.0000.0000.5810.0000.0000.008

105

Vapor

450.000330.000

95.938

0.0030.2180.6550.0040.0740.0460.000

106

Vapor

587.627320.000

56.545

0.3490.0190.0700.0100.4740.0780.000

UTILITY FLOW DIAGRAMS• ONE FOR EACH MAJOR UTILITY • ONE FOR MISCELLANEOUS

UTILITIES• GENERAL FORMAT SHOULD LOOK

LIKE A BLOCK FLOW DIAGRAM

AREA 100 AREA 200 AREA 300 AREA 400 AREA 500

SUPPLY FOR UTILITY

RETURN FOR UTILITY

UTILITY FLOW DIAGRAMS

• FLOW RATES AND CONDITIONS ARE SHOWN ON MAIN FLOW LINES

• AREAS ARE REPRESENTED BY BLOCKS

• ONLY EQUIPMENT SPECIFIC TO THE UTILITY SHOULD BE SHOWN ON THE DIAGRAM (COOLING TOWERS, BOILERS, AIR COMPRESSORS, ETC.)

• ELECTRICAL SUPPLY AND TRANSFORMING SYSTEMS

UTILITY FLOW DIAGRAMS

• MISCELLANEOUS UTILITIES - INCLUDE:

• INSTRUMENT AIR• PLANT UTILITY WATER• PLANT AIR• SATURATED STEAM• POTABLE WATER• FIRE WATER• INERT GAS• SEWERS

– SANITARY– PROCESS– STORM

ARRANGEMENT DRAWINGS

• SHOW THE PLANT PLOT PLAN AND ELEVATIONS

• PROJECT WILL USE PLOT PLAN ONLY• LOCATE MAJOR EQUIPMENT TO MINIMIZE

EXTRA UTILITY RUNS

• ALLOW ROOM BETWEEN FACILITIES FOR CONSTRUCTION, OPERATION AND MAINTENANCE.

• SEE TYPICAL DRAWING ON NEXT PAGE

TYPICAL PLOT PLAN DRAWING – FROM NORTH ALABAMA COAL TO METHANOL PROJECT, STEARNS-ROGER, FOR TVA, JAN. 1984

PIPING AND INSTRUMENT DIAGRAMS

• SHOW LINE SIZING AND CONTROL SYSTEMS FOR THE PROCESS

• NEED ONE FOR EACH PFD AND ONE FOR EACH UFD, MINIMUM

– PIPE LINE DIAMETERS, M.O.C. & INSULATION REQUIREMENTS

– MAJOR CONTROL LOOPS– MINIMUM MONITORING

INSTRUMENTATION– SAFETY SHUTDOWNS AND INTERLOCKS– MAJOR FLOW ELEMENTS - VALVES

STANDARD DRAWINGS• CAN BE USED TO SIMPLIFY P&IDs• THESE INCLUDE INSTALLATIONS SUCH

AS:– ISOLATION VALVES ON ALL PIECES OF

EQUIPMENT WITH BYPASSES WHEN PRACTICAL.

– PUMPS - FLOW CONTROL AND CHECK VALVES ON DISCHARGE, ONLY. INLET AND OUTLET P & T INDICATION.

– HEAT EXCHANGERS - HAVE P & T INDICATION ON ALL LINES

– HAZARDOUS MATERIALS - USE DOUBLE BLOCK AND BLEED ARRANGEMENTS FOR ISOLATION, WITH VENT TO PROCESS FLARE AS APPROPRIATE.