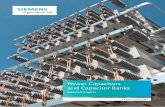

Power capacitors

-

Upload

kunsridhar8901 -

Category

Documents

-

view

9 -

download

1

description

Transcript of Power capacitors

Printed in USA

McGraw-Edison Type EX-7Li®all-film internally fused capacitors(Figure 1) feature the latestCooper Power Systems designinnovations; extended foil, solder-less connections, CLEANBREAK®

element fusing system and laser-cut aluminum foil. Designed,manufactured, and tested to meetor exceed the requirements of allapplicable ANSI/IEEE and IECstandards, their low cost per kvarmakes these capacitors a simple,economical source of reactivepower on electric power systemsfor:

■ Power factor correction.

■ Voltage support.

■ Loss reduction.

■ Improving power transfer capability.

■ Releasing system capacity.

Internally fused, power capacitorscan be installed individually or infactory-assembled switched orunswitched:

■ Open style indoor and substation banks.

■ Metal enclosed banks.

Note that Cooper Power Systemsdoes not recommend the use ofinternally fused capacitors on polemounted, distribution rack applica-tions.

McGraw Edison exclusive all-film,extended foil/mechanicallyconnected capacitors provide:

■ Low losses (0.15 watt/kvar).

■ Superior electrical performanceand reliability.

■ Environmentally acceptableEdisol® ST Non-PCB dielectricfluid.

■ CLEANBREAK® elementfusing system.

CAPACITORAPPLICATIONCapacitor application requires anevaluation of the power system todetermine:

■ The kvar requirements.

■ The most effective location.

■ Interaction with system.

■ The necessary protection.

In general, capacitors areinstalled:

■ At the substation, to supply thesystem kvar needs most effec-tively.

■ At or near the load center, toobtain the optimum kvar supplyand voltage correction.

■ At the end of the line, toachieve maximum voltagecorrection.

■ In series with a distributionfeeder to minimize flicker andprovide voltage support.

■ In series with a transmissionline to minimize the reactanceof the line, improving stabilityand controlling voltage drop.

RATINGSMcGraw Edison capacitors arerated in continuous kvar, voltage,BIL and frequency and aresubjected to all applicableANSI/IEEE or IEC routine tests.The capacitor unit rated voltage isthe voltage at rated frequency thatcan be applied terminal-to-terminalcontinuously. See the standard towhich the capacitor unit is manu-factured for guidance in operationabove rated voltage.

Single-phase capacitor units aredesigned to produce rated kvar atrated voltage and frequency withinthe tolerance of the applicablestandard. As the capacitor’s kvaroutput is proportional to thesquare of the applied voltage,proper application requires atten-tion to the applied voltage.

Available capacitor unit ratings canbe obtained by contacting thefactory.

CONSTRUCTIONFEATURESConstruction features of McGraw-Edison power capacitors include:

■ CLEANBREAK® elementfusing system. Each element isprotected with a seriesconnected CLEANBREAK®

current limiting fuse. Thispatented fusing system incor-porates the following features:

■ Polymer fuse card providesisolated fuse mountingwhich prevents potentialdamage to adjacentcapacitor elements andfuses.

■ Fuses are individuallymounted within a polymerfuse tube. The tube protectsthe fuse from damage due toadjacent element failuresand fuse operations. Thisdesign also requires no

1

Electrical Apparatus

Power CapacitorsMcGraw-Edison® Type EX-7Li®

Single-Phase Internally Fused Units 230-12

February 2000 • New

*US Patent 4,633,369

Figure 1.The McGraw Edison EX-7Li ®

single phase internally fused,all-film capacitor

Single-Phase Internally Fused Capacitors

P.O. Box 1640, Waukesha, WI 53187http://www.cooperpower.com/

McGraw-Edison® is a registered trademark of Cooper Industries, Inc.Edisol® is a registered trademark of Cooper Power Systems, Inc.©2000 Cooper Power Systems, Inc.

Printed on Recycled Paper

2

60-Hz Withstand

Creepage Strike 60-Sec. 10-Sec. Weight/BIL Distance Distance Dry Wet Bushing(kV) (mm) (mm) (kV) (kV) (kg)

75** 264 159 35 30 1.495 264 159 35 30 1.4

125 461 242 60 50 2.3125 559 242 60 50 2.3

Approximate Net

** Same bushing is used on 75 and 95 KV BIL capacitor units.Internally fused capacitors are designed based on a specific kvar requirement. For this reasonThe overall dimensions and weights of the units are not available until the particular unit isdesigned. Please contact the factory for specific unit dimensions based on your particular kvarrequirement.

TABLE 1Bushing Characteristics and Weights

paper in the fusing dielectric,thereby eliminating thegeneration of extensivecarbon arc by-products in the dielectric fluid. Thissignificantly improves thedielectric performance bypreventing fluid contaminationand promotes proper clearingof element fuse.

■ The CLEANBREAK® fuseoperates in a current limitingmode to chop the faultcurrent into the failedelement. This prevents theenergy stored in the parallelconnected elements frombeing discharged into thefault thus minimizing gassingand damage to the failedelement and adjacentdielectric.

■ EX® mechanical connectionsystem. Provides solderlessinternal connections that elimi-nate localized heating and coldsolder joints. The EX crimpingsystem also allows 100%inspection during assemblyassuring integrity of internalconnections and maximizesoperational safety.

■ Individual closed loop capacitorfluid impregnation system.Assures superior fluid impreg-nation and gas molecule evacu-ation resulting in low infantilefailure rates and long lastingelectrical performance.

■ Stainless steel tank with light-gray finish for resistance toseverely corrosive atmos-pheres. Tank is finished with anepoxy primer and a urethanetopcoat coating system. Thissystem has been tested to theANSI C57.12.31 pole mountedstandard and the ANSIC57.12.29 coastal environmentstandard.

■ High stacking factor designutilizing aluminum foil elec-trodes with a laser-cut activeedge. The region of the dielec-tric exposed to the highest elec-tric field stress is located at theactive edge of the electrode.The high stacking factor andlaser cut active edge shapesand reduces the electric fieldstress thereby significantlyincreasing the discharge incep-tion voltage (DIV). Given theirhigh DIV capability, McGrawEdison capacitors are designedto have the highest safetymargin to DIV in the industry.

■ Light-gray, wet-process-porcelain bushings; glazed forhigh strength and durability andhermetically sealed to thecapacitor tank. Single piececover construction providessuperior sealing characteristics.

■ Stainless-steel mountingbrackets with industry-standard397 mm. mounting centers forunit interchangeability; under-side of each bracket isunpainted to properly establishtank potential.

■ Parallel-groove terminalsaccommodate copper oraluminum conductors from No. 8 solid to No. 1 stranded.Parallel-groove connectors aresupplied on all capacitors soldas individual units.

■ Internal discharge resistors that reduce terminal voltage asspecified per the relevantANSI/IEEE or IEC standards.

■ Stainless-steel nameplatecontaining required IEC orNEMA/IEEE data. Nameplatelettering is mechanically scribedto ensure long lasting perfor-mance. Nameplate is mechani-cally secured to the tankensuring that it will remain inplace throughout the life of thecapacitor.

■ Blue non-PCB decal.

Figure 2.CLEANBREAK ® fuse protectionsystem