Plastic Deformation And Alloys

-

Upload

jutka-czirok -

Category

Business

-

view

7.006 -

download

0

Transcript of Plastic Deformation And Alloys

Plastic Deformation & Alloys

Keyword: Malleable, Elastic Deformation, Plasticity,

Ductile

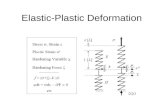

Malleable• A temporary shape change that is self-

reversing after the force is removed, so that the object returns to its original shape, is called elastic deformation. In other words, elastic deformation is a change in shape of a material at low stress that is recoverable after the stress is removed. This type of deformation involves stretching of the bonds, but the atoms do not slip past each other.

Plastic Deformation• Beyond the elastic limit the material

undergoes plastic deformation. Unlike elastic deformation, plastic deformation is not recoverable, i.e. the change is permanent.

• Ductile materials undergo large plastic deformations and waisting before fracturing; brittle materials undergo very little plastic deformation.

• Also known as placticity

Plastic Deformation

Failure by plastic deformationUse the info link to see examples of designs and materials testing, using rapid prototyping

Plastic Deformation

Alloys• A mixture containing two or more

metallic elements or metallic and non-metallic elements usually fused together or dissolving into each other when molten; "brass is an alloy of zinc and copper

• Ferrous and nonferrous alloys

Alloys• Change the melting

point• Increase strength,

hardness & ductility• Change colour• Give rise to better

casting• Change electrical

and thermal properties

Iron & Carbon• Stainless Steel is an alloy of Carbon

and Iron• Stainless steel is one of the fastest

growing metals. Today, it is difficult to imagine life without this most durable and versatile material. And, it is 100% recyclable.

Steel• Stainless steel (steel and 18% chromium,

8% nickel, 8% magnesium)• High-speed steel (steel and tungsten)• Mild steel (iron and 0.15-0.35% carbon)• Medium carbon steel (0.4-0.7% carbon)• High-carbon steel (0.8-1.5% carbon)• High tensile steel (low carbon steel &

nickel)• Manganese steel (1.5% manganese)

Task 1• Explain the term ‘alloy’ and give

examples of two ferrous and two non-ferrous alloys.

• Give one example of how the following metals might be used and state which of the material’s characteristics makes it particularly appropriate for the application that you have given.

Cast iron CopperAluminium Brass

In search of superalloys

Superalloys• A superalloy, or high-performance alloy, is

an alloy that exhibits excellent mechanical strength and creep resistance at high temperatures, good surface stability, and corrosion and oxidation resistance. Superalloys typically have an austenitic face-centred cubic crystal structure.

Superalloys• A superalloy's base alloying element is

usually nickel, cobalt, or nickel-iron. Superalloy development has relied heavily on both chemical and process innovations and has been driven primarily by the aerospace and power industries.

Superalloys• Typical applications are in the

aerospace industry, eg. for turbine blades for jet engines

Task 2• Define the following words and add a

suitable images to illustrate your answer• Plastic deformation• Elastic deformation • Superalloys

• Creep• Oxidisation

• Malleable• Ductile

Links and Revision• http://www.materialseducation.org/students/mainpage.htm• http://www.ndt-ed.org/EducationResources/CommunityCollege/Materials/Structure/deformation.htm• http://www.ornl.gov/.../Pages/Alloy-Development.html• http://www.estane.com/technology/alloys.asp• http://www.thefreedictionary.com/alloy• http://www.bssa.org.uk/• http://en.wikipedia.org/wiki/Superalloys• http://www.msm.cam.ac.uk/phase-trans/2003/nickel.html• http://www.msm.cam.ac.uk/.../superalloys.html• http://www.msm.cam.ac.uk/phase-trans/2002/1510.mpg• http://www.doitpoms.ac.uk/tlplib/creep/printall.php• http://www.jfe-21st-cf.or.jp/chapter_3/3a_3.html• http://info.wkmp.tuwien.ac.at/2003-rp_coll/