Polysoil D150 presentation

-

Upload

shaun-mchaffie -

Category

Technology

-

view

892 -

download

3

Transcript of Polysoil D150 presentation

Shaun [email protected]

Soil Stabilization and Polymer Road Building Technology

Cell No:+27 (0) 83 425 3374

Introduces

Support

Earth Ethix Group (Pty) Ltd. A dedicated ethical company with the capacity and commitment to take

on the world’s road infrastructure challenges an African Product for African Solutions!

“… What road builders dream about and never achieve…”

‘ what road builders dream about and never achieve’……….CIVILABCIVIL ENGINEERING TESTING LABORATORIES

‘For the toughest base layer available in road construction’

Base layers are the foundation

• Fast

• Cost effective

• Extremely Durable

• Absolute minimum maintenance

• Skills Transfer

FROM SOIL

TO SEAL

The Product

•Polysoil D150 is 100 % South African

•Non-toxic and environment friendly

•Advanced Polymer based technology

•Superior through aggressive dedicated research

• Specifically formulated for the Roads industry

Eco-Friendly

• Studies in 1998 found that this polymer based technology “significantly increased the strength of the soil stabilization process in Road Construction” – thereby improving the entire road quality where Polysoil D150 is used.

• Polysoil D150 is a fast effective, durable alternative for the Roads Industry

• Continued aggressive Research & Development has produced a superior product, being Polysoil D150

• Polysoil D150 works on a wide variety of materials and most in-situ soil types

• Reduces the need to bring in expensive quarry materials• Does not contain any toxins or hazardous material – its safe

for humans to handle • Productivity and Delivery at rapid rates - minimum disruption

to traffic – no detours required• Exceeds the Roads Industry requirements for UCS and CBR• The Polysoil D150 bond prevents loss of soil through erosion –

no wash away of valuable soil• Minimal maintenance required• Eco-friendly – will not harm the environment

Application

Eco-Friendly

Windrow to break up clods and remove large rocks and stones by hand - local labour.

Construction with Polysoil D150

Load Polysoil D150 in a Water Cart, add water and spray the mixed content onto the road surface.

Construction with Polysoil D150

Add water to adjust the moisture content of the material toapproximately 1% above OMC (OptimumMoisture Content) and mix again

Construction with Polysoil D150

Alternatively use state of the art equipment.The Wirtgen WR 2000 – for increased production

Construction with Polysoil D150

Level the mixed material, profile and shape the road and compact the surface(local labour)

Construction with Polysoil D150

The road is now ready for a bitumen or asphalt seal of choice with thetoughest base layer available

Construction with Polysoil D150

The “Superior Product” claims are supported by independent tests conducted by Civilab (Pty) Ltd. (CIVILAB is joint owned by international Consulting Engineering Firms)

A G7 material with an overall P.I. Described as “slightly plastic” (linear shrinkage of 0.5) was

tested with Polysoil D150 by Civilab.

The results were described by Civilab as:

“… What road builders dream about and never achieve…”

Marginal and normally ‘discarded materials’ can now be used for

Road Construction with Polysoil D150

• Cement stabilization requires a curing period of 7 days which involves a chemical bonding process

• Polysoil D150 has a mechanical bonding process requiring compaction – the more compaction, the better. It can never be over-compacted and can be opened to traffic immediately after compaction

• No detours required – depending on conditions and equipment, up to 2km of road (6m wide) per day can be stabilized and opened to traffic.

Downward migration qualities of Polysoil D150 stabilizes double the treated depth

Polysoil D150 covers a wide range of materials and can be used to stabilize most in-situ materials, therefore cutting out the need to bring in expensive quarry materials

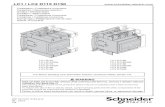

150mm Polysoil D150 treated layer

150mm untreated layer (also stabilized through migration ofPolysoil D150

Illustration of core sample

• Regardless of the material grading (G1 – G10) Polysoil D150 can be used on soils with a P.I. Ranging from ‘Slightly Plastic’ (P.I. <3 – 15) without modification to achieve results in excess of minimum required road construction standards

• The soil is tested for compatibility in our laboratory and recommendations made.

• Once stabilized, a traditional seal – Chip & Spray, Double Seal, Cape Seal, Premix, Asphalt or a clear seal can be applied

• The process to construct 1km x 6m wide road using the Polysoil method – from ripping the roadbed to finished seal (wearing course) can take as little as 5 days to complete (depending on the location, conditions and type of seal)

• To utilize Local Emerging Contractors or preferred vendors as far as possible to achieve ‘Supervising Engineer’ status

• To train & transfer skills to operators & certify them once familiar with the construction process.

Our Commitment