Product description Safety Notes Assembly instructionsxxxd… · Set sensor parameters...

Transcript of Product description Safety Notes Assembly instructionsxxxd… · Set sensor parameters...

Set sensor parameters alternatively numerically using LED-display...

T2T1

T2 T2T1

T1 + T2

Set detect distance inmm or cm

For single detectpoint press T2until »- - -« is displayed

Choose » « for NCC or » « for NOC

T1 T2

For window mode operation set far detect point in mm or cm

T1 + T2

Press T1 and T2 simultaneously for about3 s until welcome message has passed

T1 + T2

T2T1

T1 + T2

T1 + T2

T1 + T2

T2 T1

T2T1

T2 T2T1

T1 + T2

Set detect distance inmm or cm

Choose » « for NCC or » « for NOC

T1 T2

T1 + T2

T2T1

T1 + T2

T1 + T2

Set switched output D1 Set switched output D2

For single detectpoint press T2until »- - -« is displayed

For window mode operation set far detect point in mm or cm

Ready

Start here

Product descriptionThe crm+sensor with with two switchedoutputs measures the distance to an ob-ject within the detection zone contactless.Depending on the adjusted detect distan-ce the switched outputs are set.The ultrasonic transducer surface of thecrm+sensors is laminated with a PEEKfilm. The transducer itself is sealedagainst the housing by a PTFE joint ring.This composition ensures a high resitanceagainst many aggressive substances.All settings are done with two push-but-tons and a three-digit LED-display(TouchControl).Light emitting diodes (three-colour LEDs)indicate the switching status.The output functions are changeablefrom NOC to NCC. The sensors are adjustable manually usingthe numerical LED-display or may be trai-ned using Teach-in processes.Useful additional functions are set in theAdd-on-menu.Using the LinkControl adapter (optionalaccessory) all TouchControl and additio-nal sensor parameter settings may bemade by a Windows-Software.

Safety NotesRead the operating instructions prior tostart-up.Connection, installation and adjustmentworks may only be carried out by expertpersonnel.No safety component in accordance withthe EU Machine Directive.

The crm+ sensors indicate a blind zone, inwhich the distance cannot be measured. Theoperating range indicates the distance of thesensor that can be applied with normal re-flectors with sufficient function reserve.When using good reflectors, such as a calmwater surface, the sensor can also be used upto its maximum range. Objects that stronglyabsorb (e.g. plastic foam) or diffusely reflectsound (e.g. pebble stones) can also reducethe defined operating range.

SynchronisationIf the assembly distances shown in Fig.1 fortwo or more sensors are exceeded the inte-grated synchronisation should be used. Con-nect Sync/Com-channels (pin 5 at the units re-ceptable) of all sensors (10 maximum).

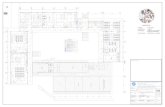

Fig. 1: Assembly distances, indicating syn-chronisation/multiplex

Multiplex modeThe Add-on-menu allows to assign an indivi-dual address »01« to »10« to each sensorconnected via the Sync/Com-channel (Pin5).The sensors perform the ultrasonic measure-ment sequentially from low to high address.Therefore any influence between the sensorsis rejected. The address »00« is reserved to synchronisa-tion mode and deactivates the multiplexmode. (To use synchronised mode all sensorsmust be set to address »00«.)

≥0.35 m≥0.40 m

≥2.50 m≥2.50 m

≥1.10 m≥2.00 m

≥8.00 m≥18.00 m

≥4.00 m ≥30.00 m

Assembly instructionsAssemble the sensor at the installation lo-cation.Plug in the connector cable to the M 12connector.

Fig. 2: Pin assignment with view onto sensorplug and colour coding of the microsonic connection cable

Start-upcrm+ sensors are delivered factory made withthe following settings:

Switched output on NOCDetecting distance at operating rangeand half operating rangeMeasurement range set to maximum ran-ge

13

colour

+UB

-UB

brownblue

425

D2D1

blackwhite

Sync/Com. grey

1

5

2

3 4

Set the parameters of the sensor manually oruse the Teach-in procedure to adjust the de-tect points.

Fig. 3: TouchControl

Operationcrm+sensors work maintenance free. Smallamounts of dirt on the surface do not influ-ence function. Thick layers of dirt and caked-on dirt affect sensor function and thereforemust be removed.

NoteAs a result of the design the assembly ofPEEK film and PTFE joint ring is not gas-proof.The chemical resistance has to be testedexperimentally if necessary.crm+ensors have internal temperaturecompensation. Because the sensors heatup on their own, the temperature com-pensation reaches its optimum workingpoint after approx. 30 minutes of operati-on.During normal mode operation, a yellowLED D2 signals that the switched outputhas connected.During normal mode operation, the mea-sured distance value is displayed on theLED-indicator in mm (up to 999 mm) orcm (from 100 cm). Scale switches auto-matically and is indicated by a point ontop of the digits.During Teach-in mode, the hysteresisloops are set back to factory settings.If no objects are placed within the detec-tion zone the LED-indicator shows »- - -«.If no push-buttons are pressed for 20 se-conds during parameter setting mode themade changes are stored and the sensorreturns to normal mode operation.You can lock the key pad to provide in-puts, see »Key lock and factory setting«.You can reset the factory settings at anytime, see »Key lock and factory setting«.

Show parametersTapping push-button T1 shortly during nor-mal mode operation shows »PAr« on theLED-display. Each time you tap push-buttonT1 the actual settings of the switched outputare shown.

Operating manualcrm+ Ultrasonic Sensors withtwo switched outputs

c m m m %

T 1 D 1 D 2 T 2

measuring range

LED D1 and D2

3-digit LED-display

Push-buttons T1 and T2

crm+25/DD/TC/Ecrm+35/DD/TC/Ecrm+130/DD/TC/Ecrm+340/DD/TC/Ecrm+600/DD/TC/E

2014/30/EU

SENSORPARTNERS.COM

Set sensor parameters alternatively numerically using LED-display...

T2T1

T2 T2T1

T1 + T2

Set detect distance inmm or cm

For single detectpoint press T2until »- - -« is displayed

Choose » « for NCC or » « for NOC

T1 T2

For window mode operation set far detect point in mm or cm

T1 + T2

Press T1 and T2 simultaneously for about3 s until welcome message has passed

T1 + T2

T2T1

T1 + T2

T1 + T2

T1 + T2

T2 T1

T2T1

T2 T2T1

T1 + T2

Set detect distance inmm or cm

Choose » « for NCC or » « for NOC

T1 T2

T1 + T2

T2T1

T1 + T2

T1 + T2

Set switched output D1 Set switched output D2

For single detectpoint press T2until »- - -« is displayed

For window mode operation set far detect point in mm or cm

Ready

Start here

Product descriptionThe crm+sensor with with two switchedoutputs measures the distance to an ob-ject within the detection zone contactless.Depending on the adjusted detect distan-ce the switched outputs are set.The ultrasonic transducer surface of thecrm+sensors is laminated with a PEEKfilm. The transducer itself is sealedagainst the housing by a PTFE joint ring.This composition ensures a high resitanceagainst many aggressive substances.All settings are done with two push-but-tons and a three-digit LED-display(TouchControl).Light emitting diodes (three-colour LEDs)indicate the switching status.The output functions are changeablefrom NOC to NCC. The sensors are adjustable manually usingthe numerical LED-display or may be trai-ned using Teach-in processes.Useful additional functions are set in theAdd-on-menu.Using the LinkControl adapter (optionalaccessory) all TouchControl and additio-nal sensor parameter settings may bemade by a Windows-Software.

Safety NotesRead the operating instructions prior tostart-up.Connection, installation and adjustmentworks may only be carried out by expertpersonnel.No safety component in accordance withthe EU Machine Directive.

The crm+ sensors indicate a blind zone, inwhich the distance cannot be measured. Theoperating range indicates the distance of thesensor that can be applied with normal re-flectors with sufficient function reserve.When using good reflectors, such as a calmwater surface, the sensor can also be used upto its maximum range. Objects that stronglyabsorb (e.g. plastic foam) or diffusely reflectsound (e.g. pebble stones) can also reducethe defined operating range.

SynchronisationIf the assembly distances shown in Fig.1 fortwo or more sensors are exceeded the inte-grated synchronisation should be used. Con-nect Sync/Com-channels (pin 5 at the units re-ceptable) of all sensors (10 maximum).

Fig. 1: Assembly distances, indicating syn-chronisation/multiplex

Multiplex modeThe Add-on-menu allows to assign an indivi-dual address »01« to »10« to each sensorconnected via the Sync/Com-channel (Pin5).The sensors perform the ultrasonic measure-ment sequentially from low to high address.Therefore any influence between the sensorsis rejected. The address »00« is reserved to synchronisa-tion mode and deactivates the multiplexmode. (To use synchronised mode all sensorsmust be set to address »00«.)

≥0.35 m≥0.40 m

≥2.50 m≥2.50 m

≥1.10 m≥2.00 m

≥8.00 m≥18.00 m

≥4.00 m ≥30.00 m

Assembly instructionsAssemble the sensor at the installation lo-cation.Plug in the connector cable to the M 12connector.

Fig. 2: Pin assignment with view onto sensorplug and colour coding of the microsonic connection cable

Start-upcrm+ sensors are delivered factory made withthe following settings:

Switched output on NOCDetecting distance at operating rangeand half operating rangeMeasurement range set to maximum ran-ge

13

colour

+UB

-UB

brownblue

425

D2D1

blackwhite

Sync/Com. grey

1

5

2

3 4

Set the parameters of the sensor manually oruse the Teach-in procedure to adjust the de-tect points.

Fig. 3: TouchControl

Operationcrm+sensors work maintenance free. Smallamounts of dirt on the surface do not influ-ence function. Thick layers of dirt and caked-on dirt affect sensor function and thereforemust be removed.

NoteAs a result of the design the assembly ofPEEK film and PTFE joint ring is not gas-proof.The chemical resistance has to be testedexperimentally if necessary.crm+ensors have internal temperaturecompensation. Because the sensors heatup on their own, the temperature com-pensation reaches its optimum workingpoint after approx. 30 minutes of operati-on.During normal mode operation, a yellowLED D2 signals that the switched outputhas connected.During normal mode operation, the mea-sured distance value is displayed on theLED-indicator in mm (up to 999 mm) orcm (from 100 cm). Scale switches auto-matically and is indicated by a point ontop of the digits.During Teach-in mode, the hysteresisloops are set back to factory settings.If no objects are placed within the detec-tion zone the LED-indicator shows »- - -«.If no push-buttons are pressed for 20 se-conds during parameter setting mode themade changes are stored and the sensorreturns to normal mode operation.You can lock the key pad to provide in-puts, see »Key lock and factory setting«.You can reset the factory settings at anytime, see »Key lock and factory setting«.

Show parametersTapping push-button T1 shortly during nor-mal mode operation shows »PAr« on theLED-display. Each time you tap push-buttonT1 the actual settings of the switched outputare shown.

Operating manualcrm+ Ultrasonic Sensors withtwo switched outputs

c m m m %

T 1 D 1 D 2 T 2

measuring range

LED D1 and D2

3-digit LED-display

Push-buttons T1 and T2

crm+25/DD/TC/Ecrm+35/DD/TC/Ecrm+130/DD/TC/Ecrm+340/DD/TC/Ecrm+600/DD/TC/E

2014/30/EU

Set sensor parameters alternatively numerically using LED-display...

T2T1

T2 T2T1

T1 + T2

Set detect distance inmm or cm

For single detectpoint press T2until »- - -« is displayed

Choose » « for NCC or » « for NOC

T1 T2

For window mode operation set far detect point in mm or cm

T1 + T2

Press T1 and T2 simultaneously for about3 s until welcome message has passed

T1 + T2

T2T1

T1 + T2

T1 + T2

T1 + T2

T2 T1

T2T1

T2 T2T1

T1 + T2

Set detect distance inmm or cm

Choose » « for NCC or » « for NOC

T1 T2

T1 + T2

T2T1

T1 + T2

T1 + T2

Set switched output D1 Set switched output D2

For single detectpoint press T2until »- - -« is displayed

For window mode operation set far detect point in mm or cm

Ready

Start here

Product descriptionThe crm+sensor with with two switchedoutputs measures the distance to an ob-ject within the detection zone contactless.Depending on the adjusted detect distan-ce the switched outputs are set.The ultrasonic transducer surface of thecrm+sensors is laminated with a PEEKfilm. The transducer itself is sealedagainst the housing by a PTFE joint ring.This composition ensures a high resitanceagainst many aggressive substances.All settings are done with two push-but-tons and a three-digit LED-display(TouchControl).Light emitting diodes (three-colour LEDs)indicate the switching status.The output functions are changeablefrom NOC to NCC. The sensors are adjustable manually usingthe numerical LED-display or may be trai-ned using Teach-in processes.Useful additional functions are set in theAdd-on-menu.Using the LinkControl adapter (optionalaccessory) all TouchControl and additio-nal sensor parameter settings may bemade by a Windows-Software.

Safety NotesRead the operating instructions prior tostart-up.Connection, installation and adjustmentworks may only be carried out by expertpersonnel.No safety component in accordance withthe EU Machine Directive.

The crm+ sensors indicate a blind zone, inwhich the distance cannot be measured. Theoperating range indicates the distance of thesensor that can be applied with normal re-flectors with sufficient function reserve.When using good reflectors, such as a calmwater surface, the sensor can also be used upto its maximum range. Objects that stronglyabsorb (e.g. plastic foam) or diffusely reflectsound (e.g. pebble stones) can also reducethe defined operating range.

SynchronisationIf the assembly distances shown in Fig.1 fortwo or more sensors are exceeded the inte-grated synchronisation should be used. Con-nect Sync/Com-channels (pin 5 at the units re-ceptable) of all sensors (10 maximum).

Fig. 1: Assembly distances, indicating syn-chronisation/multiplex

Multiplex modeThe Add-on-menu allows to assign an indivi-dual address »01« to »10« to each sensorconnected via the Sync/Com-channel (Pin5).The sensors perform the ultrasonic measure-ment sequentially from low to high address.Therefore any influence between the sensorsis rejected. The address »00« is reserved to synchronisa-tion mode and deactivates the multiplexmode. (To use synchronised mode all sensorsmust be set to address »00«.)

≥0.35 m≥0.40 m

≥2.50 m≥2.50 m

≥1.10 m≥2.00 m

≥8.00 m≥18.00 m

≥4.00 m ≥30.00 m

Assembly instructionsAssemble the sensor at the installation lo-cation.Plug in the connector cable to the M 12connector.

Fig. 2: Pin assignment with view onto sensorplug and colour coding of the microsonic connection cable

Start-upcrm+ sensors are delivered factory made withthe following settings:

Switched output on NOCDetecting distance at operating rangeand half operating rangeMeasurement range set to maximum ran-ge

13

colour

+UB

-UB

brownblue

425

D2D1

blackwhite

Sync/Com. grey

1

5

2

3 4

Set the parameters of the sensor manually oruse the Teach-in procedure to adjust the de-tect points.

Fig. 3: TouchControl

Operationcrm+sensors work maintenance free. Smallamounts of dirt on the surface do not influ-ence function. Thick layers of dirt and caked-on dirt affect sensor function and thereforemust be removed.

NoteAs a result of the design the assembly ofPEEK film and PTFE joint ring is not gas-proof.The chemical resistance has to be testedexperimentally if necessary.crm+ensors have internal temperaturecompensation. Because the sensors heatup on their own, the temperature com-pensation reaches its optimum workingpoint after approx. 30 minutes of operati-on.During normal mode operation, a yellowLED D2 signals that the switched outputhas connected.During normal mode operation, the mea-sured distance value is displayed on theLED-indicator in mm (up to 999 mm) orcm (from 100 cm). Scale switches auto-matically and is indicated by a point ontop of the digits.During Teach-in mode, the hysteresisloops are set back to factory settings.If no objects are placed within the detec-tion zone the LED-indicator shows »- - -«.If no push-buttons are pressed for 20 se-conds during parameter setting mode themade changes are stored and the sensorreturns to normal mode operation.You can lock the key pad to provide in-puts, see »Key lock and factory setting«.You can reset the factory settings at anytime, see »Key lock and factory setting«.

Show parametersTapping push-button T1 shortly during nor-mal mode operation shows »PAr« on theLED-display. Each time you tap push-buttonT1 the actual settings of the switched outputare shown.

Operating manualcrm+ Ultrasonic Sensors withtwo switched outputs

c m m m %

T 1 D 1 D 2 T 2

measuring range

LED D1 and D2

3-digit LED-display

Push-buttons T1 and T2

crm+25/DD/TC/Ecrm+35/DD/TC/Ecrm+130/DD/TC/Ecrm+340/DD/TC/Ecrm+600/DD/TC/E

2014/30/EU

+32 (0)2 - 464 96 90

sensorpartners.com

Z.1 Researchpark 310

B-1731, Zellik

Belgium

Sensor Partners BVBA

+31 (0)416 - 37 82 39

sensorpartners.com

James Wattlaan 15

5151 DP Drunen

The Netherlands

Sensor Partners BV

Contact

...or with the Teach-in procedure

Adjust detect point D1

Place object at position

Press T1 until »d« is shown

Current measu-ring value

Press T1 until »End« is shown

Adjust window mode D1

Place object at position

Press T1 until »d« is shown

Place object at position

Current measu-ring value

Press T1 until »End« is shown

Current measu-ring value

Adjust two-way reflectiv barrier D1

Place reflector at position

Set NOC/NCC D1 Adjust detect point D2

Place object at position

Press T1 until »d« is shown

Current measu-ring value

Press T1 until countdownpassed from »- 8 -« to »- 0 -«and NOC or NCC symbol is

displayed

Press T1 until countdownpassed from »- 8 -« to »- 0 -«

and »End« is displayed

To change output functionpress T1

Press T1 and T2 simultaneous-ly until »End« is displayed

Symbol NOC or NCC

Press T2 until »d« is shown

Current measu-ring value

Symbol NOC or NCC

Press T2 until »End« is shown

Adjust window mode D2

Place object at position

Adjust two-way reflectiv barrier D2

Place reflector at position

Set NOC/NCC D2

Press T2 until »d« is shown

Place object at position

Current measu-ring value

Press T2 until »End« is shown

Current measu-ring value

Press T2 until »d« is shown

Current measu-ring value

Press T2 until countdownpassed from »- 8 -« to »- 0 -«and NOC or NCC symbol is

displayed

Press T2 until countdownpassed from »- 8 -« to »- 0 -«

and »End« is displayed

To change output functionpress T2

Press T1 and T2 simultaneous-ly until »End« is displayed

Symbol NOC or NCC

Symbol NOC or NCC

Normal mode operation Normal mode operation

Usefull additional functions in Add-on menu (for experienced users only, settings not required for standard applications)

T1 + T2

T1 T2

T1 + T2

Press T1 and T2 simultaneously for about 13 suntil »Add« is shown in the LED-display

T1 + T2

T2T1

Start here

T2 T1

T1 + T2

Ready»C01«: Displaybright

»C02«: Display dim-med

»C03«: Display off

To optimize multi-plex speed the hig-hest sensor addressmay be set.

Setting range »01«to »10«

»F00«: no filter

»F01«: standard fil-ter

»F02«: averaging fil-ter

»F03«: foregroundfilter

»F04«: background filter

Defines the strengthof the chosen filter.

»P00«: weak filterup to

»P09«: strong filter

Affects the size ofthe detection zone.

»E01«: high

»E02«: standard

»E03«: slight

Minimum value:blind zone

Maximum value: ne-arwindow limit - 1

Low power mode Measurement filter Filter strength Foreground suppression

Multiplex mode device addressing

Multiplex modehighest address

»00«: synchronisati-on

»01« to »10«: sensoraddress for multi-plex mode

»oFF«: synchronisati-on deactivated

Minimum value: sen-sor-distant windowmargin

Maximum value: 999mm for crm+25/...and crm+35/... and999 cm for all othertypes

Measurement range Calibrationdisplay

Detection zonesensitivity

Put plane reflectorvertically disposed infront of sensor: inan exact distance of250 mm for crm+25/... and crm+35/...and 900 mm for allother types.Adjust display to250 mm or 900 mm.Confirm calibrationwith T1 + T2.

T1 + T2

T1 T2

T1 + T2

T2T1

T1 + T2

T1 T2

T1 + T2

T2T1

T1 + T2

T1 T2

T1 + T2

T2T1

T1 + T2

T1 T2

T1 + T2

T2T1

T1 + T2

T1 T2

T1 + T2

T2T1

T1 + T2

T1 T2

T1 + T2

T2T1

T1 + T2

T1 T2

T1 + T2

T2T1

T1 + T2

T1 T2

T1 + T2

T2T1

Delay in secondsbetween the detec-tion of an objectand the output ofthe measured dis-tance in case of ob-ject approach (beha-ves as on-delay).

"00": 0 s (no delay)up to

"20": 20 s responsetime

Response time

T1 + T2

T1 T2

T1 + T2

T2T1

Note Changes in the Add-onmenu may impair thesensor function. A6, A7, A8 , A10 , A11,A12 have influence onthe response time ofthe sensor.

Hysteresis switched output D1

Minimum value:»001«

Maximum value: dif-ference betweenmaximum range anddetect point - 1

During windowmode operation hys-teresis influencesboth detect points.

T1 + T2

T1 T2

T1 + T2

T2T1

Hysteresis switched output D2

Minimum value:»001«

Maximum value: dif-ference betweenmaximum range anddetect point - 1

During windowmode operation hys-teresis influencesboth detect points.

T1 + T2

T1 T2

T1 + T2

T2T1

Teach-in swítched output D1

Key lock and factory setting

Activate/deactivateTouchControl

Reset to factory set-ting

Turn supply voltageOFF

While pressing T1 turnsupply voltage ON

until »on« or »off« isdisplayed

Turn supply voltageOFF

While pressing T1 turnsupply voltage ON forca. 15 s until «rESET»has past through the

display

To activate or deactivate press T1

»on« or»off«

To activate or deactivate press T1

»on« or»off«

Normal mode operationTeach-in swítched output D2

SENSORPARTNERS.COM

SENSORPARTNERS.COM

*B7885* MV-DO-095977-508087

Technical data

Blind zoneOperating rangeMaximum range

Angle of beam spread

0 to 30 mm 250 mm

0 to 85 mm 350 mm

350 mmPlease see detection zone

600 mmPlease see detection zone

0 to 200 mm 1.300 mm

0 to 350 mm 3.400 mm

2.000 mmPlease see detection zone

5.000 mmPlease see detection zone

0 to 600 mm 6.000 mm8.000 mmPlease see detection zone

Transducer frequencyResolution. sampling rate

ReproducibilityAccuracy

ca. 320 kHz0.025 mm

360 kHz0.025 mm

± 0.15 %± 1 % (Temperature drift internal compensated.

± 0.15 %± 1 % (Temperature drift internal compensated.

Detection zonesfor different objects:

The dark grey areas are determind with a thin round bar (10 or 27 mm dia.) and indicate the typical operating range

of a sensor. In order to obtain the light grey areas. a plate (500 x 500 mm) is introduced

into the beam spread from the side. In doing so, the optimum angle between

plate and sensor is always employed. This therefore indicates the maximum

detection zone of the sensor. It is not possible to evaluate ultrasonic

reflections outside this area.

Opperating voltage UB

Voltage ripple

may be deactivated1). 0.17%/K without compensation) may be deactivated1). 0.17%/K without compensation)

9 V to 30 V DC. reverse polarity protection±10 %

9 V to 30 V DC. reverse polarity protection±10 %

200 kHz0.18 mm

120 kHz0.18 mm

± 0.15 %± 1 % (Temperature drift internal compensated.

± 0.15 %± 1 % (Temperature drift internal compensated.

80 kHz0.18 mm± 0.15 %± 1 % (Temperature drift internal compensated.

may be deactivated1). 0.17%/K without compensation) may be deactivated1). 0.17%/K without compensation)

9 V to 30 V DC. reverse polarity protection±10 %

9 V to 30 V DC. reverse polarity protection±10 %

may be deactivated1). 0.17%/K without compensation)

9 V to 30 V DC. reverse polarity protection±10 %

No-load supply currentHousing

Class of protection to EN 60529

≤ 80 mAStainless steel 1.4571, plastic parts: PBT, TPU;

≤ 80 mAStainless steel 1.4571, plastic parts: PBT, TPU;

Ultrasonic transducer: PEEK film, PTFEIP 67

Ultrasonic transducer: PEEK film, PTFEIP 67

Norm conformityType of connection

ControlsIndicators

EN 60947-5-25-pin initiator plug, PBT

EN 60947-5-25-pin initiator plug, PBT

2 push-buttons (TouchControl)3-digit LED-display, 2 three-colour LEDs

2 push-buttons (TouchControl)3-digit LED-display, 2 three-colour LEDs

≤ 80 mAStainless steel 1.4571, plastic parts: PBT, TPU;

≤ 80 mAStainless steel 1.4571, plastic parts: PBT, TPU;

Ultrasonic transducer: PEEK film, PTFEIP 67

Ultrasonic transducer: PEEK film, PTFEIP 67

≤ 80 mAStainless steel 1.4571, plastic parts: PBT, TPU;Ultrasonic transducer: PEEK film, PTFEIP 67

EN 60947-5-25-pin initiator plug, PBT

EN 60947-5-25-pin initiator plug, PBT

2 push-buttons (TouchControl)3-digit LED-display, 2 three-colour LEDs

2 push-buttons (TouchControl)3-digit LED-display, 2 three-colour LEDs

EN 60947-5-25-pin initiator plug, PBT2 push-buttons (TouchControl)3-digit LED-display, 2 three-colour LEDs

ProgrammableOperating temperature

Storage temperatureWeight

Yes, with TouchControl and LinkControl-25°C to +70°C

Yes, with TouchControl and LinkControl-25°C bis +70°C

-40°C to +85°C150 g

-40°C bis +85°C150 g

Switching hysteresis1)

switching frequency1)

Response time1)

Time delay before availibility

3 mm25 Hz

5 mm12 Hz

32 ms< 300 ms

64 ms< 300 ms

Yes, with TouchControl and LinkControl-25°C bis +70°C

Yes, with TouchControl and LinkControl-25°C bis +70°C

-40°C bis +85°C150 g

-40°C bis +85°C210 g

Yes, with TouchControl and LinkControl-25°C bis +70°C-40°C bis +85°C270 g

20 mm8 Hz

50 mm4 Hz

92 ms< 300 ms

172 ms< 300 ms

100 mm3 Hz240 ms< 300 ms

Order No.Switched output

crm+25/DD/TC crm+35/DD/TC2 x pnp, UB - 2 V, Imax = 2 x 200 mAswitchable NOC/NCC, short-circuit-proof

2 x pnp, UB - 2 V, Imax = 2 x 200 mAswitchable NOC/NCC, short-circuit-proof

1) Can be programmed with TouchControl and LinkControl

crm+130/DD/TC crm+340/DD/TC2 x pnp, UB - 2 V, Imax = 2 x 200 mAswitchable NOC/NCC, short-circuit-proof

2 x pnp, UB - 2 V, Imax = 2 x 200 mAswitchable NOC/NCC, short-circuit-proof

crm+600/DD/TC2 x pnp, UB - 2 V, Imax = 2 x 200 mAswitchable NOC/NCC, short-circuit-proof

+UB

-UB

D1D2Sync/Com

12453

2 pnp switched outputs

U

crm+25… crm+35… crm+130… crm+340… crm+600…

0 cm

5 cm

10 cm

15 cm

20 cm

25 cm

30 cm

35 cm

ausgerichtete Platte

Rohr ø 10 mm

10 c

m

5 cm

0 cm

5 cm

10 c

m

Plate

Round bar

0 cm

10 cm

20 cm

30 cm

40 cm

50 cm

60 cm

ausgerichtete Platte

Rohr ø 27 mm

20 c

m

10 c

m

0 cm

10 c

m

20 c

m

35 cm

Plate

Round bar

0 m

0.4 m

0.8 m

1.2 m

1.6 m

2 m

1.3 m

ausgerichtete Platte

Rohr ø 27 mm

0.8

m

0.4

m

0 m

0.4

m

0.8

m

Plate

Round bar

0 m

0.8 m

1.6 m

2.4 m

3.2 m

4 m

4.8 m

5.6 m

3.4 m

ausgerichtete Platte

Rohr ø 27 mm

1.6

m

0.8

m

0 m

0.8

m

1.6

m

Plate

Round bar

0 m

1.2 m

2.4 m

3.6 m

4.8 m

6 m

7.2 m

8.4 m

ausgerichtete Platte

Rohr ø 27 mm

2.4

m

1.2

m

0 m

1.2

m

2.4

m

Plate

Round bar

microsonic GmbH / Phoenixseestraße 7 / 44263 Dortmund / Germany / T +49 231 975151-0 / F +49 231 975151-51 / E [email protected] / W microsonic.de The content of this document is subject to technical changes. Specifications in this document are presented in a descriptive way only. They do not warrant any product features.

![1 11 B1 B12school52.org.ru/files/ege11m110210.pdf · . 11 . 1 5 B10 ( ) ( ), ( ). , ? . T1 T2 T1 100%, T1 T2 T1 40% T2 315 2B11 . y (x 4)(x 2) 22 [4;3]: B12](https://static.fdocuments.net/doc/165x107/601edf9733ac0c7ec31a9f64/1-11-b1-11-1-5-b10-t1-t2-t1-100-t1-t2-t1-40-t2-315-2b11.jpg)