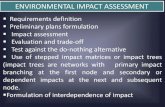

Port Planning

Transcript of Port Planning

7

1PORT PLANNING

Constantine D. MemosNational Technical University of Athens

Zografos, Greece

1.1 Introduction / 71.2 Port planning at the national level / 7

1.2.1 National port policy / 71.2.2 Definition of port functions / 8

1.3 Port planning at the individual portlevel / 101.3.1 Port development planning / 101.3.2 Principles of port design / 111.3.3 Cargo volume forecasts / 141.3.4 Port productivity / 151.3.5 The master plan / 171.3.6 General layout of port works / 17

1.4 Port planning at the terminal level / 301.4.1 Port development / 301.4.2 General cargo terminal / 311.4.3 Container terminal / 371.4.4 Marinas / 461.4.5 Fishing ports / 57

References and recommended reading / 63

1.1 INTRODUCTION

Port development can refer either to the crea-tion of a new port or to the expansion of anexisting one, usually aimed at increasing its ca-

pacity or upgrading port operations. The issueof port development is examined at three dif-ferent levels: national, local, and port terminal.Complete study of the above can be a com-plicated procedure since it presupposes acontribution by many specialists of variousdisciplines. The analysis laid out in the follow-ing pages derives from the discipline of a civilengineer specialized in port planning who hasundertaken the task of conceiving and design-ing the pertinent elements, in most cases as partof an interdisciplinary team charged with theoverall port development planning. In design-ing at the port or terminal level, aspects per-taining to the maritime aspects of ports are alsodealt with. Such issues include the general lay-out of breakwaters and quays and the design ofentrances and maneuvering areas.

1.2 PORT PLANNING AT THENATIONAL LEVEL

1.2.1 National Port Policy

Until recently, ports in many countries haveusually been developed as part of local port

8 PORT PLANNING

development programs. Such programs nor-mally do not take into consideration the cor-responding plans of other ports within thecountry, a factor that would have resulted inbetter coordination for increased national ben-efit. Indeed, in many cases, instead of attempt-ing to achieve mutual complementing of aims,undue competition tends to develop betweenports within the same country. In government-owned ports this situation can result in un-economical investment of national capital incompeting projects, and moreover, in loss ofopportunities to attract a portion of interna-tional maritime traffic.

The competitive tendencies relate to the for-eign trade of the country, foreign goods intransit, and goods being transshipped: theinternational flows that evidence potential fordevelopment as opposed to internal transports,which have more-or-less preset movement pat-terns. These trade flows can be defined as fol-lows:

• Foreign trade flows relate to the exportsand imports of a country, and conse-quently, have their origin or destination inthat country.

• Goods in transit are those goods in inter-national flow whose land transport leg usesthe territory of the country and one of itsports.

• Goods being transshipped, where both or-igin and destination are located outside thecountry but both of whose transport modesare marine. Consequently, in this flow onlythe specific ports of the country are used,not overland transport.

The latter two flows in general make up thetarget of the competition between ports in acountry.

Given that major ports constitute integral el-ements of the transport network of a country,it is evident that some sort of framework for

centralized coordination of port developmentefforts is required at a national level. A sig-nificant service that such coordination wouldproduce refers to determination of the mostsuitable ports for attracting transit or transship-ment movement on a national level. This ac-quires particular significance nowadays, wheresuch cargo movement is conducted mainly incontainers, and the corresponding port instal-lations are very costly.

In more general terms, the existence of anational port policy could broadly define therole of each port in a country, so that in thecontext of the national economy, the availablefunding can be employed as productively aspossible. Depending on a country’s develop-ment and its tendency for privatization, the al-location of roles to each port may be conductedin such a manner as to permit a large percent-age of these ports to be released from nationalcoordination and to undertake their own devel-opment.

1.2.2 Definitions of Port Functions

Today, the port has acquired its standing withinthe intermodal transport system by constitutinga nodal point between two transport modes. Inseaports, one mode concerns maritime trans-port; in river ports, this mode concerns rivertransport. The nodal linkage between two dif-ferent modes of transport should be functional,permitting efficient and secure movement ofpassengers, cargo, and vehicles. A civil port isa passenger, cargo, or combined port depend-ing on the traffic that it serves. In a combinedpart, both passengers and cargo provide a sig-nificant percentage of the traffic. Of course,specialized ports exist, such as marinas (forharboring pleasure craft), fishing ports, and na-val military bases.

There are two basic methods of loading andunloading cargo to vessels. They are lift on–liftoff (Lo-Lo), which refers to the loading andunloading method, employing either the ves-

1.2 PORT PLANNING AT THE NATIONAL LEVEL 9

sel’s gear or quay-side cranes, and roll on–rolloff (Ro-Ro), which refers to the loading andunloading method conducted by horizontallymoving equipment. Vessels allowing this typeof loading and unloading are equipped with aloading ramp that permits the movement ofcargo handling equipment and other vehicles(trucks, forklifts, straddle carriers, tractors,etc.) between quay and vessel.

At cargo ports, the type and packaging ofcargo products determine the manner of load-ing and unloading as well as of other opera-tions. Thus, the following basic categories ofport terminals can be identified, each havingvarying equipment and operational features:

• General cargo terminals. These are ter-minals equipped with conventional cranes,which handle cargo in all types of pack-aging compatible with cranes. The pack-aging could be parcels, sacks, pallets, orcontainers. The latter should not, however,constitute a major percentage of the traffic,because otherwise a specialized containerterminal would be required to improvethroughput performance.

• Container terminals. In this case, contain-ers are handled using special loading/un-loading, transfer, and stacking equipment.They are typified by extensive yard areasfor container stowage.

• Multipurpose terminals. These terminalscombine a variety of functions in a singleterminal, where containers, but also con-ventional general cargo or other packagedproducts, can be handled.

• Ro-Ro terminals. Here cargo is transferredwithin a roll on–roll off system, with load-ing and unloading of cargo by horizontallymoving lorries, forklifts, tractors, and soon.

• Bulk cargo terminals. At these terminals,liquid or dry bulk cargo without packagingis handled. Usually, pumping machinery

with suitable piping or grab cranes is usedat these terminals.

The main quantity that may be affected bya suitably implemented national port policy liesin international cargo flow. Consequently, theinitial and basic step in formulating a country’sport system includes the determination of thoseports that will undertake to serve the flows offoreign trade, transshipment, or transit. Theseflows operate more-or-less independently ofone another, and thus for simplification of theanalysis, may be studied individually.

The basic criteria to be considered in devel-oping a proposition as to the roles of a coun-try’s ports may be classified into the followingfour groups:

1. The national and regional developmentpolicies of the country

2. The transportation infrastructure of thehinterland and its prospects

3. Existing port capacity and potential fordevelopment

4. Cargo forecasts for each port

After each of the three independent inter-national flows has been examined, the findingsshould be pooled, to define the core of thecountry’s port system. Thus, the role of eachport that participates in international cargo flowwill be specified and the basic cargo through-puts can be determined. Considering thesethroughput values, and factoring in the nationalflows, master plans can be drawn up for indi-vidual ports.

Apart from international cargo flow, otheraspects of the overall port development studyare usually examined. Although these are notof primary significance in the formulation ofthe core of a national port system, they do havea role in evaluation of the main subsystems andin developing the final proposal. Such aspectsinclude:

10 PORT PLANNING

• Special bulk cargoes, such as coal, cement,petroleum products, grains

• Industrial ports• Shipbuilding and ship repair• Free zones• Coastal shipping• Passenger movement

1.3 PORT PLANNING AT THEINDIVIDUAL PORT LEVEL

1.3.1 Port Development Planning

1.3.1.1 Port Development and MasterPlanning. The master plan of a port allocatesthe land within the port to the various usesrequired, describes the projects needed to im-plement the plan, and gives an indicativeimplementation scheme by development phase.These phases are related directly to the pro-jected port traffic which has to be monitoredclosely. When in due course a decision isreached to proceed with implementation of adevelopment scheme, this should be integratedsmoothly with, or derive from, the master planfor the port. Therefore, it is important that amaster plan exist, and drafting one should beamong the primary concerns of port manage-ment. Of course, a variety of continuouslyvarying factors have a bearing on such a plan,ranging from statistical data on port traffic tointernational treaties. For this reason, the planshould be revised regularly, at least every fiveyears. Moreover, if during the design of a par-ticular development phase the need arises for areview of the plan, this should be conductedconcurrently, if possible, to ensure compatibil-ity with the other functions and operations ofthe port. However, the lack of a master plan ata particular port should not delay the makingof decisions for small-scale immediate im-provement, although it is recommended that atthe first opportunity an effort should be madeto draft a master plan for the port.

1.3.1.2 Long-Term Planning. In the eventthat a national ports plan does not exist, theconsultant should proceed with drafting a mas-ter plan, after studying the following compo-nents of long-term planning:

1. The role of the port—in particular:a. The servicing of its inland area as

regards foreign tradeb. The support that the port may offer to

the region’s commercial and industrialdevelopment

c. The attraction of transiting and trans-shipment traffic

2. The responsibility of the port for the con-struction of both port and land works.Frequently, more than one agency be-comes involved: for example, when aport area is serviced by a railroad.

3. The land use in the area and the potentialfor expansion of the port. It is importantthat there be general agreement betweeninterested parties over the proposed ex-pansions and land use so that the result-ing master plan meets with wideacceptance.

4. The policy for financing the port devel-opment, which may be formulated on thebasis of its own resources and/or througha state grant.

In general, in modern port development thebasic requirement is for large expanses of landto ensure productive operation of the individualterminals. Therefore, a careful examination ofpoint 3 assumes particular importance.

1.3.1.3 Medium-Term Planning. As stated,each port development scheme should be in-corporated in the master plan and should pro-ceed to implementation following the results ofan appropriate feasibility study. The latterstudy should refer individually to each inde-pendent section of the overall developmentproposal, such as a container terminal or a bulk

1.3 PORT PLANNING AT THE INDIVIDUAL PORT LEVEL 11

cargo terminal. Thus, under a positive but re-duced yield from the overall proposal, the riskof concealment of a nonproductive section isavoided. The drafting of a port developmentplan calls for the conduct of the following spe-cial studies:

1. Analysis of the functionality of the portas regards the services offered in con-junction with capacity

2. Designs, with budgets3. Operational design, with budget4. Financial and financing study

In large port development projects it is cus-tomary to reexamine the organization and man-agement of the port operating agency and torecommend organizational improvements on asmall or larger scale. It is possible that manyof the ports in a country do not warrant a de-velopment effort beyond maintenance of exist-ing structures or appropriate modification, suchas to serve fishing vessels or pleasure craft.Such modifications are nowadays met quite fre-quently, since old ports, traditionally being partof the core of their town, cannot easily incor-porate large land expanses needed in modernport layouts. Also, environmental and social is-sues do not allow in many cases major ex-panses of an old port site. The requirement thatthe citizenship should be granted free access tothe waterfront of their city is gradually beingrespected by more and more authorities. Nev-ertheless, the problem of what to do with theold port installations is a complex one, whereboth the needs of the local community and thebenefits of the relevant port authority should beaccommodated. As noted above a commontrend is to change the character of a past com-mercial port into a marina or fishing vesselsrefuge. There are also examples (London, Mar-seille, etc.) where old ports were completelyrefurbished into commercial or recreationalzones, some of them arousing controversialdiscussions among town-palnners.

Moreover, since ports interact in many wayswith the surrounding township, port masterplanning should take into account, apart fromstrictly engineering issues, such aspects as so-cial, economic, and environmental constraintsand should easily fit within the relevant townand regional plans. This frequently calls for acompromise between the requirements of theport and the local authorities.

1.3.2 Principles of Port Design

1.3.2.1 Guiding Principles. If the undertak-ing involves the development of an existingport, before proceeding with developmentplans it would be prudent to make efforts to (1)increase productivity and (2) improve existinginstallations. Factors that contribute to increas-ing productivity in an existing port are im-provements in loading and unloading practices,to the overall operation of the port terminals,and to modernization of cargo handling andhauling equipment. As pointed out, the expan-sions that may be required additionally to theimprovements above should be incorporated inthe master plan of the port and should be im-plemented within a time horizon in order toconstitute productive projects according to thepertinent feasibility studies.

Particularly as regards the individual termin-als within a port, the respective capacity cal-culations are based on different factors,depending on the nature of each terminal asfollows:

1. In conventional cargo terminals, the re-quired number of berths is determinedfirst, to keep vessels’ waiting time belowa specified limit, determined by eco-nomic and other criteria.

2. In container terminals, the land area re-quired for the unobstructed movement ofcargo flow is calculated.

3. For specialized bulk cargo terminals, thecargo flow during loading and unloading

12 PORT PLANNING

Figure 1.1 Port cost as a function of cargo throughput. 1, Port’s cost; 2, cost of operation; 3, capital cost.

has to be calculated first, to ensure thatvessels will be serviced within acceptableperiods of time.

As arrival times of commercial vessels atports cannot adhere to an exact schedule, en-abling ready scheduling of requisite berthingand eliminating waiting time, to determine thenumber of berths a compromise is usuallymade between two extreme situations: on theone hand, the minimization of vessel waitingtime, and on the other, the maximization ofberth occupancy.

1.3.2.2 Port Costs. Two factors constituteport costs: investment cost, which does not de-pend on traffic, and operating cost, which does.If the cost were to be expressed per unit ofcargo throughput, the relation between cost andtraffic volume is depicted as in Figure 1.1. Aship’s cost in port is also made up of two con-stituents: the cost of the vessel’s waiting timeand the cost of the ship while berthed. Theship’s total port cost curve expressed as aboveis shown in Figure 1.2. The sum of the portcost and the cost of the ship in port provides atotal cost, as shown in Figure 1.3.

Traffic corresponding to point B in Figure1.3 is less than that at point A. This means thatthe optimum traffic volume for a port is lowerwhen the total cost is taken into account thanwhen either the total port cost or the total ves-sel cost is considered. Of course, the differencebetween A and B depends on vessel types,which determines the corresponding vessel costcurves.

A measure often used to describe the levelof service offered to vessels is the ratio of wait-ing time to service time. It is generally rec-ommended that this ratio be lower than, say,20%, but there is a danger here of showing animprovement of service provided through aunilateral increase in service time. This is whyfor the purposes of evaluation, absolute valuesof total vessel waiting time at the port are alsorequired.

1.3.2.3 Traffic Fluctuations. Even a propor-tionally small but persistent increase in the traf-fic of a port may very quickly cause congestionin a port lacking in reserve spaces; the conges-tion will cause a reduction in the productivityof serviced vessels, which aggravates the prob-lem further. The increase in traffic may be

1.3 PORT PLANNING AT THE INDIVIDUAL PORT LEVEL 13

Figure 1.2 Cost of ship in port. 1, Ship cost in port; 2, cost of waiting; 3, cost of berth.

Figure 1.3 Total vessel–port cost curve. 1, Total cost; 2, cost of vessel; 3, cost of port.

caused by a new shipping line, larger cargovolumes, more frequent or occasional vesselcalls, and so on. Even a change in the packingmethod of a product of large throughput mayaffect the efficiency and productivity of a port

adversely. It is assumed that the problems cre-ated by a steady increase in traffic will be metin good time through the implementation ofsuitable development projects based on themaster plan of the port.

14 PORT PLANNING

The fluctuations around more-or-less regularaverage traffic may be faced by a carefully de-signed emergency plan according to which oldquays, anchorages, and so on, on reserve,which are not used as vessel servicing posi-tions, may be brought into operation. Usually,the reserve capacity of a port consists of in-expensive installations, which, however, giverise to a high cost of operation. These reservesshould be allocated equally among all theport’s sections. Other means of a temporary in-crease to port capacity could be an improve-ment in cargo handling: for example, anincrease in work gangs per vessel serviced, thehiring of additional mobile cranes or otherequipment, or the use of lighters for loadingand discharging on two sides.

The size of the cargo to be taken for plan-ning purposes should be selected carefully sothat potential fluctuations may be absorbedwith some acceptable increase in vessel waitingtime. As regards high-cost installations andvessels, a method of smoothing the peaks inwaiting time is that of serving by priority, ac-cording to which, when the vessel arrives at apredetermined time, it will have guaranteed ac-cess. The more such agreements between portsand liner operators are signed, the greater thesmoothing of the traffic curve.

1.3.2.4 The Optimum State. The chief ben-efit from investments in port projects is the pos-sibility if reducing total vessel time at a port.Despite the fact that ships are the first party tobenefit, in the medium term both the port andthe country benefit overall from the develop-ment of ports. From a practical point of view,optimization of the waiting time–quay use is-sue may result in a 75% occupancy factor fora group of, say, five general cargo berths,which produces a wait of half a day, for anaverage service time of 3.5 days. This meansthat over a long period of time: 55% of vesselswill berth immediately, 10% of vessels willwait for 2 days, and 5% of vessels will waitfor 5 days. It can be deduced from the above

that the fact that some vessels experience ex-cessive waiting times does not necessarilymean that the port is congested.

1.3.2.5 Grouping of Installations. De-pending on the type of cargo traffic and on theequipment required, berthing positions andother installations are grouped in more-or-lessindependently operating areas of a port. Thisgrouping implies specialization in the type ofcargo traffic being served in each port section.Thus, better utilization is achieved: for exam-ple, in wharf depths and quicker servicing ofvessels and cargoes. However, there are alsodisadvantages to grouping port installations.Basically, the flexibility obtainable by thegreater number of berths is reduced. This offersa more productive exploitation of both waterand land spaces.

Implementing a sort of grouping thereforeshould proceed when conditions are ripe: forexample, when there is high traffic or when agood number of berths are required. An inter-mediate stage of providing a multipurpose ter-minal serving two (or even three) types ofmovement may be interposed prior to the finalstage of specialized port terminal. This termi-nal will require cargo handling equipment ca-pable of handling more than one type of cargo.Such equipment may be more expensive, so theservicing of vessels and of cargoes may notattain the efficiency of specialized terminals,but there is more than acceptable utilization ofequipment and in general of the entire instal-lation of a multipurpose terminal. A multipur-pose terminal should retain some flexibility sothat in the future it may be converted into aspecialized terminal when conditions permit.

1.3.3 Cargo Volume Forecasts

1.3.3.1 Scope. Cargo volume forecasts for aport provide estimates of:

• The types and quantities of the variousgoods to be moved through the port

1.3 PORT PLANNING AT THE INDIVIDUAL PORT LEVEL 15

• Packing by type of cargo• The number of vessel calls corresponding

to the quantities above

If a national ports policy has been drawn up,the magnitudes above will already be known;otherwise, forecasts are made individually forthe specific port under consideration. There ispotentially great uncertainty in forecasts, andtherefore the planning should accommodateflexibility to enable adaptation to meet futuretraffic. The parameters considered in cargo vol-ume forecasts include:

• Population and national product• Regional development programs• The transport network and its projected fu-

ture• Coastal shipping• Diversion of a portion of the traffic to

other harbors

It is customary to hold interviews with gov-ernment and local authorities, the shippingcommunity, and interested parties to gain anunderstanding of the present and future trafficpatterns. An independent review of global com-mercial and trade prospects that play a majorrole in traffic forecasts should also be con-ducted. Usually, the dependence of the resultson the parameters is estimated on the basis ofsensitivity control of the various calculations.Thus, in addition to the central forecast, wefrequently include both an optimistic and adownside forecast, based on the correspondinggrowth scenario. An important port function in-volves monitoring the accuracy of the forecastsby comparing them with actual traffic.

1.3.3.2 Cargo Flow Combination. Usually,forecasts of significant cargo flows are con-ducted by type of cargo and by route. Bulkcargoes should be distinguished by type ofcargo; container and Ro-Ro cargoes are distin-guished by type of vessel performing the car-

riage. Ro-Ro cargoes may consist of (1)containers, (2) vehicles, (3) general cargo, and(4) products of intermediate unitization.

Container cargoes are calculated in 20-footequivalent units (TEU), inclusive of empty con-tainers. Forecasts should provide for some in-crease in the number of products acceptingcontainerization. The net weight of the TEUranges from 5 to 18 tons, depending on thestowage factor of the cargo within the con-tainer. For instance, if this factor were 2.8 m3/ton, the net weight per TEU would amount to10.4 tons. The results of cargo projections bycargo type and route should be reformulated bycargo category (e.g., dry bulk cargo). The totalprobability of a complex flow depends on thepartial probabilities of the constituent flowforecasts and on the degree of their interde-pendence. It is advisable to analyze the flowsof products with intense seasonal fluctuationseparately and then to add them to the otherflow forecasts.

1.3.3.3 National Transshipment. To esti-mate the transshipment flows either originatedfrom or directed to a national port, and of thecorresponding quays required, the alternativecargo flows between ports A and B should beexamined. The latter implies that the requiredvolume of cargo could be delivered to each porteither directly, or the total volume of cargo di-rected to both locations will be delivered to oneport only, from which it will be transshippedto the other location either by land, or by seausing smaller ships (coasters). For details, con-sult the proceedings of a United Nations con-ference (1978).

1.3.4 Port Productivity

The productivity of a port is the measure of itsability to move cargo through it within a unitof time under actual conditions. It is knownthat cargoes undergo various stages of handlingwhile in port. For example, imported goods un-dergo the following handling procedures:

16 PORT PLANNING

• Discharging while a vessel is berthed• Transport to storage area and stowage• Removal from storage and transport to

area of transshipment or to means of over-land transport

• Loading onto means of overland transport• Departure from the port

Obviously, the total productivity of a port isdetermined by the lowest partial productivity ofeach link in the cargo handling chain. The con-ditions prevailing at the port at any givenmoment, such as weather conditions, humanresources, and condition of machinery, affectthe productivity of the partial procedures con-siderably. Consequently, a substantial timerange representative of prevailing conditionshas to be assumed for the evaluation.

The cargo handling practices pursued ineach port have a decisive bearing on productiv-ity, and any attempt at their improvementshould also factor-in a period of adjustment ofthese practices to the new machinery and han-dling methods. Generally, a reference to anymeasure of productivity should be correlatedwith its corresponding time period. If this in-volves an extensive time period, on the orderof several months, productivity may be reducedto half its value achieved in a short period oftime (e.g., 1 hour). This may apply to all theparticular procedures and handling of cargoflows within the port. For instance, over a shortperiod of time, say a few hours, the containerdischarge efficiency at the dockside phase mayamount to 750 TEU per day per berthing po-sition, whereas over a period of several monthsthe corresponding output for the same berthmay drop to 400 TEU per day. Obviously, thelong-term efficiency rate is important in the de-sign of port installations.

Since the total efficiency of a commercialport or terminal is determined by the lowestproductivity of the partial handling leg, everyintervention for increased productivity should

be directed initially at the least efficient pro-cedure, with the purpose of balancing it outwith handling legs of higher efficiency. The fol-lowing are the most typical pairs of consecutivecargo handling legs in port cargo handling pro-cedures:

• Dock loading and unloading: transportfrom quay to storage area, or vice versa

• Transport from storage area to means ofoverland transport: flow of means oftransport to and from inland areas

An efficiency equalization between each ofthe constituent parts of a cargo handling pairshould be achieved, measured on an hourly (oreven daily) basis. Equalization should also beeffected between the pairs themselves, al-though over a greater time period, that of aweek, during which the cargoes remain in thestorage areas, where the various checks andother procedures are conducted. This require-ment for efficiency equalization ensuressmooth functioning of the storage areas, thusaverting the risk of congestion.

Efficiency increase may be achieved by in-tervention in three areas: (1) human resources,(2) technical matters, and (3) management andprocedures. Intervention in the first area in-volves mainly an improvement in working con-ditions; in the second area, equipment renewal,better maintenance, and backup provisions; andfor the third area, procedure simplification, im-position of a maximum time limit for cargo toremain at the storage areas, and so on.

It should be noted that an increase in pro-ductivity of a terminal by L % does not reducevessel servicing time by the same percentage,but rather by L / (1 � L), as is easily deducedby the definition of loading/unloading produc-tivity at the quay (� cargo loaded or unloaded/vessel servicing time). The efficiency of a portterminal is affected by the quantity of cargo tobe loaded to and unloaded from a vessel. It has

1.3 PORT PLANNING AT THE INDIVIDUAL PORT LEVEL 17

been found that a large quantity of homoge-neous products increases productivity, but usu-ally this is not considered in the relevantcalculations.

1.3.5 The Master Plan

1.3.5.1 Port Categories. From a construc-tion point of view, ports may be classified intothe following categories.

Artificial Ports. Artificial ports are those con-structed along a shoreline by means of earthfill or excavation (Figure 1.4). In both casesthese ports have to be protected from the ad-verse effects of waves and currents. In the for-mer case (Figure 1.4a) the land part of a portis created by means of earth fill, and in thelatter case (Figure 1.4b) the port basin is cre-ated artificially by means of excavation of landadjacent to the shoreline. The geometry of theexcavated basin depends on port size and modeof operation. The excavated harbor is joinedwith the sea via an approach channel. The en-trance to this channel is usually protected fromwaves and current by means of breakwatersand dikes. For more information on excavatedharbors, readers are referred to Memos (1999).

Ports Constructed in a Natural Harbor.Examples are shown in Figure 1.5. Significantfactors to be considered in opting for one ofthe foregoing types of port is availability ofland, land fill material, soil quality, depth ofwater, environmental conditions, and others.

1.3.5.2 Port Location. Traditionally, portsare situated in a location central to the urbanarea they serve. The port is thus surrounded byurbanized area, and both further developmentof the port and access to it are rendered diffi-cult. This situation restricts expansion of theport required to meet modern demands. In mostcases, a feasibility survey for relocation of theport outside the city will have to be conducted.

The prerequisites for such relocation are (1) se-cure maritime approaches, (2) ample availabil-ity of land area, and (3) satisfactory access byland.

For an initial new site evaluation, an exten-sive list of data to be collected is usually drawnup. Some of the items included are:

• Uses and ownership of the land• Topography and access• Existing utilities and structures at the site• Wind and rainfall data• Hydrographic information• Geotechnical data, including potential

sources of construction materials• Environmental assessment of the area

During the initial site evaluation, some as-pects of the project that may affect its devel-opment should be investigated. These mayinclude necessary permissions and ownershipimplications, dredging and spoil disposal re-quirements, environmental constraints, and soon. In cases of inability to relocate, an alter-native to be examined is that of establishingadditional land facilities inland such as an in-land depot.

1.3.5.3 Design Criteria. During the masterplanning stage of a project preliminary designcriteria should be proposed covering aspectssuch as types of operations to be undertaken(e.g., containers, transit and transshipmentflows, import/export; design vessel, operatingequipment).

1.3.6 General Layout of Port Works

1.3.6.1 Guiding Principles. The arrange-ment of port works should be such as to ensureeasy berthing of vessels, secure efficient cargoloading and unloading, and safe passenger em-barkation and disembarkation operations. Spe-cifically, easy access of vessels to a port should

18 PORT PLANNING

Figure 1.4 Conceptual arrangements of artificial ports: (a) created by earthfill; (b) created by excavation. 1–3,Breakwaters, 4, pier; 5, marginal wharf; 6, outfitting pier; 7, dry dock; 8, marina; 9, existing shoreline; 10,approach channel; 11, excavated basin.

1.3 PORT PLANNING AT THE INDIVIDUAL PORT LEVEL 19

Figure 1.5 Ports constructed in natural harbors. (a) Entrance to the harbor is naturally protected by existingislands. (b) Entrance to the harbor is protected by the breakwater. 1, Coastal line; 2, harbor; 3, existing island;4, port facilities; 5, breakwater.

be ensured through an appropriate navigationchannel, a suitably designed port entrance, anadequate maneuvering area, and avoidance ofundesirable erosion or deposition of material inand around the harbor area.

Factors to be considered in drafting a well-designed layout of port works include winds,waves, and currents and also the transportationof deposits in the study area. The existence ofriver or torrent mouths in the vicinity of theworks has to be considered seriously in choos-ing the location and arrangement of the harbor.

The disturbance of harbor basins is a signif-icant parameter, and low agitation should beachieved through a suitable arrangement ofharbor structures. Specifically, the appearanceof reflection and resonance phenomena withinthe harbor should be avoided through the useof absorbing beaches and suitable geometry ofthe structures that delineate it. The problem ofexcess wave agitation should be explored in ei-ther a physical or a mathematical model in or-der to arrive at an optimum layout of portworks. Such models may also be used to op-timize the constituent elements of the port,such as the port entrance.

Several of the subjects above may be tackledsuccessfully by providing for an outer harbor

that functions as a relief zone for the incomingwaves, thus producing easier port-entry condi-tions. Next comes a closer examination of themost important elements that have a direct im-pact on the general layout of the principal portstructures. For issues related to the navigationchannels that serve ports, readers are referredto Chapter 10.

1.3.6.2 Port Entrance. The port entrancedemands careful consideration to ensure quickand safe entry of vessels in the harbor. Theorientation and width of the entrance shouldreconcile two opposing criteria. For reasons ofcomfortable navigation, the harbor entranceshould communicate directly with the open seaand should be as wide as possible. On the otherhand, the narrower and more protected the en-trance, the smaller the degree of wave energyand deposits that penetrate the harbor basin, re-sulting in more favorable conditions for attain-ing tranquility of the in-harbor sea surface.

It is recommended that orientation of the en-trance be such that vessels entering the harborhave the prevailing wind to the fore. Transversewinds and waves create difficult conditions forsteering a vessel through the critical phase ofentering the harbor basin, and a layout of port

20 PORT PLANNING

works that would permit frequent occurrencesof such situations should be avoided.

Naturally, in most cases, the designer isobliged to compromise, as mentioned above.Obviously, the designer should avoid placingthe entrance in the zone of wave breaking be-cause of the difficulties to vessel maneuveringthat may arise. Frequently, the entrance isformed by a suitable alignment of the protec-tion works, whose structure heads are suitablymarked with navigation lights. In the event thatit is not possible to avoid transversal winds andwaves, it is recommended that calm conditionsat the harbor entrance be created by means ofextending the windward breakwater to a satis-factory length beyond the entrance, at least tothe length of one design vessel. In such casesit is advisable that the superstructure of the out-ward port structure be raised so that the windpressures on the sides of the incoming vesselare reduced.

To attain the calmest possible conditions atthe harbor entrance area, it is recommendedthat the external works in its vicinity be formedwith sloping mounds so that wave energy inthe entrance area can be absorbed. Breakwaterswith a vertical front near the entrance maycause difficult navigation conditions there, be-cause of the reflected and semistationarywavetrains created in that region. Moreover, indesigning the layout of the harbor arms thatbound the entrance, care should be taken thatany sedimentation of deposits in the area bereduced. For significant projects, study of theentrance usually culminates in a physicalmodel in which optimization of the arrange-ment is effected by conjoining all the relativerequirements.

The width of the harbor entrance is definedin terms of the smallest length vertical to theentrance axis for which the minimum requireddraft applies. The depth at the entrance is gen-erally determined by the maximum draft of thedesign vessel to be served. This figure shouldbe taken beneath the lowest low water so that

the harbor will always be accessible. In areaswith a large tidal range in which the sea levelcan fluctuate by several meters, the questionarises as to whether it is necessary to ensureaccessibility to the port at all times. To meetsuch a requirement would signify an increasein the dredge depth equal to the range in tidallevel. Alternatively, it could be accepted thatthe entrance be equipped with gates and thatthe port not be accessible during certain low-tide periods. Because such periods are foresee-able, as relying mainly on precise astronomicalpredictions, and because they are of relativelysmall duration, this solution is not to be re-jected offhand, particularly if the harbor is ac-cessible by means of long access channels.Vessels wait in the open sea up to the timewhen the channel is navigable for a specificvessel. Obviously, the internal harbor works ofa tidal harbor will be compatible as regardsdrafts, with the planned navigation channeldrafts suitably increased by a factor to com-pensate for the tidal increase during the openphase of the harbor. Thus, the vessels may al-ways be safely afloat as long as they are in theharbor. Such a solution for periodic operationof the port entrance and channel has shortcom-ings, of course, because of vessel delays andother harbor malfunctions. Consequently, acareful cost–benefit analysis should be con-ducted prior to deciding the extent to which theport will be of free or of limited navigability.Such problems do not arise in ports with rela-tively small tidal fluctuations.

A safety factor of about 15% of the designvessel draft is sufficient for purposes of defin-ing the minimum entrance depth. Alternatively,a margin of about 1.5 to 2.0 m over the draftof a loaded vessel gives a safe water depth atthe port entrance. The width of a free entranceusually ranges between 100 and 250 m, de-pending on the size of the port. It is recom-mended that width be at least equal to thelength of the design vessel the port is to serve.Thus, for small harbors it is possible to specify

1.3 PORT PLANNING AT THE INDIVIDUAL PORT LEVEL 21

Figure 1.6 Layout of a large multipurpose artificial port. 1, General cargo terminal; 2, container terminal; 3,passenger terminal; 4, oil berth; 5, fishing port; 6, dry dock; 7, ship repair area; 8, anchorage area; 9, maneu-vering circle; 10, mooring dolphins; 11, breakwater; 12, tugboat berth; 13, coastal line.

entrance width to be as low as, say, 50 m. Thecorresponding width of a closed port is signif-icantly smaller than the sizes above. For moreinformation, readers are referred to Tsinker(1997) and Chapter 9.

1.3.6.3 Maneuvering Area. When a vesselenters the harbor basin, its speed needs to bereduced to proceed with anchoring and berth-ing maneuvers. In practical terms, these ma-neuvers may be conducted at a normal speedof 8 to 11 knots over a length of 2 to 3L, Lbeing the vessel length, although larger dis-tances may be required for larger vessels withmodern hydrodynamic shapes. A significantconsideration in determining the requiredlength for minimizing speed is the vessel’s fit-tings in maneuvering equipment, as well as thetype of propeller; if the latter is of variablepitch, the distance can be reduced to 1.5L. Themaneuvering area is located either in the outer

harbor, situated between the port entrance andthe main port, or in the main harbor basin clos-est to the entrance.

Apart from reducing speed during an initialstage of straight movement, the vessel conductsmaneuvers for positioning itself appropriatelyfor the berthing position, which has been de-termined beforehand. This expanse of sea,called the maneuvering area or circle, shouldhave dimensions calculated on the basis of theharbor’s design vessel. If the port is sufficientlylarge, more than one maneuvering area may bedesigned and located at intervals of about 1 km.Figure 1.6 depicts the layout of a large artificialport with a maneuvering circle.

The diameter of the maneuvering circle re-quired is affected directly by the type of rud-ders and propellers with which a vessel isequipped, whether or not tugboats will beemployed, or whether anchors or wrappingdolphins will be used. For unfavorable ma-

22 PORT PLANNING

neuvering conditions, no tugs, and vessels withonly one rudder, a 4L diameter is required,whereas in favorable conditions with modernnavigation systems, a 3L diameter may suffice.Instead of a circle, maneuvering requirementsmay be satisfied by an ellipse with 3L and 2Laxes, the main axis being lengthwise of thevessel’s course. If maneuvers are conductedwith the aid of tugboats, the minimum diameterof the maneuvering circle may be reduced to2L. A corresponding decrease is also achievedif the vessel is fitted with a second rudder or alateral propeller, usually a bow thrust.

During towage, a vessel’s engines usuallyare stopped or are in excellent synchronizationwith the tugboats. Furthermore, if a vessel hasthe ability to use bow and stern anchors orwrapping doplhins, the diameter of the maneu-vering circle may reach the minimum dimen-sion of 1.2L.

In the maneuvering area, the sea surface isgenerally calmer than that at the entrance, andit is advisable that the lateral currents in thisarea be weaker than approximately 0.15 m/s.Furthermore, the reduction in available draftdue to squat is insignificant in the maneuveringcircle. Consequently, the required draft in themaneuvering area may be somewhat smallerthan that at the entrance. In most cases, a safetymargin of about 1.5 m below the maximumdraft of the design vessel is sufficient.

To avoid accidents, the maneuvering areashould be surrounded by a safety zone fromfixed structures or vessel moorings. It is ac-cepted that the width of this zone is a minimumof 1.5B, where B is the design vessel’s beam,and in any case it should be above 30 m. Moreinformation is given in Chapter 9.

1.3.6.4 Vessel Anchorage and Mooring.Perhaps the most significant role of a harbor isto provide shelter to vessels and to protect themfrom waves, currents, and strong winds. Onceships enter port, they generally use one or more

anchors for their maneuvers, and while they arepreparing for their berthing, mooring lines arealso used, tied to the dock bollards. It may benecessary to immobilize vessels before entryinto port, either while waiting for a free berthor for the tidal water to rise above the criticallevel at the entrance channel. This is achievedeither by using the ship’s anchors or by usingsuitable mooring buoys or dolphins located inthe waiting area. Detailed information on an-chors and anchorage area is provided in Chap-ters 7 and 8.

1.3.6.5 Wave Agitation in the Port Basin.It was mentioned previously that the basicfunction of a port is provision of a protectedanchorage for vessels and the facilitation ofquick and safe loading and unloading opera-tions and embarkation and disembarkation ofpassengers. Therefore, the absence of disturb-ing waves in the basin that would impede thesmooth functioning of the port is mandatory.The study of disturbances in a harbor basinshould take as input the prevailing wave patternand provide as output the percentage of timeduring which the port, or individual sections ofit, cannot be operational. As stated earlier, themain factor causing an interruption in the op-eration of a port, and indeed one that demandscareful examination, is that of wind-generatedwaves. Apart from penetration through the en-trance, wave transmission and overtopping atbreakwaters should be considered in determin-ing surface agitation in a basin.

It follows that planning the layout of portstructures is of crucial importance in attainingthe necessary tranquility of the sea surface ina harbor basin. That is why particular attentionmust be paid to this problem in the course ofstudying the layout of port works. A satisfac-tory answer may be obtained by laboratorytesting of various designs in a physical model.In these tests, wave disturbance is recorded atsuitably selected locations in the harbor basin,

1.3 PORT PLANNING AT THE INDIVIDUAL PORT LEVEL 23

as well as resulting movements of berthed ves-sels. The acceptable limits of these movementsare determined depending on the loading andunloading method and the type of cargo han-dling equipment being used.

Apart from physical models, a good deal ofinformation can be obtained from mathematicalmodels, which can be developed to various de-grees of accuracy. In this case, the wave heightsin sections of the harbor basin are determinedunder various environmental conditions and de-grees of absorption of the solid boundaries, al-though it is exceedingly difficult to simulatevessel movements. Wavelengths of the incidentwave field have a particularly significant effecton vessel behavior; certain wavelengths pro-duce dangerous conditions, as noted belowwhen we discuss disturbance due to long os-cillations. Any examination of port basin tran-quility does, of course, include an assessmentof the cost of the port works required to obtaineach degree of basin calmness.

Long Oscillations. Apart from wind-generatedwaves, a range of other natural factors can dis-turb a harbor basin, although to a lesser extent.Many of these have to do with extreme events,such as storms and seismically created waves.In such cases, many harbors do not offer sat-isfactory shelter to vessels, which prefer to sailout to the open sea to avoid sustaining or caus-ing damage in port.

Among these factors, those most significantas to continuous effects on harbor basins andtherefore on ships’ operations can genericallybe termed long oscillations (seiches). In effect,these refer to trapped oscillations with periodsin excess of 30 s caused by changes in atmos-pheric pressure, long waves caused in the opensea by barometric lows, surf beats, edge waves,and so on. A serious problem arises when theharbor basin’s geometry favors the develop-ment of resonance at the frequencies of the freeoscillations prevailing in the region. In such

cases, the flow velocity at the nodes of theoscillation of the free surface may reach 0.5m/s even though the vertical surface excur-sions may generally be small. Long waves withperiods usually in the region of 1 to 3 minplace stresses on docked vessels, particularlywhen this involves larger ships with taut moor-ing lines. The phase velocity of these longwaves in relatively shallow harbor waters isgiven approximately by (gd)1 / 2, d being theuniform depth of water. Consequently, for aharbor basin with a rectangular plan of dimen-sions L � W with an entrance on the W (width)side, the resonance period of standing waves,TL, along the two directions will be

4LT � n � 1, 3, 5, . . . (1.1)L 1 / 2n(gd)

with a node of the standing wave at the en-trance and an antinode at the opposite end ofthe harbor basin, and

2WT � n � 1, 2, 3, . . . (1.2)w 1 / 2n(gd)

with antinodes at both opposing docks.A basic means of avoiding resonance in a

new harbor is the design of harbor basins withsuch geometry that the frequencies above arefar from the usual frequencies of long wavesin the region. The latter may be traced throughthe use of recording devices of surface eleva-tion not sensitive to high-frequency waves. Incases where the harbor evidences complex ge-ometry, the typical resonance modes are deter-mined through mathematical models, or eventhrough physical models in some cases, in away similar to examination of the disturbancedue to wind waves. As known, low-frequencywaves may penetrate harbor basins without un-dergoing significant reduction of their ampli-tude. That is why any attempt toward a better

24 PORT PLANNING

layout of the protection works and of the en-trances will be fruitless with regards to theelimination of long waves.

Recommendations for Improving a PortBasin’s Tranquility. It is obvious that a basicelement in designing a port is to achieve thelowest possible disturbance in the harbor basin,particularly close to berths. For this reason, itis recommended that the following factors beexamined:

1. Provision for an adequate extent of theouter harbor area and of all the harborbasins, for dispersion of wave energypenetrating the harbor

2. Provision for spending beaches in suita-ble locations of the harbor, especiallythose attacked directly by waves enteringthe basin.

3. Provision for absorbent wharves withsuitable design for dissipating disturbingwave agitation. It is recommended thatthis type of work be checked throughphysical modeling because the phenom-ena of conversion of wave energy, expel-ling of air, upward loading of the crownslab of the quay, and so on, are suffi-ciently complex and do not easily lendthemselves to analysis through mathe-matical modeling.

In any case, the usefulness of absorbingquay walls is debatable, chiefly because of thewave reflection caused by berthed vessels attheir sea side, a fact that reduces the efficiencyof these structures considerably.

1.3.6.6 General Layout ofProtection Works

Layout of Main Structures. Works whosefunction is to ensure the calmest possible con-ditions within harbor basins and along quays,

particularly from wind-generated waves, aretermed harbor protection works. These may in-clude the following:

1. Breakwaters, usually constructed eitherconnected to the shore or detached.Shore-connected breakwaters are classi-fied as windward or primary and leewardor secondary. The former protect theharbor from the main wave direction,and the latter protect from waves ofsecondary directions. Frequently, leewardbreakwaters are partially protected bywindward breakwaters.

2. Jetties, usually arranged in pairs to formentrances to harbors located inward fromthe shoreline or in rivers. Paired jettiesmay also increase the flow speed and thusprevent sedimentation.

Figures 1.4 through 1.6 depict certain com-mon arrangements of outer port works, de-pending on the type of harbor. The free end ofprotection works is called the structure head,and the remainder is the structure trunk. Theeffect of harbor works to be constructed on thetransport regime of sediments in the region isparticularly important. Quite often, port worksare located in the surf zone, where the largestpercentage of sediment transport takes place.Consequently, the effect of these works oncoastal erosion or deposition may be quite sig-nificant. The phenomena usually caused byharbor protection works as regards sedimenta-tion is a concentration of deposits upstream ofthe windward breakwater, erosion of the shoredownstream of the leeward breakwater, sedi-mentation in the vicinity of the harbor entranceand the approach channel, and others (Figure1.7).

The solution to such types of problems isnot an easy matter, and in many cases recourseto the method of sand bypassing is consideredto minimize the dredging required for mainte-

1.3 PORT PLANNING AT THE INDIVIDUAL PORT LEVEL 25

Figure 1.7 Effects of harbor works on coastal sedimentation. a, Longshore littoral transport; b, accretion; c,deposition; d, erosion; 1, natural shoreline; 2, breakwater; 3, landfill for port construction; 4, artificial harbor.

nance of drafts. The general idea in designingthe layout of protection works should be to fa-vor the transfer of sediment to deeper waters,where they are less harmful. Application of thisgeneral rule is not always easy, of course; thatis why port designers usually resort to labora-tory tests of the general arrangement of a har-bor’s defense works.

The protection structures are in principlelaid out such as to provide the space requiredfor a calm harbor basin, maneuvering areas,and necessary safety margins. Following that,an examination is conducted to ascertain thedegree to which a large portion of the outerworks is located in the wave-breaking zone.Selected values of wave heights are examinedand the required modifications to the layout ofthe works are made so that the works areplaced outside the breaking zone of the crucialdesign waves. This is done to reduce waveloads on the relevant structures and conse-quently, their cost. An important step follows:that of forming the harbor entrance in accord-ance with the guidelines of Section 1.3.6.2. An-other point that relates to the shape of thebreakwaters refers to the avoidance of anglesto the open sea smaller than 180�, to evade aconcentration of wave energy, with adverse ef-fects on the structure’s integrity.

Finally, the possibility of water renewalshould be investigated, to reduce pollution ofharbor basins to the minimum possible. It is noteasy to suggest arrangements that can attainthis target. As regards intervention in the har-bor’s protection works, the matter is usuallyhandled by providing openings across the bodyof the structure, to facilitate water circulation.However, for these openings to be effective,they should be of sufficient width, which ofcourse results in allowing significant distur-bance into the harbor basin. Also, undesirablesediments may enter the harbor and be depos-ited if the openings extend down to the seabed.Therefore, in most cases the openings are notextended at depths beyond the surface layer inwhich the wind-generated water circulationgenerally takes place, to prevent the transfer ofheavy sediments that occurrs at the lower partof the water column.

1.3.6.7 General Layout of InnerPort Works

Geometric Elements. The arrangement ofberths and docking installations follows theprinciples noted in Section 1.3.6.5. Layoutsthat favor enhancement of long oscillationsshould be avoided, and it is also recommended

26 PORT PLANNING

that spending beaches be placed in suitable lo-cations in the harbor basin. The geotechnicalproperties of the seabed in the project area playa significant role in deciding the general layoutof the inner works. If a rocky seafloor is pres-ent, it is usually advisable to place the line ofwharfs close to their final depth, to avoid ex-pensive excavations of the rocky bed. If thelatter is soft, the location of the wharfs is de-termined by, among other factors, a detailedtechnical and economic comparison of reclaim-ing versus dredging.

It has been pointed out that maneuveringsurfaces should have a security distance of be-tween 30 and 50 m from any vessels docked atthe planned berths. Figures 1.4a and 1.6 givethe main elements of a harbor’s inner works.As a general rule, the plan must ensure that theshape of the docks provides for better use ofthe harbor basin and easier navigational con-ditions for vessel maneuvers, and that the func-tioning of dock equipment and machinery isnot hampered. Furthermore, to keep pollutionof harbor basins to a minimum, placing docksand basins in recessed positions of a harborshould be avoided, because the renewal of wa-ter there is weak. If narrow piers are planned(e.g., only for the mooring of small vessels), itis advisable to examine the possibility of de-signing them on piles with openings for facil-itation of water circulation. The developmentof a port over time is generally associated witha required strip of land parallel to the berths.Previously, this strip was planned to be about50 m wide; later, adapting to technological de-velopment in cargo handling, this was in-creased to 100 and 200 m. A result of thischange was a tendency to shift from narrowpiers that created a zigzag layout of docks tostraight quay lines parallel to the shore, whichensures large land areas.

The linear dock arrangement, however, takesup a far greater length of coast, which fre-quently is very expensive, or not feasible toacquire for other reasons. In such cases, wide

piers are used to increase quay length. Theirwidth can be 300 m or more, and they may beplaced at a small angle to the shoreline if thiswould have the benefit of protecting them fromwaves and provide better operational condi-tions.

Quay length is determined by the particularmethod of docking and by the number ofberths. Alongside berthing for a vessel oflength L requires a quay length of b � L � 30to 40 m or b � 1.2L. For Ro-Ro stern (or bow)-to-shore berthing, the required quay length b isdetermined by the vessel’s beam B and isroughly b � 1.2 to 1.5B. The minimum depthh of the sea at the quay is determined by thedesign vessel’s maximum draft dmax. A safetyfactor for this value (i.e., pilot’s foot) in theregion of 1 m should be added to cover for anyheaving motion due to wave disturbance. Thush � dmax � 1 m. The dimensions usually rec-ommended for seaport docks are illustrated inFigure 1.8. Other inner installations apart fromberthing quays, such as dry docks, slipways,and maintenance quays, should be situated in-dependent of the customary loading and un-loading quays and as much as possible inprotected areas of the harbor.

Connections with Inland Areas. It has alreadybeen mentioned that the nature of a moderncargo port resembles more a cargo handlinghub within a combined transport system than asea transport terminal point. Consequently, abasic element in the smooth operation and de-velopment of a terminal are the port’s inlandconnections. These connections, through whichnonsea transport of goods to and from the portis effected, may be road or rail accesses, arti-ficial or natural inland navigable routes, air-lines, or oil product pipelines. Road, rail, andriver connections (to which we refer later) canalso connect a port with specialized cargo con-centration terminals located in suitable inlanddepots. These stations serve to smooth out thepeaks in demand and supply of goods to a port

1.3 PORT PLANNING AT THE INDIVIDUAL PORT LEVEL 27

Figure 1.8 Main dimensions of sea docks.

that has limited storage areas. Figure 1.9 de-picts some general arrangements of such con-nections.

The provision of inland storage areas form-ing part of a port is a modern tendency pro-nounced in container transport, which createsthe need for larger backup areas and also aneed for boxes to stay in port for a shorter time.The transport of goods between port and inlanddepots is thus carried out quickly and effi-ciently, in contrast with the traditional servic-ing of all destination points directly from a portwithout intermediate transshipment. In additionto being effected by road, the connection be-tween port and inland depot may be by rail,particularly when the distance is great. In thelatter case, the loading of trains, when this in-volves imports, may be effected at a small dis-tance from the port, where the goods areforwarded through a system of wheeled trailersfed from the port, as shown in Figure 1.10. Ineach case, the traditional arrangement in gen-eral cargo terminals in which rail (or road)vehicles approach the docks for immediateloading and unloading of cargo through the useof dock cranes is being abandoned. The main

reason for this development is that loading/un-loading vehicles obstruct dock operations, inaddition to the frequent inability to coordinateship–train operations, resulting in vessel delay.Two alternative handling options are availablein this respect: (1) the full cargo can be for-warded inland via port sheds, or (2) ‘‘direct’’loading/unloading to and from rail or road ve-hicles can be retained but conducted at somedistance from the docks. The second alternativedemands an additional fleet of tractors and plat-forms to link docks with transshipment areasto means of overland transportation. This alter-native solution is depicted in Figure 1.11 to-gether with the traditional arrangement, which,as mentioned, is gradually being abandoned bymany ports.

The tendency to shift land transportationaway from docks is even more prevalent incontainer or Ro-Ro port terminals. Inland con-nections are allowed only to reach a deliveryand receiving area, which in container termin-als is generally located near the containerfreight station (for details, see Section 1.4.3).In most cases, road access to ports is appealing,particularly for small and moderate distances.

28 PORT PLANNING

Figure 1.9 Connection of a port with an inland cargo collection terminal. (From United Nations, 1978.)

Figure 1.10 Combination of road–rail connections of the port with the inland depot. (From United Nations,1978.)

1.3 PORT PLANNING AT THE INDIVIDUAL PORT LEVEL 29

Figure 1.11 Restricting the approach of vehicles to the docks: (a) traditional approach; (b) alternative ap-proach. (From United Nations, 1978.)

The variety and types of road vehicles renderthem versatile, and in conjunction with a denseroad network in many regions, make them suit-able for ‘‘door-to-door’’ service. Rail connec-tion at ports offers security, speed, andeconomical transport of bulky goods over largedistances.

Many ports throughout the world are con-structed at the mouths of navigable rivers orcanals, to connect them with other areas by

means of inland navigable routes. Connectionsby inland navigation offer economy and areparticularly suitable for the transport of bulkcargoes and for supporting combined transportsbetween river ports and seaports that servebarge-carrying vessels.

Additional Points to Be Considered. Severalissues of general application to the layout ofland installations of a port are listed below.

30 PORT PLANNING

1. The conventional berthing positions forgeneral cargo require a smaller draft atthe quay (usually 7.70 to 10 m) thanthose required for containers or bulkcargo.

2. Much larger land areas are required interminals where containers are to be han-dled.

3. Care should be taken in drawing up theland use so that smells from bulk cargoescarried by prevailing winds do not dam-age the environment.

4. Security issues should be examined, par-ticularly as regards flammable materialsor explosives.

5. Product compatibility should be exam-ined for cargoes adjacent to their re-spective handling areas. For instance,pairing coal with grains is incompatible,as is pairing grains with fertilizers.

6. The overall traffic pattern in the land areaat a port should be examined, to avoidpotential congestion or a need for bridg-ing.

1.4 PORT PLANNING AT THETERMINAL LEVEL

1.4.1 Port Development

1.4.1.1 Phases of Port Development. Thecourse of development of a port or port ter-minal usually undergoes phases, which also in-dicate its age. Evolution from a traditionalbreak-bulk cargo port to a specialized unitizedcargo port may be gradual. However, it is dis-tinguishable into qualitative changes that takeplace in specific periods throughout the overalllife of the port. These phases are as follows:

Phase 1: Traditional General Cargo Flow. Aport with break-bulk or packaged bulk cargo

terminals, such as for bagged grains or petro-leum in barrels.

Phase 2: Break-Bulk Cargoes. When break-bulk cargo flow exceeds an economically ac-ceptable limit, these cargoes are transported inbulk form and the port develops a special bulk-cargo terminal. At the same time, the break-bulk berths are increased, to accommodate thehigher demand.

Phase 3: Unit Loads. Unit loads start beingcarried on conventional vessels in small quan-tities in units such as palettes, containers, orpackaged lumber. At the same time, break-bulkcargo flows, particularly those of bulked break-bulk cargoes, start diminishing to levels thatrequire separation of cargo terminals for vari-ous cargo categories.

Phase 4: Multipurpose Terminal. Unitized car-goes on specialized vessels start appearing inquantities that do not yet require developmentof a specialized terminal. Thus, a multipurposeterminal is created in which break-bulk cargotraffic is diminished, although unitized cargo isalso handled. At the same time, the speciali-zation of dry bulk cargo terminals continues.

Phase 5: Specialized Terminal. With an in-crease in unit loads beyond certain levels,specialized cargo terminals are created forhandling containers, packaged lumber, and Ro-Ro. The multipurpose terminal of phase 4 isconverted into a specialized terminal, with theaddition of specialized cargo handling equip-ment. Break-bulk general cargo is reduced fur-ther.

It should be noted that in normal situations,the transition from phase 3 to phase 5 shouldprogress through phase 4, so as to provide anopportunity to the port to increase unitizedcargo traffic to volumes that will enable eco-nomically feasible development of a special-

1.4 PORT PLANNING AT THE TERMINAL LEVEL 31

ized terminal in phase 5. Moreover, in the eventthat a port has entered phase 3 of its develop-ment, care should be taken to avoid creatingadditional general cargo berths.

1.4.1.2 Review of Existing Port Installa-tions. The examination of existing installa-tions should precede any decision to expandold, or to construct new, port terminals. Thepurpose of such a study is to identify any func-tional difficulties that would detract signifi-cantly from the theoretical productivity of themarine and land sector of the port terminal. Inmany cases, improved organization of the com-ponent operations of the port terminal producesa significant increase in its productivity. In ad-dition to an improvement in the terminal’s or-ganizational structure, there is the possibility ofintroducing structural changes and upgrades ofport installations, which will usually necessi-tate a considerable expenditure. It should benoted that in many cases, technological devel-opments and changes in packaging and cargohandling methods frequently render the up-grading of existing installations a difficult andcomplicated task. At the same time, the exis-tence of spare capacity is always a desirablefeature in a modern port able to accommodatepeaks in cargo flows, albeit with reduced pro-ductivity. Thus in cases where the recom-mended installation upgrade marginally coversthe expected demand, it is recommended thatold installations be placed on standby to coverunforeseen requirements and that expansion ofan existing, or construction of a new, port ter-minal be opted for.

1.4.1.3 General Cargo Terminal. The firstphase in a design for expansion of an existingbreak-bulk cargo terminal or for the creation ofa new one involves diligent collection and anal-ysis of statistical data regarding the existingterminal’s output. This analysis will also deter-mine the ‘‘age’’ of the existing terminal—inother words, the degree to which the owners of

this break-bulk cargo terminal are prepared tosee it evolve into a multipurpose terminal oreven into a specialized container or bulk-cargoterminal. This decision will be based on thepercentages of the flows and the unit loadingthat conventionally packaged cargoes assumeover time.

Analysis of these data will also revealwhether berth productivity falls short of theo-retical values. In this case, and particularly ifsignificant vessel waiting times are observed,the cause of the reduced output should belooked into carefully. Usually, a standard effi-ciency rating per berth with a high degree ofbreak-bulk cargo traffic is 100,000 tons peryear, whereas if unitized cargoes constitute 30to 40% of the traffic, this productivity figuremay rise to more than 150,000 tons per year.

1.4.1.4 Bulk Cargo Terminal. To decide onthe expansion of a bulk cargo terminal, the datafrom the existing terminal have to be consid-ered. Just as in the case of break-bulk termin-als, the purpose of this examination is todetermine whether the lower productivity ofthe terminal is due to malfunctioning or toincreases in traffic volume. In ore-exportingterminals, the latter case may be due toimprovements in mining technology or to dis-coveries of new deposits. The study should fo-cus on such issues as coordination between thevarious phases of product movement, on lags,if such exist, during which no product is avail-able for loading on the vessel, and on themethod of cargo movement over land. Thefindings of this examination will lead to a de-cision either to improve the operational pro-cedures and the equipment of the existingterminal, or to create an additional bulk cargoterminal.

1.4.2 General Cargo Terminal

Despite the fact that the general cargo terminalis becoming increasingly scarce, the main fac-

32 PORT PLANNING

tors pertinent to its organization and operationare presented below, so they may also be usedin the study of a multipurpose terminal.

1.4.2.1 Vessel Waiting Time. It is generallyaccepted that arrivals of general cargo vesselsfollow a Poisson distribution. According tothis, the probability P(n) for n vessels to arrivein port within a specified period—usually 1day—is

e �N(N) eP(n) � (1.3)

n!

where N is the average number of arrivals perday over a long time period. The observationabove is equivalent to saying that the distribu-tion of the time intervals t between successivearrivals is negative-exponential:

�t / TP(t) � e (1.4)

where T is the average of these intervals overa large time period. On the basis of existingdata it is estimated that the time periods t forservicing of berthed vessels follow an Erlangdistribution with K � 2. The Erlang distributionis expressed by the formula

K�1 (Kt /T)n�Kt / TP(t) � e (1.5)�

n!n�0

where T is the average servicing time. Withinreasonable accuracy, queue theory can providevalues of vessel waiting time for various de-grees of utilization of the system. In the caseof the general cargo terminal, assumptions aremade of random arrivals and distribution ofservicing times according to an Erlang2 distri-bution. This in fact corresponds to an M /E2 /aqueue, where M denotes the Poisson distribu-tion of arrivals and a is the number of berths.

1.4.2.2 Berth Occupancy. The occupancyrate of a group of berths expresses the per-centage of time that berth positions are occu-pied by ships being serviced. The effect ofberth occupancy on waiting time depends onthe probability distributions of arrivals and ofservicing times as well as on the number ofberths available to the sector of the port beingexamined. With regard to a general cargo ter-minal, an M /E2 /n queue is usually assumed, asstated above. The effect that the grouping ofberthing places on vessel waiting times can beseen through the congestion factor, defined be-low, values of which are contained in Table 1.1.In general, a larger number of berths enablesgreater occupancy rates for the same waitingperiods.

For the sake of demonstration, let us assume10 general cargo berths and an average of twovessel calls per day headed for these berths. Ifthe average servicing time is 3.5 days, the oc-cupancy factor k0 is

2 � 3.5k � � 0.700 10

in which case the congestion factor , whichk�0in average terms expresses waiting time as apercentage of servicing time, amounts to 6% or0.2 day. Now, if the total of these berths is di-vided into two independently operating groups,with one vessel call per day per group, the oc-cupancy rate remains the same, while the con-gestion factor is tripled, to 19%. Table 1.1provides an approximation of the waiting timefor the queue above expressed as a percentageof the average servicing time as a function ofthe number of berths and of their occupancy.

The optimum berth use depends on the costratio between berths and vessels. The valuesgiven in Table 1.2 give occupancy factors gen-erally recommended for a 1:4 cost ratio, de-pending on the number of berths of the generalcargo terminal. It should be noted that the

1.4 PORT PLANNING AT THE TERMINAL LEVEL 33

Table 1.1 Congestion factor in queue M /E2 /n

OccupancyFactor

Number of Berths

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

0.10 0.08 0.01 0 0 0 0 0 0 0 0 0 0 0 0 00.15 0.13 0.02 0 0 0 0 0 0 0 0 0 0 0 0 00.20 0.19 0.03 0.01 0 0 0 0 0 0 0 0 0 0 0 00.25 0.25 0.05 0.02 0 0 0 0 0 0 0 0 0 0 0 00.30 0.32 0.08 0.03 0.01 0 0 0 0 0 0 0 0 0 0 00.35 0.40 0.11 0.04 0.02 0.01 0 0 0 0 0 0 0 0 0 00.40 0.50 0.15 0.06 0.03 0.02 0.01 0.01 0 0 0 0 0 0 0 00.45 0.60 0.20 0.08 0.05 0.03 0.02 0.01 0 0 0 0 0 0 0 00.50 0.75 0.26 0.12 0.07 0.04 0.03 0.02 0.01 0.01 0.01 0 0 0 0 00.55 0.91 0.33 0.16 0.10 0.06 0.04 0.03 0.02 0.02 0.01 0.01 0.01 0 0 00.60 1.13 0.43 0.23 0.14 0.09 0.06 0.05 0.03 0.03 0.02 0.02 0.01 0.01 0.01 0.010.65 1.38 0.55 0.30 0.19 0.12 0.09 0.07 0.05 0.04 0.03 0.03 0.02 0.02 0.02 0.020.70 1.75 0.73 0.42 0.27 0.19 0.14 0.11 0.09 0.07 0.06 0.05 0.04 0.03 0.03 0.030.75 2.22 0.96 0.59 0.39 0.28 0.21 0.17 0.14 0.12 0.10 0.08 0.07 0.06 0.05 0.050.80 3.00 1.34 0.82 0.57 0.42 0.33 0.27 0.22 0.18 0.16 0.13 0.11 0.10 0.09 0.080.85 4.50 2.00 1.34 0.90 0.70 0.54 0.46 0.39 0.34 0.30 0.26 0.23 0.20 0.10 0.160.90 6.75 3.14 2.01 1.45 1.12 0.91 0.76 0.65 0.56 0.50 0.45 0.40 0.36 0.33 0.30

Source: United Nations Conference on Trade and Development (UNCTAD), 1978.

Table 1.2 Recommended occupancy factors

Number ofBerths

OccupancyFactor k0 (%)

CongestionFactor (%)k�0

1 40–50 50–752 50–60 26–433 53–65 14–304 56–65 11–195 60–70 9–19

6–10 62–75 2–21�10 70–85 0–26

higher factor values are more fitted for E2 /E2 /n queues, which are more applicable to con-tainer terminals.

1.4.2.3 Number of Berths. The key param-eter in the design of a general cargo port ter-minal is that of the number of berths. Thisparameter depends mainly on the annual cargo

throughput of the terminal and on the prede-termined level of vessel servicing to be offeredby the terminal. The latter depends on the cor-responding waiting periods discussed previ-ously. The number of berths n can be expressedas

Qn � (1.6)

24k qprN0

where Q is the annual cargo flow estimate(tonnes), k0 the berth occupancy factor, q theaverage tonnage handled by one gang per hour(calculated from statistical data of this or a sim-ilar port), p the fraction of time during whichthe berths are operational (e.g., if the total dailyworking hours per berth is 16 over 6 days perweek, this factor would be 16 � 6/24 � 7 �0.572), r the average number of gangs concur-rently loading or unloading an average-sizedvessel (depends on cargo type and vessel size),

34 PORT PLANNING

Table 1.3 Typical cargo densities

CargoStowage Factor

(m3 / ton)Cargo Density

(tons/m3)

Bagged cement 1.0 1.00Plaster, bagged 1.2 0.83Sand, bagged 0.5 2.00Animal feed,

bagged1.5 0.67

Bagged coffee 1.8 0.56Citrus fruits 2.5 0.40Cotton bales 2.7 0.37Bagged flour 1.3 0.77Grapes 3.9 0.26Frozen fish

(boxed)2.1 0.48

Paper rolls 2.5 0.40

and N the days of berth operation in a year(days when berths are in a position to receivevessels, e.g., not closed for maintenance).

The number of berths, n, may also be ex-pressed approximately as a function of cargothroughput, Q, expressed in units of 100,000tons per year as follows:

Qn � (1.7)

k0

where k0 is the occupancy factor. Having de-termined the number of berths in the terminal,berth length is then calculated on the basis ofthe length of the design vessel to be calling atthe terminal. Berth length is generally taken tobe 20% above the design vessel length. Wharfwidth should typically include free sea spaceof at least two design vessel widths. The pro-ductivity per running meter of a general cargoberth usually ranges from 600 to 1200 tons ofcargo per year for average occupancy. Wherecontainer units are handled by conventionalquay cranes or by vessel gear, this output mayreach 1600 tons per year.

1.4.2.4 Storage Area. A small portion ofthe total throughput of a general cargo terminalis either loaded directly to or discharged di-rectly from land transportation means withoutrequiring storage at the terminal. The othercargo is stored for a period of time in sheds,open areas, or warehouses. The required cargostorage area A (thousands of m2) can be ex-pressed as a function of known parameters, byadopting the following simple relation:

1.7 QD pA � 1 � (1.8)� � � �365 dH 100

where Q is the annual tonnage to be stored(thousands of tons; this refers to the portion oftotal cargo flow that requires storage); D theaverage storage duration (days; it is assumed

on the basis of existing statistical data); d thecargo density [tons/m3; this may be calculatedusing the stowage factor (in m3/ton), typicalvalues of which are shown in Table 1.3]; H theaverage stowage height (m; depends on type ofcargo, its packing, and stowage means; an av-erage value is 2 to 3 m; the smaller the stowageheight, the larger the storage areas, but simplermechanical means are required for cargo han-dling; for this reason, comparisons should bemade between various alternatives); and p thepeak factor, multiplies the average area re-quired to accommodate cargo flow peaks (usu-ally, this increase is between 25 and 40%).