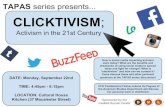

PreDiCon Flier

description

Transcript of PreDiCon Flier

-

PreDiCon SUPPLYING AFDABLE COMPLETE SOLUTIONS PreDiCon

Wilmar House, 23-25 Windermere Road,Blackpool FY4 2BX

Tel (01253) 400541 Fax: (01253) 400552 Email: [email protected]

SUPPLYING AFFORDABLE COMPLETE SOLUTIONS

TRAINING

SYSTEM AUDITS

SYSTEM SETUP

REMOTE ANALYSIS

VIA MODEM

CONTRACT MEASUREMENT,

ANALYSIS &

REPORTING

ON LINE & OFF-LINE

MONITORING

TRAINING IN VIBRATION ANALYSIS,

THERMOGRAPHY & OTHER TECHNIQUES

NEEDS ANALYSIS

TRIBOLOGY

AWARD WINNING SYSTEMS

CONSULTANCY & TROUBLE SHOOTING

-

Phone: (01253) 400554 Fax (01253) 400553 UK (517) 764-6800 (phone) 6869 (fax) USA

E-Mail: [email protected]

PreDiCon SUPPLYING AFFORDABLE COMPLETE SOLUTIONS

PreDiCon. Company Profile PreDiCon is the Predictive Maintenance (PdM) engineering company specialising in the practical application of predictive maintenance technologies. PreDiCon is fully independent and has no formal links with any of the off-line PdM hardware manufacturers or PdM software houses; this has been a conscious decision on behalf of the management at PreDiCon to ensure that our customers realize that we have no axe to grind when making equipment recommendations. If PreDiCon makes a recommendation for monitoring equipment then that recommendation is made solely with the customers interest at heart and with no regard for any commission from subsequent sales. PreDiCon installs systems from all of the leading PdM manufacturers including On-Line monitoring, Entek/IRD, CSI, SKF, DLI etc. but is totally independent from all of them.

The Company PreDiCon was incorporated in the USA in 1989 and in England in 1999. PreDiCon has built an enviable reputation for service and quality solutions supplied to North American and European manufacturers. The range of activities is extensive, but PreDiCon remains totally committed and focused on providing the customer with systematic solutions for maximizing equipment up-time and quality, while reducing the cost of maintenance and non-production inventories.

Vibration Standards PreDiCon has developed comprehensive standards of vibration practice and acceptable levels for new and rebuilt equipment. A copy of the standards is available if required.

Work Procedures PreDiCon has developed work procedures for all aspects of work in the condition monitoring and predictive maintenance technologies. All procedures are available for inspection by our business partners.

Reporting All analysis results and recommendations for PreDiCon work are recorded in an Access database. Reports and work requests are user definable and may be issued on paper or electronically according to the customers requirements. Special reports according to the customers requirements may be defined so as to be automatically generated at given periods.

Company Relationships PreDiCon can provide you with a complete service to ensure that you achieve your internal objectives with minimal disruption in the process. PreDiCon has successfully installed PdM systems in many facilities in North America and Mexico and the on-board engineers have installed numerous systems world-wide. PreDiCon installed systems have won several prizes for Excellence at the National (US) PdM System of the Year Awards. These great honours are not bestowed lightly and we at PreDiCon feel justly proud of our achievements.

Potential Failure Analysis The most challenging aspect of running and operating a predictive maintenance system (bar none) is the initial system set up. This is the stage at which the most experience and operating knowledge of predictive maintenance is required yet the set up is almost always carried out by people who are new to the field. The appropriate structure of the individual machine set up in the database is crucial to successful implementation and operation of the predictive maintenance system. The Potential Failure Analysis is a method of formalizing the set up and allows audit tracking and integration with ISO 9000 Quality Assurance systems. PreDiCon developed the PFA structure and uses it at all levels of operation.

Technical Authoring PreDiCon engineers have been contracted to develop many predictive maintenance technical papers and procedures. The latest addition to our technical library is the Press Monitoring Handbook which was written to help PdM engineers understand the sometimes complex failure mechanisms in large slow speed stamping presses for the automotive industry.

PDCreion

-

Phone: (01253) 400554 Fax (01253) 400553 UK (517) 764-6800 (phone) 6869 (fax) USA

E-Mail: [email protected]

PreDiCon SUPPLYING AFFORDABLE COMPLETE SOLUTIONS

PreDiCon. Contract services for Predictive MaintenancePreDiCon has implemented PdM solutions for many industries encompassing many PdM vendor solutions. We have installed and operated systems of all sizes with PreDiCon installed systems winning joint first and first runner up in the last independent PdM awards. All PdM services are performed by engineers with experience in implementing multiple vendor and technology solutions. PreDiCon is not tied to any particular vendor and can give completely independent advice. Outside of the vendors themselves we have setup more off-line vibration, on-line vibration and thermographic systems from many different vendors in a variety of applications than anyone we know. This has provided us with a sound grasp of what makes PdM work in industry

PdM feasibility studies Our engineers have the expertise to identify whether PdM will work effectively for your plant, focused on your particular equipment and program goals. We will recommend the best fit solution for your needs and help you and train you in how to best implement it.

On-Line Remote Vibration Analysis If your capital expenditure will not allow you to purchase an on-line monitoring system, let us install a system and we will interrogate the system remotely on a daily basis. All data is transferred via internet and we report back to you immediately we find an exception condition. We also provide a full report every month giving you an overview of all monitored equipment.

Existing system audits If you are an existing system user and are not achieving the goals intended there may be a reason. We have the experience to find the causes and get you back on track.

Thermographic Surveys Our qualified technicians and engineers can carry out a thermographic survey of your plant. The survey is carried out on equipment that you nominate and we will tell you the condition as determined by the infra-red signature.

On Site Vibration Analysis Surveys If you are an existing PdM user but lack the experience for detailed data analysis, let us do it for you. Either you collect the data and modem it to PreDiCon for analysis or we will send in one of our engineers to take the readings for you. We do the analysis and send you results.

Training PreDiCon offers focused on-site and off-site training programs aimed at equipping your people with the knowledge they need to be successful with applying PdM. techniques. We focus on programmatic implementation as well as data analysis and offer tailored programs to fit your needs.

-

Phone: (01253) 400554 Fax (01253) 400553 UK (517) 764-6800 (phone) 6869 (fax) USA

E-Mail: [email protected]

PreDiCon SUPPLYING AFFORDABLE COMPLETE SOLUTIONS

PreDiCon. On Line Continuous Vibration Monitoring Carried Out Remotely by our Engineering Staff

Effective, continuous condition monitoring for less than the cost of a data collector system!

Vibration analysis provides an indication of the health of a machine and is non-intrusive. When we know the condition of the machine, we can decide to carry out maintenance or repair work only when needed, avoiding production losses through machine failure as well as avoiding excessive machine outages because of unnecessary maintenance. Often we would like to monitor the vibration of a machine but we feel we cannot due to any of a number of reasons such as cost, safety or extreme machine operating conditions. For the first time it is now possible to install an on-line, full capability, spectral vibration analysis system, which is extremely easy to use, for less than the price of a data collector and software.

Quick & Effective Vibration Analysis For the first time, a system is available which can provide inexpensive and effective vibration analysis - the On-Line monitoring on-line monitoring system. The new On-Line monitoring system has the following advantages: Improved Safety No manpower requirement Excellent reliability Data collection interval improved from once per

month to less than 30 seconds Quick failure mechanisms can be trended &

predicted Excellent data consistency All this for less than the price of a data collector and software!

The software PreDiCons On-Line monitoring system is based on the industry standard Windows NT operating system. Navigation through the software is carried out via the intuitive photo/graphical interface. Once all connections are made and PreDiCon has carried out the necessary configuration, the user monitors all attached machines through the straightforward on-line screen.

Once the on-line screen displays an alarm (yellow or red depending on severity), it is a simple matter to click on the analyze button and the software will then tell the operator the cause of the problem and the recommended course of action. This system is very easy to use, belying the hidden complexity which drives the expert system.

Below are three analysis results from the same point taken at different times and indicating the differing levels of machine degradation.

Level 1 Green The vibration is normal and does not indicate a defect.

Level 2 Yellow Gives early warning of a developing problem.

Level 3 Red The most serious warning level. At this stage the machine is suffering (or is very close to) actual damage.

The hardware The system hardware consists of a server PC and several data collection nodes. Each node has sixteen channel inputs which may be configured as a dynamic vibration input or as a simple voltage input. Each channel may be configured with up to 4 different types of readings. Nodes can be ordered in ARCNet or Ethernet configuration.

Many machines may be connected and monitored simultaneously. The node is very easy to configure and install. All data collection configuration is done through the software.

This system is very sophisticated but with an easy to use, intuitive interface. Advances in micro-electronics allow us to offer this system for sale at a hitherto unheard of low price making our On-Line monitoring the most effective and cost-effective machine monitoring system in the world. We can provide the system on a direct sale basis or on an ongoing contract basis where we install the system and carry out routine vibration analysis from our office on a daily basis. All data is transferred by internet connection. We assess the data every day and report back to you immediately we find a problem. We also provide a full report every month giving you an overview of the condition of all monitored equipment.

-

Phone: (01253) 400554 Fax (01253) 400553 UK (517) 764-6800 (phone) 6869 (fax) USA

E-Mail: [email protected]

PreDiCon SUPPLYING AFFORDABLE COMPLETE SOLUTIONS

PreDiCon. Data Collection & Reporting Vibration analysis can be very difficult to analyze. Why not get the experts to carry out all of the work for you and present you with a simple set of results and recommendations after every visit? Our engineers are the best in the business and we will ensure that the reports give you good, practical advice.

After each visit for off-line or every day for on-line remote, you will receive a verbal report immediately if anything is dangerously close to failure. For off line systems you will then get a fax or e-mail report within 2 working days and a complete written report mailed to you within one week. On-line remote monitoring systems will provide a same day verbal and e-mail report and a full condition analysis every month.

Vibration Analysis

The written reports for vibration analysis include not only a copy of the plot but also, more importantly, recommendations for repair. Reports are stored in a database for easy data retrieval and custom report generation. A cost analysis module is available if required.

Typical Vibration Analysis Report

Thermography

The thermographic reports include the thermal image as well as a digitally stored visual image. A further report may be generated if required after the repair work is carried out. Reports may be custom designed at no extra charge.

Typical Thermographic Report

-

Phone: (01253) 400554 Fax (01253) 400553 UK (517) 764-6800 (phone) 6869 (fax) USA

E-Mail: [email protected]

PreDiCon SUPPLYING AFFORDABLE COMPLETE SOLUTIONS

PreDiCon. Infra Red Thermography As an object gets hotter, it emits more radiation in the infrared part of the electromagnetic spectrum. With a device that could measure infrared radiation you could indirectly measure the temperature of an object. We call this device an infrared camera and we call the science of its use Infrared Thermography. PreDiCon has the best cameras available with a reporting system second to none. Thermographic techniques can be used to detect a host of different problems. Our engineers are all qualified in the use of thermographic cameras and have extensive experience in the various applications.

Area4Min Mean Max 31.0 51.2 73.7

Area4Min Mean Max 31.0 51.2 73.7

*>60.5C

5.0

10.0

15.0

20.0

25.0

30.0

35.0

40.0

45.0

50.0

55.0

60.0

Electrical Defects Switch room and bus surveys are quick and extremely effective. One section of blown bus can put your factory out of operation for a full day. Compare that cost to a single day for one of our engineers with an infra red camera at a cost of 300 (or 55 p.h. for smaller jobs) including a comprehensive written report.

Area1Min Mean Max 24.839.7 49.3

Area1Min Mean Max 24.839.7 49.3

Spot 1 45.2

Spot 2 45.4 Spot 3

45.6

*>49.7C

15.0

20.0

25.0

30.0

35.0

40.0

45.0

Mechanical Defects Bearings with lubrication problems, dry push rods or screws, slipping belts, bad compressor valves, insulation defects, bad steam traps - the list goes on and on. If the defect causes a temperature change, we can see it and tell you about it.

Spot Welding Problems We have a wealth of experience in detecting problems in secondary weld cables, transformers, and weld guns. This image shows a weld tip with a cooling water connection that is too short causing overheating of the weld tip - resulting in bad welds.

Building Structural Surveys Concrete structures are vulnerable to internal delamination and debonding of render coatings or other surface finishes. This may be a result of corrosion of the internal reinforcing bars or may have been a result of the original pour due to poor compaction. Thermography can detect the areas of delamination or debonding by measuring the heat transfer.

Wall Insulation & Flat Roof Surveys Use thermography to detect excessive heat loss or external draughts. Avoid the huge expense of a complete roof repair by using thermography to pinpoint the areas where repairs are necessary.

Underground Pipe Leak Detection The traditional method for locating leaks is to isolate one section of the system at a time until the general area of the leak is identified and then dig several trial holes on a hit and miss basis. Using thermography, any leak or defective insulation will cause a slight increase in the temperature of the ground above the leak enabling quick accurate location..

-

Phone: (01253) 400554 Fax (01253) 400553 UK (517) 764-6800 (phone) 6869 (fax) USA

E-Mail: [email protected]

SUPPLYING AFFORDABLE COMPLETE SOLUTIONS PreDiCon

PreDiCon. Predictive Maintenance Consultancy & Trouble- Shooting In many cases it is difficult for the maintenance or production engineer to identify the cause of a fault. Very often the cause can be traced back to a structural natural frequency coinciding with a machine operating speed or other forcing function. Using advanced techniques and equipment, our engineers have the knowledge and experience to help identify the causes of such problems and recommend realistic solutions. We have identified several case histories from our files and include these as examples.

Vibration Analysis Vibration influence on a load cell

We were called in to investigate a problem that a client of ours was having with a load cell on a copper smelter. The problem was variations in the poured weight of the copper and the engineer in charge had a suspicion that environmental vibration could be playing a role. There is a load cell under each spoon, which accurately measures the weight of the copper during the pour process so that the finished product is at an exact weight. Variations in the weight appeared to occur randomly so our engineer set out to determine any causal link between vibration and load cell output. The time trace showed that vibration was measurable at the load cell. The surprise was that this vibration was caused not only by the pour process but also by exterior influences such as the movement of the overhead cranes and fork-lift trucks. The time trace below shows the filter-out vibration over one full

operating cycle. The next stage was to identify the vibration source. An FFT spectrum of the floor showed a dominant frequency at about 7

Hz. This was shown to be the natural frequency of the floor and was excited by all of the external forces named above. The spectrum analyzer was then connected to the voltage output of the load cell. Interestingly, the load cell output also showed a frequency at about 7 Hz. It was now obvious that the vibration in the floor was directly affecting the load cell output. The intermittent nature of the problem was due to the random impacting from external influences and the fact that the controller samples twice during each process pour. The answer was to first put a notch filter in the load cell output to remove the problem frequency and secondly to install vibration isolators under the load cell feet. The long term solution is to grout under the floor to remove the vibration completely. Machine Operator Vibration Induced Sickness One client called us in to identify the cause of excessive vibration at the operator station. The vibration was causing the operator to feel nauseous at particular machine speeds.

The subject machine was an extruder used in the manufacture of insulation for electrical cables. Noise and vibration frequency domain readings showed that the main frequency of concern was at 300 Hz. The amplitude at this frequency was extremely severe at specific speeds of the extruder but became innocuous (although always measurable) at other speeds. Operating the machine over a wide speed range, our engineer saw two main frequencies of vibration caused by the DC motor electrical drive (constant at 300 Hz) and the frequency of the main drive gears which changed with the speed. When the speed was such that the gear meshing vibration coincided with the DC drive vibration, amplitudes were measured in excess of 75 mm/s RMS. The cause of the problem was two-fold. There was an SCR fault on the motor drive and one gear wheel had been incorrectly machined to give an inaccurate tooth profile. The SCR was repaired and the gear wheel renewed. The machine now operates satisfactorily and at low noise and vibration levels. Thermography Induction heating of a weld robot wrist This data was captured during a routine check of the secondary circuit weld cables on a spot welding robot at an automotive fabricating plant. High temperatures were noted at the robot wrist at 28C (50F) above ambient. PreDiCon was asked to find the cause of the over-heating. The initial avenue of research was to look for a mechanical source of heat at the wrist. The advanced analytical capabilities of the thermal imaging software indicated that the source was internal rather than external. The wrist bearings were ruled out as a source as the bearings were not in the same place as the source. It was then noticed that that the weld secondary circuit jumper cables were unusually routed on either side of the wrist. It became apparent that the very high currents (>15kA) in the secondary circuit were developing high magnetic fields resulting in induction heating of the wrist. The jumper cables were re-routed and the problem disappeared.

-

Phone: (01253) 400554 Fax (01253) 400553 UK (517) 764-6800 (phone) 6869 (fax) USA

E-Mail: [email protected]

SUPPLYING AFFORDABLE COMPLETE SOLUTIONS PreDiCon

PreDiCon. Predictive Maintenance Training for Industry PreDiCon. has developed a modular approach to training PdM technology users, aimed at developing an effective PdM program. We focus not only on the technology and how to interpret data, but we also provide help in program set up and tracking your PdM goals.

Courses can be tailor made to suit your individual requirements and are held either at our comprehensive training facility or at your plant.

Training courses start from as little as 140 per student.

Modules I. PdM Management 1 day

a. Maintenance strategies b. Project management c. Choosing the right technologies d. Integration into maintenance e. Procedures f. Reporting

II. Basic Vibration Analysis 2 day a. Frequency -v- time domain b. How the FFT works c. Examples of basic defects d. Transducers e. Accelerometer mounting f. Measurement parameters

III. Advanced Vibration Analysis 2 day a. Resonance b. Dynamic range c. Frequency calculations d. Effects of windowing e. Amplitude demodulation f. Phase g. Fault analysis h. Single plane balancing i. ODS

IV. Two Channel Analysis 1 day a. File capture of vibration data b. Variable speed machines c. Triggering d. Measurement parameters e. Capture and display options f. Two-channel functions g. Impact testing

V. Industrial Thermography 2 days a. Infra red theory b. Qualitative thermography c. Radiometric thermography d. Fault analysis e. PdM integration

VI. Passive Ultra Sound in PdM 1 day a. Ultra sound theory b. Detecting leaks c. Electrical applications d. Mechanical applications e. Integration into spectrum analyzers

VII. Potential Failure Analysis 1 day a. Identifying potential failures b. Determination of applicable technologies c. Definition of suitable measurement parameters

Specialized training courses

IIX. PdM on Rolling Element Bearings 1 day

a. Bearing construction b. Elastohydrodynamic lubrication c. stages of bearing failure d. Failure modes e. Fault frequency generation f. Vibration examples of common defects g. Tribology

IX. PdM on AC & DC Motor 1 day a. AC motor construction b. Failure modes c. Generation of electrical frequencies

d. Vibration examples of common defects e. Motor current analysis f. DC motor construction g. Failure modes h. DC drives i. Vibration examples of common defects j. Thermography

X. PdM on Pumps 1 day a. Centrifugal pumps - theory of operation b. Centrifugal pump construction c. Positive displacement pumps construction d. Failure modes e. Vibration examples of common defects f. Performance analysis

XI. PdM on Fans 1 day a. Theory of operation b. Failure modes c. Vibration examples of common defects d. Performance analysis e. Adjusting bedplate resonance

XII. PdM on Large Stamping Presses 2 day a. Press construction b. Failure modes c. Specific monitoring problems d. Sensors & installation e. Defining vibration measurements f. Using advanced vibration techniques