PRE FABRICATION.pdf

-

Upload

dharna-garg -

Category

Documents

-

view

215 -

download

0

Transcript of PRE FABRICATION.pdf

-

8/20/2019 PRE FABRICATION.pdf

1/8

SUBMITTED BY-

DHARNA GARG

B.ARCH. VII SEM

1221018

Report on prefabrication, post

tensioning and pre tensioning

-

8/20/2019 PRE FABRICATION.pdf

2/8

PREFABRICATION

What is prefabrication?

PREFABRICATION IS THE METHOD OF CONSTRUCTIONWHICH INCLUDES ASSEMBLING COMPONENTS OFA STRUCTURE IN A MANUFACTURING OR PRODUCTIONSITE , TRANSPORTING COMPLETE ASSEMBLIES OR PARTIALASSEMBLIESTO THE SITE WHERE THE STRUCTURE IS TO BELOCATED.

IT IS COMBINATION OF GOOD DESIGN WITH MODERN HIGHPERFORMANCE COMPONENTS AND QUALITY CONTROLLEDMANUFACTURING PROCEDURES.

THE PREFABRICATION AS DEFINED WILL BE DONE IN STAGES-

MANUFACTURING AT FACTORY CONDITION AND ERECTION OFCOMPONENTS AT THE REQUIRED LOCATION.

THIS REQUIRES CERTAIN STAGES OF PREPARATION. THEY ARECASTING, CURING, TRANSPORTATION AND ERECTION .

CASTING: – PRECAST COMPONENTS ARE CASTED WITHCONTROLLED CEMENT CONCRETE IN MOULDS OFREQUIRED SHAPE AND SIZES . THE VIBRATOR IS USED TOVIBRATE CONCRETE AND THIS REMOVES ANYHONEYCOMBING INSIDE THE COMPONENTS.

CURING:AFTER 24 HOURS OF CASTING, THE CASTEDCOMPONENTS ARE RELEASED FROM THE MOULD ANDTRANSPORTED TO CURING TANKS .

CASTING OF CONCRETE BLOCKS

-

8/20/2019 PRE FABRICATION.pdf

3/8

TRANSPORTATION AND ERECTION: – AFTER COMPLETECURING IS DONE THE COMPONENTS ARE TRANSPORTED TO THE SITE WITH HEAVY TRUCKS AND ERECTION WILL BE

DONE USING CRANES WITH SKILLED LABOUR FORCE.

ADVANTAGES OF PREFABRICATION-

SAVING IN COST, MATERIAL, TIME & MANPOWER. SHUTTERING AND SCAFFOLDING IS NOT NECESSARY. INSTALLATION OF BUILDING SERVICES AND FINISHES CAN

BE DONE IMMEDIATELY .

INDEPENDENT OF WEATHER CONDITION.

COMPONENTS PRODUCED AT CLOSE SUPERVISION SOQUALITY IS GOOD

CLEAN AND DRY WORK AT SITE. POSSIBILITY OF ALTERATIONS AND REUSE CORRECT SHAPE AND DIMENSIONS AND SHARP EDGES ARE

MAINTAINED. VERY THIN SECTIONS CAN BE ENTIRELY PRECAST WITH

PRECISION. CONTINUING ERECTION IN WINTER TIME UNTIL -20 °C

CURING OF CONCRETE BLOCKS

ERECTION OF BUILDING

-

8/20/2019 PRE FABRICATION.pdf

4/8

QUALITY SURVEILLANCE SYSTEM ENVIRONMENTALLY FRIENDLY WAY OF BUILDING WITH

OPTIMUM USE OF MATERIALS, RECYCLING OF WASTEPRODUCTS, LESS NOISE AND DUST, ETC.

DISADVANTAGES OF PREFABRICATION-

HANDLING AND TRANSPORTATION MAY CAUSEBREAKAGES OF MEMBERS DURING THE TRANSIT ANDEXTRA PROVISION IS TO BE MADE.

DIFFICULTY IN CONNECTING PRECAST UNITS SO AS TOPRODUCE SAME EFFECT AS MONOLITHIC. THIS LEADS TO

NON-MONOLITHIC CONSTRUCTION. THEY ARE TO BE EXACTLY PLACED IN POSITION ,

OTHERWISE THE LOADS COMING ON THEM ARE LIKELY TOGET CHANGED AND THE MEMBER MAY BE AFFECTED.

HIGH TRANSPORT COST NEED OF ERECTION EQUIPMENT SKILLED LABOUR AND SUPERVISION IS REQUIRED. LEAKS CAN FORM AT JOINTS IN PREFABRICATED

COMPONENTS.

PRE FABRICATED BUILDING COMPONENTS-

FLOORS ROOFS BEAMS COLUMNS WALLS STAIRCASE LINTELS SUNSHADE

APPLICATIONS-

HOUSING APARTMENTS OFFICE BLOCKS WAREHOUSES FACTORY BUILDINGS DETACHED HOUSES COTTAGES

PREFABRICATED SLAB TO BEAM CONNECTIONPREFABRICATED

COLUMN TO COLUMNCONNECTION

PREFABRICATEDCOLUMN TO BEAM

-

8/20/2019 PRE FABRICATION.pdf

5/8

LOG CABIN METRO TRACKS

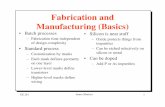

PRE-TENSIONING AND POST TENSIONING

PRESTRESSED CONCRETE-

PRESTRESSED CONCRETE IS A METHOD FOR OVERCOMINGCONCRETE'S NATURAL WEAKNESS IN TENSION .

RESTRESSING TENDONS (GENERALLY OF HIGH TENSILESTEEL CABLE OR RODS) ARE USED WHICH PRODUCES ACOMPRESSIVE STRESS THAT OFFSETS THE TENSILE STRESS

THAT THE CONCRETE COMPRESSION MEMBER WOULDOTHERWISE EXPERIENCE DUE TO SELF – WEIGHT ANDGRAVITY LOADS.

TRADITIONAL REINFORCED CONCRETE IS BASED ON THE USEOF STEEL REINFORCEMENT BARS, REBAR, AND INSIDEPOURED CONCRETE.

PRESTRESSING CAN BE ACCOMPLISHED IN TWO WAYS:

PRE-TENSIONED CONCRETE POST-TENSIONED CONCRETE

PRE-TENSIONED CONCRETE

PRE-TENSIONING IS ACCOMPLISHED BY STRESSING WIRESOR STRANDS, CALLED TENDONS, TO PREDETERMINEDAMOUNT BY STRETCHING THEM BETWEEN TWOANCHORAGES PRIOR TO PLACING CONCRETE .

THE CONCRETE IS THEN PLACED AND TENDONS BECOMEBOUNDED TO CONCRETE THROUGHOUT THEIR LENGTH.

AFTER CONCRETE HAS HARDENED, THE TENDONS ARERELEASED BY CUTTING THEM AT THE ANCHORAGES.

THE TENDONS TEND TO REGAIN THEIR ORIGINAL LENGTH BYSHORTENING AND IN THIS PROCESS TRANSFER THROUGHBOND A COMPRESSIVE STRESS TO THE CONCRETE.

THE TENDONS ARE USUALLY STRESSED BY THE USE OFHYDRAULIC JACKS.

THE STRESS IN TENDONS IS MAINTAINED DURING THEPLACING AND CURING OF CONCRETE BY ANCHORING THE

-

8/20/2019 PRE FABRICATION.pdf

6/8

ENDS OF THE TENDONS TO ABUTMENTS THAT MAY BE ASMUCH AS 200M APART.

THE ABUTMENTS AND OTHER FORMWORK USED IN THISPROCEDURE ARE CALLED PRESTRESSING BENCH OR BED.

MOST OF THE PRE-TENSIONING CONSTRUCTION TECHNIQUESARE PATENTED ALTHOUGH THE BASIC PRINCIPLE USED INALL OF THEM IS COMMON AND IS WELL KNOWN.

POST-TENSIONED CONCRETE

IN A POST-TENSIONED, THE TENDONS ARE STRESSED ANDEACH END IS ANCHORED TO THE CONCRETE SECTIONAFTER THE CONCRETE HAS BEEN CAST AND HAS

ATTAINED SUFFICIENT STRENGTH TO SAFELY WITHSTANDTHE PRESTRESSING FORCE.

IN POST-TENSIONING METHOD, TENDONS ARE COATEDWITH GREASE OR A BITUMINOUS MATERIAL TO PREVENTTHEM FROM BECOMING BONDED TO CONCRETE .

ANOTHER METHOD USED IN PREVENTING THE TENDONSFROM BONDING TO THE CONCRETE DURING PLACING ANDCURING OF CONCRETE IS TO ENCASE THE TENDON IN AFLEXIBLE METAL HOSE BEFORE PLACING IT IN THE FORMS.

THE METAL HOSE IS REFERRED TO AS SHEATH OR DUCT ANDREMAINS IN THE STRUCTURE.

PRESTRESSED CONCRETE DIAGRAM

PRESTRESSED CONCRETE SLAB

-

8/20/2019 PRE FABRICATION.pdf

7/8

AFTER THE TENDON HAS BEEN STRESSED, THE VOIDBETWEEN THE TENDON AND THE SHEATH IS FILLED WITHGROUT .

THUS THE TENDONS BECOME BONDED TO CONCRETE AND

CORROSION OF STEEL IS PREVENTED. IN POST-TENSIONING IT IS NECESSARY TO USE SOME TYPESOF DEVICE TO ATTACH OR ANCHOR THE ENDS OF THETENDONS TO THE CONCRETE SECTION. THESE DEVICES AREUSUALLY REFERRED TO AS END ANCHORAGES.

ROLLS OF POST TENSION CABLES PULLING ANCHORS FOR POST-TENSION CABLES

POSITIONED POST TENSION CABLES

Post-tension cable ends extending fromconcrete slab

HYDRAULIC JACKS FOR TENSIONING

-

8/20/2019 PRE FABRICATION.pdf

8/8

ADVANTAGES OF PRESTRESSED CONCRETE-

PRESTRESSED MEMBER IS FREE FROM CRACK ,SO THERESISTING IMPACT, SHOCK AND REVERSAL OF STRESSES IS

MUCH MORE THAN REINFORCED CONCRETE. IT IS MORE DURABLE THAN REINFORCED CONCRETE. THE SECTION OF PRESTRESSED CONCRETE MEMBER IS LESS

COMPARED TO RCC MEMBER AS IT UTILIZES THE MAXIMUMTENSION AND COMPRESSION OF CONCRETE, SO IT REDUCESTHE COST.

PRESTRESSED CONCRETE CAN BE USED IN LONG SPANS ASTHE SECTION OF MEMBER CAN BE REDUCED.

AS THE SECTIONS ARE LIGHTER, THEY CAN BETRANSPORTED EASILY.

THE CONCRETE DIAGONAL TENSION CAN ALSO BEREDUCED .

SHEAR RESISTANCE CAN BE INCREASED USING CURVEDTENDONS.

NO JOINTS ARE VISIBLE AS IT IS MONOLITHIC STRUCTURE.

DISADVANTAGES OF PRESTRESSED CONCRETE-

THE MAJOR PROBLEM WITH PRESTRESSED CONCRETE ISTHAT IT NEEDS SPECIALIZED CONSTRUCTIONMACHINERIES LIKE JACKS ANCHORAGE ETC.

ADVANCED TECHNICAL KNOWLEDGE AND STRICTSUPERVISION IS VERY IMPORTANT.

FOR CONCRETE PRESTRESSING, HIGH TENSILEREINFORCEMENT BARS ARE NEEDED WHICH COSTSGREATER THAN GENERALLY USED MILD STEELREINFORCEMENT BARS.

HIGHLY SKILLED LABOR IS NEEDED FOR PRESTRESSED

CONCRETE CONSTRUCTIONS .

APPLICATIONS OF POST-TENSIONED CONCRETE-

METRO TRACKS BRIDGES HIGH RISE APARTMENTS OFFICE BLOCKS PARKING GARAGES

LARGE SPAN STRUCTURES WAREHOUSES