Pipeextp-Asme Ug 28

-

Upload

alvinchuan -

Category

Documents

-

view

125 -

download

1

Transcript of Pipeextp-Asme Ug 28

6/10/2011 PipeExtP-b.xls

Theoretical External Collapsing Pressure for Pipelines(Method is not per ASME.)

1 of 1

Client: Description: Date Rev.

0 Customer No.: Item No.: 1

2 Owner No.: Dwg. No.: 3

4

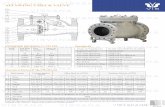

As per ASME B31.3, 303.5.3(b), 304.1.3, ASME BPV Code, UG-28

A = factor determined from Fig. G in Subpart 3 of Section II, Part D

B = factor determined from the applicable material chart or table in Subpart 3 of Section II, Part D for maximum design metal temperatureDo = outside diameter of cylindrical shell course or tubeE = modulus of elasticity of material at design temperatureL = total length, in. (mm), of a tube between tubesheets, or design length of a vessel section between lines of supportP = external design pressurePa = calculated value of maximum allowable external working pressure for the assumed value of t,t = minimum required thickness of cylindrical shell or tube, or spherical shell, in. (mm)

ts = nominal thickness of cylindrical shell or tube, in. (mm)

(1) Cylinders having Do /t values ≥ 10 ONLY

or

For values of A falling to the left of the applicable material /temperature line

Design Temperature: 100 F, or -254 C to 38 C ambient temp. = 70 F, or 21 C

Material data is per ASME B31.3 - 2006, Tables A-1 and A-1A

Electric fusion welded pipe, single butt seam

Basic allowable stress at design temp: S = 16.7 ksi = 115 MPa Min. tensile stress, St = 70 ksi = 482.6 MPa

Elastic modulus (Young's) at design temp., E = 28.1 Msi = 194008 MPa Min. yield stress, Sy = 25.0 ksi = 172.4 MPa

Poisson's ratio, µ = 0.305

Outside diameter D = 3.500 in. = 88.9 mm Dimension units:

Nominal thickness T = 0.120 in. = 3.05 mm

The symbol D in ASME B31.3 is equivalent to Do in Section VIII

External pressure, P = 1 Remark : due to 1 bar vaccum Safety Factor, Fs = 3.0

14.5 psi = 100 kPa = 1.02 kg/sqcm = 1 bar

External design pressure, P Fs = Pd = 43.5 psi = 300 kPa = 3.06 kg/sqcm = 3 bar

L= 78.7 in. L/D= 22.5

D/T = 29.2 Factor A = 0.0012 Factor B= 9000

Pa = 4B/3(D/T) Pa= 411 psi = 2837 kPa = 28.93 kg/sqcm = 28.37 bar

OK. The external design pressure is less than theoretical collapse pressure.

Grease Trap Vacuum suction Pipe for Somerset @313

Prepared By

A 312 TP304L SS S30403 EFW(S) 18Cr-8Ni

NPS 3 (DN 75)

Sch 10S per ASME B36.19M

Imperial

bar