PRACTICAL STRAIN GAGE MEASUREMENTS - OMEGA · PDF fileexperimental stress analysis and ......

Transcript of PRACTICAL STRAIN GAGE MEASUREMENTS - OMEGA · PDF fileexperimental stress analysis and ......

E-94

E

ST

RA

IN G

AG

ES

PRACTICAL STRAIN GAGE MEASUREMENTS

INTRODUCTION

W ith today’s emphasis onproduct liability and

energy efficiency, designs must notonly be lighter and stronger, butalso more thoroughly tested thanever before. This places newimportance on the subject ofexperimental stress analysis andthe techniques for measuring strain. The main theme of thisapplication note is aimed at strain

Appendix B contains schematics ofmany of the ways strain gages areused in bridge circuits and theequations which apply to them.Readers wishing a more thoroughdiscussion of bridge circuit theory are invited to read Item 7 referenced in the bibliography.

measurements using bondedresistance strain gages. We willintroduce considerations that affectthe accuracy of this measurementand suggest procedures forimproving it.

We will also emphasize thepractical considerations of straingage measurement, with anemphasis on computer controlledinstrumentation.

E-95

PRACTICAL STRAIN GAGE MEASUREMENTS

STRESS & STRAIN

T he relationship betweenstress and strain is one of the

most fundamental concepts fromthe study of the mechanics ofmaterials and is of paramountimportance to the stress analyst. Inexperimental stress analysis, weapply a given load and thenmeasure the strain on individualmembers of a structure or machine.Then we use the stress-strainrelationships to compute thestresses in those members to verifythat these stresses remain withinthe allowable limits for the particularmaterials used.

STRAINWhen a force is applied to a body,the body deforms. In the generalcase, this deformation is calledstrain. In this application note, wewill be more specific and define theterm STRAIN to mean deformationper unit length or fractional change

in length and give it the symbol, .See Figure 1. This is the strain thatwe typically measure with a bondedresistance strain gage. Strain maybe either tensile (positive) or

compressive (negative). See Figure 2. When this is written inequation form, = L/L, we cansee that strain is a ratio and,therefore, dimensionless.

To maintain the physicalsignificance of strain, it is oftenwritten in units of inches/inch. Formost metals, the strains measuredin experimental work are typicallyless than 0.005000 inch/inch. Sincepractical strain values are so small.they are often expressed as micro-strain, which is x 106 (note this isequivalent to parts per million orppm) with the symbol . Still

SYMBOLS normal stress

shear stress

strain (normal)

micro-strain ( x 106)

shear strain

E modulus of elasticityor Young’s modulus

Poisson Ratio

GF gage factor

Rg gage resistance in ohms

Kt transverse sensitivity ratio

L length

L change in length

Rg change in gage resistance(due to strain)

%GF % change in gage factor(due to temperature)

Rl lead wire resistance

T temperature in °C

VIN bridge excitation voltage

VOUT bridge output voltage

Vr [(VOUT/VIN)[strained] — (VOUT/VIN)[unstrained]]

Figure 1: Uniaxial Force Applied

Figure 2: Cantilever in Bending

E-96

E

ST

RA

IN G

AG

ES

another way to express strain is aspercent strain, which is x 100. Forexample: 0.005 inch/inch = 5000=0.5%.As described to this point, strain isfractional change in length and isdirectly measurable. Strain of thistype is also often referred to asnormal strain.

SHEARING STRAINAnother type of strain, calledSHEARING STRAIN, is a measureof angular distortion. Shearing strainis also directly measurable, but notas easily as normal strain. If we hada thick book sitting on a table topand we applied a force parallel tothe covers, we could see the shearstrain by observing the edges of thepages.

See Figure 3. Shearing strain, , isdefined as the angular change inradians between two line segmentsthat were orthogonal in theundeformed state. Since this angleis very small for most metals,shearing strain is approximated bythe tangent of the angle.

POISSON STRAINIn Figure 4 is a bar with a uniaxialtensile force applied, like the bar inFigure 1. The dashed lines show theshape of the bar after deformation,

pointing out another phenomenon,that of Poisson strain. The dashedlines indicate that the bar not onlyelongates but that its girth contracts.This contraction is a strain in thetransverse direction due to aproperty of the material known asPoisson’s Ratio. Poisson’s ratio, ,is defined as the negative ratio ofthe strain in the transverse directionto the strain in the longitudinaldirection. It is interesting to note thatno stress is associated with thePoisson strain. Referring to Figure4, the equation for Poisson’s ratio is = – t /1. Note that isdimensionless.

NORMAL STRESSWhile forces and strains aremeasurable quantities used by thedesigner and stress analyst, stressis the term used to compare theloading applied to a material with itsability to carry the load. Since it is

Figure 4: Poisson Strain

usually desirable to keep machinesand structures as small and light aspossible, component parts shouldbe stressed, in service, to thehighest permissible level. STRESSrefers to force per unit area on agiven plane within a body.

The bar in Figure 5 has a uniaxialtensile force, F, applied along the x-axis. If we assume the force to beuniformly distributed over the cross-sectional area, A, the “average”stress on the plane of the section isF/A. This stress is perpendicular tothe plane and is called NORMALSTRESS,. Expressed in equationform, = F/A, and is denoted inunits of force per unit area. Sincethe normal stress is in the xdirection and there is no componentof force in the y direction, there isno normal stress in that direction.The normal stress is in the positivex direction and is tensile.

Figure 5: Normal Stress

PRACTICAL STRAIN GAGE MEASUREMENTS

Figure 3: Visualizing Shearing Strain

E-97

SHEAR STRESSJust as there are two types of strain,there is also a second type of stresscalled SHEAR STRESS. Wherenormal stress is normal to thedesignated plane, shear stress isparallel to the plane and has thesymbol . In the example shown inFigure 5, there is no y component offorce, therefore no force parallel tothe plane of the section, so there isno shear stress on that plane. Sincethe orientation of the plane isarbitrary, what happens if the planeis oriented other than normal to theline of action of the applied force?

Figure 6 demonstrates this conceptwith a section taken on the n-tcoordinate system at some arbitraryangle, , to the direction of actionof the force.

We see that the force vector, F, canbe broken into two components, Fnand Ft, that are normal and parallelto the plane of the section. Thisplane has a cross-sectional area ofA' and has both normal and shearstresses applied. The averagenormal stress,, is in the ndirection and the average shearstress, , is in the t direction. Theirequations are: = Fn /A' and = Ft /A'. Note that it was the forcevector that was broken into

components, not the stresses, andthat the resulting stresses are afunction of the orientation of thesection. This means that stresses(and strains), while having bothmagnitude and direction, are notvectors and do not follow the laws ofvector addition, except in certainspecial cases, and they should notbe treated as such. We should alsonote that stresses are derivedquantities computed from othermeasurable quantities, and are notdirectly measurable. [3]

PRINCIPAL AXESIn the preceding examples, the x-yaxes are also the PRINCIPAL AXESfor the uniaxially loaded bar. Bydefinition, the principal axes are theaxes of maximum and minimumnormal stress. They have theadditional characteristic of zeroshear stress on the planes that liealong these axes. In Figure 5, thestress in the x direction is themaximum normal stress, and wenoted that there was no forcecomponent in the y direction andtherefore zero shear stress on theplane. Since there is no force in they direction, there is zero normal

stress in the y direction and in thiscase zero is the minimum normalstress. So the requirements for theprincipal axes are met by the x-yaxes. In Figure 6, the x-y axes arethe principal axes, since that bar isalso loaded uniaxially. The n-t axesin Figure 6 do not meet the zeroshear stress requirement of theprincipal axes. The correspondingSTRAINS on the principal axes isalso maximum and minimum andthe shear strain is zero.

The principal axes are veryimportant in stress analysis becausethe magnitudes of the maximumand minimum normal stresses areusually the quantities of interest.Once the principal stresses areknown, then the normal and shearstresses in any orientation can becomputed. If the orientation of theprincipal axes is known, throughknowledge of the loading conditionsor experimental techniques, the taskof measuring the strains andcomputing the stresses is greatlysimplified.

In some cases, we are interested inthe average value of stress or loadon a member, but often we want todetermine the magnitude of thestresses at a specific point. Thematerial will fail at the point wherethe stress exceeds the load-carryingcapacity of the material. This failuremay occur because of excessivetensile or compressive normalstress or excessive shearing stress.In actual structures, the area of thisexcessive stress level may be quitesmall. The usual method ofdiagramming the stress at a point isto use an infinitesimal element thatsurrounds the point of interest. Thestresses are then a function of theorientation of this element, and, inone particular orientation, the

Figure 6: Shear Stress

PRACTICAL STRAIN GAGE MEASUREMENTS

materials. Written in equation form,this stress-strain relationship is = E •. Some materials do nothave a linear portion (for example,cast iron and concrete) to theirstress-strain diagrams. To doaccurate stress analysis studies forthese materials, it is necessary todetermine the stress-strainproperties, including Poisson’s ratio,for the particular material on atesting machine. Also, the modulusof elasticity may vary withtemperature. This variation mayneed to be experimentallydetermined and considered whenperforming stress analysis attemperature extremes. There aretwo other points of interest on thestress-strain diagram in Figure 7:the yield point and the ultimatestrength value of stress.

The yield point is the stress level atwhich strain will begin to increaserapidly with little or no increase instress. If the material is stressedbeyond the yield point, and then thestress is removed, the material willnot return to its original dimensions,but will retain a residual offset orstrain. The ultimate strength is themaximum stress developed in thematerial before rupture.

The examples we have examined tothis point have been examples ofuniaxial forces and stresses. Inexperimental stress analysis, the

E-98

E

ST

RA

IN G

AG

ES

PRACTICAL STRAIN GAGE MEASUREMENTS

element will have its sides parallelto the principal axes. This is theorientation that gives the maximumand minimum normal stresses onthe point of interest.

STRESS-STRAINRELATIONSHIPSNow that we have defined stressand strain, we need to explore thestress-strain relationship, for it isthis relationship that allows us tocalculate stresses from measuredstrains. If we have a bar made ofmild steel and incrementally load itin uniaxial tension and plot thestrain versus the normal stress inthe direction of the applied load, theplot will look like the stress-straindiagram in Figure 7.

From Figure 7, we can see that, upto a point called the proportionallimit, there is a linear relationshipbetween stress and strain. Hooke’sLaw describes this relationship. Theslope of this straight-line portion ofthe stress-strain diagram is theMODULUS OF ELASTICITY orYOUNG’S MODULUS for thematerial. The modulus of elasticity,E, has the same units as stress(force per unit area) and isdetermined experimentally for

biaxial stress state is the mostcommon. Figure 8 shows anexample of a shaft with both tensionand torsion applied. The point ofinterest is surrounded by aninfinitesimal element with its sidesoriented parallel to the x-y axes. The point has a biaxial stress stateand a triaxial strain state (rememberPoisson’s ratio). The element,rotated to be aligned with theprincipal (p-q) axes, is also shownin Figure 8. Figure 9 shows theelement removed with arrowsadded to depict the stresses at thepoint for both orientations of theelement.

We see that the element orientedalong the x-y axes has a normalstress in the x direction, zero normalstress in the y direction and shearstresses on its surfaces. Theelement rotated to the p-q axesorientation has normal stress in

Figure 7: Stress-Strain Diagram for Mild Steel

Figure 8: Shaft in Torsion and Tension

Figure 9: Element on X-Y Axes and Principal Axes

E-99

PRACTICAL STRAIN GAGE MEASUREMENTS

both directions but zero shear stressas it should, by definition, if the p-qaxes are the principal axes. Thenormal stresses,p and q , arethe maximum and minimum normalstresses for the point. The strains inthe p-q direction are also themaximum and minimum, and thereis zero shear strain along theseaxes. Appendix C gives theequations relating stress to strain forthe biaxial stress state.

If we know the orientation of theprincipal axes, we can then measurethe strain in those directions andcompute the maximum andminimum normal stresses and themaximum shear stress for a givenloading condition. We don’t alwaysknow the orientation of the principalaxes, but if we measure the strain inthree separate directions, we cancompute the strain in any directionincluding the principal axes’directions. Three- and four-elementrosette strain gages are used tomeasure the strain when theprincipal axes’ orientation isunknown. The equations forcomputing the orientation andmagnitude of the principal strainsfrom 3-element rosette strain dataare found in Appendix C.

For further study of the mechanicsof materials, refer to Items 1, 4, and6 referenced in the Bibliography.Properties of several commonengineering materials are listed inAppendix A.

MEASURINGSTRAIN

S tress in a material can’t bemeasured directly. It must be

computed from other measurableparameters. Therefore, the stress

analyst uses measured strains inconjunction with other properties ofthe material to calculate thestresses for a given loadingcondition. There are methods ofmeasuring strain or deformationbased on various mechanical,optical, acoustical, pneumatic, andelectrical phenomena. This sectionbriefly describes several of the morecommon methods and their relative merits.

GAGE LENGTHThe measurement of strain is themeasurement of the displacementbetween two points some distanceapart. This distance is the GAGELENGTH and is an importantcomparison between various strainmeasurement techniques. Gagelength could also be described asthe distance over which the strain isaveraged. For example, we could,on some simple structure such asthe part in Figure 10, measure thepart length with a micrometer bothbefore and during loading. Then wewould subtract the two readings toget the total deformation of the part.Dividing this total deformation bythe original length would yield anaverage value of strain for the entirepart. The gage length would be theoriginal length of the part.

If we used this technique on the partin Figure 10, the strain in thereduced width region of the part

would be locally higher than themeasured value because of thereduced cross-sectional areacarrying the load. The stresses willalso be highest in the narrowregion; the part will rupture therebefore the measured average strainvalue indicates a magnitude ofstress greater than the yield point of the material as a whole.

Ideally, we want the strainmeasuring device to have aninfinitesimal gage length so we canmeasure strain at a point. If we hadthis ideal strain gage, we wouldplace it in the narrow portion of thespecimen in Figure 10 to measurethe high local strain in that region.Other desirable characteristics forthis ideal strain measuring devicewould be small size and mass, easyattachment, high sensitivity tostrain, low cost and low sensitivity to temperature and other ambientconditions. [2,6]

MECHANICAL DEVICESThe earliest strain measurementdevices were mechanical in nature.We have already considered anexample (using a micrometer tomeasure strain) and observed aproblem with that approach.Extensometers are a class ofmechanical devices used formeasuring strain that employ asystem of levers to amplify minute

Figure 10

E-100

E

ST

RA

IN G

AG

ES

PRACTICAL STRAIN GAGE MEASUREMENTS

strains to a level that can be read. Aminimum gage length of 1⁄2 inch anda resolution of about 10 is thebest that can be achieved withpurely mechanical devices. Theaddition of a light beam and mirrorarrangements to extensometersimproves resolution and shortensgage length, allowing2 resolution and gage lengthsdown to 1⁄4 inch.

Still another type of device, thephotoelectric gage, uses acombination of mechanical, optical,and electrical amplifications tomeasure strain. This is done byusing a light beam, two fine gratingsand a photocell detector to generatean electrical current that isproportional to strain. This devicecomes in gage lengths as short as1⁄16 inch, but it is costly and delicate.All of these mechanical devicestend to be bulky and cumbersometo use, and most are suitable onlyfor static strain measurements.

OPTICAL METHODSSeveral optical methods are usedfor strain measurement. One ofthese techniques uses theinterference fringes produced byoptical flats to measure strain. Thisdevice is sensitive and accurate, butthe technique is so delicate thatlaboratory conditions are requiredfor its use. Item 5 referenced in theBibliography gives excellentintroductions to the optical methodsof photoelasticity, holography, andthe moiré method of strain analysis.[2,5]

ELECTRICAL DEVICESAnother class of strain measuringdevices depends on electricalcharacteristics which vary inproportion to the strain in the bodyto which the device is attached.Capacitance and inductance strain

gages have been constructed, butsensitivity to vibration, mountingdifficulties, and complex circuitrequirements keep them from beingvery practical for stress analysiswork. These devices are, however,often employed in transducers. Thepiezoelectric effect of certaincrystals has also been used tomeasure strain. When a crystalstrain gage is deformed or strained,a voltage difference is developedacross the face of the crystal. Thisvoltage difference is proportional tothe strain and is of a relatively highmagnitude. Crystal strain gages are,however, fairly bulky, very fragile,and not suitable for measuring static strains.

Probably the most importantelectrical characteristic which varies in proportion to strain iselectrical resistance. Devices whose output depends on thischaracteristic are the piezoresistiveor semiconductor gage, the carbon-

Figure 11: Large Area Strain Gages

E-101

resistor gage, and the bondedmetallic wire and foil resistancegage. The carbon-resistor gage isthe forerunner of the bondedresistance wire strain gage. It is low in cost, can have a short gage length, and is very sensitive to strain. A high sensitivity totemperature and humidity are thedisadvantages of the carbon-resistor strain gage.

The semiconductor strain gage isbased on the piezoresistive effect incertain semiconductor materialssuch as silicon and germanium.

Semiconductor gages have elasticbehavior and can be produced tohave either positive or negativeresistance changes when strained.They can be made physically smallwhile still maintaining a high nominal resistance. The strain limit for these gages is in the 1000 to 10000 range, with most tested to 3000 in tension.Semiconductor gages exhibit a highsensitivity to strain, but the changein resistance with strain is nonlinear.Their resistance and output aretemperature sensitive, and the highoutput, resulting from changes inresistance as large as 10-20%, can cause measurement problems when using the devices in a bridge circuit. However, mathematical correctionsfor temperature sensitivity, thenonlinearity of output, and thenonlinear characteristics of thebridge circuit (if used) can be madeautomatically when using computer-controlled instrumentation tomeasure strain with semiconductorgages. They can be used tomeasure both static and dynamicstrains. When measuring dynamicstrains, temperature effects areusually less important than for staticstrain measurements and the highoutput of the semiconductor gage isan asset.

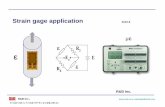

The bonded resistance strain gageis by far the most widely used strain measurement tool for today’s experimental stress analyst. It consists of a grid of very fine wire (or, more recently, of thin metallic foil) bonded to a thin insulating backing called a carrier matrix. The electrical resistance of this grid material varies linearly with strain. In use, the carrier matrix is attached to the test specimen withan adhesive.

When the specimen is loaded, the strain on its surface istransmitted to the grid material bythe adhesive and carrier system.The strain in the specimen is foundby measuring the change in theelectrical resistance of the gridmaterial. Figure 12 is a picture of abonded resistance strain gage witha Constantan foil grid and polyimidecarrier material. The bondedresistance strain gage is low in cost,can be made with a short gagelength, is only moderately affectedby temperature changes, has smallphysical size and low mass, andhas fairly high sensitivity to strain. Itis suitable for measuring both staticand dynamic strains. The remainderof this application note deals withthe instrumentation considerationsfor making accurate, practical strainmeasurements using the bondedresistance strain gage. [2, 5, 6]

THE BONDEDRESISTANCESTRAIN GAGE

T he term “bonded resistancestrain gage” can apply to the

nonmetallic (semiconductor) gageor to the metallic (wire or foil) gage.Wire and foil gages operate on the

same basic principle, and both canbe treated in the same fashion fromthe measurement standpoint. Thesemiconductor gage, having a muchhigher sensitivity to strain thanmetallic gages, can have otherconsiderations introduced into itsmeasurement. We will use the termSTRAIN GAGE or GAGE to refer tothe BONDED METALLIC FOILGRID RESISTANCE STRAINGAGE throughout the rest of thisapplication note. These foil gagesare sometimes referred to as metal-film gages.

Strain gages are made with aprinted circuit process usingconductive alloys rolled to a thin foil.The alloys are processed, includingcontrolled-atmosphere heat treating,to optimize their mechanicalproperties and temperaturecoefficients of resistance. A gridconfiguration for the strain sensitiveelement is used to allow highervalues of gage resistance whilemaintaining short gage lengths.Gage resistance values range from30 to 3000 Ω, with 120 Ω and 350 Ωbeing the most commonly usedvalues for stress analysis. Gagelengths from 0.008 inch to 4 inchesare commercially available. Theconductor in a foil grid gage has alarge surface area for a given cross-sectional area. This keeps the shearstress low in the adhesive andcarrier matrix as the strain istransmitted by them. This largersurface area also allows good heattransfer between grid andspecimen. Strain gages are smalland light, operate over a widetemperature range, and canrespond to both static and dynamicstrains. They have wide applicationand acceptance in transducers aswell as in stress analysis.

In a strain gage application, thecarrier matrix and the adhesivemust work together to faithfully

PRACTICAL STRAIN GAGE MEASUREMENTS

E-102

E

ST

RA

IN G

AG

ES

transmit strain from the specimen tothe grid. They also act as anelectrical insulator between the gridand the specimen and must transferheat away from the grid. Threeprimary factors influencing gageselection are 1) operatingtemperature; 2) state of strain(including gradients, magnitude andtime dependence); and 3) stabilityrequirements for the gageinstallation. The importance ofselecting the proper combination of

carrier material, grid alloy, adhesive,and protective coating for the givenapplication cannot be over-emphasized. Strain gagemanufacturers are the best sourceof information on this topic and havemany excellent publications toassist the customer in selecting theproper strain gages, adhesives and protective coatings.

GAGE FACTORWhen a metallic conductor isstrained, it undergoes a change inelectrical resistance, and it is thischange that makes the strain gagea useful device. The measure of thisresistance change with strain isGAGE FACTOR, GF. Gage factor isdefined as the ratio of the fractionalchange in resistance to thefractional change in length (strain)along the axis of the gage. Gage

Figure 12: Foil BondedResistance Strain Gages

PRACTICAL STRAIN GAGE MEASUREMENTS

Figure 13: Strain Gage Nomenclature

Overall Pattern Length

Gage LengthEnd Loops

Solder Tab Length

Tab Spacing Grid Width

Solder Tab WidthGrid Center Alignment Marks Inner Grid Lines

Outer Grid Lines

Transition

E-103

PRACTICAL STRAIN GAGE MEASUREMENTS

factor is a dimensionless quantity,and the larger the value, the moresensitive the strain gage. Gagefactor is expressed in equation form as:

It should be noted that the change inresistance with strain is not duesolely to the dimensional changes inthe conductor, but that the resistivityof the conductor material alsochanges with strain: The term gagefactor applies to the strain gage as awhole, complete with carrier matrix,not just to the strain-sensitiveconductor. The gage factor forConstantan and nickel-chromiumalloy strain gages is nominally 2,and various gage andinstrumentation specifications areusually based on this nominal value.

TRANSVERSE SENSITIVITYif the strain gage were a singlestraight length of conductor of smalldiameter with respect to its length, itwould respond to strain along itslongitudinal axis and be essentiallyinsensitive to strain appliedperpendicularly or transversely tothis axis. For any reasonable valueof gage resistance, it would alsohave a very long gage length. Whenthe conductor is in the form of a gridto reduce the effective gage length,there are small amounts of strain-sensitive material in the end loops orturn-arounds that lie transverse tothe gage axis. See Figure 13. Thisend loop material gives the gage anon-zero sensitivity to strain in the

transverse direction.TRANSVERSE SENSITIVITYFACTOR, Kt, is defined as:

and is usually expressed in percent.Values of K range from 0 to 10%.

To minimize this effect, extramaterial is added to the conductorin the end loops, and the grid linesare kept close together. This servesto minimize resistance in thetransverse direction. Correction fortransverse sensitivity may benecessary for short, wide-gridgages, or where there isconsiderable misalignment betweenthe gage axis and the principal axis,or in rosette analysis where hightransverse strain fields may exist.Data supplied by the manufacturerwith the gage can be entered intothe computer that controls theinstrumentation, and corrections fortransverse sensitivity can thus bemade to the strain data as it iscollected.

TEMPERATURE EFFECTSIdeally, we would prefer the straingage to change resistance only inresponse to stress-induced strain inthe test specimen, but the resistivityand strain sensitivity of all knownstrain-sensitive materials vary withtemperature. Of course this meansthat the gage resistance and thegage factor will change when thetemperature changes. This changein resistance with temperature for amounted strain gage is a function ofthe difference in the thermalexpansion coefficients between thegage and the specimen and of thethermal coefficient of resistance ofthe gage alloy. Self-temperature-compensating gages can beproduced for specific materials byprocessing the strain-sensitive alloyin such a way that it has thermalresistance characteristics thatcompensate for the effects of themismatch in thermal expansioncoefficients between the gage andthe specific material. A temperaturecompensated gage produced in this

Equation No. 10

GF =R/R

=R/R

L/L

Kt =GF (transverse)

GF (longitudinal)

E-104

E

ST

RA

IN G

AG

ES

PRACTICAL STRAIN GAGE MEASUREMENTS

manner is accurately compensatedonly when mounted on a materialthat has a specific coefficient ofthermal expansion. Table 2 is a listof common materials for which self-temperature-compensated gagesare available.

The compensation is only effectiveover a limited temperature range

or 240 micro-ohms. That means weneed to have micro-ohm sensitivityin the measuring instrumentation.Since it is the fractional change inresistance that is of interest, andsince this change will likely be onlyin the tens of milliohms, somereference point is needed fromwhich to begin the measurement.The nominal value of gageresistance has a toleranceequivalent to several hundredmicrostrain, and will usually changewhen the gage is bonded to thespecimen, so this nominal valuecan’t be used as a reference.

An initial, unstrained gageresistance is used as the referenceagainst which strain is measured.Typically, the gage is mounted onthe test specimen and wired to theinstrumentation while the specimenis maintained in an unstrained state.

because of the nonlinear characterof both the thermal coefficient ofexpansion and the thermalcoefficient of resistance.

THE MEASUREMENTFrom the gage factor equation, wesee that it is the FRACTIONALCHANGE in resistance that is theimportant quantity, rather than theabsolute resistance value of thegage. Let’s see just how large thisresistance change will be for a strainof 1. If we use a 120 Ω straingage with a gage factor of +2, the gage factor equation tells usthat 1 applied to a 120 Ω gageproduces a change in resistance of

APPROXIMATE THERMAL EXPANSION COEFFICIENT

MATERIAL PPM/°CQuartz 0.5

Titanium 9

Mild Steel 11

Stainless Steel 16

Aluminum 23

Magnesium 26

Table 2: Thermal Expansion Coefficientsof Some Common Materials for WhichTemperature Compensated Strain GagesAre Available

Figure 14: Typical Temperature-Induced Apparent Strain

R = 120 x 0.000001 x 2 = 0.000240 Ω

E-105

PRACTICAL STRAIN GAGE MEASUREMENTS

A reading taken under theseconditions is the unstrainedreference value, and applying astrain to the specimen will result in aresistance change from this value. Ifwe had an ohmmeter that wasaccurate and sensitive enough tomake the measurement, we wouldmeasure the unstrained gageresistance and then subtract thisunstrained value from thesubsequent strained values.Dividing the result by the unstrainedvalue would give us the fractionalresistance change caused by strainin the specimen. In some cases, it ispractical to use this very method,and these cases will be discussed ina later section of this applicationnote. A more sensitive way ofmeasuring small changes inresistance is with the use of aWheatstone bridge circuit, and, infact, most instrumentation formeasuring static strain uses thiscircuit. [2,5,6,7,8]

MEASUREMENTMETHODS

WHEATSTONE BRIDGECIRCUITBecause of its outstandingsensitivity, the Wheatstone bridgecircuit (depicted in Figure 15) is themost frequently used circuit forstatic strain measurement. Thissection examines this circuit and its

application to strain gagemeasurement. By using a computerin conjunction with themeasurement instrumentation, wecan simplify use of the bridgecircuit, increase measurementaccuracy, and compile largequantities of data from multichannelsystems. The computer alsoremoves the necessity of balancingthe bridge, compensates fornonlinearities in output, andhandles switching and data storagein multichannel applications.

BALANCED BRIDGE STRAINGAGE MEASUREMENTIn Figure 15, VIN is the inputvoltage to the bridge, Rg is theresistance of the strain gage, R1, R2and R3 are the resistances of thebridge completion resistors, andVOUT is the bridge output voltage. A1⁄4 bridge configuration exists whenone arm of the bridge is an activegage and the other arms are fixedvalue resistors or unstrained gages,as is the case in this circuit. Ideally,the strain gage, Rg, is the onlyresistor in the circuit that varies,and then only due to a change instrain on the surface of the

specimen to which it is attached.VOUT is a function of VIN, R1, R2, R3and Rg. This relationship is:

When (R1/R2) = (Rg/R3), VOUTbecomes zero and the bridge isbalanced. If we could adjust one ofthe resistor values (R2, for

example), then we could balancethe bridge for varying values of theother resistors. Figure 16 shows aschematic of this concept.

Referring to the gage factorequation,

we see that the quantity we need tomeasure is the fractional change ingage resistance from the unstrainedvalue to the strained value. If, whenthe gage is unstrained, we adjust R2

VIN VOUT

R1

R2

Rg

R3

Figure 15: Wheatstone Bridge Circuit

Figure 16: Bridge Circuit with Provision for Balancing the Bridge

Equation No. 11

VOUT = VIN

R3 – R2[ R3 + Rg R1 + R2 ]

Equation No. 10

GF = Rg/Rg

E-106

E

ST

RA

IN G

AG

ES

PRACTICAL STRAIN GAGE MEASUREMENTS

until the bridge is balanced andthen apply strain to the gage, thechange in Rg due to the strain willunbalance the bridge and VOUT willbecome nonzero. If we adjust thevalue of R2 to once again balancethe bridge, the amount of thechange required in resistance R2will equal the change in Rg due tothe strain. Some strain indicatorswork on this principle byincorporating provisions forinputting the gage factor of thegage being used and indicating thechange in the variable resistance,R2, directly in micro-strain.

In the previous example, the bridgebecomes unbalanced when strain isapplied. VOUT is a measure of thisimbalance and is directly related tothe change in Rg, the quantity ofinterest. Instead of rebalancing thebridge, we could install an indicator,calibrated in micro-strain, thatresponds to VOUT. Refer to Figure16. If the resistance of this indicatoris much greater than that of thestrain gage, its loading effect on thebridge circuit will be negligible, i.e.,negligible current will flow throughthe indicator. This method oftenassumes: 1) a linear relationshipbetween VOUT and strain; 2) abridge that was balanced in theinitial, unstrained, state; and 3) aknown value of VIN. In a bridgecircuit, the relationship betweenVOUT and strain is nonlinear, but forstrains up to a few thousand micro-strain, the error is usually smallenough to be ignored. At largevalues of strain, corrections mustbe applied to the indicated readingto compensate for this nonlinearity.

The majority of commercial strainindicators use some form ofbalanced bridge for measuringresistance strain gages. Inmultichannel systems, the numberof manual adjustments required forbalanced bridge methods becomes

This new equation is:

Note that it was assumed in thisderivation that Rg was the onlychange in resistance from theunstrained to the strained condition.Recalling the equation for gagefactor:

and combining these two equations,we get an equation for strain interms of Vr and GF:

The schematic in Figure 17 showshow we can instrument theunbalanced bridge.

A constant voltage power supplyfurnishes VIN, and a digital voltmeter(DVM) is used to measure VOUT.The DVM for this application shouldhave a high (greater than 109 Ω)input resistance, and 1 microvolt orbetter resolution. The gage factor issupplied by the gage manufacturer.In practice, we would use acomputer to have the DVM read andstore VOUT under unstrainedconditions, then take anotherreading of VOUT after the specimenis strained. Since the values forgage factor and excitation voltage,VIN, are known, the computer cancalculate the strain value indicatedby the change in bridge outputvoltage. If the value of VIN is

cumbersome to the user.Multichannel systems, undercomputer control, eliminate theseadjustments by using anunbalanced bridge technique.

UNBALANCED BRIDGESTRAIN GAGEMEASUREMENTThe equation for VOUT can berewritten in the form of the ratio ofVOUT to VIN:

This equation holds for both theunstrained and strained conditions.Defining the unstrained value ofgage resistance as Rg and thechange due to strain as Rg, thestrained value of gage resistance isRg + Rg. The actual effectivevalue of resistance in each bridgearm is the sum of all the resistancesin that arm, and may include suchthings as lead wires, printed circuitboard traces, switch contactresistance, interconnections, etc. Aslong as these resistances remainunchanged between the strainedand unstrained readings, themeasurement will be valid. Let’sdefine a new term, Vr, as thedifference of the ratios of VOUT toVIN from the unstrained to thestrained state:

By substituting the resistor valuesthat correspond to the two (VOUT/VIN) terms into this equation, wecan derive an equation for Rg/Rg.

Equation No. 12

VOUT =R3 –

R2

VIN[ R3 + Rg R1 + R2

]Equation No. 10

GF = Rg/Rg

Equation No. 15

=-4Vr

GF(1 + 2Vr )

Equation No. 14

Rg =

-4Vr

Rg 1 + 2Vr

Equation No. 13

Vr = VOUT

–VOUT[(VIN

)strained(VIN )unstrained]

E-107

PRACTICAL STRAIN GAGE MEASUREMENTS

unknown or subject to variation overtime, we can have the DVMmeasure it at the time VOUT ismeasured to get a more precisevalue for Vr. This “timely”measurement of VIN greatly reducesthe stability requirements of thepower supply, allowing a lower-costunit to be used. Note that, in thepreceding 1⁄4 bridge example, thebridge was not assumed to bebalanced nor its outputapproximated as truly linear.Instead, we just derived theequation for strain in terms ofquantities that are known or can bemeasured, and let the computersolve the equation to obtain theexact strain value.

In the preceding example, we madesome assumptions that affect theaccuracy of the strainmeasurement:

• resistance in the three inactive bridge arms remained constantfrom unstrained to strainedreadings,

• DVM accuracy, resolution, andstability were adequate for therequired measurement,

• resistance change in the activebridge arm was due only tochange in strain, and

• VIN and the gage factor wereboth known quantities.

Appendix B shows the schematicsof several configurations of bridgecircuits using strain gages, andgives the equation for strain as afunction of Vr for each.

MULTICHANNELWHEATSTONE BRIDGEMEASUREMENTSIn the preceding example,measurement accuracy wasdependent upon all four bridgearms’ resistances remainingconstant from the time of theunstrained reading to the time of the

strained reading, except for thechange in the gage resistance dueto strain. If any of the bridge armresistances changed during thattime span, there would be acorresponding change in bridgeoutput voltage which would beinterpreted as strain-induced, so wewould see an error. The samewould be true of any other variationthat changed the bridge outputvoltage. Any switching done in thebridge arms can cause a change inresistance due to variations in theswitch or relay contact resistanceand can affect the bridge outputvoltage. For that reason, it is notdesirable to do switching inside thebridge arms for multichannelsystems, but, rather, to allow thoseinterconnections to be permanentlywired and switch the DVM frombridge to bridge. Since a DVM hasextremely high input impedancecompared to the bridge arms, itdoesn’t load the bridge, andswitching the DVM has no effect onthe bridge output voltage level.Figures 18 and 19 show theschematics of these two methods of switching. We can see thatswitching inside the bridge armsallows the same bridge completionresistors to be used for multiplegages, but that the power to thegage is removed when it is not

Figure 18: Switching Inside Bridge Arms

Figure 17: Instrumentation for Unbalanced Bridge Strain Gage Measurement

E-108

E

ST

RA

IN G

AG

ES

PRACTICAL STRAIN GAGE MEASUREMENTS

being read. Also, any variations inswitch contact resistance will appearin series with the gage resistanceand will be indistinguishable fromresistance changes due to strain.

Figure 19 shows a multiple-channelarrangement that switches the DVMand also shares the power supplyand internal half-bridge. This circuitis known as a “Chevron Bridge” andis often used for strain measurementon rotating machine elements tominimize the number of slip rings.One channel is shown as a 1⁄4 bridgeand the other as a 1⁄2 bridge (twoactive gages). The midpoint of theinternal half-bridge for either ofthese configurations serves as avoltage reference point for the DVMand isn’t affected by strain. Sincethe bridge completion resistors musthave excellent stabilityspecifications, they are relativelyexpensive, and there is a costadvantage to sharing the internalhalf-bridge in multichannel systems.

For this method to function properly,the circuit must be designed andconstructed such that a change incurrent due to strain in one armdoes not change the current in anyof the other arms. Also, the

become inoperative. However, themeasurement of the excitation

voltage permits the power supply todrift, be adjusted, or even bereplaced with no loss inmeasurement accuracy.

FOUR-WIRE OHM STRAINGAGE MEASUREMENTAs we mentioned before, we canmeasure the change in absolutevalue of gage resistance to computestrain. This can be done quiteaccurately using a four-wire Ωmeasurement technique with a highresolution (e.g., 1 milliohm per leastsignificant digit) digital multimeter(DMM). Figure 20 depicts the four-wire Ω method of resistance measurement. The current source isconnected internally in the DMM to

excitation voltage, VIN, must bemeasured across points A-B, and itmay be desirable to measure thisvoltage each time a new set ofreadings is taken from this group ofchannels. The DVM is switchedbetween points C-D, C-E, etc., toread the output voltages of thevarious channels in the group. Thismethod keeps all of the gagesenergized at all times, whichminimizes dynamic heating andcooling effects in the gages andeliminates the need for switchinginside the bridge arms. If the DVMhas good low-level measurementcapability, the power supply voltagecan be maintained at a low level,thereby keeping the gage's self-heating effects to a minimum. Forexample, using a 2 volt powersupply for the bridge yields a powerdissipation, in a 350 Ω gage, of only3 milliwatts. Yet even with this lowpower, 1 microstrain sensitivity isstill maintained with a 1⁄4 bridgeconfiguration (assuming GF=2),when using a DVM with 1 microvoltresolution. Since several channelsare dependent upon one powersupply and one resistor pair, afailure of one of these componentswill cause several channels to

Figure 19: Schematic of Bridge Circuit with Shared Internal Half-Bridge and Power Supply

Figure 20: Schematic of Four-Wire Ohm Circuit

E-109

PRACTICAL STRAIN GAGE MEASUREMENTS

the source terminals, while thevoltmeter is connected to the Ωsense terminals of the DMM. Whena measurement is taken, the currentsource supplies a known fixed valueof direct current through the circuitfrom the Ω source terminals, whilethe voltmeter measures the dcvoltage drop across the gageresistance. The absolute resistancevalue is computed from the valuesof current and voltage by the DMMand displayed or output to acomputer. The lead resistances, Rl, from the Ω source terminals to thegage, are in series with the gageresistance, but do not affect theaccuracy of the measurement, sincethe voltage is read directly acrossthe gage. The input impedance tothe sense terminals is extremelyhigh, so the current flow in that loopis negligible. The source currentvalue is typically very low, whichmeans the power dissipated in thestrain gage is also very low, andself-heating effects are virtuallyeliminated. For example, 1 milliamp is a typical value for the source current, and thiscorresponds to a power dissipationof 120 microwatts in a 120 Ω gageor 350 microwatts in a 350 Ω gage.

A technique for voltage offsetcompensation can be used withfour-wire Ω measurements tocorrect for these effects. This isaccomplished by first measuring thevoltage across the gage withoutcurrent flow from the sourceterminals, and then subtracting thisvalue from the voltage read withsource current flow. The resultingnet voltage is then used to computethe gage resistance. Offsetcompensated four-wire Ωmeasurements can be madeautomatically by the DMM if it hasthat capability, or the offsetcompensation can be accomplishedby the computer controlling theinstrumentation.

To use four-wire Ω for measuringstrain, we first make a resistancemeasurement of the gage in theunstrained condition and store thisreading. Then we apply strain to thespecimen and make anothermeasurement of gage resistance.The difference between these tworeadings divided by the unstrainedreading is the fractional change inresistance that we use in the gagefactor equation to compute strain.Of course the DMM can input thesereadings directly to a computer,which calculates strain using thegage factor for the particular gage.This technique also lends itself tomultichannel systems, sincevariations in switch resistance in thecircuit have the same effect as leadresistances and do not affect theaccuracy of the measurement.

CONSTANT CURRENTTECHNIQUESIn the discussion of bridge circuits,we assumed that the bridgeexcitation was furnished by aconstant voltage source. We couldhave assumed constant currentexcitation for those discussions andderived the correspondingequations for strain as a function ofvoltage out and current supplied. Inthe example of Figure 19, the

constant voltage supply which isshared by multiple bridges cannotbe directly replaced by a constantcurrent source, since we wouldn’tknow how the current was dividedamong the various bridge circuits. In some cases, the bridge output ismore nearly linear when usingconstant current rather thanconstant voltage excitation, but thatis of little consequence if we solvean equation for strain versus outputvoltage with a computer. The use ofa constant current source for a full-bridge configuration does eliminatethe need to sense the voltage at thebridge, which eliminates the need torun two wires to the bridge. Ingeneral, there is no realmeasurement advantage to usingconstant current rather thanconstant voltage excitation forbridge circuits as applied to straingage measurements.

The four-wire Ω measurementdiscussed in the preceding sectionused a constant current source forexcitation, and we noted that thelead wires had no effect on themeasurement. That methodrequired four wires to be connectedto the gage. Constant currentexcitation is sometimes used with atwo-wire gage connection fordynamic strain measurementswhere temperature drift effects are

Figure 21: Constant Current Circuit Dynamic Strain Measurement

E-110

E

ST

RA

IN G

AG

ES

PRACTICAL STRAIN GAGE MEASUREMENTS

negligible or can be filtered out fromthe strain data. In the circuit ofFigure 21, changes in gageresistance result in proportionalchanges in VOUT. Note that VOUT isalso affected by changes in the leadresistances, Rl. By measuring onlythe time-varying component ofVOUT, the dynamic strain can beobserved, while slowly- changingeffects, such as temperature, arerejected.

The use of very sensitive DMM’s tomeasure the bridge imbalancevoltage or the gage resistancedirectly with four-wire Ω limits thespeed at which the measurementcan be taken, and only lowfrequency dynamic strains can bemeasured with these methods.Higher speed analog-to-digitalconverters typically have lowersensitivities, so higher signal levelsare needed when measuring higherfrequency dynamic or transientstrains. One way to achieve this isto amplify the bridge output voltageto an acceptable level. Anothermethod is to use a semiconductorstrain gage and exploit its largegage factor. A semiconductor gagecan be used in a bridge circuit (suchas Figure 19) with a DVM havinglower resolution and higher speedthan that required with metal gages.A semiconductor gage can also be

The results of this type of electricalinterference can range from anegligible reduction in accuracy todeviances that render the datainvalid.

THE NOISE MODELIn Figure 23, the shaded portionincludes a Wheatstone bridge straingage measuring circuit seenpreviously in Figures 15 and 17.The single active gage, Rg, is shownmounted on a test specimen — e.g.,an airplane tail section. The bridgeexcitation source, VIN, bridgecompletion resistors, R1 , R2 and R3,and the DVM represent themeasurement equipment located asignificant distance (say, 100 feet)from the test specimen. The straingage is connected to the measuringequipment via three wires havingresistance Rl in each wire. Theelectrical interference whichdegrades the strain measurement iscoupled into the bridge through anumber of parasitic resistance andcapacitance elements. In thiscontext, the term “parasitic” impliesthat the elements are unnecessaryto the measurement, are basicallyunwanted, and are to some extentunavoidable. The parasitic elementsresult from the fact that lead wireshave capacitance to other cables,gages have capacitance to the testspecimen, and gage adhesives andwire insulation are not perfectinsulators — giving rise to leakageresistance.

Examining the parasitic elements inmore detail, the active gage Rg isshown to be made up of two equalresistors with Ciso connected at thecenter. Ciso represents thecapacitance between the airplanetail section and the gage foil. Sincethe capacitance is distributeduniformly along the gage grid

used in a circuit similar to that forfour-wire Ω (see Figure 22). In thiscase, the current source and theDVM should be separateinstruments, to allow the currentlevel to be adjusted to obtain thebest output voltage for the expectedmaximum strain level.

The lead wires do not affect themeasurement, since the voltage, asin four-wire Ω, is measured directlyacross the gage. This arrangementalso allows the use of a lesssensitive, higher speed DVM whilemaintaining reasonable strainresolution. For example, a DVMwith 100 microvolt sensitivity gives astrain resolution of 6 with a0.44 milliamp current source (350 Ω semiconductor gage with GF = 100).RACTICALSTRAINEASUREMESHIELDING AND GUARDINGINTERFERENCE REJECTIONThe low output level of a strain gagemakes strain measurementssusceptible to interference fromother sources of electrical energy.Capacitive and magnetic coupling tolong cable runs, electrical leakagefrom the specimen through the gagebacking, and differences ingrounding potential are but a few ofthe possible sources of difficulty.

Figure 22: Circuit for Semiconductor Gage and High Speed Digital Voltmeter

E-111

PRACTICAL STRAIN GAGE MEASUREMENTS

length, we approximate the effect asa “lumped” capacitance connectedto the gage’s midpoint. Riso and Cisodetermine the degree of electricalisolation from the test specimen,which is often electrically groundedor maintained at some “floating”potential different than the gage.Typical values of Riso and Ciso are1000 megohms and 100 pF,respectively. Elements Cc and Rcrepresent the wire-to-wirecapacitance and insulationresistance between adjacent poweror signal cables in a cable vault orcable bundle. Typical values for Ccand Rc are 30 pF and 1012 Ω perfoot for dry insulated conductors inclose proximity.

The power supply exciting thebridge is characterized by parasiticelements Cps and Rps. A line-powered, “floating output” power

interference in a practical, industrialenvironment. Typical values for Cpsand Rps for floating output,laboratory grade power supplies are0.01 f and 100 megohms,respectively. It is important torealize that neither the measuringequipment nor the gages have been“ grounded” at any point. The entiresystem is “floating” to the extentallowed by the parasitic elements.

To analyze the sources of electricalinterference, we must first establisha reference potential. Safetyconsiderations require that thepower supply, DVM, bridgecompletion, etc., cabinets all beconnected to earth ground throughthe third wire of their power cords.In Figure 23, this reference potentialis designated as the measurementearth connection. The testspecimen is often grounded

supply usually has no deliberateelectrical connection between thenegative output terminal and earthvia the third wire of its power cord.However, relatively large amountsof capacitance usually existbetween the negative outputterminal circuits and the chassisand between the primary andsecondary windings of the powertransformer. The resistive elementRps is caused by imperfectinsulators, and can be reducedseveral decades by ioniccontamination or moisture due tocondensation or high ambienthumidity. If the power supply doesnot feature floating output, Rps maybe a fraction of an Ω. It will beshown that use of a non-floating orgrounded output power supplydrastically increases themechanisms causing electrical

Figure 23: Remote Quarter-Bridge Measurement Illustrating Parasitic Elements and Interference Sources

Rl

Rl

RlRg

Riso

CisoR3

R1

R2

Vcm

Cc

100 FT

DVM

RpsCps

VINVs

RcMeasurement Unit

Measurement EarthConnection

Adjacent Power or Signal Cable

++

––

++

––

+ –+ –

– +– +

E-112

E

ST

RA

IN G

AG

ES

PRACTICAL STRAIN GAGE MEASUREMENTS

(for safety reasons) to the powersystem at a point some distanceaway from the measurementequipment. This physical separationoften gives rise to differentgrounding potentials as representedby the voltage source Vcm. In somecases, functional requirementsdictate that the test specimen be“floated” or maintained many voltsaway from the power system groundby electronic power supplies orsignal sources. In either case, Vcmmay contain dc and time- varyingcomponents — most often at power-line related frequencies.

Typical values of Vcm, the commonmode voltage, range from millivoltsdue to IR drops in “clean” powersystems to 250 volts for specimensfloating at power-line potentials (forexample, parts of an electric motor).The disturbing source, Vs, is shown

measurement leads as a result ofthe source Vs. Negligible currentflows through the DVM because ofits high impedance. The currentsthrough Rg and Rl develop error-producing IR drops inside themeasurement loops.

In Figure 25, a shield surrounds thethree measurement leads, and thecurrent has been intercepted by theshield and routed to the point wherethe shield is connected to thebridge. The DVM reading error hasbeen eliminated. Capacitivecoupling from the signal cable tounshielded measurement leads willproduce similar voltage errors, evenif the coupling occurs equally to allthree leads. In the case where Vs isa high voltage sine wave powercable, the DVM error will besubstantially reduced if thevoltmeter integrates the input for a

connected to measurement earthand represents the electricalpotential of some cable in closeproximity (but unrelated functionally)to the gage wires. In manyapplications, these adjacent cablesmay not exist or may be so farremoved as to not affect themeasurement. They will be includedhere to make the analysis generaland more complete.

SHIELDING OFMEASUREMENT LEADSThe need for using shieldedmeasurement leads can be seen byexamining the case shown in Figure 24. Here, an insulation failure(perhaps due to moisture) hasreduced parasitic dc to a fewthousand Ω, and dc current isflowing through the gage

Figure 24: Current Leakage from Adjacent Cable Flows Through Gage Wires Causing Measurement Error

Rl

Rl

RlRg

Riso

Ciso

R3

R1

R2

Vcm

Cc

DVM

RpsCps

VINVs

Rc

++

––

++

––

+ –+ –

– +– +

E-113

PRACTICAL STRAIN GAGE MEASUREMENTS

entering the measurement loop viathe gage parasitic elements, Cisoand Riso. In the general case, bothac and dc components must beconsidered. Again, current flowthrough gage and lead resistancesresult in error voltages inside thebridge arms. Tracing either loopfrom the DVM’s negative terminal tothe positive terminal will revealunwanted voltages of the samepolarity in each loop. The symmetryof the bridge structure in no wayprovides cancellation of the effectsdue to current entering at the gage.

Whereas shielding kept error-producing currents out of themeasurement loop by interceptingthe current, guarding controlscurrent flow by exploiting the factthat no current will flow through anelectrical component that has bothof its terminals at the samepotential.

time equal to an integral number ofperiods (e.g., 1, 10, or 100) of thepower line wave form. The exactamount of the error reductiondepends upon the DVM’s normalmode rejection, which can be aslarge as 60-140 dB or 103:1 - 107:1.If the DVM is of a type having a veryshort sampling period, i.e., less than100 sec, it will measure theinstantaneous value of the dc signal(due to strain) plus interference.Averaging the proper number ofreadings can reduce the error dueto power line or other periodicinterference.

Where the measurement leads runthrough areas of high magneticfield, near high-current powercables, etc., using twistedmeasurement leads will minimizethe loop areas formed by the bridgearms and the DVM, thereby

reducing measurement degradationas a result of magnetic induction.The flat, three-conductor side-by-side, molded cable commonly usedfor strain gage work approaches theeffectiveness of a twisted pair byminimizing the loop area betweenthe wires. The use of shielded,twisted leads and a DVM whichintegrates over one or more cyclesof the power line wave form shouldbe considered whenever leads arelong, traverse a noisyelectromagnetic environment, orwhen the highest accuracy isrequired.

GUARDING THE MEASURING EQUIPMENTFigure 26 shows the error-producing current paths due to thecommon mode source, Vcm,

Figure 25: Addition of a Metal Shield Around the Gage Wires Keeps Current Due to Vs out of Measurement Leads

Rl

Rl

RlRg

Riso

Ciso

R3

R1

R2

Vcm

Cc

DVM

RpsCps

VINVs

RcMeasurement Unit

++

––

++

––

+ –+ –

– +– +

E-114

E

ST

RA

IN G

AG

ES

PRACTICAL STRAIN GAGE MEASUREMENTS

Figure 26: Error-Producing Common Mode Current Path

Figure 27

E-115

In Figure 27, a “guard” lead hasbeen connected between the testspecimen (in close proximity to thegage) and the negative terminal ofthe power supply. This connectionforces the floating power supply andall the measuring equipment —including the gage — to the sameelectrical potential as the testspecimen. Since the gage and thespecimen are at the same potential,no error-producing current flowsthrough Riso and Ciso into themeasuring loops. Another way ofinterpreting the result is to say thatthe guard lead provides an alternatecurrent path around the measuringcircuit. It should be observed that, ifthe power supply and the rest of themeasuring circuits could not floatabove earth or chassis potential,the guarding technique wouldreduce the interference by factors ofonly 2:1 or 4:1. Proper guardingwith a floating supply should yieldimprovements on the order of 105:1 or 100 dB.

In situations where it is possible toground the test specimen atmeasurement earth potential, thecommon mode source, Vcm, will beessentially eliminated.

EXTENSION TOMULTICHANNELMEASUREMENTSFigure 28 shows the extension ofthe guarding technique to a multi-channel strain gage measurementusing a shared power supply andinternal half-bridge completionresistors. For simplicity, only thecapacitive parasitic elements areshown. In ordinary practice,capacitive coupling is usually moresignificant and more difficult toavoid than resistive coupling. Forgenerality, we’ve used two testspecimens at different potentialswith respect to measurement earth.The switching shown in the figureallows simultaneous selection of the

DVM and the associated guardconnection.

Figure 29 illustrates the currentsflowing due to the specimenpotentials Vcm1 and Vcm2. Note that,regardless of which channel isselected, the guard line (alsofunctioning as the shield for thewires to the gage) keeps thecommon mode current out of thegage leads selected for themeasurement. Common modecurrent flows harmlessly throughthe gage leads of the unselectedchannel. It should be noted thateach lead wire shield is “grounded”at only a single point. The commonmode current through eachcombined guard and shield islimited by the relatively highimpedance of the parasitic elementCps, and should not be confusedwith the “heavy” shield currentwhich might occur if a shield weregrounded at both ends, creating a“ground loop”.

PRACTICAL STRAIN GAGE MEASUREMENTS

Figure 28: Multichannel Strain Measurement Including Two Separate Test Specimens

E-116

E

ST

RA

IN G

AG

ES

PRACTICAL STRAIN GAGE MEASUREMENTS

Figure 29: Multichannel Guard Switch Keeps Common Mode Current out of Selected Gage Leads

Figure 30: Unguarded Capacitance of Multiplexer and DVM Result in Measurement Error Due to Vcm2 of Selected Channel

Rg1 Ciso1

R1

R2

DVM

R31

Cps

VIN

++

––

++

––

– +– +

Vcm2

++

––

Vcm1

Ciso2

Rg2

DVM Switch

GuardSwitch

Cps

R32

E-117

PRACTICAL STRAIN GAGE MEASUREMENTS

CMR LIMITATIONSThe schematics and discussion ofguarding presented thus far mightconvey the impression that infiniterejection of common modeinterference is possible. It seemsreasonable to ask what, if anything,limits common mode rejection?Figure 30 includes a new parasiticelement, Cug, the unguardedcapacitance to chassis associatedwith the DVM and multiplexer. Inpractice, the DVM and multiplexerare usually realized as guardedinstruments [Reference 13]featuring three-wire switching andmeasurements, but the guardisolation is not perfect. Capacitanceranging from 15 pF to 20 f can befound between the instrument lowconnection and chassis. In Figure30, this capacitance causes aportion of the common modecurrent in the selected channel toflow through the internal half-bridgeresistors R1 and R2, giving rise to ameasurement error. In amultichannel system, all of theunselected channels (gages)sharing the same power supply also contribute current, but thiscurrent exits the bridge via thepower supply and returns throughthe guard wire, causing noadditional error.

In Figure 30, the ac interferencevoltage presented to the terminalsof the DVM causes an errorbecause the dc measuringvoltmeter does not totally reject theac. A DVM’s ability to measure dcvoltage in the presence of acinterference is called the normalmode rejection ratio (NMRR) and isusually stated for 50 and 60 Hzinterference.

A dc voltmeter’s NMRR is afunction of input filtering and theanalog-to-digital conversiontechnique employed.

Additionally, the DVM andmultiplexer system reject acinterference via guarding anddesign control of parasitics. Thequantitative measure of a system’sability to reject common mode acvoltage is the common moderejection ratio, (CMRR), defined as:

where Vcm and VDVM are bothsinusoids at the power-linefrequency of interest - 50, 60, or400 Hz. Note that VDVM is an acwave form presented to theterminals of a dc voltmeter. Thus,CMRR is an ac voltage transferratio from the common modesource to the DVM terminals.Caution must be exercised incomparing CMRR specifications toinsure that identical procedures areemployed in arriving at thenumerical result.

The overall figure of merit for ameasurement system is theeffective common mode rejectionratio (ECMRR), which reflects thesystem’s ability to measure dcvoltage (strain) in the presence ofac common mode interference. Ifall measurements same frequency,

and if the rejection ratios areexpressed in dB,

Thus, ECMRR describes how wellthe parasitics are controlled in thesystem and the samplingcharacteristics of the DVM, i.e.,integrating or instantaneoussampling.

Reference 10 provides additionalinformation on the subjects offloating, guarded measurementsand rejection ratios. Appendix Dcontains measurement sensitivitydata which can be used to computemeasurement error (in ) as afunction of DVM, power supply, andbridge completion resistorspecifications.

BRIDGE EXCITATION LEVELThe bridge excitation voltage levelaffects both the output sensitivityand the gage self-heating. From ameasurement standpoint, a highexcitation level is desirable, but a

lower level reduces gage self-heating. The electrical power in thegage is dissipated as heat whichmust be transferred from the gageto the surroundings. In order for thisheat transfer to occur, the gagetemperature must rise above that ofthe specimen and the air. The gage

Equation No. 16

NMRR = 20 log VNM (ac)

VDVM (dc)

Equation No. 17

CMRR = 20 log Vcm (ac)

VDVM (ac)

Equation No. 18

EMCRR = CMRR x NMRR

ac interference = ac interference x ac @DVM

dc response error ac @DVM dc response error

transmission dc voltmetervia parasitics response toand guarding ac input

Equation No. 19

ECMRR(dB) = CMRR(dB) + NMRR(dB)

E-118

E

ST

RA

IN G

AG

ES

through the gage, and V is thebridge excitation voltage. FromEquation 20, we see that loweringthe excitation voltage (or gagecurrent) or increasing the gageresistance will decrease powerdissipation. Where self-heating maybe a problem, higher values of gageresistance should be used. Table 3illustrates the relationship betweenvoltage, gage resistance and powerdissipation.

The temperature rise of the grid isdifficult to calculate because manyfactors influence heat balance.Unless the gage is submerged in aliquid, most of the heat transfer willoccur by conduction to thespecimen. Generally, cooling of thegage by convection is undesirablebecause of the possibility of creatingtime-variant thermal gradients onthe gage. These gradients cangenerate voltages due to thethermocouple effect at the lead wirejunctions, causing errors in thebridge output voltage. Heat transferfrom the gage grid to the specimenis via conduction. Therefore, thegrid surface area and the materialsand thicknesses of the carrier andadhesive influence gagetemperature. The heat sinkcharacteristics of the specimen arealso important.

temperature is therefore a functionof the ambient temperature and thetemperature rise due to powerdissipation.

An excessive gage temperature cancause various problems. The carrierand adhesive materials will nolonger be able to transmit strainfaithfully from the specimen to thegrid if the temperature becomes toohigh. This adversely affectshysteresis and creep and may showup as instability under load. Zero orunstrained stability is also affectedby high gage temperature.Temperature-compensated gagessuffer a loss of compensation whenthe temperature difference betweenthe gage grid and the specimenbecomes too large. When the gageis mounted on plastics, excessivepower dissipation can elevate thetemperature of the specimen underthe gage to the point that theproperties of the specimen change.

The power that must be dissipatedas heat by the gage in a bridgecircuit with equal resistance arms isgiven by the following equation:

where P is the power in watts, Rg isthe gage resistance, I is the current

POWER DENSITY is a parameterused to evaluate a particular gagesize and excitation voltage level fora particular application. Powerdensity is the power dissipated bythe gage divided by the gage gridarea, and is given in units ofwatts/in2. Recommended values ofpower density vary, depending uponaccuracy requirements, from 2-10for good heat sinks (such as heavyaluminum or copper sections), to0.01-0.05 for poor heat sinks (suchas unfilled plastics). Stackedrosettes create a special problem, inthat the temperature rise of thebottom gage adds to that producedby the two gages above it, and thatof the center gage adds to the topgage’s. It may require a very lowvoltage or different voltages foreach of the three gages to maintainthe same temperature at each gage.[6 ]

One way we can determine themaximum excitation voltage thatcan be tolerated is by increasing thevoltage until a noticeable zeroinstability occurs. We then reducethe voltage until the zero is oncemore stable and without asignificant offset relative to the zeropoint at a low voltage. Bridgecompletion resistors also dissipatepower and in practice may be moresusceptible to drift from self-heatingeffects than the strain gage. Thestability of the bridge completionresistors is related to load-life, andmaintaining only a fraction of ratedpower in them will give better longterm stability. If the above method offinding the maximum voltage level isused, care should be exercised toinsure that the power rating of thecompletion resistors is notexceeded as the voltage isincreased.

Reducing the bridge excitationvoltage dramatically reduces gagepower, since power is proportional

PRACTICAL STRAIN GAGE MEASUREMENTS

STRAIN GAGE POWER DISSIPATIONBRIDGE GAGE POWER IN MILLIWATTS

EXCITATIONVOLTAGE 1000 Ω 500 Ω 350 Ω 120 Ω

0.1 0.0025 0.005 0.007 0.0210.2 0.010 0.020 0.029 0.0830.5 0.0625 0.125 0.179 0.5211.0 0.250 0.500 0.714 2.0832.0 1.000 2.000 2.857 8.3333.0 2.250 4.500 6.429 18.7504.0 4.000 8.000 11.429 33.3335.0 6.250 12.500 17.857 52.08310.0 25.000 50.000 71.400 208.300

Equation No. 20

P = V2/4Rg = (I2)Rg

Table 3

E-119

PRACTICAL STRAIN GAGE MEASUREMENTS

to the square of voltage. However,bridge output voltage is proportionalto excitation voltage, so reducing itlowers sensitivity. If the DVM usedto read the output voltage has1 microvolt resolution, 1 micro-strainresolution can be maintained with a1⁄4 bridge configuration, using a 2 voltbridge excitation level. If the DVMhas 0.1 microvolt resolution, theexcitation voltage can be lowered to0.2 volts while maintaining the samestrain resolution. From Table 3 wesee that, at these excitation levels.the power dissipated by a 350 ohmgage goes from 2.857 to 0.029milliwatts. Thus, using a sensitiveDVM for measuring the bridgeoutput permits the use of lowexcitation voltages and low gageself-heating while maintaining goodmeasurement resolution.

The four-wire Ω technique is also agood way to keep the power in thegage extremely low. This is due tothe low value of constant currentsupplied to the gage by the DMM,typically 1 milliamp. This current (1 milliamp) corresponds to a powerdissipation of 0.12 milliwatts in a 120 Ω gage and 0.35 milliwatts in a350 Ω gage. With four-wire Ω, agage is energized only when it isselected and is actually beingmeasured by the DMM. Asmentioned previously, resolution willbe lower using four-wire Ω than witha bridge, but will be adequate formany applications.

LEAD WIRE EFFECTSIn the preceding chapter, referencewas made to the effects of lead wireresistance on strain measurementfor various configurations. In abridge circuit, the lead wireresistance can cause two types oferror. One is due to resistancechanges in the lead wires that are

indistinguishable from resistancechanges in the gage. The othererror is known as LEAD WIREDESENSITIZATION and becomessignificant when the magnitude ofthe lead wire resistance exceeds0.1% of the nominal gageresistance. The significance of thissource of error is shown in Table 4.

If the resistance of the lead wires isknown, the computed values ofstrain can be corrected for LEADWIRE DESENSITIZATION. In aprior section, we developedequations for strain as a function ofthe measured voltages for a 1⁄4bridge configuration:

These equations are based on theassumptions that Vr is due solely tothe change in gage resistance,Rg, and that the total resistance ofthe arm of the bridge that containedthe gage was Rg. Referring toFigure 32, we see that one of thelead wire resistances, Rl, is inseries with the gage, so the total

resistance of that bridge arm isactually Rg + Rl. If we substitute thisinto Equation 14, it becomes:

Rewriting the equation to solve forstrain, we see that the previousstrain equation is in error by a factorof the ratio of the lead wireresistance to the nominal gageresistance.

This factor is lead wiredesensitization, and we see fromEquation 22 and from Table 4 thatthe effect is reduced if the lead wireresistance is small and/or thenominal gage resistance is large. Ifignoring this term (1 + Rl/Rg) willcause an unacceptable error, then itshould be added to the computerprogram such that the strains

computed in Equation 15 aremultiplied by this factor. Appendix Bgives the equations for variousbridge configurations and the leadwire resistance compensation termsthat apply to them. Appendix A hasa table containing the resistance, atroom temperature, of somecommonly used sizes of copperwire.

LEAD WIRE DESENSITIZATION(REFER TO FIGURE 32)

1⁄4 AND 1⁄2 BRIDGE, 3-WIRE CONNECTIONS

AWG Rg = 120 Ω Rg = 350 Ω18 .54% .19%20 .87 .3022 1.38 .4724 2.18 .7526 3.47 1.1928 5.52 1.8930 8.77 3.01

Magnitudes of computed strain values will below by the above percent per 100 feet of hard drawn solid copper lead wire at 25°C (77°F)

Table 4

Equation No. 14

Rg =

-4Vr

Rg (1 + 2Vr)Equation No. 15

=-4Vr

GF(1 + 2Vr )

Equation No. 21

Rg =

-4Vr Rg + Rl Rg

(1 + 2Vr )( Rg

)

Equation No. 22

=-4Vr Rl

GF(1 + 2Vr ) • (1 +

Rg)

Error Term

E-120

E

ST

RA

IN G

AG

ES

PRACTICAL STRAIN GAGE MEASUREMENTS

The most common cause ofchanges in lead wire resistance istemperature change. The copperused for lead wires has a nominaltemperature coefficient ofresistance, at 25°C/77°C, of0.00385 Ω/Ω °C. For the 2-wirecircuit in Figure 31, this effect willcause an error if the temperatureduring the unstrained reading isdifferent than the temperatureduring the strained reading. Erroroccurs because any change inresistance in the gage arm of thebridge during this time is assumedto be due to strain. Also, both leadwire resistances are in series with

the gage in the bridge arm, furthercontributing to the lead wiredesensitization error.

The THREE-WIRE method ofconnecting the gage, shown inFigure 32, is the preferred methodof wiring strain gages to a bridgecircuit. This method compensatesfor the effect of temperature on thelead wires. For effectivecompensation, the lead wires musthave approximately the samenominal resistance, the sametemperature coefficient ofresistance and be maintained at thesame temperature. In practice, this

is effected by using the same sizeand length wires and keeping themphysically close together.

Temperature compensation ispossible because resistancechanges occur equally in adjacentarms of the bridge and, therefore,the net effect on the output voltageof the bridge is negligible. Thistechnique works equally well for 1⁄4and 1⁄2 bridge configurations. Thelead wire desensitization effect isreduced over the two-wireconnection because only one leadwire resistance is in series with thegage. The resistance of the signalwire to the DVM doesn’t affect the

Figure 31: Two-Wire 1⁄4 Bridge Connection

Figure 32: Three-Wire 1⁄4 Bridge Connection

E-121

PRACTICAL STRAIN GAGE MEASUREMENTS

measurement, because the currentflow in this lead is negligible due tothe high input impedance of the DVM.

Mathematical correction for leadwire desensitization requires thatthe resistances of the lead wires beknown. The values given in wiretables can be used, but, for extremetemperatures, measurement of thewires after installation is required forutmost accuracy. Two methods forarriving at the resistance of the leadwires from the instrumentation sideof the circuit in Figure 32 follow:

(1) If the three wires are the samesize and length, the resistancemeasured between points A andB, before the wires areconnected to theinstrumentation, is 2Rl.

(2) Measure the voltage from A-B(which is equivalent to B-C) andthe voltage from B-D. Since R3is typically a precision resistorwhose value is well known, thecurrent in the C-D leg can becomputed using Ohm’s Law.This is the current that flowsthrough the lead resistance, sothe value of Rl can becomputed, since the voltagefrom B-C is known. Theequation for computing Rl is:

These measured values for leadresistance should be retained forlater calculations.

DIAGNOSTICSTo insure strain data that is as error free as possible, variousdiagnostic checks can be performed

on the gage installation andinstrumentation. In a stress analysisapplication, the entire gageinstallation can’t be calibrated ascan be done with certaintransducers. Therefore, potentialerror sources should be examinedprior to taking data.

MOUNTED GAGERESISTANCEThe unstrained resistance of thegage should be measured after thegage is mounted but before thewiring is connected to theinstrumentation. This test will helpidentify gages that may have beendamaged during installation. Underlaboratory conditions with room-temperature curing adhesives, themounted resistance value of metalfoil gages will usually fall within thepackage tolerance range for thegage. Under field conditions, theshift in gage resistance will usuallybe less than 2%. Greater shifts mayindicate damage to the gage. Thefarther the gage resistance valuedeviates from the nominal value, thelarger the unstrained bridge outputvoltage. This limits the strain rangeat maximum resolution when usingthe unbalanced bridge technique.The easiest, most accurate way tomeasure this resistance is with thefour-wire Ω function of a DMM.

GAGE ISOLATIONThe isolation resistance from thegage grid to the specimen, if thespecimen is conductive, should alsobe measured before connecting thelead wires to the instrumentation.This check should not be made witha high-voltage insulation tester,because of possible damage to thegage, but rather with an ohmmeter.A value of isolation resistance of