PRODUCTION OF TOILET SOAP

-

Upload

ing-nana-nhyira-boateng -

Category

Documents

-

view

299 -

download

7

description

Transcript of PRODUCTION OF TOILET SOAP

CHAPTER 1

1.0 INTRODUCTION

Soap is a salt of a fatty acid. Soap is mainly used for washing, bathing, and cleaning, but

soaps are also important components of lubricants. Soaps for cleansing are obtained by

treating vegetable or animal oils and fats with a strongly alkaline solution. Fats and oils

are composed of triglycerides: three molecules of fatty acids attached to a single

molecule of glycerol. The alkaline solution, often lye, promotes a chemical reaction

known as saponification. In saponification, fats are broken down (hydrolyzed) yielding

crude soap. Fats are transformed into salts of fatty acids and glycerol is liberated,

leaving glycerin as a byproduct. Soaps are key components of most lubrication greases,

which are usually emulsions of calcium and lithium soaps in a mineral oil. Lithium-

based greases are widely used. Many other metal ions are used, including aluminium,

sodium, and mixtures of various metal ions. Such soaps are sometimes classified as

thickeners, meaning that they elevate the viscosity of the oil. In ancient times,

lubricating greases were prepared by the addition of lime to olive oil.

Toilet Soaps, to this class belongs to the finer kinds of scented soaps, which have

emollient properties. They are rarely made direct by the perfumer, the body or basis

being a well-selected white soap, subsequently cleaned and purified. For the choicest

grades, the body should be made of a mixture of olive and sweet-almond oil, as the fat

stock. Lard and beef tallow make the next best stock; and for palm soap a small quantity

of bleached palm oil is to be added to them. Cocoa oil and pale yellow resin

saponaceous matters also enter into the composition of certain toilet soaps. These body

soaps may be obtained as wanted from any well-conducted soap factory. To be adapted

to the purposes of perfumery they must be perfectly neutral, firm, free from unpleasant

odor and all tendency to crust in cold, or sweat in damp weather. They should,

moreover, give a rich lather without wasting too rapidly in the water. Soaps, generally,

in their original condition, are usually deficient in many of those points; and must, for

the purposes of perfumery, undergo a refining procests.

1

Main objective

To design a plant to manufacture 50 tonnes/day of toilet soap from animal fat.

Specific Objective

The specific objectives are the processes we need to go through in order to achieve the

main objective and these are as follows:

To select a suitable process for the manufacture of toilet soap.

To draw a process flow chart

To calculate for material and energy balance for all the equipment in the plant

To select a suitable site for the plant.

To determine the economic analysis of the plant.

2

CHAPTER 2

2.0 LITERATURE REVIEW

The most popular soapmaking process today is the cold process method, where fats such

as olive oil react with lye, while some soapers use the historical hot process. Handmade

soap differs from industrial soap in that, usually, an excess of fat is used to consume the

alkali (superfatting), and in that the glycerin is not removed, leaving a naturally

moisturizing soap and not pure soap. Additional processing of this glycerin containing

soap produces glycerin soap. Superfatted soap, which contains excess fat, is more skin-

friendly than industrial soap, though if too much fat is added, it can leave users with a

"greasy" feel to their skin. Sometimes an emollient such as jojoba oil or shea butter is

added "at trace" (the point at which the saponification process is sufficiently advanced

that the soap has begun to thicken) in the belief that it will escape the saponification and

remain intact, or in the case of hot process soap - after most of the oils have saponified

so that they remain unreacted in the finished soap. Superfatting can also be

accomplished through a process called a lye discount, where, instead of putting in extra

fats, the soap maker puts in less lye.

In cold-process and hot-process soapmaking, heat may be required for saponification.

Cold-process soapmaking takes place at a sufficient temperature to ensure the

liquefication of the fat being used. The lye and fat may be kept warm after mixing to

ensure that the soap is completely saponified. Unlike cold-processed soap, hot-

processed soap can be used right away because lye and fat saponify more quickly at the

higher temperatures used in hot-process soapmaking. Hot-process soapmaking was used

when the purity of lye was unreliable, and this process can use natural lye solutions,

such as potash. The main benefit of hot processing is that the exact concentration of the

lye solution does not need to be known to perform the process with adequate success.

Cold-process soapmaking requires exact measurements of lye and fat amounts and

computing their ratio, using saponification charts to ensure that the finished product is

mild and skin-friendly. Saponification charts can also be used in hot-process

soapmaking, but are not as necessary as in cold-process soapmaking.

3

Hot process

In the hot-process method, lye and fat are boiled together at 80–100 °C until

saponification occurs, which before modern thermometers, the soapmaker determined

by taste (the bright, distinctive taste of lye disappears once all the lye is saponified) or

by eye; the experienced eye can tell when gel stage and full saponification have

occurred. Beginners can find this information through research, and classes. It is highly

recommended to not "taste" soap for readiness. Lye, when not saponified is a highly

caustic material. After saponification has occurred, the soap is sometimes precipitated

from the solution by adding salt, and the excess liquid drained off. The hot, soft soap is

then spooned into a mold. The soap lye is processed for recovery of Glycerine.

Cold process

A cold-process soapmaker first looks up the saponification value of the fats being used

on a saponification chart, which is then used to calculate the appropriate amount of lye.

Excess unreacted lye in the soap will result in a very high pH and can burn or irritate

skin. Not enough lye, and the soap is greasy. Most soap makers formulate their recipes

with a 4-10% deficit of lye so that all of the lye is reacted and that excess fat is left for

skin conditioning benefits.

The lye is dissolved in water. Then oils are heated, or melted if they are solid at room

temperature. Once both substances have cooled to approximately 100-110 °F (37-43

°C), and are no more than 10°F (~5.5°C) apart, they may be combined. This lye-fat

mixture is stirred until "trace" (modern-day amateur soapmakers often use a stick

blender to speed this process). There are varying levels of trace. Depending on how

additives will affect trace, they may be added at light trace, medium trace or heavy

trace. After much stirring, the mixture turns to the consistency of a thin pudding.

"Trace" corresponds roughly to viscosity. Essential oils, fragrance oils, botanicals,

herbs, oatmeal or other additives are added at light trace, just as the mixture starts to

thicken.

The batch is then poured into molds, kept warm with towels, or blankets, and left to

continue saponification for 18 to 48 hours. Milk soaps are the exception. They do not

require insulation. Insulation may cause the milk to burn. During this time, it is normal

for the soap to go through a "gel phase" where the opaque soap will turn somewhat

4

transparent for several hours, before once again turning opaque. The soap will continue

to give off heat for many hours after trace.

After the insulation period the soap is firm enough to be removed from the mold and cut

into bars. At this time, it is safe to use the soap since saponification is complete.

However, cold-process soaps are typically cured and hardened on a drying rack for 2–6

weeks (depending on initial water content) before use. If using caustic soda it is

recommended that the soap is left to cure for at least four weeks.

Molds

Many commercially available soap molds are made of silicone or various types of

plastic, although many soap making hobbyists may use cardboard boxes that are lined

with plastic wrap. Soaps can be made in long loaves that are cut into individual bars,

block molds that are cut into loaves and then bars, or individual molds.

Purification and finishing

The common process of purifying soap involves removal of sodium hydroxide, glycerol

and some impurities. These components are removed by boiling the crude soap curds in

water and re-precipitating the soap with salt.

Most of the water is then removed from the soap. This was traditionally done on a chill

roll which produced the soap flakes commonly used in the 1940s and 1950s. This

process was superseded by spray dryers and then by vacuum dryers.

The dry soap (approximately 6-12% moisture) is then compacted into small pellets.

These pellets are now ready for soap finishing, the process of converting raw soap

pellets into a saleable product, usually bars.

The batch is then poured into molds, kept warm with towels, or blankets, and left to

continue saponification for 18 to 48 hours. Milk soaps are the exception. They do not

require insulation. Insulation may cause the milk to burn. During this time, it is normal

for the soap to go through a "gel phase" where the opaque soap will turn somewhat

transparent for several hours, before once again turning opaque. The soap will continue

to give off heat for many hours after trace.

5

Soap pellets are combined with fragrances and other materials and blended to

homogeneity in an amalgamator (mixer). The mass is then discharged from the mixer

into a refiner which, by means of an auger, forces the soap through a fine wire screen.

From the refiner the soap passes over a roller mill (French milling or hard milling) in a

manner similar to calendering paper or plastic or to making chocolate liquor. The soap

is then passed through one or more additional refiners to further plasticize the soap

mass. Immediately before extrusion it passes through a vacuum chamber to remove any

trapped air. It is then extruded into a long log or blank, cut to convenient lengths, passed

through a metal detector and then stamped into shape in refrigerated tools. The pressed

bars are packaged in many ways.

Sand or pumice may be added to produce a scouring soap. The scouring agents serve to

remove dead skin cells from the surface being cleaned. This process is called

exfoliation. Many newer materials are used for exfoliating soaps which are effective but

do not have the sharp edges and poor particle size distribution of pumice.

Nanoscopic metals are commonly added to certain soaps specifically for both coloration

and anti-bacterial properties. Titanium powder is commonly used in extreme "white"

soaps for these purposes; nickel, aluminium and silver are less commonly used. These

metals provide electron-robbing behavior when in contact with bacteria, stripping

electrons from the organism's surface and thereby disrupting their functioning (typically

killing the bacteria when it has lost too many electrons). Because some of the metal is

left behind on the skin and in the pores, the benefit can also extend beyond the actual

time of washing, helping reduce bacterial contamination and reducing potential odors

from bacteria on the skin surface.

6

CHAPTER 3

3.0 EQUIPMENT LIST AND PROCESS DESCRIPTION

3.1 EQUIPMENT LIST

Table 3.1 Equipment List

Item no. Service Quantity Type

VE-101 NaOH Storage tank 1 Vertical Cylindrical

VE-105 Water Storage tank 1 Vertical Cylindrical

VE-110 Saponifier vessel 1 Vertical Cubic

VE-205 Lye Preparation tank 1 Vertical Cylindrical

DA-101 Soap dryer 1 Vacuum Shelf

HE-101 1st Soap Heater 1

SE-101 Static Seperator 1

CO-101 Washing Column 1

CE-201 Centrifuge 1 Tubular Centrifuge

VE-105 Neutralizer Vessel 1

7

Vacuum Dryer

Saponification vessel

Static Separator

Washing Column

Centrifuge

Neutralizer

Lye

Tallow wet soap Lye

NaOH Crude Soap (13% Glycerine)

Fresh lye Glycerine

35% Glycerine

65% lye

Washed soap

20% lye

Lye

0.3% NaOH wet soap

0.5% NaCl

68.2% Solids

Salt produced

Toilet soap Additives

31% H2O

88% Solids 68% Solid

12% H2O 1% Impurities

Water H3PO4 (Weak acid)

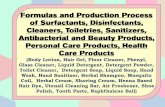

Fig. 3.1 Flow diagram for Toilet Soap Production

8

Neutralizer

Centrifuge

Vacuum DryerNeutralizerNeutralizer

3.2 PROCESS DESCRIPTION

This is a continuous process which uses a plant. The process is best understood in terms

of two streams: soap flowing in the order given below against a counter-current of lye.

Step 1 - Saponification

The raw materials are continually fed into a reactor in fixed proportions.

Tallow: 735.29 kg hr-1

NaOH solution: 272.33 kg hr-1

Lye: 35.22 kg hr-1

These ingredients alone would give a low water, high glycerine soap. Soap needs to be

about 30% water to be easily pumpable, and even then needs to be held at around 70oC,

so excess lye is added to hydrate the soap and dissolve out some of the glycerine. The

lye added is known as "half spent lye" and is the lye discharged from the washing

column. This lye already contains some glycerine, but it is further enriched by that

formed in the saponification reaction.

Step 2 - Lye separation

The wet soap is pumped to a "static separator" - a settling vessel which does not use any

mechanical action. The soap / lye mix is pumped into the tank where it separates out on

the basis of weight. The spent lye settles to the bottom from where it is piped off to the

glycerine recovery unit, while the soap rises to the top and is piped away for further

processing.

Step 3 - Soap washing

The soap still contains most of its glycerine at this stage, and this is removed with fresh

lye in a washing column. The column has rings fixed on its inside surface. The soap

solution is added near the bottom of the column and the lye near the top. As the lye

flows down the column through the centre, a series of rotating disks keeps the soap / lye

mixture agitated between the rings. This creates enough turbulence to ensure good

mixing between the two solutions. The rate of glycerine production is calculated and the

rate at which fresh lye is added to the washing column then set such that the spent lye is

25 - 35 % glycerine. Glycerine is almost infinitely soluble in brine, but at greater than

35% glycerine the lye no longer efficiently removes glycerine from the soap.

The soap is allowed to overflow from the top of the column and the lye ("half spent

lye") is pumped away from the bottom at a controlled rate and added to the reactor.

Step 4 - Lye separation

9

The lye is added at the top of the washing column, and the soap removed from the

column as overflow. As the lye is added near the overflow pipe the washed soap is

about 20% fresh lye, giving the soap unacceptably high water and caustic levels.

Separating off the lye lowers the electrolyte levels to acceptable limits.

The soap and lye are separated in a centrifuge, leaving a soap which is 0.5% NaCl and

0.3% NaOH, and about 31% water. The lye removed is used as fresh lye.

Step 5 - Neutralisation

Although the caustic levels are quite low, they are still unacceptably high for toilet and

laundry soap. The NaOH is removed by reaction with a weak acid such as coconut oil

(which contains significant levels of free fatty acids), coconut oil fatty acids, citric acid

or phosphoric acid, with the choice of acid being made largely on economic grounds.

Some preservative is also added at this stage.

Step 6 - Drying

Finally, the water levels must be reduced down to about 12%. This is done by heating

the soap to about 125oC under pressure (to prevent the water from boiling off while the

soap is still in the pipes) and then spraying it into an evacuated chamber at 40 mm Hg

(5.3 kPa). The latent heat of evaporation lost as the water boils off reduces the soap

temperature down to 45oC, at which temperature it solidifes onto the chamber walls.The

soap chips are scraped off the walls and "plodded" (i.e. squeezed together) by screws

known as "plodder worms" to form soap noodles. The soap is now known as base or

neat soap chip, and can be converted into a variety of different soaps in the finishing

stages. The moisture evaporated off the wet soap is transported to a barometric

condensor, which recondenses the vapour without the system losing vacuum. The

moisture can contain soap dust (.Fines.) which is removed by cyclones and returned by

augers to the spray chamber, while the water is recycled.

10

Fig.3.2 Process Flow Diagram of Toilet Soap Production

11

CHAPTER 4

4.0 MATERIAL AND ENERGY BALANCES

4.1 MATERIAL BALANCES

4.1.1 ASSUMPTIONS

1. The process is an open system

2. The process occurs at a steady-state condition.

4.1.2 PLANT ATTAINMENT

This is defined as the percentage of available hours in a year that the plant operates

usually between 90-95%. The process plant will operate three shifts of 8 hours per day.

The total downtime (maintenance, shutdowns, and holidays) will take 35 days per year.

330 days 24hours = 7920 hours

1 year 1 day

Basis chosen is in kg/hr

Productivity is 50 tonnes per day

In a year, productivity is 50tonnes x 330 days = 16500 tones per year

Converting,

16500 tons 1 year 1 day 1000kg

1 year 330 days 24 hours 1 ton

= 16500,000 kg

7920 hr

= 2083.333 kg /hr

12

SAPONIFICATION VESSEL

Material balance on saponification vessel

NaOH

Tallow

Lye

Table 4.1 Summary of material balance on saponification vessel

INPUT OUTPUT

Component Amount (kg) Component Amount (kg)

Tallow 735.29 Wet soap 3707.62

NaOH 272.33

Lye 2700

Total 3707.62 Total 3707.62

13

STATIC SEPERATOR

Material Balance on Static Separator.

Wet soap Lye

Crude soap

Table 4.2 Summary of material balance on static separator.

INPUT OUTPUT

Component Amount (kg) Component Amount (kg)

Wet soap 3707.62 Crude soap 3672.4

Lye 35.22

Total 3707.62 Total 3707.62

14

Material Balance on Washing Column.

Fresh lye

Crude soap Washed soap

Glycerin

Table 4.3 Summary of material balance on Washing Column.

INPUT OUTPUT

Component Amount (kg) Component Amount (kg)

Crude soap 3672.4 Washed soap 3360.16

Fresh lye 2500 Glycerine 2812.26

Total 6172.4 Total 6172.4

15

WASHING COLUMN

Material Balance on Centrifuge.

Washed soap Wet soap

Lye

Table 4.4 Summary of material balance on Centrifuge.

INPUT OUTPUT

Component Amount (kg) Component Amount (kg)

Washed soap 3360.16 Lye 672.03

Wet soap 2688.13

Total 3360.16 Total 3360.16

16

CENTRIFUGE.

Material balance on Neutralizing Vessel.

H3PO4 (Weak acid)

Wet soap

Salt Soap

Additives

Salt

Table 4.5 Summary of Material Balance on Neutralizing vessel.

INPUT OUTPUT

Component Amount (kg) Component Amount (kg)

Wet soap 2688.13 Soap 2696.07

Additives 12.57 Salt 24.394

Weak acid 19.76

Total 2720.43 Total 2720.43

.

17

NEUTRALIZING

VESSEL.

Material balance on Dryer.

Solid soap Toilet soap

Water

Table 4.6 Summary of Material Balance on Dryer.

INPUT OUTPUT

Component Amount (kg) Component Amount (kg)

Soap 2696.07 Toilet Soap 2083.33

Water 585.79

Impurities 26.96

Total 2696.07 Total 2696.07

4.2 ENERGY BALANCE FOR THE VARIOUS UNITS

ENERGY BALANCES

The conservation of energy however differs from that of mass in that energy can be

generated (consumed) in a chemical process. Material can change form and new

molecular species can be formed by the chemical reaction, but the total mass flow into a

process unit must be equal to the flow out at steady state. This is not true for energy.

The total enthalpy of the outlet streams will not equal that of the inlet streams if energy

is generated or consumed in the process due to heat of reaction. (Sinnott, 1999)

18

DRYER.

In process design, energy balances are made to determine the energy requirements of

the process: the heating, cooling and power required. It shows the pattern of energy

usage and suggests areas for conservation and savings. (Sinnott, 1999)

4.2.1ASSUMPTIONS:

1. No accumulation of material and energy;

2. Open systems only;

3. The type of process taking place is continuous; and

4. No change in density of material along the process line.

1.Energy Balance on Saponification Vessel

∆ H=Q−W S

Q=∆ H+W S

Where

w s=12.5 kw for a turbineagitator

But for,

∆ H=H 2−H 1

∆ H =m [∫ cpdt−∫ cpdt ]

At reference state of 250c

∆ H=m [∫25' c

70' c

cpdt−∫25 ' c

25 ' c

cpdt ]Hence

19

∆ H=m [∫25' c

70' c

cpdt ]Where

Cp (wet soap)=1.22kj∕kg.k

M(mass flow rate)=3707.48kg∕hr

T at 250c=298.15 k

T at 700 c=343.15k

Then

∆ H=3707.48kgh (1.22

kjkg .k |(343.15−298.15 ) k| h

3600 s|)∆ H=56.5 kw

Where Q=∆ H+W S

¿ (56.5+12.5 ) kw

Q=¿69.04 kw is the amount of heat energy required by the saponification

vessel.

2. Energy balance on washing column

∆ H=Q−W S

Q=∆ H+W S

Where

w s=12.5 kw for a turbineagitator

But for,

∆ H=H out−H ¿

Where

Hout ¿ H glycrinee+H wet soap : T at 800 c=353.15k

20

H ¿=H wet soap+H lye : T at 70

0 c=343.15k

For

Hglycerine=m∫

70c

80c

cpdt

¿ ⟨2812.26kgh |2.43

kjkg . k|(353.15−343.15 ) k| 1h

3600 s|⟩H glycerin e=18.98 kw

Hwashed soap=m ∫

70 c

80 c

cpdt

¿ ⟨3360.16kgh |1.22

kjkg . k |(353.15−343.15 ) k| 1 h

3600 s|⟩Hwashed soap=11.39 kw

Hlye=m∫

70c

80c

cpdt

¿ ⟨2500kgh |3.1

kjkg . k|(353.15−343.15 ) k| 1h

3600 s|⟩H lye=21.53kw

Hcrude soap=m ∫

70 c

80 c

cpdt

¿ ⟨3672.4kgh |1.22

kjkg . k|(353.15−343.15 ) k| 1 h

3600 s|⟩H crude soap=12.45 kw

21

Hence

∆ H=H out−H ¿

¿ (18.98+11.39 )−(21.53+12.45 )

¿30.37−33.98

∆ H=−3.61 kw

Then

Q=∆ H+W S

¿−3.61+12.5

Q=8.89 k w

3. Energy balance on centrifuge

The energy consumption of a tubular bowl centrifuge handling dilute slurries is 1.49kw

Tubular centrifuge bowl diameter =4.25in

Maximum centrifuge force × gravity =13200

Ref.(Robert H.Perry and Don W. Green,Perrys chemical engineershandbook, 7 th

edition ,page 18-112,table 18-12)

Where Q=WS

Q=1.49kw

Separation factor (ks)

k s=¿39.48 n2 r

g¿

k

s=¿39.48 (2502) 4.125

9..81¿

k s=¿1037557.3 ¿

22

4. Energy balance on Neutralizer

NaOH+H 3 PO 4→ NaHP O4+H 2 O

Q=∆ H

Where ∆ H is by definition ∆ Ĥ rxn for the chemicalreactionequqtion

Compound ∆ Ĥ f (kj ∕ mol)

NaOH - 469.43

H3PO4 - 1294.23

H 2 O - 1748.1

NaHPO4 - 285. 85

Hence

∆ Ĥ rxn=¿

∆ Ĥ rxn=[ (V NaHPO 4 ∆ Ĥ f NaHPO 4+V H2 O ∆ Ĥ f H 2O )−(V NaOH ∆ Ĥ f NaOH+V H3 PO 4 ∆ Ĥ f H 3 PO 4 ) ]

∆ Ĥ rxn=[ (1 × (−1748.1 ) )+(1 × (−285.85 ) ) ]−[ ( 1× (−469.43 ) )+ (1× (−1294.23 ) ) ]

∆ Ĥ rxn=(−2033.95 ) — (−1763.66 )

23

∆ Ĥ rxn=−270.29 kj /mol

Hence Q= -270.29kj/mol

The negative value of Q means heat is removed from the reaction.

5.Energy balance on dryer

Qs

ms

=CPS (T sb−T sa )+ Xa Cpl (T v−T sa )+( X a−Xb )⋋+X bC pl (T va−T v )+( X a−Xb ) C pv (T va−T v)

WhereT sa=feed temperature

T v=vapourizationtemperature

T sb=final solidstemperature

T va=final vapour temperature

CPS , Cpl ,C pv=h eat capcities of solids ,liquid∧vapour

Then

C pl=4.187 kj

kg. k

C pv=4.285 kj

kg. k

CPS=1.22 kj

kg. k

T sa=700 c+273.15 k=343.15 k

T v=100oc+273.15 k=373.15 k

T sb=45oc+273.15 k=318.15 k

⋋=225 kj /kg

X a=0.31 X b=0.12 ms=2083.33 kg/h

Then total rate of heat transfer (Qs ¿

24

Qs

ms

=1.22 (318.15−343.15 )+( 0.3 ) ( 4.1897 ) (373.15−343.15 )+ (0.31−0.12 ) 225+(0.12 ) (4.1897 )(318.15−373.15)+ (0.31−0.12 )(4.2859)(38.15−398.15 )

Qs

ms

=(−30.5 )+(38.964 )+(42.75 )−27.652+3.986

Qs

ms

=−58.152+85.7

Qs

ms

=27.548

Qs=ms(27.548)

Qs=2083.33(27.548)

Qs=57391.6|kjh | 1 h

3600 s

Qs=15.94kw

Hence the enegy needed by the dryer is 15.94kw

CHAPTER 5

25

5.0 EQUIPMENT SPECIFICATION AND PIPELINE SCHEDULE

5.1 EQUIPMENT SPECIFICATIONS

Equipment specification typically includes the determination of vessel dimensions and

description of other internal parts of the equipment. It also involves the determination of

parameters like speed, power and any other operating parameters pertaining to the

particular equipment. Specification of equipment can be approached from a duty

specification viewpoint.

(Cheremisinoff, 2000)

Summary of equipment specification

The major considerations under equipment specification are:

1. Identification of the equipment

2. Function of the equipment

3. Material handled

4. Basic design data

5. Material of construction

Information and data used are from Peter and Timmerhaus, McCabe and Smith and

Chemical Engineering handbook, 5th edition.

Saponification vessel

Duty: To react sodium hydroxide, tallow and lye.

Type: Non reversible

Capacity: 50 tonnes/hr

Number required: 1

Static separator

26

Duty: separates the soap from the lye.

Type: a settling vessel which does not use any mechanical action

Material of Construction: carbon steel

Area: 2.0m2

Width: 1.15m

Length: 1.725m

Storage Tank 1

Duty: To serve as a stock pile for the tallow.

Description: Vertical cylindrical tank with flat ends.

Capacity: 1362 m3

Height: 24m

Diameter: 8.5m

Thickness: 7mm

Number required: 6

Material of construction: Carbon Steel.

Washing colunm

Duty: To remove glycerine from the soap by introducing fresh lye.

Type: column with rings fixed on its inside surface.

Description: Cylindrical and slightly inclined to the horizontal

Inside diameter of washing column: 1570m3

Length: 80m

Diameter: 5 m

Rotational speed of rings : 1.324 rpm

Material of construction: Mild Steel

Number required: 1

Storage Tank 227

Duty: To temporarily store sodium hydroxide.

Description: Vertical cylindrical tank with flat ends.

Capacity: 480.66 m3

Height: 17m

Diameter: 6m

Thickness: 7mm

Number required: 2

Material of construction: Carbon Steel

Thickness: 7mm

Number required: 1

Material of construction: Carbon Steel

Neutralizer

Duty: to react weak acid with sodium hydroxide.

Type: Continuous Stirred Tank Reactor

Capacity: 185m3

Height: 8 m

Diameter: 5m

Material of Construction: Carbon Steel

Storage Tank 3

Duty: To temporarily store lye solution before entering saponifier.

Description: Vertical cylindrical tank with flat ends.

Capacity: 124.8 m3

Height: 11m

Diameter: 3.8m

Thickness: 7mm

Number required: 1

28

Material of construction: Carbon Steel

Dryer

Duty: to reduce water levels to about 12% in the toilet soap

Type: vacuum shelf dryer

Number: 1

Capacity: 2083.33kg/hr

Moisture content: 3%

Column diameter: 0.9m

Number of trays: 10

Hole diameter: 20mm

Distance between trays: 20mm

Centrifuge

Duty: To separate soap and lye

Type: Tubular centrifuge

Diameter: 4.25in

Number: 1

The energy consumption of a tubular bowl centrifuge handling dilute slurries is 1.49kw

Tubular centrifuge bowl Maximum centrifuge force × gravity =13200

Separation factor ( kS ) ; 1037557.3

5.1 SPECIFICATION OF PIPELINES

29

Table 5.1: Pipeline Specifications

Pipeline

Location

Fluid

Transpor

ted

Mass

Flow

Rate,

(kg/hr)

Fluid

Velocit

y, m/s

Diamete

r, In.

Sched

ule

Numb

er

Material

Of

Construct

ion

Between the

saponification

vessel and the

static separator

Wet soap 3707.62 9.67 8 40-S 304

Stainless

Steel

Between the

static separator

and the washing

column

Crude

soap

3672.4 9.67 8 40-S 304

stainless

steel

Between the

washing colunm

and the

centrifuge

Washed

soap

2812.26 2.73 6 40-S 304

stainless

steel

Between

centrifuge and

neutralizer

Wet soap 2688.13 2.23 6 40-S 304

stainless

steel

Between

neutralizer and

the vacuum

Soap 2696.07 2.22 6 40-S 304

stainless

30

shelf dryer steel

From vacuum

shelf dryer

Toilet

soap

2083.33 2.34 1.5 40-S 304

stainless

steel

31

CHAPTER 6

6.0 PLANT SITING AND LOCATION

6.1 PLANT SITING AND LAYOUT

Application of sound engineering principles, exhaustive costing and profitability

analysis only will not be enough for successful operation. The success and profitability

of the plant is largely dependent on so many factors. These factors are:

1. Plant location

2. Availability of raw materials

3. Marketing areas

4. Maintenance

5. Availability of utilities: water, fuel, power, etc.

6. Availability of cheap labour

7. Personal safety measures

8. Control and instrumentation

9. Storage facilities

10. Pollution control

11. Quality control

6.1.1 PLANT LOCATION

The geographical location of the plant has a strong influence on the success or failure of

the plant. In other words, it has a crucial effect on the profitability of the plant, and the

scope of future expansion. Therefore, a plant should be located where minimum cost of

production, as well as distribution could be obtained, amongst other factors.

6.1.2 CHOICE OF LOCATION

In order to make the design project realistic, the aspect of site selection must be given

some consideration. There are a number of considerations concerning the choice of site

locations for a toilet soap plant within the country. Some of these are general

considerations whilst others relate directly to the process and its requirements. The

following list contains a few of the important considerations.

30

a. Designation as a heavy industrial development area.

b. Prior existence of similar chemical plants and location of other industrial centers

c. Existing roads and services and also appropriate terrain, sub surface, drainage

etc.

d. Suitable access for transportation for transportation of raw materials and

chemicals and for construction of a chemical plant.

e. Availability of a local workforce and distance from local communities.

f. Environmental discharge regulation and cost of land and services etc

g. Climatic condition

h. Proximity to both the raw materials supply and the market for the product

chemical.

i. Political and strategic considerations.

j. Location community considerations.

k. Proximity to major transportation networks e.g. roads, railways.

l. Availability of suitable land etc.

The importance of the geographical location of the plant cannot be over emphasized.

The locations considered for the sitting of the toilet soap plant are Kumasi in the

Ashanti Region, Tema in the Greater-Accra Region and Takoradi in the Wetern Region.

After detailed analysis of the various locations appropriate for sitting the toilet soap

plant has been done, the location of the toilet soap plant will be Takoradi in the Western

Region of Ghana.

Some of the factors considered were:

31

Availability of Raw Material

The main raw materials for the toilet soap plant are tallow and Sodium hydroxide.

Looking at the probable site location, Takoradi in the Western Region was selected as

the most probable for this plant since it is the capital of the Western region. Takoradi

and some of its surrounding towns produce a high level of animal fat which is

obtained at the abattoir and thus imply a good availability of tallow in that area. It being

a coastal town, NaOH can easily be imported from overseas for the purpose of soap

production and thus if the plant is sited in Takoradi , raw materials will not be a

problem.

Availability of Suitable land

The suitability of land is judged based on some factors including: drainage, load bearing

characteristics and flatness. The sites must therefore be evaluated to determine the need

for any special foundations, and Takoradi qualifies because it has all this positive

characteristics.

Transportation Facilities

The fact that Takoradi is a regional capital assures any investor of good transportation

facilities. The town’s proximity to the port serves as a good means of easily transporting

the sodium hydroxide by sea. Also the ease of moving the raw materials from the sites

is assured. The region has a good railway and road network to transport some of the

product; toilet soap, to some local customers.

Utilities

There exists a power line network connecting, Takoradi to the national source of

hydroelectric power. With respect to the current trend of power outages, we envisage

that the by the time the project is completed and ready to commence, this problem

would have capsized. But if the worse happens, the plant would have to resort to the

Thermal Plant or any other cheaper form of energy available. Moreover because some

units will run on gaseous fuel (natural gas) it is a good site because of the West-African

Gas pipeline project which is expected to be operational by the commencement of this

32

project. Water is also needed for the various processes involved in the production, as

well as other non-production related purposes such as drinking, washing and sanitary

purposes among others. Takoradi has a good source of water supply which is of good

quality to our plant. All the major towns in and around the regional capital have their

buildings well laid out with defined access routes and well planned layouts.

Availability of labour

Generally, skilled labour must be brought in for the construction of the plant. However,

there must be adequate labour (skill and unskilled) in the locality for the operation of

the plant. The availability of cheap labour in developing countries including Ghana and

therefore, favours this possible plant location.

Takoradi having attained metropolitan status and the region’s jubilee field (crude oil)

sector in particular and agriculture in general attracts migrants to Takoradi. The migrant

population shows that males are attracted to the town than females. With the advent of

the toilet soap plant in that area, the youth will be employed on the plant site in various

forms of casual work. Unemployment among the youth like any other densely populated

area is high. Thus labour, especially unskilled labour will not be a problem. Skilled

labour can also be brought in for special purposes.

Market Areas

The local consumption and export needs are the primary focus for production, since

future expansion would seek to explore opportunities in the West African Region as

well as other parts of the world. Because transportation cost takes up a significant

fraction of the sales price, it is one of the reasons why our plant will be situated close to

the primary market and closer to the seaport and habour which is also in this town

Takoradi.

Moreover the major market for the highly manufactured toilet soap is the foreign

market. Since a higher percentage of the product would be exported out of the country.

With the plant site being Takoradi which has a Sea Port renders the site very suitable.

The local market can also be served with adequate supply of toilet soap by the means of

good road and rail networks in the region and across the other regional and district

capitals.

33

Climate

This is considered a very important factor when choosing a location for the plant.

Generally, adverse climate conditions at a plant site will increase cost. Ghana has two

major seasons (dry and rainy seasons) which is common to all the possible plant

location. This factor thus favours the possible plant location.

Political and strategic considerations

Sometimes, the choice of location provides certain benefits from the government in

terms of capital grants, tax concessions and other inducements. For this factor however,

since government benefits of this sort are spread around Ghana, the possible location is

also favoured by this factor.

Local community consideration

It is important to locate the plant in a safe community and where it is accepted. The

community should also be able to provide adequate facilities for plant personnel such as

schools, banks, housing, and recreational and cultural facilities. Since Takoradi is the

regional capital; schools, banks, housing and other recreational facilities are present

with more to be created upon the establishment of the plant thus making it a favourable

location.

34

CHAPTER 7

7.0 ECONOMIC ANALYSIS

This plant design project aims to present a process that is capable of operating under

conditions which will yield profit. As a necessity the economic viability of this

manufacturing business must be addressed considering the society and government with

which it will operate. The primary concern of an investor lies in the rate of return

(ROR) based on accurate cost estimates and sound data.

Since net profit equals total income minus all expenses, it is essential that all the costs

involved in manufacturing processes are considered. A capital investment is required for

any industrial process and the determination of the process consists of fixed capital

Investment of physical equipment and facilities in the plant plus necessary investment is

an important part design project. The total investment for any working capital which

must be available to pay salaries, keep raw materials and products on hand and handle

other special items requiring a direct cash outlay. Thus in this analysis income tax is

taken into consideration.

Using the payback period, rate of return and unit product cost a profitability analysis

will be conducted to see the viability of this plant design.

Basis of economic analysis:

Start of construction: January, 2011

Completion of construction: January, 2012

Commencement of processing: Jan 2013

Plant operation: 3 shifts per day

Process: Continuous

Plant life: 15years (Peters et al,1986)

Plant production rate: 16,500 tonnes per annum

Working period: 330 days

Production capacity: varied over the years

Selling price of toilet soap: $1.50

Chemical Engineering Cost index for 2008 = 1495.7

Time value of money is not neglected

Exchange rate of dollar :GH ¢ 1.40

35

7.1 TOTAL CAPITAL INVESTMENT

Before an industrial plant can be put into operation, a large sum of money is needed to

purchase and install the necessary machinery and equipments, obtain land and service

facilities and also the plant must be erected complete with all piping, controls and

services. Many must also be available for the payment of expense and involved in the

plant operation (peter et al). The total capital investment is the sum of the following:

Fixed Capital Investment (FCI) is the capital needed to supply all manufacturing and

plant facilities. FCI can also be defined as the total cost of the plant ready for start up

(Coulson and Richardson, Volume 6). This includes:

Direct (manufacturing) fixed capital investment – the amount of money

necessary for the installed process equipment with all auxiliaries needed for

a complete process operation (e.g. purchased equipment cost, equipment

installation cost, instrumentation and control cost, piping cost, electrical

equipment and material cost, building (including services) cost, yard

improvement cost, service facilities coat, land cost, etc)

Indirect (non manufacturing) fixed capital investment – construction

overheads and all plant components which are directly related to the process

operation. (e.g. engineering and supervision cost, construction expenses,

contractors fee, contingency fees, warehouse, laboratories, transportation,

utility etc)

Working Capital is the capital needed for the daily running of the plant. In other words ,

it is the additional investment capital needed over and above the fixed capital

investment to start the plant, to operate it to the point when income is earned. This

consists of the total amount of money invested in

Start up

Raw material and supplies carried in stock

Finished and semi finished products in stock

Accounts receivable and payable

Cash kept on hand for monthly payment of operating expenses

Taxes payable

It is estimated that working capital is approximately 15% of total capital investment.

36

7.2 FIXED CAPITAL INVESTMENT

The fixed capital investment is the capital needed to supply the necessary manufacturing and

plant facilities (peter et al). It can also be defined as the total cost of the plant ready for start up

(Coulson and Richardson, volume 6). The fixed capital investment can be divided into two. That

is:

1. The direct fixed capital investment

2. The indirect fixed capital investment.

7.3 ESTIMATION OF DIRECT FIXED CAPITAL INVESTMENT

Table 7.1: Cost of Equipment in 2009

Item no. Service Cost $

VE-101 NaOH Storage tank 14904

VE-105 Water Storage tank 6505

VE-110 Saponifier vessel 146302

VE-205 Lye Preparation tank 8280

DA-101 Soap dryer 7300

HE-101 1st Soap Heater 2505.3

SE-101 Static Separator 649,600

CO-101 Washing Column 21,900

CE-201 Centrifuge 6900

VE-105 Neutralizer Vessel 265,700

Source: Perry’s

Total Equipment Cost = $1,129,896.3

Purchased Equipment Installation Cost

The installation of the equipment includes factors directly related to the erection of

purchased equipment (e.g. painting, platforms, insulation, formulation, construction

expenses). This is estimated to be 25% of the purchased equipment cost (Peter et al,

1990).

37

Instrumentation and Control Cost

Instrument cost, installation-labour cost and expenses of auxiliary equipment and

materials constitute the major portion of the capital investment required for

instrumentation (peter et al). This component is estimated to be 8% (for normal solid-

fluid chemical process plant) of the purchased equipment cost (Peter et al, 1990).

Piping Cost

This refers to the cost for raw material, intermediate-product, finished-product, steam,

water, and waste products piping (Peter et al). Items involved in the complete erection

of all piping used directly in the process which include the labour, valves, fittings, pipe,

support etc. The piping cost is estimated to be 30% of purchased equipment cost (Peter

et al, 1990).

Cost of Electrical Systems

The electrical system consists of the power wiring, lighting, transformation and

services, and instrument and control wiring. This component is estimated to be 12% of

the purchased cost (Peter et al, 1990).

Cost of Buildings and Structures

The cost involved in the erection of all buildings connected with the plant (labour,

materials and supplies). Cost for plumbing, heating, lighting, ventilation, and similar

building services are included here. This component is estimated to be 47% (for solid-

fluid process plant, new plant and new site) of the purchased equipment (Peter et al,

1990).

Cost of Yard Improvement

This involves costs for fencing, grading, roads, sidewalks, rail road sidings, landscaping

and similar items. Yard improvement cost for chemical plant is estimated to be 10% of

the purchased equipment cost (Peter et al, 1990).

38

Service Facility and Utility Cost

Utilities for supplying steam, water, power and fuel are part of the service facilities of a

chemical process plant. Services include the cost of waste disposal, fire protection, and

miscellaneous service items (shop, first aid, cafeteria equipment etc). This component is

estimated to be 30% of the purchased equipment cost (Peter et al, 1990).

Cost of Land

The plant will be sited at Takoradi in the Western Region. The cost of land per plot

(30mx30m) is GH¢600. The number of plots needed for the construction of the plant is

10, making room for future expansion of the company, 25% of the land needed will be

added, and the total land needed is 11,025m2. The total cost will be GH¢7500

($5357.14)

7.4 ESTIMATION OF INDIRECT FIXED CAPITAL INVESTMENT

Engineering and Supervision Cost

This involves construction design and engineering, drafting, purchasing accounting,

construction and cost engineering, travel, reproductions, communications and home

office expenses including overhead. This component is estimated as 8% of the total

direct costs of the process plant (Peter et al, 1990).

Construction Expenses

This cost component involves construction and operation, construction tools and rentals,

construction payroll, taxes, insurance and other overheads. This component is estimated

as 10% of the total direct cost (Peter et al, 1990).

Contractors’ Fee

The contractors’ fee can be taken as 5% of the total direct cost (Peter et al, 1990).

39

Contingency Fees

A contingency amount is included in all estimates of total capital investment in

recognition of the fact that, there will be unexpected events and changes that will

inevitably increase the cost of the project (i.e. strikes, price changes, small design

changes, storms, floods etc). This component is estimated as 8% of the total direct and

indirect cost (Peter et al, 1990).

Table 7.2: Summary of the Total Capital Investment Estimation

Item

Estimated Cost,

$

Purchased equipment cost 1129896.3

Purchased equipment installation 1955890.93

Instrumentation and controls 625885.1

Piping (installed) 2347069.116

Electrical (installed) 938827.65

Building (Including services) 3677075

Yard improvements 782356.37

Service facilities 2347069.116

Land 5357.14

Total Direct Cost(TDC) 13,809,426.72

40

TOTAL INDIRECT COST (TIC)

Item Estimated cost

Engineering and Supervision 1640247-531

Construction expense 2050309.414

Contractors Fee 1025154.707

Contingencies 1640247.531

TOTAL TIC 6355959.183

TOTAL FIXED CAPITAL INVESTMENT

(TFCI) = (TDC) + (TIC) 20165385.90

WORKING CAPITAL (WC)= 15%(TFCI) 3024807.885

TOTAL CAPITAL INVESTMENT(TCP)$ =

(TFCI + WC) 23,190,193.79

7.5 ESTIMATION OF TOTAL PRODUCT COST

The two basic components that affect product pricing are costs of manufacture and

competition in selling. It is unprofitable to sell a product below the manufacturer’s

production costs and unfeasible to sell it at a price higher than that at which comparable

merchandise is being offered. Other variables also affect pricing. Company policy may

require a minimum profit on new product lines or a specified return on investments, or

discounts may be offered on purchases in quantity.

This involves the estimation of cost for operating the plant and selling the products.

Total product cost is broken down into two:

Total Product Cost = Manufacturing Cost + General Expenses

41

The manufacturing cost (direct product cost) is also subdivided into the fixed charges,

plant overheads and variable production cost. The fixed charges are costs that do not

vary with production rate, where as the variable production cost is the cost dependent on

the amount of product produced. Plant overheads comprise hospital and medical bills,

general plant maintenance cost safety services among others (Peter et al, 1990).

The general expenses comprise administrative expenses, distribution and marketing

expenses and research and development expenses.

An additional 12.5% 0f the total cost for direct and indirect labour is included to

account for the social security contributions for each employee.

Operating Labour

Table 7.3: Direct and Indirect Labour Costs (DLC and ILC)

42

Direct Labour Cost (DLC)

Staff Number Annual Salary Per

Head, $

Total Annual

Salary, $

Plant Manager 1 80,000 80,000

Production Manager 1 70,000 70,000

Chemical Engineer 2 65,000 130,000

Mechanical

Engineer

2 63,000 126,000

Electrical Engineer 2 63,000 126,000

Quality Assurance

Manager

1 55,000 55,000

Supervisors 5 45,000 225,000

Lab Technicians 5 18,000 90,000

Plant Site Workers 15 4,800 72,000

Total (DLC) 34 974000

Indirect Labour Cost (ILC)

Staff Number Annual Salary Per Total Annual

43

Head, $ Salary, $

Managing Director 1 80,000 80,000

Human Resource

Manager

1 50,000 50,000

Sales Manager 1 45,000 45,000

Accountant 2 40,000 80,000

Store Keeper 2 15,000 30,000

Receptionist and

Secretary

1 10,000 10,000

Cleaners 5 2,400 12,000

Drivers 6 3600 21,600

Security men 8 3000 24,000

Total (ILC) 352600

(DLC + ILC) 1326600

Social Security

Contributions

12.5%(DLC +

ILC)

165825

TOTAL LABOUR

COST

1492425

44

7.6 DETERMINATION OF MANUFACTURING COST

Raw Material

The raw materials needed in this project are

Table 7.4: Raw Materials

Raw Material Annual Quantity

Unit Cost/kg,

$ Annual Cost ($)

Tallow 5823496.80 kg 0.714/20kg 207,898.84

Sodium

hydroxide

2156853.60 kg 0.178 383,919.94

Total 591,818.78

Utilities

This includes the cost of the total cost of electricity, process cooling water, and other

forms of utility that is required to keep the plant in operation. This component is

estimated as 10% of the total equipment cost.

Maintenance and repairs

If a plant is to be kept in efficient operating condition, a considerable amount of

expenses is necessary for maintenance and repairs. Since the annual cost for the plant is

high, this component is estimated as 6% of the fixed capital investment.

Operating supplies

45

This includes the cost of items such as lubricants, test chemicals, charts etc, required to

keep the plant functioning efficiently. It is assumed to be 15% of maintenance and

repairs.

Laboratory Charges

This involves cost of laboratory tests for control operation and product quality control.

It is taken as 20% of operating labour.

Table 7.5: Total Annual Direct Product Cost

Description Total Annual Cost, ($)

Raw Materials 591,818.78

Operating Labour 1,492,425

Operating Supplies 181,488.47

Power and Utilities 112,989.63

Maintenance and Repairs 1,209,923.15

Laboratory Charges 298,485

Total Annual Direct Product Cost 3,887,130.03

.

CHAPTER 8

46

8.0 PLANT SAFETY AND POLLUTION CONTROL

8.1 PLANT SAFETY

Every organisation (company or industry) has the moral and legal obligation to protect

the health and welfare of its employees as well as that of the general public. Therefore,

good safety measures have to be put in place to ensure the safety of lives and prevent

damage to equipment. The primary aim of these safety measures therefore is to prevent

or minimize workers exposure to the potential hazard, injury to workers, loss of lives,

and destruction of properties. They are also needed to ensure safe as well as efficient

operation.

These safety measures are employed in industry mainly to prevent or control hazards.

A hazard is a property which in particular circumstances could lead to harm. Common

safety hazards in the manufacturing industry include; dangerous machinery, explosion

to fires, faulty electrical connections and falling materials due to poor housekeeping

among others.

The potential hazards that could be present in the toilet soap plant include hazards due

to materials handling and hazards due to the various processes.

Hazards due to materials handling

Potentially hazardous situations include handling and packaging operations, equipment

cleaning and repair, decontamination following spills and equipment failure. Hazards

that workers are likely to be exposed to can be prevented by a number of ways, example

of which is the provision of PPEs (Personal Protective Equipment). These equipments

include chemical splash goggles, overcoat/chemical suit, rubber boots, ear plugs, face

shield, etc. These equipment are worn to protect the worker from the dangers of

handling some of the chemicals especially sodium hydroxide.

Hazards due to various processes

Hazards that might be caused during processes in this plant include fire hazards,

electrical and mechanical hazards.

Fire Hazards: During the process of heating the raw materials, for example,

heating takes place at high temperatures of about 600-650⁰C with the production

of hot flue gases through a chimney. Care must be taken near or during

47

operation of the saponification vessel for example the control of temperature.

Labourers are so careless and tend to attempt checking temperature manually.

This and many other careless practices may lead to a fire hazard. Overheating of

vessel should also be avoided to prevent explosions or fire outbreak.

Electrical Hazards: The main source of energy for this plant is electricity since

most of the process units would be powered by it .Care must be taken in dealing

with electric powered units, power should be shut down immediately when

faulty electrical connections are detected and alternative power source be sought

for use. Workers must also be careful especially during power fluctuations as

this might cause electrocution or explosions that might lead to fires.

Mechanical Hazards: These hazards may be due to improperly fixed or

dangerous machinery. Some machines are designed in such a way that it picks

everything in its path. For example packaging. Such equipment is likely to cause

a mechanical hazard. Parts of machinery should not be left just anywhere on the

plant site. Rather, good housekeeping of machine parts should be employed.

With the above mentioned safety measures, the plant can be safe to work on.

8.2 POLLUTION CONTROL

Pollution according to the Dangerous Substances Directive 76/464/EEC of the

European Union is the discharge by man directly or indirectly of substances or energy

into the environment, the result of which causes hazards to human health, harm to living

resources and to ecosystems, damage to amenities or interference with other legitimate

uses of the environment.

Pollution in any industry is of major concern because the more or less it produces

pollutants indicates the level of control measures in place. Pollution can either be abated

by preventing it at the source or using the end-of-pipe technology. The concept of zero

emissions and pollution prevention at source is the best and less expensive option for

any industry. This is where raw materials are prepared and purified through initial

cleaning processes before production.

However most of the pollution control measures are end- of- pipe technology where

waste at the end of production is treated before released.

48

CHAPTER 9

49

9.0 DISCUSSION

At this end, one can envisage that the production process is a feasible one within the

confines of the country. With the abundance of tallow in Ghana and its neighboring

country, Ivory Coast, the possibility of raw materials shortage is extremely low.

This plant can be duplicated in regions in the country in which the raw materials are

readily available. The establishment of this plant in other locations will provide

employment.

From the literature, the tallow, when left to decompose, tend to be very toxic to the soil.

This process introduces a way out whereby almost all of the tallow would be utilized in

this very lucrative venture.

The glycerine, also, obtained after the saponification process, serves as a valuable

source of product for export and other purposes. With the advancement of this project

some measures will have to be put in place to ensure that the quality of the toilet soap

remains unaltered. Thus the farmers (animal rearers) will have to be motivated to

produce a high quality of tallow required for efficient production.

With the high rate of return over the plant life, this project is very viable and rewarding

to investors and the nation (product is for exportation).

A continuous operation is preferred for the plant due to the following reasons (Peters et

al, 1991):

1. A specific product (toilet soap)

2. The production rate is far greater than 16500 tonnes per annum.

The chosen process for the production of toilet soap will be the best since the batch

method will not be cost effective.

CHAPTER 10

50

10.0 RECOMMENDATION

We recommend that, in the near future, the industry should partner with the

abattoirs and oil companies to reduce the purchase cost of raw materials.

Due to the cost intensive nature of this project, a lower annual production rate

should be used.

The issue of safety and control should be enforced at all levels and times to

ensure the smooth running of the plant, to protect lives and the environment as a

whole.

The marketing department should market the product to raise the profitability

measure higher than as shown during the plant life.

The processes and product of the plant be subjected to ISO audit to give the

company the needed recognition on the world market.

REFERENCES51

http://www.answers.com/topic/toilet soap. 14th March, 2011. 8:46 pm

Sinnott, R.K. (1999). Coulson and Richardson’s Chemical Engineering Design,

Vol. 6, Third Edition, pp. 407, 435

Perry Robert H., Green Don W., (1999), Perry’s Chemical Engineer’s

Handbook, 7th Edition, McGraw-Hill Companies Inc., pp. section 18-2 to 18-12.

Liddell, Donald M. 1922. Handbook of Chemical Engineering, Volume 1,1st

edition, McGraw Hill.

Walas, Stanley M. (1990) Chemical Process Equipment (Selection and

Design).In Mixing and Agitation Chapter 10, pp. 287-296.

APPENDIX

52

MATERIAL BALANCE ON THE PRODUCTION OF 50TONS TOILET SOAP

PER DAY

ASSUMPTIONS

The process is an open system

The process occurs at a steady-state condition.

PLANT ATTAINMENT

This is defined as a percentage of available hours in a year that plant operates usually

between 90-95%. The process plant will operates three shifts of 8 hours per day.

The total downtime (maintenance, shutdowns and holidays) will take 35days per year.

330days 24hrs

1year 1day

Basis: kg/hr

Productivity is 50 tonnes per day

In a year, productivity is 50 tonnes × 330days = 16500tonnes per year

Converting,

16500 1year 1day 1000kg

1year 330days 24hrs 1ton

= 16500 000kg

7920hr

=2083.33kg/hr

BALANCES ON SAPONIFICATION VESSEL

53

Reaction: (C17H35COO) C3H5 + 3NaOH 3[C17H35COONa] + C3H5(OH)3

Mass of soap to be produced = 2083.33kg/hr

Molecular weight of soap = 306g/mol

n = 2083.33kg mol 1000g

hr 306g 1kg

= 2083330

306

= 6808.27mol/hr

Hence,

1 mol Tallow 6808.27mol/hr

3mol Soap

= 2269.42mol/hr

But,

n= m/M m=nM

m = 2269.42mol 324g 1kg

hr mol 1000g

= 735293.16

1000

= 735.29kg/hr

Also,

n(NaOH) = n(Soap)

n(NaOH) = 6808.29

m = n × M

= 6808.29mol 40g 1kg

54

Hr mol 1000g

= 272.33kg/hr

Amount of lye to be used at the saponification vessel = 2700kg/hr

BALANCES ON STATIC SEPERATOR

Wet soap = Lye + Crude soap

Lye = Wet soap – Crude soap

Lye = 3707.48 – 3672.4

Lye = 35.08kg/hr

BALANCE ON WASHING COLUMN

Total Material Balance

C.S + F.L = B + 3360.163

Where,

C.S = Crude soap; F.L = Fresh lye

B = Washed soap

F.L = 2500kg/hr

C.S + 2500 = B + 3360.163

Fresh Lye Component Balance

F.L = 0.65B + 0.2 (3360.163)

2500 = 0.65B + 672.033

0.65B = 1827.967

B = 2812.257

From T.M.B,

C.S + 2500 = 2812.257 + 3360.163

C.S = 2812.257 + 3360.163 – 2500

C.S = 3672.4kg/hr

BALANCES ON CENTRIFUGE

Total Material Balance

55

W.S = L + W.S

Where,

W.S = Washed soap

L = Lye

W.S = Wet soap

WS = L + 2688.13------- (1)

Lye Component Balance

0.2 W.S = L--------- (2)

Substituting (2) into (1)

W.S = 0.2W.S + 2688.13

0.85W.S = 2688.13

W.S = 3360.163kg/hr

BALANCES ON NEUTRALIZER

Neutralization reaction

NaOH + H3PO4 NaH2PO4 + H2O

Soap (Solid) Component Balance

W.S (0.682) = 2656.96 (0.69)

W.S (0.682) = 1833.302

W.S = 2688.126kg/hr

NaOH Balance

0.003 (2688.126) = 8.064kg/hr

Therefore,

1 mol NaOH

1 mol H3PO4

But n = m M (NaOH) = 40g/mol

M

56

n (NaOH) = 8.064 kg mol 1000g

Hr 40g 1kg

n = 201.6mol/hr

Therefore,

1 mol H3PO4 201.6 NaOH

1mol NaOH

n (H3PO4) = 201.6mol/hr

m (H3PO4) = n × M

= 201.6 mol 98g 1kg

Hr mol 1000g

m (H3PO4) = 19.76kg/hr

From Stiochiometric Ratio

1mol NaH2PO4 201.6 NaOH

1 mol NaOH

= 201.6mol/hr

M (NaH2PO4) = 121g/mol

n = m / M

m (NaH2PO4) = 121g 201.6mol 1kg

mol hr 1000kg

m (NaH2PO4) = 24.349kg/hr

Then,

Total Material Balance

W.S + H3PO4 + Additives = S + NaH2PO4

2688.13 + 19.76 + Additives = 2696.04 + 24.394

Additives = 12.54kg/hr

BALANCE ON VACUUM DRYER

Total Material Balance

S = W + 2083.3kg/hr

57

Where,

S = Soap

W = Water

Solid Component Balance

S (0.68) = 2083.33 (0.88)

0.68S = 1833.33

S = 2696.07kg/hr

Water Component Balance

2696.07 (0.31) = 2083.3 (0.12) + W

835.782 = 249.996 + W

W = 835.782-249.996

W = 585.79kg/hr

For Impurities

0.01 (2696.07) = 26.96kg/hr

58