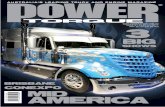

PowerTorque Issue 46

-

Upload

motoring-matters-magazine-group -

Category

Documents

-

view

231 -

download

0

description

Transcript of PowerTorque Issue 46

ISS

UE

46 AP

RIL / M

AY 2012

ww

w.pow

ertorque.com

.auIS

SU

E 46

April /

May 2

01

2R

RP: $

7.9

5 (N

Z $

8.9

5)

AUSTRALIA’S LEADING TRUCK AND ENGINE MAGAZINE

POW

ERST

AR R

OAD

TRAI

N

FEATURE

22 PowerTorque ISSUE 46

THE

LEAGUEBIGDAF’s

DAF moves from being a mid-field player to the front row

flagship truck, the XF105, is the highlight of this year’s new product releases, as it substantially increases the ability of the PACCAR group of Kenworth and DAF to take on all comers.

The XF105 has achieved an almost iconic status in the United Kingdom, where it is renowned for its ability to attract and keep new drivers for transport companies, at a time when driver availability, worldwide, is known to be a problem.

When launched onto the European market in 2007, the XF105 immediately gained the accolade of International Truck of the Year, voted by a panel of specialist transport media, achieving recognition for providing the most spacious cab in its class.

For an industry, where the driver travels across Europe relying on the cab to provide the highest levels of comfort, the

DAF XF105 offers a degree of spaciousness that underpins its attraction.

The Space Cab stands some 1,885 mm, from road to roof, offering an internal standing height of 1,735 mm, within a width of 2,490 mm and a depth of 2,250 mm. The lower bunk width is 810 mm, with a length of 2,100 mm, and, with twin bunks fitted, there’s a 555 mm and 550 mm distance between the two mattresses.

The Super Space Cab version stands some 2,255 mm, from road to roof, offering an internal standing height of 2,105 mm. When fitted with twin bunks, the bunk spacing is 810 mm from lower mattress to upper bunk, and 615 mm from upper bunk mattress to roof.

There are high levels of storage space around the cab, in over-windshield lockers and under the lower bunk, as well as in the door pockets. There’s room for a microwave in the centre locker above the windscreen, and for those who want to practise their role in MasterChef, there’s a slide out table

FEATURE

22 PowerTorque ISSUE 46

THE

LEAGUEBIGDAF’s

DAF moves from being a mid-field player to the front row

flagship truck, the XF105, is the highlight of this year’s new product releases, as it substantially increases the ability of the PACCAR group of Kenworth and DAF to take on all comers.

The XF105 has achieved an almost iconic status in the United Kingdom, where it is renowned for its ability to attract and keep new drivers for transport companies, at a time when driver availability, worldwide, is known to be a problem.

When launched onto the European market in 2007, the XF105 immediately gained the accolade of International Truck of the Year, voted by a panel of specialist transport media, achieving recognition for providing the most spacious cab in its class.

For an industry, where the driver travels across Europe relying on the cab to provide the highest levels of comfort, the

DAF XF105 offers a degree of spaciousness that underpins its attraction.

The Space Cab stands some 1,885 mm, from road to roof, offering an internal standing height of 1,735 mm, within a width of 2,490 mm and a depth of 2,250 mm. The lower bunk width is 810 mm, with a length of 2,100 mm, and, with twin bunks fitted, there’s a 555 mm and 550 mm distance between the two mattresses.

The Super Space Cab version stands some 2,255 mm, from road to roof, offering an internal standing height of 2,105 mm. When fitted with twin bunks, the bunk spacing is 810 mm from lower mattress to upper bunk, and 615 mm from upper bunk mattress to roof.

There are high levels of storage space around the cab, in over-windshield lockers and under the lower bunk, as well as in the door pockets. There’s room for a microwave in the centre locker above the windscreen, and for those who want to practise their role in MasterChef, there’s a slide out table

THE BIG LEAGUE

PowerTorque ISSUE 46 23

from the dashboard that suits anyone sitting on the lower bunk. And, while on the subject of bunks, these have full 150 mm thick, pocket sprung mattresses.

Electrically heated and power adjusted mirrors give a great rear vision, plus there’s the added safety of a kerb-side mirror to spot cyclist and pedestrians in the city. The standard headlamp system is halogen with a Lexan lens to prevent stone damage, but Xenon headlamps are available as an option.

In terms of active safety, as you’d expect from a class-leading European specification, it’s all there for those who tick the right boxes. Systems such as Vehicle Stability Control

(VSC), Lane Departure Warning System (LDWS), Electronic Braking Systems (EBS), Adaptive Cruise Control (ACC), and Forward Collision Warning (FCW) are all available.

Passive safety also plays a major role in minimising accident risk, and the cab structure features an integral steel safety cage and provides knee protection for the driver and passenger. Three-point seat belts are integrated into the air-suspended seats. There’s also an airbag SRS in the steering wheel, and, if triggered, this also activates automatic seat belt tensioning.

Given that the Europeans are very big on spreading salt over their roads in winter, DAF has paid considerable attention to corrosion protection. The cab sheet metal is of double-sided, hot-dipped, galvanized steel for inner and outer panels, the cab rear wall and various brackets and sections in exposed areas. The metal parts are degreased during cab assembly and treated with zinc phosphate before receiving a cataphoretically applied primer, followed by a filler coat. The underbody is treated to a PVC-coating and then the entire body is painted in a two-component polyurethane topcoat. Finally, wax fluid is sprayed into box sections and cavities for added protection.

The heart of the truck is, of course, the engine, and here, the 12.9-litre PACCAR MX comes with an already proven track record. In the XF 105, this engine has a horsepower output of 510 hp, providing a torque rating 2,500 Nm through from 1,000 to 1,410 rpm. For Euro V emissions ratings and EEV exhaust gas emissions standards, the engine uses SCR (Selective Catalytic Reduction), requiring the addition of AdBlue/DEF (Diesel Exhaust Fluid).

In January 2010, PACCAR, the parent company of DAF, Kenworth and Peterbilt, announced the introduction of the PACCAR MX engine to be installed in Kenworth and Peterbilt trucks built in the United States.

This decision effectively changed the way that PACCAR does business, and heralded in the first signs of vertical integration, where the truck maker also manufactures their own engine, and, in some cases, gearboxes and axles.

Initially, the first MX engines for the United States market came from the DAF engine plant in Holland, but, as we featured in PowerTorque last year (June 2011), engine supply soon came on stream from the PACCAR engine plant in Columbus, Mississippi, which was built uniquely for the MX engine production.

Australian operators will be seeing much more of the MX engine in coming years, and it won’t just be confined to DAF product. The move in technical development, globally, is towards an increasing dominance of 13-litre engines, and our own market for Kenworth products will also be adopting the PACCAR MX engine, while remaining with the Cummins engine range as an alternative option.

Over 125,000 PACCAR MX engines are successfully operating in DAF trucks, globally. It already meets the United States’ Environmental Protection Agency’s (EPA) 2010 emissions regulations and has accumulated over 50 million test miles in rigorous and severe conditions in North America. PACCAR pioneered the design and manufacture of high-strength compacted graphite iron (CGI) used in the MX

PROFILE

30 PowerTorque ISSUE 46

DUBBOCELEBRATION

It

Thompson Bros. Transport enjoys its 50th anniversary with a new logo

and a positive future As truck makes and models developed more

competitively, Thompson Bros. Transport added Western Star Constellation 4800 Series prime movers into a mixed fleet, and they remain today an effective and reliable product that works mainly on the road train and B-double operations.

“The 4800 Series has proven to be ideal for what we do, giving us the flexibility to run as a pocket B-double at 19 metres, and as a full 26-metre FUPS approved B-double,” said Mark.

“It’s also strong enough to run in a road train operation, and it’s not over specified or too heavy if you want to run it with a single semi-trailer. It’s a good looking truck, and the

drivers like the ride, handling and comfort levels of a conventional,” he added.

was back in 2007 that PowerTorque last visited Mark Thompson at Thompson Bros. Transport, the company founded by his father and uncle, Noel and Harold, in Dubbo, NSW.

The two brothers had started the business from scratch and today it remains in the Thompson family, under the control of Mark and his brother Steven.

In the earlier days of the business, the familiar orange and brown Macks were a regular sight on Australian highways as they carted livestock, and then expanded to carry general freight, fuel and LPG.

A rationalisation of the business back in 1995, as a result of changes in the industry, saw the company sell off the livestock and fuel cartage side of the business to what was then Finemore’s Transport. That timing also coincided with the decision to change the company livery to the current white and orange in use

today, and for the company’s area of specialisation to

stay firmly with that of general freight.

PROFILE

30 PowerTorque ISSUE 46

DUBBOCELEBRATION

It

Thompson Bros. Transport enjoys its 50th anniversary with a new logo

and a positive future As truck makes and models developed more

competitively, Thompson Bros. Transport added Western Star Constellation 4800 Series prime movers into a mixed fleet, and they remain today an effective and reliable product that works mainly on the road train and B-double operations.

“The 4800 Series has proven to be ideal for what we do, giving us the flexibility to run as a pocket B-double at 19 metres, and as a full 26-metre FUPS approved B-double,” said Mark.

“It’s also strong enough to run in a road train operation, and it’s not over specified or too heavy if you want to run it with a single semi-trailer. It’s a good looking truck, and the

drivers like the ride, handling and comfort levels of a conventional,” he added.

was back in 2007 that PowerTorque last visited Mark Thompson at Thompson Bros. Transport, the company founded by his father and uncle, Noel and Harold, in Dubbo, NSW.

The two brothers had started the business from scratch and today it remains in the Thompson family, under the control of Mark and his brother Steven.

In the earlier days of the business, the familiar orange and brown Macks were a regular sight on Australian highways as they carted livestock, and then expanded to carry general freight, fuel and LPG.

A rationalisation of the business back in 1995, as a result of changes in the industry, saw the company sell off the livestock and fuel cartage side of the business to what was then Finemore’s Transport. That timing also coincided with the decision to change the company livery to the

current white and orange in use today, and for the company’s

area of specialisation to stay firmly with that of

general freight.

DUBBO CELEBRATION

PowerTorque ISSUE 46 31

DUBBO “The Volvo’s are only rated for B-double work, and, if you run them on road train application, you shorten their warranty support from four years back to two years,” said Mark.

“The decision to include the Volvo product follows our belief the company has completed more research in engineering performance to suit our environment, and sealed-for-life joints are just one example of this. The comfort involved in the Volvo is a major contributor to a reduction of fatigue in our drivers, and this is obviously also of major importance to us,” said Mark. The Volvos are returning excellent tyre life reports, with 170,000 km for steer tyre life becoming a normal experience. All tyres used are Bridgestone, with the 150s on the steer axle and 722s on the drive axles. The fleet policy is to use new tyres throughout both the prime mover and trailer fleet, and not to use re-caps in any position.

The company has recently standardised on using Vawdrey curtainsider trailers, and these run with PBR electrical connections and Jost fifth-wheel couplings. “We are now looking at the safety benefits of fitting electronic braking systems with roll stability as part of an electronic stability programme. This is the next natural progression for improving safety levels for drivers and other road users,” said Mark.

The road train operation between Brisbane and Dubbo is typical of the approach by the company to operating a transport system with minimum fatigue. There are three drivers staged at different locations that combine to complete the run. The first driver handles the Dubbo to Warwick leg, the second driver takes the Warwick to Brisbane and return to Warwick stage, whereupon the original first driver, having completed his rest periods, then takes the road train back from Warwick to Dubbo. Driver number three covers the onward movement to Bathurst or Orange and return.

“This type of roster keeps the truck running while enabling us to stay well within fatigue legislation,” said Mark.

“With seven B-doubles and four road trains, the remainder of our fleet operates with single trailers. We then augment our fleet with tow operators, using 14 drivers plus general contractors. We encourage our tow operators to run their vehicles in our company livery,” added Mark.

The celebration of the company’s 50th year in transport coincided with the delivery of a new Western Star, this time featuring the first Detroit Diesel DD15 engine in the fleet.

“We have worked with David Rice and the team at Rice Graphics, in Wodonga, to develop a new logo to commemorate our 50 years in transport,” said Mark.

“The new Western Star is the first application for the new logo, and we are teaming it with a brand new Vawdrey trailer which, will be used for road train work.

There are now twelve Western Star 4800 prime movers and each is powered by the Detroit Diesel Series 60 engine at 505 hp with EGR and VGT (Exhaust gas Recycling and Variable Geometry Turbocharging).

“Originally, we ran Caterpillar C15s at 550 hp and two CAT C12s running at 430 hp within the prime mover fleet, but the Detroit Diesels proved to be much more fuel efficient.

“Fuel economy is obviously something we watch very closely. The Detroits have been returning over 2.0 km/litre in single semitrailer work, and, when running as a B-double, this figure has been stable at 1.5-1.7 km/litre.

“In recent years we have also added Volvo prime movers to the fleet and have subsequently gained further improvements in fuel economy.

“In B-double application, the Volvos have improved our fuel economy to a regular consumption rate of 1.9-1.98 km/litre. But it’s with single trailer operation that we have noticed the most improvement, achieving 2.5-2.9 km/litre,” said Mark.

The lower running costs of the Volvos are obviously contributing to a better bottom line for Thompson Bros. Transport, and the savings continue beyond that of fuel economy. Unlike the service schedules for the Western Star, involving oil drain intervals at 20,000 km, the Volvo servicing is completed at between 40,000-60,000 km periods, dependent on the vehicle application.

“There are other advantages with the Volvos – as there are no grease points, all joints are sealed for life. It’s also an advantage having disc brakes on the Volvos, although we are currently staying with drum brakes on our trailers. Our Western Stars also run with a drum brake fitment,”

added Mark.

The company is these days running a two-trailer road train

operation on a daily basis between Dubbo and Warwick, in

Queensland, and it’s here the Western Stars come into their own.

Images by Rob Lacey Photography

PROFILE

34 PowerTorque ISSUE 46

CAT

Graham

There’s a definite change of attitude amongst operators testing the water with a new Cat truck

Parsons is a typical truckie. With an abundance of white hair and a smile that shows he’s got the patience and understanding that comes with coping with whatever the road transport industry can throw at him, he knows what he likes. He’s also prepared to tell anyone what he thinks, and with many operators wanting to know how the new Cat trucks are going in service, what he thinks, is what we want to know.

Graham works for Lara, Victoria, based transport operator Malec Bros. Transport. This is a family-operated business that is growing strongly from its original roots some 16 years ago, when it handled general freight haulage, to the present day where it has also diversified into container transport and logging.

Ordinarily, we would discuss trucks first with the company management, and, secondly, chat to the drivers. But, with Graham bubbling over with all the good things he wanted to

say about the new Cat truck he’s driving, we thought we had better listen first and ask questions later.

“The new Cat is marvellous,” said Graham. “It’s the quietest truck I’ve driven and one of the most comfortable. It’s really well put together and the comfort levels are excellent. The engine pulls really strongly and it’s very easy to see as far as vision goes. I am really happy with it,” he added.

With that level of enthusiasm amongst its workforce, it was only a logical step to discuss the appeal of the Cat truck that had led managing director of Malec Bros. Transport, Matthew Malec, to bring in the relatively unproven product to a fleet that had traditionally run Kenworth and Freightliner prime movers.

The company was founded by Matthew’s father, Les Malec, to handle general freight movements, but has since grown into encompassing the container transport market as well as working in the logging industry.

PROFILE

34 PowerTorque ISSUE 46

CAT

Graham

There’s a definite change of attitude amongst operators testing the water with a new Cat truck

Parsons is a typical truckie. With an abundance of white hair and a smile that shows he’s got the patience and understanding that comes with coping with whatever the road transport industry can throw at him, he knows what he likes. He’s also prepared to tell anyone what he thinks, and with many operators wanting to know how the new Cat trucks are going in service, what he thinks, is what we want to know.

Graham works for Lara, Victoria, based transport operator Malec Bros. Transport. This is a family-operated business that is growing strongly from its original roots some 16 years ago, when it handled general freight haulage, to the present day where it has also diversified into container transport and logging.

Ordinarily, we would discuss trucks first with the company management, and, secondly, chat to the drivers. But, with Graham bubbling over with all the good things he wanted to

say about the new Cat truck he’s driving, we thought we had better listen first and ask questions later.

“The new Cat is marvellous,” said Graham. “It’s the quietest truck I’ve driven and one of the most comfortable. It’s really well put together and the comfort levels are excellent. The engine pulls really strongly and it’s very easy to see as far as vision goes. I am really happy with it,” he added.

With that level of enthusiasm amongst its workforce, it was only a logical step to discuss the appeal of the Cat truck that had led managing director of Malec Bros. Transport, Matthew Malec, to bring in the relatively unproven product to a fleet that had traditionally run Kenworth and Freightliner prime movers.

The company was founded by Matthew’s father, Les Malec, to handle general freight movements, but has since grown into encompassing the container transport market as well as working in the logging industry.

CAT LOVERS

PowerTorque ISSUE 46 35

Les had been involved in transport back in his native Poland some 30 years earlier, so already had experience of some of the demands of the transport business.

The company fleet now numbers some 52 vehicles, of which 25 are prime movers hauling either single of B-double trailer sets. There are ten B-doubles working in on-road transport and 14 units working on the logging contract.

“You’d expect the Cats to handle the container work easily,” said Matthew, “but it’s been really interesting to see how they stand up to the rougher world of logging. There’s nothing easy about where these trucks go with log trailers out to the Otways.

“Before committing to four Cat CT630s, we trialled one unit on container work for five

months. That now has 70,000 km of work under its belt, and it’s performed very well.

“It’s our intention to continue to expand our container work with a doubling of traffic flow and the opening of a second depot closer to Melbourne, in Sunshine.

“Our container traffic is currently running on a 24-hour/five day week roster, operating between Port Melbourne and Lara on three runs on the day shift and three runs on the night shift, loaded on both the outbound and inbound runs,” said Matthew.

The Cat CT 630 features an alloy cab construction that keeps tare weight down and resists corrosion and conforms to ECE 29 rollover and crash protection requirements. The steep rake of the hood design provides much clearer forward vision, which is usually obtained with conventional bonneted trucks in this segment.

“The logging areas we travel are tough off-road sections with steep grades. The Cats are handling the rough going well. So far, nothing is falling off them, which hasn’t been the case with some of the competition, where dashboards have cracked and dropped off in the cab. There’s nothing impressive about a dashboard dropping off its mountings,” added Matthew.

The Malec Bros fleet is used to using Cat engines, with a C15 rated at 550 hp still running in a Freightliner, matching a Cummins ISX running in a Kenworth and rated at 520 hp.

“We now have four Cat CT 630 day-cab prime movers, each fitted with a C15 rated at 550 hp and running through manual 18-speed Eaton Roadranger transmissions.

We’ve always liked the torque and the way a Cat motor behaves. I prefer to have the Cat option, and of course, these days, it’s the only new truck able to provide a Cat engine,” he added.

With all four vehicles only recently delivered, fleet fuel figures are not yet ready for drawing exact analysis, but, according to Les Malec, the early indications are that fuel economy is currently very similar to that of other previous ACERT Cat motors the company has used.

“I like the way the Cat motors pull through the torque band, and the smoothness of their performance,” said Les. “William Adams may be new to the business of selling trucks, but the way they have supported the product, combined with the service we are receiving, is very reassuring that we’ve made

the right decision,” said Les.

“One of the benefits of buying the Cat was that they come with cross and

inter-axle differential locks as standard. You don’t have to add them to the options list.

PROFILE

38 PowerTorque ISSUE 46

PROGRESSIVETHINKING

THere’s

For Willaton Transport of Morwell, Victoria, future technology is an important part of its fleet choice. Chris Mullett reports

Bernie Willaton is a firm advocate for SCR and bio-fuel combinations to reduce emissions and control costs.

a major difference in the transport industry between

long-standing, family-owned businesses in rural areas and the national conglomerates that have their headquarters in major cities.

For starters, there’s the personal inter-action between staff and employers where everyone lives in the same town or surrounding area. It’s a different staff/employer relationship and it often comes from generations of families that know each other, go to school together and belong to the same community.

“The transport industry is obviously dominated by the major national fleets, but we find that while their main ability is based on the transport requirements surrounding the Metropolitan area, they lack the same strengths when it comes to more rural areas,” said Managing Director Bernie Willaton.

“In these situations we find they turn to local operators that are better established and have a stronger infrastructure for rural distribution. In Melbourne we find that city-based operators rely on country-based operators to promote their

service. It’s also these same country operators that have a more sustainable and longer association with staff.

“Having been in the transport business for as along we have as a family, it becomes much easier for us to remain profitable and efficient than it would be for a smaller company. We have the size of an operation that can cope with business fluctuation whereas it must be difficult for others trying to come in from scratch,” said Bernie.

PowerTorque met with Bernie Willaton as the company took delivery of its latest IVECO Powerstar prime mover, one of three recently delivered by Melbourne International Truck Centre and each being powered by a Cummins ISX engine with ZF-AS-tronic automated manual transmissions.

The latest Powerstar was fresh from the recent Trucks in Action rural show in East Gippsland where it had formed the centrepiece of the Melboure International Trucks’ display.

The Willaton Transport fleet is particularly interesting as it operates with a variation of makes ranging from Kenworth, IVECO, Freightliner and Volvo.

PROFILE

38 PowerTorque ISSUE 46

PROGRESSIVETHINKING

THere’s

For Willaton Transport of Morwell, Victoria, future technology is an important part of its fleet choice. Chris Mullett reports

Bernie Willaton is a firm advocate for SCR and bio-fuel combinations to reduce emissions and control costs.

a major difference in the transport industry between

long-standing, family-owned businesses in rural areas and the national conglomerates that have their headquarters in major cities.

For starters, there’s the personal inter-action between staff and employers where everyone lives in the same town or surrounding area. It’s a different staff/employer relationship and it often comes from generations of families that know each other, go to school together and belong to the same community.

“The transport industry is obviously dominated by the major national fleets, but we find that while their main ability is based on the transport requirements surrounding the Metropolitan area, they lack the same strengths when it comes to more rural areas,” said Managing Director Bernie Willaton.

“In these situations we find they turn to local operators that are better established and have a stronger infrastructure for rural distribution. In Melbourne we find that city-based operators rely on country-based operators to promote their

service. It’s also these same country operators that have a more sustainable and longer association with staff.

“Having been in the transport business for as along we have as a family, it becomes much easier for us to remain profitable and efficient than it would be for a smaller company. We have the size of an operation that can cope with business fluctuation whereas it must be difficult for others trying to come in from scratch,” said Bernie.

PowerTorque met with Bernie Willaton as the company took delivery of its latest IVECO Powerstar prime mover, one of three recently delivered by Melbourne International Truck Centre and each being powered by a Cummins ISX engine with ZF-AS-tronic automated manual transmissions.

The latest Powerstar was fresh from the recent Trucks in Action rural show in East Gippsland where it had formed the centrepiece of the Melboure International Trucks’ display.

The Willaton Transport fleet is particularly interesting as it operates with a variation of makes ranging from Kenworth, IVECO, Freightliner and Volvo.

PROGRESSIVE THINKING

PowerTorque ISSUE 46 39

“The IVECO Powerstar with Cummins ISX and AS-tronic comes complete with a four year, bumper to bumper warranty and I don’t think you could find a better overall package,” said Bernie.

“Because we maintain a fleet that is consistently replacing vehicles and updating equipment, we have found that in terms of overall costs the resale value is having less of an influence on vehicle selection. Rather than relying on a higher resale return on a particular make, there may be a lower purchase price and a lower sale price. At the end of the day each vehicle has a book price and it’s all down to whatever the book value is at the time.

“We usually run with vehicles for a five year life, but we have the luxury of being able to run a new vehicle for three to

company extend its operation to include specific return work from Melbourne through to Perth with specialised loads. As well as general freight, much of the company work includes container handling and transshipment for which the company has its own fleet of skeletal trailers.

“Our Melbourne to Perth and return operation runs over a seven to eight day trip cycle that expands

four years on linehaul and then bring it back to run on more local distribution work,” he added.

In recent years the Willaton Transport fleet has continued to expand, now comprising around 60 vehicles in total of which 45 units are prime movers and 30 of these being in B-double configuration.

Recent developments have seen the

FEATURE

46 PowerTorque ISSUE 46

ROAD TRAINIveco takes its Powerstar to a

new dimension with a full road train application

Stralis buyers will be treated to a material colour change for the cab interior, and there will be a campaign by IVECO to show the advantages of moving to a 4x2 prime mover format in order to reduce running costs and purchase pricing.

So far sold in 6x6 application mainly to companies working in the super-spreader and mining areas and for selective work in tough terrain for regional council application, we will now see TRAKKER expand into an 8x8 configuration. At this level, the TRAKKER 8x8 is then capable of rivaling Mercedes-Benz and MAN in their traditionally held segments in mining and drilling.

Power comes from a Cursor 13 engine with 450 hp and 500 hp options matching to a ZF AS-Tronic 16-speed automated manual transmission.

The ZF AS-Tronic, or EuroTronic as IVECO likes to call it, also makes its appearance in 16-speed as well as 12-speed versions in the Stralis and PowerStar.

loss of the International Trucks brand from the IVECO portfolio was seen by some industry analysts

as the precursor (no pun intended) to Iveco gradually disappearing from the Australian market. The established dealer group that had committed resources and infrastructure to a twin-product line was also considered to be immediately more vulnerable, losing a second string to their bow as they no longer represented the International product line.

Now, a couple of years down the track since the creation of NC2 Global, the Caterpillar/International and Navistar conglomerate, the Australian truck industry can see signs of strength returning to the Iveco brand and its remaining dealer group.

No new development at IVECO Australia would be complete without a change of managing director. Managing Director, Georgio Gallia, has returned to his native Italy, replaced by Danilo Salvatore Martelli. Mr. Martelli has a background as director of key global accounts and has also served IVECO in overseas markets including the United Kingdom, South America and France.

ACCO has been an absolute stalwart component of the strength of IVECO in Australia, and it continues to develop way beyond any original expectations. In 2012, the ACCO brand turns 40 years old, but nowhere does it seem to be any less appealing in terms of its competitiveness in the tandem tipper, agitator and refuse collection applications.

Indeed, as it readies to celebrate its 40th birthday, yet another new derivative is about to be launched, that of an ACCO hybrid version. This has been developed by the company in conjunction with the well know transport operator, J.J. Richards and Sons, a company that also has a long heritage, established through over 75 years of experience in the waste industry.

It’s not only the ACCO brand that has cause to celebrate in 2012. IVECO itself is celebrating its 100 years anniversary, and, in so doing, will also be launching new products into the Australian marketplace.

The TRAKKER all-wheel-drive unit has been available in our market for the past three years, but 2012 marks the start of a more serious approach by the company to expand the offering.

FEATURE

46 PowerTorque ISSUE 46

ROAD TRAINIveco takes its Powerstar to a

new dimension with a full road train application

Stralis buyers will be treated to a material colour change for the cab interior, and there will be a campaign by IVECO to show the advantages of moving to a 4x2 prime mover format in order to reduce running costs and purchase pricing.

So far sold in 6x6 application mainly to companies working in the super-spreader and mining areas and for selective work in tough terrain for regional council application, we will now see TRAKKER expand into an 8x8 configuration. At this level, the TRAKKER 8x8 is then capable of rivaling Mercedes-Benz and MAN in their traditionally held segments in mining and drilling.

Power comes from a Cursor 13 engine with 450 hp and 500 hp options matching to a ZF AS-Tronic 16-speed automated manual transmission.

The ZF AS-Tronic, or EuroTronic as IVECO likes to call it, also makes its appearance in 16-speed as well as 12-speed versions in the Stralis and PowerStar.

loss of the International Trucks brand from the IVECO portfolio was seen by some industry analysts

as the precursor (no pun intended) to Iveco gradually disappearing from the Australian market. The established dealer group that had committed resources and infrastructure to a twin-product line was also considered to be immediately more vulnerable, losing a second string to their bow as they no longer represented the International product line.

Now, a couple of years down the track since the creation of NC2 Global, the Caterpillar/International and Navistar conglomerate, the Australian truck industry can see signs of strength returning to the Iveco brand and its remaining dealer group.

No new development at IVECO Australia would be complete without a change of managing director. Managing Director, Georgio Gallia, has returned to his native Italy, replaced by Danilo Salvatore Martelli. Mr. Martelli has a background as director of key global accounts and has also served IVECO in overseas markets including the United Kingdom, South America and France.

ACCO has been an absolute stalwart component of the strength of IVECO in Australia, and it continues to develop way beyond any original expectations. In 2012, the ACCO brand turns 40 years old, but nowhere does it seem to be any less appealing in terms of its competitiveness in the tandem tipper, agitator and refuse collection applications.

Indeed, as it readies to celebrate its 40th birthday, yet another new derivative is about to be launched, that of an ACCO hybrid version. This has been developed by the company in conjunction with the well know transport operator, J.J. Richards and Sons, a company that also has a long heritage, established through over 75 years of experience in the waste industry.

It’s not only the ACCO brand that has cause to celebrate in 2012. IVECO itself is celebrating its 100 years anniversary, and, in so doing, will also be launching new products into the Australian marketplace.

The TRAKKER all-wheel-drive unit has been available in our market for the past three years, but 2012 marks the start of a more serious approach by the company to expand the offering.

THE POWERSTAR ROAD TRAIN

PowerTorque ISSUE 46 47

ROAD TRAINIveco takes its Powerstar to a

new dimension with a full road train application

around 700 kg from the tare weight, bringing down the kilos to an impressive 7.5 tonnes. With a GVM of 55 tonnes, this will run with RT40 or RT46 axles with cantilever or Hendrickson HAS suspension, and using a different chassis. Transmission choice will offer either the 12-speed or 16-speed EuroTronic, or an Eaton Roadranger 16-speed or 18-speed manual gearbox, all in an engine package of 450-500 hp.

The Powerstar has itself gone through a continuing development programme since its initial release. In 2010, it was rated for performance in B-double applications, then the Cursor engine was mated to the EuroTronic, and this was followed by the availability of the Cummins ISX engine, matched also to the EuroTronic transmission or an Eaton 18-speed Roadranger manual gearbox.

Now stand by for the big news for 2012. Powerstar has grown its credentials and can now boast a full road train specification. This is serious weight ability

IVECO believes that many operations using prime movers for urban distribution could benefit from downsizing from either 6x4 or 6x2, to a 4x2 alternative. It’s something that’s very common in Europe, but has never achieved huge popularity in the Australian market where every operator has traditionally purchased a vehicle on the expectation that it could handle interstate work at higher gross weight.

There’s a new, lighter weight Powerstar on the stocks for this year, with IVECO engineers in Australia shaving off

PROFILE

54 PowerTorque ISSUE 46

A FAMILY

When

AFFAIRTripodi’s Haulage Contractors is the epitome of how an Italian family moved from farming to trucking

you talk to Pat Tripodi, you can’t help but notice the enthusiasm he has for the

trucking business. Having gained his truck licence at the age of 19 years old, Pat has been involved in the family trucking business started by his father, John, for as long as he can remember.

“I think I was actually born under a 1418 Benz,” said Pat.

“As a young kid I was always helping Dad out with cleaning his truck or just being around trucks. Ours was a family business that started out when my grandparents moved here from Italy and started cotton farming in Queensland. They subsequently moved to Sydney and the Mascot area, and then to Camden.

“Dad started with a Thames Trader carting brewers’ grain to the family farm in Camden. When the coal mining in the Burragorang Valley got underway we moved into carrying coal in the mid-1960s with a 1418 Benz. Then we had a Transtar with a 250 hp Cummins on tipper work, before

getting involved in refrigerated transport with R-Model Macks,” said Pat.

“Trucking is in the family. We can be proud of what we do, and very proud of our reputation in this industry and what we’ve achieved over 20-25 years,” he added.

The Paul Keating inspired recession proved to be a difficult time for the transport industry, and the Tripodi family was no exception.

“We switched from running coal to having a couple of ex-Telstra ACCOs with which we carted Gyproc. Then I started with an R600 Mack with a 285 hp engine and five-speed gearbox carting quarry products and coal,” said Pat.

PROFILE

54 PowerTorque ISSUE 46

A FAMILY

When

AFFAIRTripodi’s Haulage Contractors is the epitome of how an Italian family moved from farming to trucking

you talk to Pat Tripodi, you can’t help but notice the enthusiasm he has for the

trucking business. Having gained his truck licence at the age of 19 years old, Pat has been involved in the family trucking business started by his father, John, for as long as he can remember.

“I think I was actually born under a 1418 Benz,” said Pat.

“As a young kid I was always helping Dad out with cleaning his truck or just being around trucks. Ours was a family business that started out when my grandparents moved here from Italy and started cotton farming in Queensland. They subsequently moved to Sydney and the Mascot area, and then to Camden.

“Dad started with a Thames Trader carting brewers’ grain to the family farm in Camden. When the coal mining in the Burragorang Valley got underway we moved into carrying coal in the mid-1960s with a 1418 Benz. Then we had a Transtar with a 250 hp Cummins on tipper work, before

getting involved in refrigerated transport with R-Model Macks,” said Pat.

“Trucking is in the family. We can be proud of what we do, and very proud of our reputation in this industry and what we’ve achieved over 20-25 years,” he added.

The Paul Keating inspired recession proved to be a difficult time for the transport industry, and the Tripodi family was no exception.

“We switched from running coal to having a couple of ex-Telstra ACCOs with which we carted Gyproc. Then I started with an R600 Mack with a 285 hp engine and five-speed gearbox carting quarry products and coal,” said Pat.

A FAMILY AFFAIR

PowerTorque ISSUE 46 55

A FAMILY

Camden Soil, keeping the trucks as a separate business.

“At that stage we were running a wide variety of trucks that included Internationals, Ivecos, Fords, Sterlings, Mack and Freightliner. We had around 30 trucks in all sorts of configurations from 6x4 and 6x6 to 8x4s, with tippers and prime movers and semi-trailers. Over the years we tried just about every different sort of vehicle make.

“Towards the end of 2007, I realised we really needed to rationalise the fleet. We discussed where one make would provide all our requirements, and with the aid of Bill Anderson, at Sydney’s Gilbert & Roach, we settled on a standard specification.

“With the changing legislation, we can see an advantage in running five-axle dogs, but, with the amount of work we do in central Sydney, the added manoeuvrability of the typical three-axled dog trailer is really valuable in our type of work.

“The key to our success comes from streamlining our business. A typical truck spec would now be the Kenworth SAR 409 powered by a Cummins ISX at 525 hp, an 18-speed 20-Series Eaton manual transmission, and Kenworth Air-Glide airbag suspension. The Sloanebuilt trailers run on Hendrickson axles.

“Providing excellent customer service is the key to our business, but we apply the same criteria to purchasing decisions,” said Pat.

“We buy from Sloanebuilt for the quality they provide. The company is very approachable and their people are very knowledgeable when it comes to working with us to discuss load weights, axle positioning etc.

At this stage, the family was still based at the farm. The business continued to grow and they diversified into carrying waste meat from butchers’ shops to a processing plant at Riverstone, using Mitsubishi rigids.

Pat’s father, John, was ready for retirement, but as a change from trucking and farming he started a separate business, and subsequently grew Camden Soil, providing soil mix and top dressing to customers throughout Western Sydney.

“Dad looked after the soil business and I looked after the truck and transport side for the ten years from 1998 through to 2008 before we then sold

“Choosing a standard specification truck with one make in the fleet has provided substantial benefits in the long term. We have been dealing with Bill Anderson since as early as 2005, and found the company excellent to work with,” said Pat.

“We settled on one make, Kenworth, and on one type of truck, which was the SAR. We stayed with one engine supplier, Cummins, and with one tyre supplier, Southern Tyres Service of Ingleburn. We standardised on Sloane Built trailers and they now provide all our bodywork and trailer requirements.

“The reliability of Kenworth and the high resale value means that we are now very confident. Initially, we purchased SAR 404 models, then moved to have 408s and now buy the SAR 409. We’ve got 12 trucks and dog trailers, eight Mitsubishi 4x4, 6x4 and 8x2 rigids, and two prime movers.

“We don’t add what we consider are unnecessary items to our vehicles. We run with a single exhaust

stack and concealed air cleaners in all vehicles except those that we had to buy at short notice

that were originally stock trucks with the dealer. This means we benefit from

lower tare weight. They look good in service and our trucks are always

clean and well presented.

PROFILE

58 PowerTorque ISSUE 46

live in an age of word definition. If you think about

it, a vehicle wrecker’s was a place where you went in search of a used part, for your vehicle, that had been reclaimed from another. Subsequently, the name changed from “Vehicle Wrecker” to “Auto Dismantler”. Each depot took on a cleaner and more efficient look and feel (well, most did), the industry became more professional in its appearance and attitude and prices of used parts subsequently increased.

Another company description that’s currently being under consideration for a name change is that of “Tow Truck

PROFILE

58 PowerTorque ISSUE 46

live in an age of word definition. If you think about

it, a vehicle wrecker’s was a place where you went in search of a used part, for your vehicle, that had been reclaimed from another. Subsequently, the name changed from “Vehicle Wrecker” to “Auto Dismantler”. Each depot took on a cleaner and more efficient look and feel (well, most did), the industry became more professional in its appearance and attitude and prices of used parts subsequently increased.

Another company description that’s currently being under consideration for a name change is that of “Tow Truck

THE EAGLE HAS LANDED

PowerTorque ISSUE 46 59

Operator. Without putting too fine a point on the definition, towing is actually the very minimum that most “Vehicle Accident Recovery Specialists” do on a day-to-day basis.

Gone are the days when a tow truck turned up at the scene of an accident with a small hand-operated winch and crane jib on the back and attempted to restore order out of chaos at the scene of an accident.

The whole process of dealing with an accident is now highly specialised. It requires extremely expensive equipment with highly trained and skillful operators capable of recovering a vehicle involved in an accident without inflicting any further damage to it or the surrounding area.

John Sampson, the managing director of Ringwood, Victoria, based Eagle Towing, is a typical example of someone who has spent much of his working life learning and practising the art of heavy vehicle recovery.

As a young bloke back in the early 70s, John was completing his apprenticeship as a letterpress printer during the day. At night, and at weekends, he went on call to recover vehicles with Vermont Motors. This was vehicle recovery at the light end of the scale, with a Ford 600 and International 1640 as the tow and recovery units to bring in anything up to a single-drive tipper.

Printing never seemed to remain the drawcard in John’s career, and he was soon driving a butterbox ACCO, and then a truck while delivering chemicals and pharmaceutical products. In what passed as his spare time, he was building his own tow truck based on a Dodge chassis.

Full control of all functions is available from duplicated stations on either side of the vehicle. The distinctive paint treatment of all Eagle Towing vehicles sets an industry standard.

82 PowerTorque ISSUE 46

TRAILER TORQUE

MAXIMISING POTENTIALThere's

Freighter and Broadbent Bulk Services work together to benefit from Performance Based Standards

something really impressive about our transport industry in

the way that companies continue to find different solutions to the same problem of how to improve profitability and productivity. When Broadbent Bulk Services had an idea for a new trailer combination that they thought could revolutionise their business, they turned to leading trailer manufacturer, Freighter, to help bring it to fruition.

Until now, the A-double has been somewhat of a holy grail to transport operators in Australia: always there in the distance and yet seemingly unattainable due to regulations that meant it couldn’t be driven on most roads in the eastern states of Australia. Freighter’s new solution, however, could change the landscape dramatically.

Broadbent Bulk Services (BBS) is a leading Toowoomba-based container packing facility and transport company, which services the vast grain growing regions of the Darling Downs and Northern NSW. Beginning as a container packing facility only, BBS acquired Findlay Bulk Haulage in March 2007, and has grown from strength-to-strength as a result. With the ability to containerise and then transport bulk grains, the “full service” aspect of the business has meant the demand for its services have grown a great deal.

With more and more trucks required on the road every day to meet their customers’ expectations, BBS operations manager, Shane Noble, discovered himself continually being drawn back to the idea of the A-double. Something that has been considered by transport operators and trailer manufacturers alike for some time, the A-double would provide the ability to give a higher payload and increase operational efficiency. Shane had seen it done before, but thought there must be a better solution. Consequently, he went about finding a manufacturer who shared his vision.

“It was something I’d had in the back of my mind for a long time,” said Shane. “I’d seen an A-double combination before, running with a steerable dolly, but the inclusion of the steerable dolly made the price exorbitant when I investigated it. If we were able to use the Performance Based Standards (PBS) laws to find an A-double combination that wasn’t only legal, but affordable, it would mean that we would be able to be that much more efficient when it came to getting our loads to their final destination.”

The concept, however, proved to be a challenging one. “Freighter was the only company that would consider getting it approved,” said Shane.

“Anyone else I approached wasn’t willing to go through the PBS approval process, and just wanted to sell me another trailer ‘off the shelf’. Eric Ey at

82 PowerTorque ISSUE 46

TRAILER TORQUE

MAXIMISING POTENTIALThere's

Freighter and Broadbent Bulk Services work together to benefit from Performance Based Standards

something really impressive about our transport industry in

the way that companies continue to find different solutions to the same problem of how to improve profitability and productivity. When Broadbent Bulk Services had an idea for a new trailer combination that they thought could revolutionise their business, they turned to leading trailer manufacturer, Freighter, to help bring it to fruition.

Until now, the A-double has been somewhat of a holy grail to transport operators in Australia: always there in the distance and yet seemingly unattainable due to regulations that meant it couldn’t be driven on most roads in the eastern states of Australia. Freighter’s new solution, however, could change the landscape dramatically.

Broadbent Bulk Services (BBS) is a leading Toowoomba-based container packing facility and transport company, which services the vast grain growing regions of the Darling Downs and Northern NSW. Beginning as a container packing facility only, BBS acquired Findlay Bulk Haulage in March 2007, and has grown from strength-to-strength as a result. With the ability to containerise and then transport bulk grains, the “full service” aspect of the business has meant the demand for its services have grown a great deal.

With more and more trucks required on the road every day to meet their customers’ expectations, BBS operations manager, Shane Noble, discovered himself continually being drawn back to the idea of the A-double. Something that has been considered by transport operators and trailer manufacturers alike for some time, the A-double would provide the ability to give a higher payload and increase operational efficiency. Shane had seen it done before, but thought there must be a better solution. Consequently, he went about finding a manufacturer who shared his vision.

“It was something I’d had in the back of my mind for a long time,” said Shane. “I’d seen an A-double combination before, running with a steerable dolly, but the inclusion of the steerable dolly made the price exorbitant when I investigated it. If we were able to use the Performance Based Standards (PBS) laws to find an A-double combination that wasn’t only legal, but affordable, it would mean that we would be able to be that much more efficient when it came to getting our loads to their final destination.”

The concept, however, proved to be a challenging one. “Freighter was the only company that would consider getting it approved,” said Shane.

“Anyone else I approached wasn’t willing to go through the PBS approval process, and just wanted to sell me another trailer ‘off the shelf’. Eric Ey at

PowerTorque ISSUE 46 83

MAXIMISING POTENTIAL

Freighter Maxi-CUBE, on the other hand, was only too happy to help, and managed the whole process from start to finish.

“He treated the whole thing as a partnership – it was a great result. Perhaps, even more importantly, the trailers have performed beyond expectations,” Shane added.

Freighter Maxi-CUBE Western Queensland area manager, Eric Ey, was heavily involved in the purchase.

“Our engineering team had told us for some time that a steerable dolly didn’t really change the performance of the A-double trailer combination,” he said. “In fact, changing from a steerable dolly to a regular dolly eliminated a few problems, in our eyes, such as tyre wear and poor performance on rough roads. To us, the steerable dolly seemed to be an unnecessary and ongoing expense, so it was just a matter of waiting for the right customer to be willing to put the theory into practice.

“BBS came to us wanting to buy two sets of A-double skels without a steerable dolly. “That was the first challenge, but we already had our idea for a solution to that.

“The second request was to use a Kenworth T909 as the prime mover. A lot of people said that you couldn’t use a bonneted truck to run the A-double, so Shane’s request gave us the opportunity to prove two industry myths wrong,” added Eric.

The Freighter engineering team went to work on creating a workable solution for BBS, designing a lightweight trailer set incorporating a regular dolly in the place of a steerable dolly, and using wider axle spacings on both the skels and dolly to counteract the bonneted truck.

“Of course, with PBS applications you have to factor in more than just the trailer configuration,” Eric continued. “The truck weight and specifications are involved too, as well as reaching certain benchmarks with regards to performance, such as acceleration ability, ability to maintain speed up a hill, swept paths, frontal and tail swing, amongst other things.

“Our solution got through the entire approval process without a hitch,” said Eric.

The end result was a finished A-double, with a lightweight design and regular dolly, which could carry two full 29-tonne containers and still fall within the 79-tonne gross specified on the route.

Broadbent Bulk Services has achieved significant gains in efficiency through the introduction of A-double combinations.

FEATURE

86 PowerTorque ISSUE 46

Trucks in Action and the Civil Works Expo provide the look and touch advantage to rural showgoers

advent of the Internet and the worldwide web, instant

communication and the almost unlimited access to information has changed the face of traditional truck shows. Buyers who want information can access all they need without travelling. Whether

they investigate the Internet for their own

information or rely on qualified industry publications and their editorial reports, the information stream is available for anyone who cares to look.

The Brisbane Truck Show has managed to reinvent itself, with a move to a sophisticated new venue at the Brisbane Expo Centre, and integrates the technical innovation in the transport industry into an easy to visit event where information is available for all. Other major events have not managed to move into the same level of ability, and, where visitors and exhibitors alike are at the mercy of weather conditions, there’s always the risk that a downpour or excessive heat can effectively keep the visitors away.

Trucks in Action, at Lardner Park on the outskirts of Warragul, east of Melbourne, is currently going through its own reinvention, broadening its own horizons away from being so dependent on trucks displayed to rural buyers, to a

position where, today, it also covers the light earthmoving and civil works equipment industries.

The point of difference, with the Lardner Park event, is that visitors have the opportunity to drive vehicles,

evaluate plant and equipment, or to simply watch, as experts from the exhibitors concerned show off their products in a simulated working environment.

FEATURE

86 PowerTorque ISSUE 46

Trucks in Action and the Civil Works Expo provide the look and touch advantage to rural showgoers

advent of the Internet and the worldwide web, instant

communication and the almost unlimited access to information has changed the face of traditional truck shows. Buyers who want information can access all they need without travelling. Whether

they investigate the Internet for their own

information or rely on qualified industry publications and their editorial reports, the information stream is available for anyone who cares to look.

The Brisbane Truck Show has managed to reinvent itself, with a move to a sophisticated new venue at the Brisbane Expo Centre, and integrates the technical innovation in the transport industry into an easy to visit event where information is available for all. Other major events have not managed to move into the same level of ability, and, where visitors and exhibitors alike are at the mercy of weather conditions, there’s always the risk that a downpour or excessive heat can effectively keep the visitors away.

Trucks in Action, at Lardner Park on the outskirts of Warragul, east of Melbourne, is currently going through its own reinvention, broadening its own horizons away from being so dependent on trucks displayed to rural buyers, to a

position where, today, it also covers the light earthmoving and civil works equipment industries.

The point of difference, with the Lardner Park event, is that visitors have the opportunity to drive vehicles,

evaluate plant and equipment, or to simply watch, as experts from the exhibitors concerned show off their products in a simulated working environment.

MEETING THE LOCALS

PowerTorque ISSUE 46 87

Once the showcase for major exhibits by vehicle and original equipment manufacturers, the Trucks in Action Show, today, has moved to increase its focus on local distributors, with stands and exhibits manned by the local sales outlets. While that has diminished some of the glitz and glamour, it has restored itself to its original rural roots, where country people can talk to the same person who sells the equipment and provides the personal level of customer service throughout its life.

For the major truck manufacturers, such as IVECO, the product range and advice at Warragul came from the local dealership at Dandenong, the Melbourne International Truck Centre.

On display were the latest members of the IVECO Powerstar family, with the Cummins ISX engine now available as an option to the European Cursor engine. For the truck operator, the range provides an almost unique offering, these days, for those wanting the choice between a North American engine with North American driveline, or a European engine from IVECO that’s matched to what is arguably the best AMT on the market, the ZF AS-tronic.

Making its showing, for the first time in Australia, was the all-wheel-drive TRAKKA that IVECO is currently introducing to Australia. This new addition to the range has a huge potential in rural applications for off-road super spreading, but also has the strength to extend that ability to provide the perfect base for drill rig operations in the mining industry.

IVECO has also not forgotten the medium and higher weight on-highway transport operators, and, with the Stralis and Eurocargo, there’s a model that suits all requirements, whether the operator wants manual gearboxes or Allison automatics or AMTs (automated manual transmissions).

The centrepiece of the IVECO stand featured a new Powerstar in the livery of East Gippsland haulier, Willaton Transport.

William Adams, the Victorian distributor of Caterpillar products, was able to cover the spread of earthmoving and

Detroit Diesel and Bearcat hosted

in-depth discussions on new technology.

IVECO’s all-wheel-drive TRAKKER plus Cummins ISX-engined PowerStar for Willaton Transport.

AUSTRALIA’S GUIDETO ECO FRIENDLY,

FUEL EFFICIENT CARS

AUSTRALIA’S LEADINGTRUCK & ENGINE

MAGAZINE

AUSTRALIA’S GUIDETO UTES, VANS, LIGHT

TRUCKS & PEOPLE MOVERS

Subscribe Onlinewww.motoringmatters.com.au

Name: .............................................................................................. Address: .......................................................................................................................

Telephone:.............................................. Email: ......................................................................................................

Choose your Subscription:

Card holders name:...................................................................

$60.00 (12 months) $120.00 (24 months)

$60.00 (12 months) $120.00 (24 months)

$60.00 (12 months) $120.00 (24 months)

Cheque/Money Order for the amount of...........................payable to Motoring Matters or please charge my

Post to: Motoring Matters, Subscriptions Manager, PO Box 307, Mittagong, NSW 2575

Bankcard Visa Mastercard

*Offer applicable in Australia only

Card holders signature:.............................................................Expiry:............../...................