PPT on Mini Water Supply Scheme

-

Upload

arvind-kumar -

Category

Documents

-

view

66 -

download

5

Transcript of PPT on Mini Water Supply Scheme

1

Public Health Engineering Department, Govt of Bihar

Brief Overviewof

The Project

Construction of Mini Piped Water Supply Schemes with provision of suitable Treatment

Technology and solar pumps in Fluoride affected

habitations in Bihar

Arvind Kumar ( DFID- SWASTH)

Ground water is perhaps the most accepted source particularly in areas where safe and dependable surface water sources are not available within easy reach or not available at all.

Ground water is generally considered as a safe source but in recent times research and investigations have shown that quality of ground water has deteriorated at many locations thus making it unfit for use for human consumption. In Bihar excessive levels of arsenic and fluoride in ground water have been noticed in many areas.

Public Health Engineering Department, being conscious of this serious problem has decided to install small water purification plants for treating ground water drawn through tube wells and supplying the treated safe water local through stand posts to the consumers.

2

Objective of Scheme

SALIENT FEATURES OF THE SCHEME

• Capacity of Plant. - 40000 liters /day

• Borewell Discharge 5100/6000 liters/Hr• Benefitted Population – 1000• Per Capita per day Supply of Water- 40 liters• Operation Time of Plant /day - 8 Hours• Capacity of Overhead tank - 5000 liters • Genset for Non Sun days Operation.• Use of rustproof vessels & pipes. • Three Months Trial Run , & thereafter Six Months of O& M

3

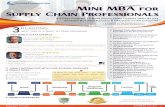

SEQUENCE OF THE PROJECT CONSTRUCTION

Marking of land

Bore well Construction

Testing of Raw water

Commencement of Civil Work

Completion of Civil Work

Solar Panel Installation

Pipe line & Stand Post Plant Installation

Commencement of Trial Run

Site Selection

5

MAJOR COMPONENTS OF THE PROJECT

SITE DEVELOPMENT & BOUNADRY WALL

WATER (BOREWELL)

TREATMENT PLANT BUILDING

ENERGY (SOLAR SYSTEM)

TREATMENT UNIT

DISTRIBUTION SYSTEM

STAND POSTS

SITE DEVELOPMENT & BOUNDARY WALL

• Plant Building

• Boundary Wall

• Storage System

• Gate

• Approach Road

• Landscaping

6

7

TubewellSchematic Drawing

BUILDING

One R.C.C/ Brick Masonary housing Treatment Plant and auxiliary units. The building has one room Treatment Plant, one room for Operator , one store and one Toilet with necessary facilities

8

Solar System

9

Submersible PumpSecurity features:

• Protection against dry running• Protection from Over/Under

Voltage• Protection from Overload• Protection from Over Temperature

Solar PV module array is of high efficiency Solar Modules utilizing Crystalline Silicon Solar PV cells. The modules are warranted for power output conforming to IEC-61215, ISPRA Italy, IECQ (PV-GAP), MNES & BIS standards.

10

WATER TREATMENT PLANT

SOLAR OPERATED PUMP

OXIDATION CHAMBER

IRON REMOVAL FILTER

ALUM DOSER

FLUORIDE/ ARSENIC REMOVAL UNIT

CONTROL PANEL

SEQUENCE OF TREATMENT PROCESS

PUMPED BY SOLAR PUMP

OXIDATION CHAMBER

IRON REMOVAL FILTER

ALUM DOZER

FLUORIDE REMOVAL FILTER

OVER HEAD TANK

POTABLE WATER AT STANDPOSTFOR VILLAGERS

DISTRIBUTION SYSTEM

Raw water

12

The Treatment System

FLUORIDEREMOVAL FILTER

IRON REMOVAL FILTER

OXIDATION CHAMBER

ALUMDOSINGUNIT

Treatment Plant : A Overview

Components of Treatment Plant…….

• One cylindrical MS/ FRP Vessel (400 mm dia X 1200 mm) filled with media

• For oxidizing & removal of Iron from raw water.

• The high oxidizing capacity catalytic media is Manganese Dioxide Granules – 12 mm to 25 mm (Natural Mineral) for oxidizing iron in raw water for its quick precipitation in IRF.

• The system provides for auto backwash of the filter bed.

• No regular maintenance required only media needs to be replaced once in a year

13

Contd…

Oxidation Chamber :

14

Iron Removal Filter (IRF)

Components of Treatment Plant.

Contd…

Process Flow Diagram:

One cylindrical FRP Vessel (Size – 36” x 72”) with Top & Bottom distribution Kit, Air valve & 1.5" Side Mounted Multiport Valve (MPV-F).(Opening Pressure - 4–10 Bar)The vessel is filled with gravel, course sand and green sand (natural mineral) for further oxidation of residual iron and also filtration of water to make it free from precipitated and deposited iron on filter bed. The media needs to be replaced once in a year

• The Iron Removal Filter (IRF) and the Fluoride Removal Filter (FRF) are equipped with a Multiport Filter Valve (MPV-Filter type) and a Multiport Softener Valve (MPV-Softener type) respectively.

15

Components of Treatment Plant…….

• The Multiport Valve (MPV) controls the flow of water through the granular media of a filter. The handle on top of the MPV can be set at any of the slotted positions to select the necessary function of the valve.

Contd…

Multiport Valve :

16

Components of Treatment Plant…….

Contd…

Alum Dosing System

This purpose of this unit is for pH correction for adjustment of pH of water to the range of 5.5 to 6.5 to suit filtering media in FRF/ARF

The system comprises of 8 gallons capacity MS Cast vessel with 50 mm Ventury fitted with PVC flexible pipes and brass taps

It operates automatically and hydraulically for direct dosing of saturated alum solution

No regular maintenance required other than replenishing of chemical once it gets consumed.

17

Components of Treatment Plant…….

Contd…

Fluoride Removal Filter/ Media

• . One cylindrical FRP Vessel (Size – 36” x 72”) with Top & Bottom distribution Kit, air valve & 1.5" Side Mounted Multiport Valve (Opening Pressure : 4–10 Bar).

• The vessel is filled with gravel, course sand and Activated Alumina Grade AAFS50. (Certified by M/S Alcan U.S.A)

• It works on adsorption principle• The greater adsorptive capacity of

Activated Alumina AAFS50 makes it economical for one-time use and disposal.

• Spent material has met the Toxicity characteristic leaching procedure U.S.A (TCLP) and California Waste Extraction Test ( WET)Test

• Media Life 15/ 18 Months( expected ) depending on the concentration of Fluoride in raw water

• Backwash of Media Once a Month

18

Components of Treatment Plant…….

Contd…

Internal Piping of the Treatment Plant :uPVC Pipes and Fittings have been used as:

uPVC pipes being lead free so are non-toxic and hence favoured for use in applications such as potable water pipes. Selected and used

Do not corrode and are totally unaffected by Acids, Alkalies and electrolytic corrosion from any source

Have extremely smooth bore due to which frictional losses are at minimum and flow rates are at the highest possible from any other pipe materials

Low friction loss & UV Resistant

Due to smoothness of inner surface of the pipe, it prevents Algai, Bacteria and Fungi Formation inside the pipe

Solvent joint plumbing system makes its pressure bearing capacity twice than that of the threaded pipe

The established aging factor of the commonly used pipe are not applicable on uPVC Pipe thus providing a very long life.

19

Distribution Network System…….

Contd…

Distribution Network comprises of GI pipes of diameters ranging between 65mm to 20mm, covering an approximate total length of 1000 metres conforming to relevant standard and specification in trenches.

20

Distribution Network System…….

Contd…

The system also includes 8 nos. of Stand Posts located at strategic points of the villages. The water being supplied from the overhead tank constructed on the roof of the treatment plant building.

INNOVATIONS

Unique & compact building design to meet the specific purposes of rural water supply scheme

Use of latest technology for vessels and internal plumbing to reduce maintenance yet provide reliability and strength

Solar panels requires minimum maintenance .

21

• Village-Kolakhurd ,Block-Jagdishpur

04/18/23

Village-Jogibeer,Block-Jagdishpur

22

• Village –Rannuchak-1,Block-Nathnagar

Village-Rannuchak-2,Block-Nathnagar

23

• Village-Makandpur-1,Block-Sultanganj

04/18/23

Village-Makandpur-2,Block-Nathnagar

24