Process Validation: Life Cycle Approach · Current Regulatory Guidance The expectations for process...

Transcript of Process Validation: Life Cycle Approach · Current Regulatory Guidance The expectations for process...

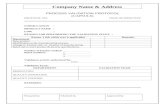

Process Validation: Life Cycle

Approach

Catherine Neary, GMP Inspector

GMP Conference

7 February 2017

Dublin

Presentation Contents

1• Current Regulatory Landscape & Observations on Annex 15 of EU GMP Guide

2• Considerations for Process Validation (PV) Studies

3• Ongoing Process Verification (OPV)

4• Traditional Approach vs. Quality by Design (QbD)

5• Conclusions

207/02/2017

Definition & Principles of PV

Definition: ‘The documented evidence that the process, operated within

established parameters, can perform effectively and reproducibly to

produce a medicinal product meeting its predetermined specifications and

quality attributes’

Effective process validation contributes significantly to assuring medicinal

product quality

Basic principle of QA that a medicinal product should be produced that is

fit for its intended use

07/02/2017 3

407/02/2017

Definition & Principles of PV

• Quality, safety & efficacy are designed or built into the product

• Quality cannot be adequately assured merely by in-process & finished product inspection or testing

• Each step of the manufacturing process is controlled to assure that the finished product meets all design characteristics & quality attributes including specifications

This principle incorporates the understanding that the following conditions exist:

Current Regulatory Guidance

The expectations for process validation and process control have changed and are continuing

to change, for the better

An enhanced, risk and science based approach is encouraged, in addition to, or instead of the

traditional approach

A traditional approach can be accepted but science and risk based (continuous process

verification) approach is encouraged for the better control over the manufacturing process

The implementation of ICH Q8 “Pharmaceutical Development”, ICH Q9 “Quality Risk

Management” & ICH Q10 “Pharmaceutical Quality Systems” sets the framework for a life

cycle approach to process validation

Considering simply three batches for the process validation shall not confirm the process

consistency

07/02/2017 5

Current Regulatory Guidance

To verify the process consistency and the product quality there should be a science

and risk based rationale for the no. of batches to be selected for the process

validation

Before going to the process validation, the product requirements should be well

understood, and the process should be developed in line to the product

requirements. After development of the process, the process should be well

understood before going for the commercialisation

Process validation should establish whether all quality attributes and process

parameters, which are considered important for ensuring the validated state and

acceptable product quality, can be consistently met by the process

07/02/2017 6

Current Regulatory Guidance

The basis by which process parameters and quality attributes were identified as being critical or non-critical should be clearly documentedtaking into account the results of risk assessment activities

There are 3 approaches to the process validation

After completion of process validation ongoing process verification should be done whatever the approach for the process validation

07/02/2017 7

Lifecycle Concept

07/02/2017 8

Maintenance

of process in

state of control

during routine

production

Product & Process

Development

Qualification of

commercial

manufacturing

process

Definitions

• ‘An alternative approach to process validation in which manufacturing process

performance is continuously monitored and evaluated’

Continuous Process Verification

• ‘A product development approach where set points and operating ranges for process

parameters are defined to ensure reproducibility’

Traditional Approach

• ‘A development approach where risk management and scientific knowledge is

used to identify and understand the material attributes and process parameters

which influence the critical quality attributes of a product’

Enhanced Approach

07/02/2017 9

Considerations for PV Studies

Process Development

• Traditional Approach

• Continuous Verification Approach

• Hybrid Approach

For all products irrespective of the approach used:

• Process knowledge should be accessible to the manufacturing site

• Ongoing process verification during lifecycle is applicable

• Critical Process Parameters (CPPs), Critical Quality Attributes (CQAs),In-process Control Tests should be identified, explained and justifiedusing the principles of Quality Risk Management (QRM)

07/02/2017 10

Considerations for PV Studies - Process Design

Considerations for Manufacturers:

• Collate and assess prior knowledge to understand materials, process and product with

their impact, based on experience obtained from similar processes, development studies,

technology transfer activities, manufacturing experience etc.

• Risk assess process steps and variables; process variables should be gleaned from

process design

• Understand the sources of variation; understanding and controlling process variation

is key

• Understand the impact of variation on the process and ultimately on product attributes

• Control the variation in a manner commensurate with the risk it represents to the

process and product

07/02/2017 11

Considerations for PV Studies - Process Design

Considerations for Manufacturers continued:

• Focus on the critical parts of the process

• Evaluate all attributes (e.g. quality, product, raw material/component) in terms

of their roles in the process and impact on the product or in-process material

• Evaluate all parameters (e.g. process, operating, and equipment) in terms of

their roles in the process and impact on the product or in-process material

• Re-evaluate as new information becomes available

• Ensure all CPPs are identified during risk assessment

• Process control is assured through process design, not testing

07/02/2017 12

Considerations for PV Studies

Process Validation

• The use of risk assessments for validation should be defined in detail;

they should be repeated, as required, in light of increased

knowledge and understanding

• Number of validation batches made, number of samples taken &

sampling locations should be based on QRM principles, with

rationale documented in the protocols

• There should be appropriate checks incorporated into qualification

and validation work to ensure the integrity of all data obtained

07/02/2017 13

Considerations for PV Studies

The number of batches can depend on several factors including:

• the complexity of the process/product being validated

• the level of process variability

• the amount of experimental data and/or process

knowledge/understanding available on the specific process

• production volumes

• More variability ⋙ more runs

• More uncertainty ⋙ more runs

07/02/2017 14

Considerations for PV Studies - Process Validation (continued)

Concurrent validation:

• under special circumstances concurrent release of PV

batches may be acceptable

• must be strong benefit risk ratio for patient, e.g.

• infrequently manufactured (orphan drugs)

• short half lives

• drug shortage

07/02/2017 15

Considerations for PV Studies

EMA Guideline on PV for regulatory submissions – standard vs. non-standard methods of

manufacture:

• Relevant to processes validated using traditional approach

• Process validation scheme to be followed should be included in the dossier

• Production scale validation data should be included in the dossier for biological/biotech

products or where applicant is proposing a non-standard method of manufacture. Data on a

minimum of 3 production scale batches should be submitted, unless otherwise justified

• Designation of a process as non-standard is determined by a combination of:

• nature of active substance, nature of finished product, actual process itself and the

production experience of the manufacturer

• all biological products are considered to be non-standard

• examples included in Annex II of the guideline

07/02/2017 16

Ongoing Process Verification (OPV)

A new regular GMP requirement; applicable also to the traditional approach

It is a monitoring process to confirm that a state of control is maintained

throughout the product lifecycle

A system for detecting unplanned departures or unintended process variability fromthe process as designed

07/02/2017 17

• ‘Documented evidence that the process remains in a state

of control during commercial manufacture’

Definition.....

Ongoing Process Verification (OPV)

How frequent?

How many batches?

Review periodically

The number of process runs should be sufficient to allow the normal extent of

variation and trends to be established to provide sufficient data for evaluation

The product lifecycle stage should be considered

A new product where process knowledge is limited should be reviewed more

frequently than a mature product

07/02/2017 18

Ongoing Process Verification (OPV)

Process trends should be evaluated

• This could be done in conjunction with the annual

Product Quality Review (PQR), if appropriate

• A formal statement in the PQR on OPV may be sufficient

• The relationship between a PQR and the use of OPV

needs to be defined in a procedure or perhaps in the

VMP

07/02/2017 19

Ongoing Process Verification (OPV)

Execute according to protocol & report - if the PQR is appropriate then a protocol may not be required

Protocol may be of benefit for:

a new product where the PQR has not yet been completed and the status of control is being assessed, e.g. after 6 months

For significant changes to products, where specific trends are noted and further information is required to be generated

07/02/2017 20

Ongoing Process Verification (OPV)

Statistical tools should be used to support any conclusions

regarding variability and capability of process, e.g. Cpk or Ppk

Impact on OPV should be considered as part of the change

control process or where incremental change may have an impact

Necessity for additional actions (e.g. enhanced sampling) should

be assessed, e.g. in case of individual or successive incremental

changes; this should be done under a protocol

07/02/2017 21

Ongoing Process Verification – Incorporate Knowledge Management

Knowledge

Management

Process validation studies

Manufacturing experience

/ history; trend data; in-

process control data

Internal & vendor audits,

change controls,

deviations, technical

investigations, CAPA

reports, product quality

reviews, complaints,

adverse events, recall

information

Raw material testing data,

finished product testing

data, stability data, OOS

results

07/02/2017 22

Traditional Approach vs. QbD

A number of Marketing Authorisation Application (MAA) submissions using QbD

Various levels of QbD – from very simple approaches (e.g. control of one step) up to the

full Active Substance/Finished Product QbD involving Process Analytical Technology (PAT)

and Real Time Release (RTR)

A number of MAAs with some level of QbD/PAT/RTR have been approved in the period

2005-2016

Initiated in 2011, to work towards harmonising QbD/PAT approach and to reduce

regulatory burden on industry, EMA and US FDA jointly assessed one MAA as part of a

pilot project

07/02/2017 23

Traditional Approach vs. QbD

In April 2014, EMA and US FDA agreed on a two-year extension of their

joint pilot programme for the parallel evaluation of QbD applications

Majority of MAAs with QbD/PAT concepts have been New Chemical

Entities (NCEs) compared to very small number of established products

New products not registered using Irish sites, therefore no experiences

to share regarding pre-approval inspections in the territory

07/02/2017 24

Conclusions

• Aligns process validation activities with product lifecycle

concept

• Reflects changed manufacturing & regulatory environment

• No longer a one-off exercise (i.e. 3 validation batch approach);

over the lifecycle rather than a one time event

• Incorporates QRM Principles and Knowledge Management

• Came into operation – 1 October 2015

Revised Annex

07/02/2017 25

Final Thoughts

A true lifecycle approach to process validation requires gathering useful,

scientific information as process and control strategies are developed, thus

saving time and resources during later qualification and validation stages

The key is better understanding of the process, its sources of variation and their

control, and the correlation between validation studies, sampling plans,

process performance, product quality, and ongoing process verification

A need for critical thinking and focus on manufacturing science

07/02/2017 26

Final Thoughts

• If something has not happened yet, it will likely not happen…

• If something has not been cited during an inspection, it must be OK…

• People related problems are the result of people making mistakes…

Beware of common process control misconceptions

07/02/2017 27

Regulatory References

• EU GMP Guide Annex 15 : Qualification and Validation (2015)

• EMA Guideline on process validation for finished products –information and data to be provided in regulatory submissions(2016)

• US FDA Guidance for Industry Process Validation: General Principlesand Practices (2011)

• ICH Q8 – Pharmaceutical Development

• ICH Q9 – Quality Risk Management

• ICH Q10 – Pharmaceutical Quality System

• ICH Q11 – Development and Manufacture of Drug Substances

07/02/2017 28