Pipe Shoe Catalog

-

Upload

anonymous-asbor1dc -

Category

Documents

-

view

287 -

download

2

Transcript of Pipe Shoe Catalog

7/27/2019 Pipe Shoe Catalog

http://slidepdf.com/reader/full/pipe-shoe-catalog 1/26

A A A T E C H N O L O G Y & SPECIALTIES CO., INC.

P R O D U C T C A T A L O G

2012

www.aaatech.com

TOTAL SOLUTION SERVICE

For the Industrial Piping Marketplace

4 1 Y E A R S S E R V I N G I N D U S T

7/27/2019 Pipe Shoe Catalog

http://slidepdf.com/reader/full/pipe-shoe-catalog 2/26

AAA Technology & Speciales Co., Inc.

TABLE OF CONTENTS

Introducon 1

Shoe Types 2

How to Order 3

Slot Opon Detain 4

Slide Bearing Detail 5

Guide Detail 6

Base Plate Detail 7

SHOE TYPES AND SPECIFICATIONS

Fig 5000 - Split Beam T-Shoe 8

Fig 5001 - Split Beam T-Shoe with Gusset 9

Fig 5010 - Split Beam T-Shoe with U-Bolts 10

Fig 5011 - Split Beam T-Shoe with U-Bolts and Gusset 11

Fig 5020 - Split Beam T-Shoe with Clamps 12

Fig 5021 - Split Beam T-Shoe with Clamps and Gusset 13

Fig 5100 - Fabricated T-Shoe 14

Fig 5101 - Fabricated T-Shoe with Gusset 15

Fig 5110 - Fabricated T-Shoe with U-Bolts 16

Fig 5111 - Fabricated T-Shoe with U-Bolts and Gusset 17

Fig 5120 - Fabricated T-Shoe with Clamps 18

Fig 5121 - Fabricated T-Shoe with Clamps and Gusset 19

Fig 5200 - Double Upright T-Shoe 20

Fig 5210 - Double Upright T-Shoe with U-Bolts 21

Fig 5220 - Double Upright T-Shoe with Clamps 22

Fig 5500 - Heavy Duty Pipe Saddle 23

7/27/2019 Pipe Shoe Catalog

http://slidepdf.com/reader/full/pipe-shoe-catalog 3/26

713-849-3366 | www.aaatech.com | [email protected] Page 1

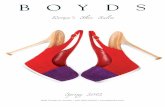

PIPE SHOES

Pipe Support and T– Shoes

AAA Technology & Specialty Co., Inc. is proud to provide a complete line of Pipe Shoes and Supports. These pipe shoes are con-

structed in accordance with the rules and regulaons specied and dened by the Quality Assurance Procedures for Pipe Sup-

ports Manufactured per ASME B31.1, B31.2, B31.3, B31.4, B31.5, B31.8, B31.9 & B31.11 Piping Codes, the ANSI/AWS D1.1 and

the MSS SP-58 & MSS SP-69 Standards. Well trained and experienced personal using formal standardized document systems

and fabricaon control methods supervise all projects.

The Pipe Shoes and Supports oered

herein are built in three categories:

Split Beam Construcon, Welded FlatBar or Double Upright Construcon in

accordance to your requirements. In

addion, we can supply these in vari-

ous Guided Shoe Assemblies as illus-

trated in the pages hereaer.

These shoes can be built with our

TRI*SLIDE™ slide bearings furnished

in PTFE over PTFE, Stainless Steel over

PTFE , Stainless Steel over Graphite,

or any other combinaon that you

require. We are also able to supply

Meehanite & Alloys for high tempera-

ture applicaons, Permali or Compo-

site Supports for cryogenic applica-

ons, and can fabricate these out of

machined block or poured to your

specic needs.

To beer assist you please do not

hesitate to call AAA Technology & Speciales Co., Inc. to tell us about your requirements in order to beer serve you in yourPipe Support soluons.

7/27/2019 Pipe Shoe Catalog

http://slidepdf.com/reader/full/pipe-shoe-catalog 4/26

AAA Technology & Speciales Co., Inc. Page 2

PIPE SHOES

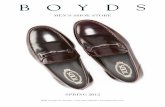

SHOE TYPES

Choose from three designs of pipe shoe: 1) Split Beam T -Shoe; 2) Fabricated (from at bar) T-Shoe; or 3) Double Upright T-Shoe. Each design, in turn, can be fabricated : 1)

Plain; 2) With U-Bolts; or 3) With Clamps.

5000 - Split Beam—Plain 5010 - Split Beam with U-Bolts 5020 - Split Beam with Clamps

5100 - Fabricated-Plain 5110 - Fabricated with U-Bolts 5120 - Fabricated with Clamps

5200 - Double Upright—Plain 5210 - Double Upright with U-Bolts 5220 - Double Upright with Clamps

Fig. 5000, 5010, & 5020 SPLIT BEAM T-SHOES

Fig. 5100, 5110, 5120 FABRICATED T-SHOES

Fig. 5200, 5210, & 5220 DOUBLE UPRIGHT T-SHOES

7/27/2019 Pipe Shoe Catalog

http://slidepdf.com/reader/full/pipe-shoe-catalog 5/26

713-849-3366 | www.aaatech.com | [email protected] Page 3

PIPE SHOES

HOW TO ORDER

T-Shoes are ordered by indicang the following dimensions and choices:

Fig. Descripon of Pipe Shoe

5000 Split Beam T-Shoe

5010 Split Beam T-Shoe w/U-Bolts

5020 Split Beam T-Shoe w/Clamps

5100 Fabricated T-Shoe

5110 Fabricated T-Shoe w/U-Bolts

5120 Fabricated T-Shoe w/Clamps

5200

Double Upright T-Shoe

5210 Double Upright T-Shoe w/U-Bolts

5220 Double Upright T-Shoe w/Clamps

Type Descripon of Guide Support

NG No Guide

CG Clip Guide

AG Angle Guide

AG2 Angle Guide 2

AG&ST Angle Guide and Line Stop

Type Descripon of Slot Opons

S1 No Slots

S2 Expansion Slots

S3 Insulaon Band Slots

S4 Expansion Slots & Insulaon Band Slots

GP Gusset Plates

Type Descripon of Slide Bearings

T/T PTFE on PTFE

S/T Stainless Steel on PTFE

S/P Stainless Steel on Polyethylene

S/G Stainless Steel on Graphite

G/G Graphite on Graphite

7/27/2019 Pipe Shoe Catalog

http://slidepdf.com/reader/full/pipe-shoe-catalog 6/26

AAA Technology & Speciales Co., Inc. Page 4

SLOT OPTION DETAIL

Type S1, No Slots

Type S2, Expansion Slots

Type S3, Insulaon Slots

Type S4, Expansion & Insulaon Slots

Type GP, Gusset Plates

PIPE SHOES

7/27/2019 Pipe Shoe Catalog

http://slidepdf.com/reader/full/pipe-shoe-catalog 7/26

713-849-3366 | www.aaatech.com | [email protected] Page 5

PIPE SHOES

GUIDE DETAIL

Type NG, No Guide

Type CG, Clip Guide

Type AG, Angle Guide

Type AG2, Angle Guide 2

Type AG&ST, Angle Guide & Line Stop

7/27/2019 Pipe Shoe Catalog

http://slidepdf.com/reader/full/pipe-shoe-catalog 8/26

AAA Technology & Speciales Co., Inc. Page 6

PIPE SHOES

SLIDE BEARING OPTION DETAIL

Property T/T - PTFE on PTFE S/T - SS on PTFE S/P - SS on Polyethylene

G/G - Graphite on

Graphite

Compressive

Strength

2000 PSI 4000 PSI 1200 PSI 5625 PSI

Maximum Tem-

perature

300° F (150° C) 300° F (150° C) 200° F (95° C) 800° F (430° C)

Opon T/T, S/T and S/P

Opon G/G

7/27/2019 Pipe Shoe Catalog

http://slidepdf.com/reader/full/pipe-shoe-catalog 9/26

713-849-3366 | www.aaatech.com | [email protected] Page 7

PIPE SHOES

BASE PLATE DETAIL

L (in)

Single Upright Shoes (e.g. Fig Double Upright Shoes (e.g. Fig

Pipe Size Type NG

Type AG

or AG2

Type CG Type NG

Type AG

or AG2

Type CG T (in)

2 6 6 3/4 8 1/4 -- -- --1/4" or 3/8 or 1/2"

2 1/2 6 6 3/4 8 1/4 -- -- --1/4" or 3/8 or 1/2"

3 6 6 3/4 8 1/4 -- -- --1/4" or 3/8 or 1/2"

4 6 6 3/4 8 1/4 -- -- --1/4" or 3/8 or 1/2"

6

6

6 3/4

8 1/4-- -- --

1/4" or 3/8 or 1/2"

8 6 6 3/4 8 1/4 -- -- --1/4" or 3/8 or 1/2"

10 6 6 3/4 8 1/4 8 8 3/4 10 1/4 1/4" or 3/8 or 1/2"

12 10 10 3/4 12 1/4 10 10 3/4 12 1/4 1/4" or 3/8 or 1/2"

14 10 10 3/4 12 1/4 10 10 3/4 12 1/4 1/4" or 3/8 or 1/2"

16 10 10 3/4 12 1/4 12 12 3/4 14 1/4 1/4" or 3/8 or 1/2"

18 10 10 3/4 12 1/4 12 12 3/4 14 1/4 1/4" or 3/8 or 1/2"

20 12 12 3/4 14 1/4 14 14 3/4 16 1/4 1/4" or 3/8 or 1/2"

24 12 12 3/4 14 1/4 14 14 3/4 16 1/4 1/4" or 3/8 or 1/2"

30 -- -- -- 19 1/2 20 1/4 21 3/4 1/4" or 3/8 or 1/2"

36 -- -- -- 22 1/2 23 1/4 24 3/4 1/4" or 3/8 or 1/2"

42

-- -- --25 1/2

26 1/4

27 3/4

1/4" or 3/8 or 1/2"

Type NG Base Plate

Type AG or AG2 Base Plate

Type CG Base Plate

Dierent lengths, widths and thicknesses available upon request.

7/27/2019 Pipe Shoe Catalog

http://slidepdf.com/reader/full/pipe-shoe-catalog 10/26

PIPE SHOES

Nominal

Pipe Dia.

(in)

Actual

O.D. (in.) A (in)

BOP to

TOS (in) H (in)

Load

Capacity

(lbs.)

Unit Wt.

(lbs.)*

BOP to

TOS (in) H (in)

Load

Capacity

(lbs.)

Unit Wt.

(lbs.)*

2 2.375 4 4 5 3/16 5000 6.50 6 7 3/16 5000 8.00

2 1/2 2.875 4 4 5 7/16 5000 6.50 6 7 3/16 5000 8.00

3 3.5 4 4 5 3/4 5000 6.50 6 7 3/4 5000 8.00

3 1/2 4 4 4 6 5000 6.50 6 8 5000 8.00

4 4.5 4 4 6 1/4 5000 6.50 6 8 1/4 5000 8.00

5

5.5625

4

4

6 25/32

6000

6.50

6

8 25/32

6000

8.00

6 6.625 4 4 7 5/16 6000 6.50 6 9 5/16 6000 8.00

8 8.625 4 4 8 5/16 6000 6.50 6 10 5/16 6000 8.00

10 10.75 4 4 9 3/8 8000 6.50 6 11 3/8 8000 8.00

12 12.75 6.5 4 10 3/8 8000 12.00 6 12 3/8 8000 13.00

14 14 6.5 4 11 8000 12.00 6 13 8000 13.00

16 16 6.5 4 12 8000 12.00 6 14 8000 13.00

18 18 6.5 4 13 8000 12.00 6 15 8000 13.00

20 20 8 4 14 8000 15.50 6 16 8000 20.00

24 24 8 4 16 8000 15.50 6 18 8000 20.00

(All slot opons are available with each pipe shoe)

APPLICATION: The Fig 5000 Pipe Shoe is to be welded to the pipe along the top edge and can also be welded to the base.

CONSTRUCTION: The Pipe Shoe is constructed from a split beam of A-36 steel. FINISH: The Pipe Shoe can be provided with a black, painted or hot dip galvanized finish.

OPTIONAL FEATURES: The Pipe Shoe can be supplied in different BOP to TOS dimensions as well as different lengths.

ORDERING: See beginning of this section for ordering instructions.

EXAMPLE: 3” - Fig.5000 - 4”x12” - S1 - T/T - AG

FIG. 5000

* - Weights shown are for 12” long shoes

* - For pipe shoes larger than 24” NPS, contact AAAT for further assistance.

713-849-3366 | www.aaatech.com | [email protected] Page 8

7/27/2019 Pipe Shoe Catalog

http://slidepdf.com/reader/full/pipe-shoe-catalog 11/26

PIPE SHOES

FIG. 5001

* - Weights shown are for 12” long shoes

APPLICATION: The Fig 5001 Pipe Shoe with End Gusset Plates is to be welded to the pipe along the top edges of the shoe and the gussets and can also be

welded to the base.

CONSTRUCTION: The Pipe Shoe is constructed from a split beam of A-36 steel with End Gussets of Plate. FINISH: The Pipe Shoe can be provided with a black, painted or hot dip galvanized finish.

OPTIONAL FEATURES: The Pipe Shoe can be supplied in different BOP to TOS dimensions as well as different lengths.

ORDERING: See beginning of this section for ordering instructions.

EXAMPLE: 3” - Fig.5001 - 4”x12” - S1 - T/T - AG

Nominal

Pipe Dia.

(in)

Actual

O.D. (in.) A (in)

BOP to

TOS (in) H (in)

Load

Capacity

(lbs.)

Unit Wt.

(lbs.)*

BOP to

TOS (in) H (in)

Load

Capacity

(lbs.)

Unit Wt.

(lbs.)*

2 2.375 4 4 5 3/16 6500 8.73 6 7 3/16 6500 11.22

2 1/2 2.875 4 4 5 7/16 6500 8.73 6 7 3/16 6500 11.22

3 3.5 4 4 5 3/4 6500 8.73 6 7 3/4 6500 11.22

3 1/2 4 4 4 6 6500 8.73 6 8 6500 11.22

4 4.5 4 4 6 1/4 6500 8.73 6 8 1/4 6500 11.22

5 5.5625 4 4 6 25/32 7800 8.73 6 8 25/32 7800 11.22

6 6.625 4 4 7 5/16 7800 8.73 6 9 5/16 7800 11.22

8 8.625 4 4 8 5/16 7800 8.73 6 10 5/16 7800 11.22

10 10.75 4 4 9 3/8 10400 8.73 6 11 3/8 10400 11.22

12 12.75 6.5 4 10 3/8 10400 16.78 6 12 3/8 10400 19.90

14 14 6.5 4 11 10400 16.78 6 13 10400 19.90

16 16 6.5 4 12 10400 16.78 6 14 10400 19.90

18 18 6.5 4 13 10400 16.78 6 15 10400 19.90

20 20 8 4 14 10400 21.23 6 16 10400 28.28

24 24 8 4 16 10400 21.23 6 18 10400 28.28

* - For pipe shoes larger than 24” NPS, contact AAAT for further assistance.

(All slot opons are available with each pipe shoe)

AAA Technology & Speciales Co., Inc. Page 9

7/27/2019 Pipe Shoe Catalog

http://slidepdf.com/reader/full/pipe-shoe-catalog 12/26

Nominal

Pipe Dia.

(in)

Actual

O.D. (in.) A (in) D (in)

BOP to

TOS (in) H (in)

Load

Capacity

(lbs.)

Unit Wt.

(lbs.)*

BOP to

TOS (in) H (in)

Load

Capacity

(lbs.)

Unit

Wt.

(lbs.)*

2 2.375 4 3 7/8" 4 5 3/16 5000 7.94 6 7 3/16 5000 9.44

2 1/2 2.875 4 4 3/16" 4 5 7/16 5000 8.30 6 7 3/16 5000 9.80

3 3.5 4 4 5/8" 4 5 3/4 5000 8.66 6 7 3/4 5000 10.16

3 1/2 4 4 4 7/8" 4 6 5000 9.39 6 8 5000 10.88

4 4.5 4 5 7/16" 4 6 1/4 5000 10.10 6 8 1/4 5000 11.60

5 5.5625 4 6 1/8" 4 6 25/32 6000 10.46 6 8 25/32 6000 11.96

6 6.625 4 7 3/8" 4 7 5/16 6000 14.78 6 9 5/16 6000 16.28

8 8.625 4 8 1/4" 4 8 5/16 6000 16.10 6 10 5/16 6000 17.60

10 10.75 4 10 1/4" 4 9 3/8 8000 25.70 6 11 3/8 8000 27.20

12 12.75 6.5 11 5/8" 4 10 3/8 8000 33.30 6 12 3/8 8000 34.30

14 14 6.5 12 1/2" 4 11 8000 39.90 6 13 8000 40.90

16 16 6.5 13 3/4" 4 12 8000 42.60 6 14 8000 43.60

18 18 6.5 15 1/4" 4 13 8000 55.20 6 15 8000 56.20

20 20 8 16 3/4" 4 14 8000 64.70 6 16 8000 69.20

24 24 8 19 1/4" 4 16 8000 85.10 6 18 8000 89.60

PIPE SHOES

APPLICATION: The Fig. 5010 Pipe Shoe is to be clamped to the pipe along the top edge and can also be welded to the base.

CONSTRUCTION: The Pipe Shoe is constructed from a split beam of A-36 steel. FINISH: The Pipe Shoe can be provided with a black, painted or hot dip galvanized finish.

OPTIONAL FEATURES: The Pipe Shoe can be supplied in different BOP to TOS dimensions as well as different lengths.

ORDERING: See beginning of this section for ordering instructions.

EXAMPLE: 3” - Fig.5010 - 4”x12” - S1 - T/T - AG

FIG. 5010

* - Weights shown are for 12” long shoes

* - For pipe shoes larger than 24” NPS, contact AAAT for further assistance.

(All slot opons are available with each pipe shoe)

713-849-3366 | www.aaatech.com | [email protected] Page 10

7/27/2019 Pipe Shoe Catalog

http://slidepdf.com/reader/full/pipe-shoe-catalog 13/26

PIPE SHOES

Nominal

Pipe Dia.

(in)

Actual

O.D. (in.) A (in) D (in)

BOP to

TOS (in) H (in)

Load

Capacity

(lbs.)

Unit Wt.

(lbs.)*

BOP to

TOS (in) H (in)

Load

Capacity

(lbs.)

Unit

Wt.

(lbs.)*

2 2.375 4 3 7/8" 4 5 3/16 6500 11.13 6 7 3/16 6500 12.66

2 1/2 2.875 4 4 3/16" 4 5 7/16 6500 11.63 6 7 3/16 6500 13.02

3 3.5 4 4 5/8" 4 5 3/4 6500 12.33 6 7 3/4 6500 13.38

3 1/2 4 4 4 7/8" 4 6 6500 13.53 6 8 6500 14.10

4 4.5 4 5 7/16" 4 6 1/4 6500 14.73 6 8 1/4 6500 14.82

5 5.5625 4 6 1/8" 4 6 25/32 7800 15.33 6 8 25/32 7800 15.18

6 6.625 4 7 3/8" 4 7 5/16 7800 22.53 6 9 5/16 7800 19.50

8 8.625 4 8 1/4" 4 8 5/16 7800 24.73 6 10 5/16 7800 20.82

10 10.75 4 10 1/4" 4 9 3/8 10400 40.73 6 11 3/8 10400 30.42

12 12.75 6.5 11 5/8" 4 10 3/8 10400 52.28 6 12 3/8 10400 41.20

14 14 6.5 12 1/2" 4 11 10400 63.28 6 13 10400 47.80

16 16 6.5 13 3/4" 4 12 10400 67.78 6 14 10400 50.50

18 18 6.5 15 1/4" 4 13 10400 88.78 6 15 10400 63.10

20 20 8 16 3/4" 4 14 10400 103.23 6 16 10400 77.48

24 24 8 19 1/4" 4 16 10400 137.23 6 18 10400 97.88

APPLICATION: The Fig. 5011 Pipe Shoe with End Gusset Plates is to be clamped to the pipe along the top edges and can also be welded to the base.

CONSTRUCTION: The Pipe Shoe is constructed from a split beam of A-36 steel. FINISH: The Pipe Shoe can be provided with a black, painted or hot dip galvanized finish.

OPTIONAL FEATURES: The Pipe Shoe can be supplied in different BOP to TOS dimensions as well as different lengths.

ORDERING: See beginning of this section for ordering instructions.

EXAMPLE: 3” - Fig.5011 - 4”x12” - S1 - T/T - AG

FIG. 5011

* - Weights shown are for 12” long shoes

* - For pipe shoes larger than 24” NPS, contact AAAT for further assistance.

(All slot opons are available with each pipe shoe)

AAA Technology & Speciales Co., Inc. Page 11

7/27/2019 Pipe Shoe Catalog

http://slidepdf.com/reader/full/pipe-shoe-catalog 14/26

PIPE SHOES

FIG. 5020

* - Weights shown are for 12” long shoes

Nominal

Pipe Dia.

(in)

Actual

O.D. (in.) A (in) D (in)

BOP to

TOS (in) H (in)

Load

Capacity

(lbs.)

Unit Wt.

(lbs.)*

BOP to

TOS (in) H (in)

Load

Capacity

(lbs.)

Unit

Wt.

(lbs.)*

2 2.375 4 3 7/8" 4 5 3/16 5000 8.90 6 7 3/16 5000 10.40

2 1/2 2.875 4 4 3/16" 4 5 7/16 5000 9.50 6 7 3/16 5000 11.00

3 3.5 4 4 5/8" 4 5 3/4 5000 10.10 6 7 3/4 5000 11.60

3 1/2 4 4 4 7/8" 4 6 5000 11.30 6 8 5000 12.80

4 4.5 4 5 7/16" 4 6 1/4 5000 12.50 6 8 1/4 5000 14.00

5 5.5625 4 6 1/8" 4 6 25/32 6000 13.10 6 8 25/32 6000 14.60

6 6.625 4 7 3/8" 4 7 5/16 6000 20.30 6 9 5/16 6000 21.80

8 8.625 4 8 1/4" 4 8 5/16 6000 22.50 6 10 5/16 6000 24.00

10 10.75 4 10 1/4" 4 9 3/8 8000 38.50 6 11 3/8 8000 40.00

12 12.75 6.5 11 5/8" 4 10 3/8 8000 47.50 6 12 3/8 8000 48.50

14 14 6.5 12 1/2" 4 11 8000 58.50 6 13 8000 59.50

16 16 6.5 13 3/4" 4 12 8000 63.00 6 14 8000 64.00

18 18 6.5 15 1/4" 4 13 8000 84.00 6 15 8000 85.00

20 20 8 16 3/4" 4 14 8000 97.50 6 16 8000 102.00

24 24 8 19 1/4" 4 16 8000 131.50 6 18 8000 136.00

APPLICATION: The Fig. 5020 Pipe Shoe is to be clamped to the pipe along the top edge and can also be welded to the base.

CONSTRUCTION: The Pipe Shoe is constructed from a split beam of A-36 steel. FINISH: The Pipe Shoe can be provided with a black, painted or hot dip galvanized finish.

OPTIONAL FEATURES: The Pipe Shoe can be supplied in different BOP to TOS dimensions as well as different lengths.

ORDERING: See beginning of this section for ordering instructions.

EXAMPLE: 3” - Fig.5020 - 4”x12” - S1 - T/T - AG

* - For pipe shoes larger than 24” NPS, contact AAAT for further assistance.

(All slot opons are available with each pipe shoe)

713-849-3366 | www.aaatech.com | [email protected] Page 12

7/27/2019 Pipe Shoe Catalog

http://slidepdf.com/reader/full/pipe-shoe-catalog 15/26

PIPE SHOES

FIG. 5021

* - Weights shown are for 12” long shoes

Nominal

Pipe Dia.

(in)

Actual

O.D.

(in.)

A (in) D (in) BOP to

TOS (in) H (in)

Load

Capacity

(lbs.)

Unit Wt.

(lbs.)*

BOP to

TOS (in) H (in)

Load

Capacity

(lbs.)

Unit

Wt.

(lbs.)*

2 2.375 4 3 7/8" 4 5 3/16 6500 11.13 6 7 3/16 6500 13.62

2 1/2 2.875 4 4 3/16" 4 5 7/16 6500 11.93 6 7 3/16 6500 14.22

3 3.5 4 4 5/8" 4 5 3/4 6500 12.33 6 7 3/4 6500 14.82

3 1/2 4 4 4 7/8" 4 6 6500 13.53 6 8 6500 16.02

4 4.5 4 5 7/16" 4 6 1/4 6500 14.73 6 8 1/4 6500 17.22

5 5.5625 4 6 1/8" 4 6 25/32 7800 15.33 6 8 25/32 7800 17.82

6 6.625 4 7 3/8" 4 7 5/16 7800 22.53 6 9 5/16 7800 25.02

8 8.625 4 8 1/4" 4 8 5/16 7800 24.73 6 10 5/16 7800 27.22

10 10.75 4 10 1/4" 4 9 3/8 10400 40.73 6 11 3/8 10400 43.22

12 12.75 6.5 11 5/8" 4 10 3/8 10400 52.28 6 12 3/8 10400 55.40

14 14 6.5 12 1/2" 4 11 10400 63.28 6 13 10400 66.40

16 16 6.5 13 3/4" 4 12 10400 67.78 6 14 10400 70.90

18 18 6.5 15 1/4" 4 13 10400 88.78 6 15 10400 91.90

20 20 8 16 3/4" 4 14 10400 103.23 6 16 10400 110.28

24 24 8 19 1/4" 4 16 10400 137.23 6 18 10400

APPLICATION: The Fig. 5021 Pipe Shoe with End Gusset Plates is to be clamped to the pipe along the top edges and can also be welded to the base.

CONSTRUCTION: The Pipe Shoe is constructed from a split beam of A-36 steel. FINISH: The Pipe Shoe can be provided with a black, painted or hot dip galvanized finish.

OPTIONAL FEATURES: The Pipe Shoe can be supplied in different BOP to TOS dimensions as well as different lengths.

ORDERING: See beginning of this section for ordering instructions. EXAMPLE: 3” - Fig.5020 - 4”x12” - S1 - T/T - AG

* - For pipe shoes larger than 24” NPS, contact AAAT for further assistance.

(All slot opons are available with each pipe shoe)

AAA Technology & Speciales Co., Inc. Page 13

7/27/2019 Pipe Shoe Catalog

http://slidepdf.com/reader/full/pipe-shoe-catalog 16/26

PIPE SHOES

FIG. 5100

* - Weights shown are for 12” long shoes

APPLICATION: The Fig. 5100 Pipe Shoe is to be welded to the pipe along the top edge and can also be welded to the base.

CONSTRUCTION: The Pipe Shoe is constructed from two pieces of A-36 steel flat bar welded together. FINISH: The Pipe Shoe can be provided with a black, painted or hot dip galvanized finish.

OPTIONAL FEATURES: The Pipe Shoe can be supplied in different BOP to TOS dimensions as well as different lengths.

ORDERING: See Page 2 for ordering instructions.

EXAMPLE: 3” - Fig.5100 - 4”x12” - S1 - T/T - AG

Nominal

Pipe Dia.

(in)

Actual

O.D. (in.) A (in)

BOP to

TOS (in) H (in)

Load

Capacity

(lbs.)

Unit Wt.

(lbs.)*

BOP to

TOS (in) H (in)

Load

Capacity

(lbs.)

Unit Wt.

(lbs.)*

2 2.375 4 4 5 3/16 5000 6.58 6 7 3/16 5000 8.28

2 1/2 2.875 4 4 5 7/16 5000 6.58 6 7 3/16 5000 8.28

3 3.5 4 4 5 3/4 5000 6.58 6 7 3/4 5000 8.28

3 1/2 4 4 4 6 5000 6.58 6 8 5000 8.28

4 4.5 4 4 6 1/4 5000 6.58 6 8 1/4 5000 8.28

5 5.5625 4 4 6 25/32 6000 6.58 6 8 25/32 5000 8.28

6 6.625 4 4 7 5/16 6000 6.58 6 9 5/16 6000 8.28

8 8.625 4 4 8 5/16 6000 6.58 6 10 5/16 6000 8.28

10 10.75 4 4 9 3/8 8000 6.58 6 11 3/8 8000 8.28

12 12.75 8 4 10 3/8 8000 9.87 6 12 3/8 8000 12.26

14 14 8 4 11 8000 9.87 6 13 8000 12.26

16 16 8 4 12 8000 9.87 6 14 8000 12.26

18 18 8 4 13 8000 9.87 6 15 8000 12.26

20 20 10 4 14 8000 9.87 6 16 8000 12.26

24 24 10 4 16 8000 9.87 6 18 8000 12.26

* - For pipe shoes larger than 24” NPS, contact AAAT for further assistance.

(All slot opons are available with each pipe shoe)

713-849-3366 | www.aaatech.com | [email protected] Page 14

7/27/2019 Pipe Shoe Catalog

http://slidepdf.com/reader/full/pipe-shoe-catalog 17/26

PIPE SHOES

FIG. 5101

* - Weights shown are for 12” long shoes

Nominal

Pipe Dia.

(in)

Actual

O.D. (in.) A (in)

BOP to

TOS (in) H (in)

Load

Capacity

(lbs.)

Unit Wt.

(lbs.)*

BOP to

TOS (in) H (in)

Load

Capacity

(lbs.)

Unit Wt

(lbs.)*

2 2.375 4 4 5 3/16 6500 8.81 6 7 3/16 6500 11.50

2 1/2 2.875 4 4 5 7/16 6500 8.81 6 7 3/16 6500 11.50

3 3.5 4 4 5 3/4 6500 8.81 6 7 3/4 6500 11.50

3 1/2 4 4 4 6 6500 8.81 6 8 6500 11.50

4 4.5 4 4 6 1/4 6500 8.81 6 8 1/4 6500 11.50

5 5.5625 4 4 6 25/32 7800 8.81 6 8 25/32 7800 11.50

6 6.625 4 4 7 5/16 7800 8.81 6 9 5/16 7800 11.50

8 8.625 4 4 8 5/16 7800 8.81 6 10 5/16 7800 11.50

10 10.75 4 4 9 3/8 10400 8.81 6 11 3/8 10400 11.50

12 12.75 8 4 10 3/8 10400 14.65 6 12 3/8 10400 17.09

14 14 8 4 11 10400 14.65 6 13 10400 17.09

16 16 8 4 12 10400 14.65 6 14 10400 17.09

18 18 8 4 13 10400 14.65 6 15 10400 17.09

20 20 10 4 14 10400 15.60 6 16 10400 17.09

24 24 10 4 16 10400 15.60 6 18 10400 17.09

APPLICATION: The Fig. 5101 Pipe Shoe with End Gusset Plates is to be welded to the pipe along the top edges and can also be welded to the base.

CONSTRUCTION: The Pipe Shoe is constructed from two pieces of A-36 steel flat bar welded together. FINISH: The Pipe Shoe can be provided with a black, painted or hot dip galvanized finish.

OPTIONAL FEATURES: The Pipe Shoe can be supplied in different BOP to TOS dimensions as well as different lengths.

ORDERING: See beginning of this section for ordering instructions.

EXAMPLE: 3” - Fig.5101 - 4”x12” - S1 - T/T - AG

* - For pipe shoes larger than 24” NPS, contact AAAT for further assistance.

(All slot opons are available with each pipe shoe)

AAA Technology & Speciales Co., Inc. Page 15

7/27/2019 Pipe Shoe Catalog

http://slidepdf.com/reader/full/pipe-shoe-catalog 18/26

PIPE SHOES

FIG. 5110

* - Weights shown are for 12” long shoes

Nominal

Pipe Dia.

(in)

Actual

O.D. (in.) A (in) D (in)

BOP to

TOS (in) H (in)

Load

Capacity

(lbs.)

Unit Wt.

(lbs.)*

BOP to

TOS (in) H (in)

Load

Capacity

(lbs.)

Unit Wt.

(lbs.)*

2 2.375 4 3 7/8" 4 5 3/16 5000 8.02 6 7 3/16 5000 9.72

2 1/2 2.875 4 4 3/16" 4 5 7/16 5000 8.29 6 7 3/16 5000 10.08

3 3.5 4 4 5/8" 4 5 3/4 5000 8.74 6 7 3/4 5000 10.44

3 1/2 4 4 4 7/8" 4 6 5000 9.46 6 8 5000 11.16

4

4.5

4

5 7/16"

4

6 1/4 5000

10.18

6

8 1/4 5000

11.88 5 5.5625 4 6 1/8" 4 6 25/32 5000 10.54 6 8 25/32 5000 12.24

6 6.625 4 7 3/8" 4 7 5/16 6000 14.86 6 9 5/16 6000 16.56

8 8.625 4 8 1/4" 4 8 5/16 6000 16.18 6 10 5/16 6000 17.88

10 10.75 4 10 1/4" 4 9 3/8 6000 25.78 6 11 3/8 6000 27.48

12 12.75 8 11 5/8" 4 10 3/8 8000 31.17 6 12 3/8 8000 33.56

14 14 8 12 1/2" 4 11 8000 37.77 6 13 8000 40.16

16 16 8 13 3/4" 4 12 8000 40.47 6 14 8000 42.86

18 18 8 15 1/4" 4 13 8000 53.07 6 15 8000 55.46

20 20 10 16 3/4" 4 14 8000 59.07 6 16 8000 61.46

24 24 10 19 1/4" 4 16 8000 79.47 6 18 8000 81.86

APPLICATION: The Fig. 5110 Pipe Shoe is to be clamped to the pipe along the top edge and can also be welded to the base.

CONSTRUCTION: The Pipe Shoe is constructed from two pieces of A-36 steel flat bar welded together. FINISH: The Pipe Shoe can be provided with a black, painted or hot dip galvanized finish.

OPTIONAL FEATURES: The Pipe Shoe can be supplied in different BOP to TOS dimensions as well as different lengths.

ORDERING: See Page 2 for ordering instructions.

EXAMPLE: 3” - Fig. 5110 - 4”x12” - S1 - T/T - AG

* - For pipe shoes larger than 24” NPS, contact AAAT for further assistance.

(All slot opons are available with each pipe shoe)

713-849-3366 | www.aaatech.com | [email protected] Page 16

7/27/2019 Pipe Shoe Catalog

http://slidepdf.com/reader/full/pipe-shoe-catalog 19/26

PIPE SHOES

FIG. 5111

* - Weights shown are for 12” long shoes

APPLICATION: The Fig. 5111 Pipe Shoe with End Gusset Plates is to be clamped to the pipe along the top edges and can also be welded to the base.

CONSTRUCTION: The Pipe Shoe is constructed from two pieces of A-36 steel flat bar welded together. FINISH: The Pipe Shoe can be provided with a black, painted or hot dip galvanized finish.

OPTIONAL FEATURES: The Pipe Shoe can be supplied in different BOP to TOS dimensions as well as different lengths.

ORDERING: See Page 2 for ordering instructions.

EXAMPLE: 3” - Fig. 5110 - 4”x12” - S1 - T/T - AG

Nominal

Pipe Dia.

(in)

Actual

O.D.

(in.)

A (in) D (in) BOP to

TOS (in) H (in)

Load

Capacity

(lbs.)

Unit Wt.

(lbs.)*

BOP to

TOS (in) H (in)

Load

Capacity

(lbs.)

Unit Wt.

(lbs.)*

2 2.375 4 3 7/8" 4 5 3/16 6500 10.25 6 7 3/16 6500 12.94

2 1/2 2.875 4 4 3/16" 4 5 7/16 6500 10.61 6 7 3/16 6500 13.30

3 3.5 4 4 5/8" 4 5 3/4 6500 10.97 6 7 3/4 6500 13.66

3 1/2 4 4 4 7/8" 4 6 6500 11.69 6 8 6500 14.38

4

4.5

4

5 7/16"

4

6 1/4 6500

12.41

6

8 1/4 6500

15.10

5 5.5625 4 6 1/8" 4 6 25/32 7800 12.77 6 8 25/32 7800 15.46

6 6.625 4 7 3/8" 4 7 5/16 7800 17.09 6 9 5/16 7800 19.78

8 8.625 4 8 1/4" 4 8 5/16 7800 18.41 6 10 5/16 7800 21.10

10 10.75 4 10 1/4" 4 9 3/8 10400 28.01 6 11 3/8 10400 30.70

12 12.75 8 11 5/8" 4 10 3/8 10400 35.95 6 12 3/8 10400 38.39

14 14 8 12 1/2" 4 11 10400 42.55 6 13 10400 44.99

16 16 8 13 3/4" 4 12 10400 45.25 6 14 10400 47.69

18 18 8 15 1/4" 4 13 10400 57.85 6 15 10400 60.29

20 20 10 16 3/4" 4 14 10400 64.80 6 16 10400 66.29

24 24 10 19 1/4" 4 16 10400 85.20 6 18 10400 86.69

* - For pipe shoes larger than 24” NPS, contact AAAT for further assistance.

(All slot opons are available with each pipe shoe)

AAA Technology & Speciales Co., Inc. Page 17

7/27/2019 Pipe Shoe Catalog

http://slidepdf.com/reader/full/pipe-shoe-catalog 20/26

PIPE SHOES

FIG. 5120

* - Weights shown are for 12” long shoes

APPLICATION: The Fig. 5120 Pipe Shoe is to be clamped to the pipe along the top edge and can also be welded to the base.

CONSTRUCTION: The Pipe Shoe is constructed from two pieces of A-36 steel flat bar welded together. FINISH: The Pipe Shoe can be provided with a black, painted or hot dip galvanized finish.

OPTIONAL FEATURES: The Pipe Shoe can be supplied in different BOP to TOS dimensions as well as different lengths.

ORDERING: See Page 2 for ordering instructions.

EXAMPLE: 3” - Fig. 5120 - 4”x12” - S1 - T/T - AG

Nominal

Pipe Dia.

(in)

Actual

O.D. (in.) A (in) D (in)

BOP to

TOS (in) H (in)

Load

Capacity

(lbs.)

Unit Wt.

(lbs.)*

BOP to

TOS (in) H (in)

Load

Capacity

(lbs.)

Unit Wt.

(lbs.)*

2 2.375 4 3 7/8" 4 5 3/16 5000 8.98 6 7 3/16 5000 10.68

2 1/2 2.875 4 4 3/16" 4 5 7/16 5000 9.58 6 7 3/16 5000 11.28

3 3.5 4 4 5/8" 4 5 3/4 5000 10.18 6 7 3/4 5000 11.88

3 1/2 4 4 4 7/8" 4 6 5000 11.38 6 8 5000 13.08

4

4.5

4

5 7/16"

4

6 1/4 5000

12.58

6

8 1/4 5000

14.28

5 5.5625 4 6 1/8" 4 6 25/32 6000 13.18 6 8 25/32 6000 14.88

6 6.625 4 7 3/8" 4 7 5/16 6000 20.38 6 9 5/16 6000 22.08

8 8.625 4 8 1/4" 4 8 5/16 6000 22.58 6 10 5/16 6000 24.28

10 10.75 4 10 1/4" 4 9 3/8 8000 38.58 6 11 3/8 8000 40.28

12 12.75 8 11 5/8" 4 10 3/8 8000 45.37 6 12 3/8 8000 47.76

14 14 8 12 1/2" 4 11 8000 56.37 6 13 8000 58.76

16 16 8 13 3/4" 4 12 8000 60.87 6 14 8000 63.26

18 18 8 15 1/4" 4 13 8000 81.87 6 15 8000 84.26

20 20 10 16 3/4" 4 14 8000 91.87 6 16 8000 94.26

24 24 10 19 1/4" 4 16 8000 125.87 6 18 8000 128.26

* - For pipe shoes larger than 24” NPS, contact AAAT for further assistance.

(All slot opons are available with each pipe shoe)

713-849-3366 | www.aaatech.com | [email protected] Page 18

7/27/2019 Pipe Shoe Catalog

http://slidepdf.com/reader/full/pipe-shoe-catalog 21/26

PIPE SHOES

FIG. 5121

* - Weights shown are for 12” long shoes

Nominal

Pipe Dia.

(in)

Actual

O.D.

(in.)

A (in) D (in) BOP to

TOS (in) H (in)

Load

Capacity

(lbs.)

Unit Wt.

(lbs.)*

BOP to

TOS (in) H (in)

Load

Capacity

(lbs.)

Unit Wt.

(lbs.)*

2 2.375 4 3 7/8" 4 5 3/16 6500 11.21 6 7 3/16 12000 13.90

2 1/2 2.875 4 4 3/16" 4 5 7/16 6500 11.81 6 7 3/16 14000 14.50

3 3.5 4 4 5/8" 4 5 3/4 6500 12.41 6 7 3/4 15000 15.10

3 1/2 4 4 4 7/8" 4 6 6500 13.61 6 8 15000 16.30

4

4.5

4

5 7/16"

4

6 1/4 6500

14.81

6

8 1/4 18000

17.50

5 5.5625 4 6 1/8" 4 6 25/32 7800 15.41 6 8 25/32 18000 18.10

6 6.625 4 7 3/8" 4 7 5/16 7800 22.61 6 9 5/16 18000 25.30

8 8.625 4 8 1/4" 4 8 5/16 7800 24.81 6 10 5/16 24000 27.50

10 10.75 4 10 1/4" 4 9 3/8 10400 40.81 6 11 3/8 29000 43.50

12 12.75 8 11 5/8" 4 10 3/8 10400 50.15 6 12 3/8 30000 52.59

14 14 8 12 1/2" 4 11 10400 61.15 6 13 34000 63.59

16 16 8 13 3/4" 4 12 10400 65.65 6 14 38000 68.09

18 18 8 15 1/4" 4 13 10400 86.65 6 15 41000 89.09

20 20 10 16 3/4" 4 14 10400 97.60 6 16 41000 99.09

24 24 10 19 1/4" 4 16 10400 131.60 6 18 47000 133.09

APPLICATION: The Fig. 5121 Pipe Shoe with End Gusset Plates is to be clamped to the pipe along the top edges and can also be welded to the base.

CONSTRUCTION: The Pipe Shoe is constructed from two pieces of A-36 steel flat bar welded together. FINISH: The Pipe Shoe can be provided with a black, painted or hot dip galvanized finish.

OPTIONAL FEATURES: The Pipe Shoe can be supplied in different BOP to TOS dimensions as well as different lengths.

ORDERING: See Page 2 for ordering instructions.

EXAMPLE: 3” - Fig. 5120 - 4”x12” - S1 - T/T - AG

* - For pipe shoes larger than 24” NPS, contact AAAT for further assistance.

(All slot opons are available with each pipe shoe)

AAA Technology & Speciales Co., Inc. Page 19

7/27/2019 Pipe Shoe Catalog

http://slidepdf.com/reader/full/pipe-shoe-catalog 22/26

AAA Technology & Specialties Co., Inc. Page 20

PIPE SHOES

(All possible slot options pictured for information purposes only)

FIG. 5200 DOUBLE UPRIGHT PIPE SHOE

* - Weights shown are for 12” long shoes

Nominal

Pipe Dia.

(in)

Actual

O.D. (in.) A (in)

BOP to

TOS (in) H (in)

Load

Capacity

(lbs.)

Unit Wt.

(lbs.)*

BOP to

TOS (in) H (in)

Load

Capacity

(lbs.)

Unit Wt.

(lbs.)*

10 10.75 6 4 9 3/8 19000 11.89 6 11 3/8 19000 15.27

12 12.75 8 4 10 3/8 19000 20.38 6 12 3/8 19000 23.76

14 14 8 4 11 19000 20.38 6 13 19000 23.76

16 16 10 4 12 26000 23.78 6 14 26000 27.16

18 18 10 4 13 26000 23.78 6 15 26000 27.16

20 20 12 4 14 26000 30.56 6 16 26000 35.66

24 24 12 4 16 35000 30.56 6 18 35000 35.66

30 30 17 1/2 4 19 38000 43.36 6 15 38000 50.16

36 36 20 1/2 4 22 41000 48.46 6 16 41000 55.26

42 42 23 1/2 4 25 44000 53.57 6 18 44000 60.37

APPLICATION: The Fig. 5200 Shoe is to be welded to the pipe along the two top edges and can also be welded to

the base.

CONSTRUCTION: The Pipe Shoe is constructed of two braced vertical flat bars welded on a support flat bar of A -

36 steel.

FINISH: The Pipe Shoe can be provided with a black, painted or hot dip galvanized finish.

OPTIONAL FEATURES: The Pipe Shoe can be supplied in different BOP to TOS dimensions as well as different

lengths.

ORDERING: See Page 2 for ordering instructions.

EXAMPLE: 3” - Fig. 5200 - 4”x12” - S1/GP - T/T - AG

7/27/2019 Pipe Shoe Catalog

http://slidepdf.com/reader/full/pipe-shoe-catalog 23/26

713-849-3366 | www.aaatech.com | [email protected] Page 21

PIPE SHOES

(All possible slot opons pictured for informaon purposes only)

FIG. 5210

DOUBLE UPRIGHT PIPE SHOE w/U-BOLTS

* - Weights shown are for 12” long shoes

Nominal

Pipe Dia.

Actual

O.D. (in.) A (in) D (in)

BOP to

TOS (in) H (in)

Load

Capacity

Unit Wt.

(lbs.)*

BOP to

TOS (in) H (in)

Load Ca-

pacity

Unit Wt.

(lbs.)*

10 10.75 6 14 4 9 3/8 19000 19.77 6 11 3/8 19000 23.15

12 12.75 8 16.75 4 10 3/8 19000 33.18 6 12 3/8 19000 36.56

14 14 8 18 4 11 19000 36.98 6 13 19000 40.36

16 16 10 19.75 4 12 26000 42.18 6 14 26000 45.56

18

18

10

22

4

13 26000

50.78

6

15 26000

54.16

20 20 12 24 4 14 26000 59.76 6 16 26000 64.86

24 24 12 28 4 16 35000 64.36 6 18 35000 69.46

30 30 17 1/2 34 4 19 38000 88.96 6 15 38000 95.76

36 36 20 1/2 40 4 22 41000 112.46 6 16 41000 119.26

42 42 23 1/2 46 4 25 44000 129.57 6 18 44000 136.37

APPLICATION: The Fig. 5210 Shoe is to be clamped to the pipe along the top edge and can also be welded to the base.

CONSTRUCTION: The Pipe Shoe is constructed of two braced vertical flat bars welded on a support flat bar of A-36 steel.

FINISH: The Pipe Shoe can be provided with a black, painted or hot dip galvanized finish.

OPTIONAL FEATURES: The Pipe Shoe can be supplied in different BOP to TOS dimensions as well as different lengths.

ORDERING: See Page 2 for ordering instructions.

EXAMPLE: 3” - Fig. 5210 - 4”x12” - S1/GP - T/T - AG

7/27/2019 Pipe Shoe Catalog

http://slidepdf.com/reader/full/pipe-shoe-catalog 24/26

AAA Technology & Speciales Co., Inc. Page 22

PIPE SHOES

(All possible slot opons pictured for informaon purposes only)

FIG. 5220

DOUBLE UPRIGHT PIPE SHOE w/CLAMPS

* - Weights shown are for 12” long shoes

Nominal

Pipe Dia.

(in)

Actual

O.D. (in.) A (in) D (in)

BOP to

TOS (in) H (in)

Load

Capacity

(lbs.)

Unit Wt.

(lbs.)*

BOP to

TOS (in) H (in)

Load Ca-

pacity

(lbs.)

Unit Wt.

(lbs.)*

10 10.75 6 17 4 9 3/8 19000 43.49 6 11 3/8 19000 46.87

12 12.75 8 19 1/4 4 10 3/8 19000 55.66 6 12 3/8 19000 59.04

14 14 8 21 4 11 19000 66.76 6 13 19000 70.14

16 16 10 23 4 12 26000 74.58 6 14 26000 77.96

18 18 10 25 4 13 26000 96.02 6 15 26000 99.4

20 20 12 27 4 14 26000 111.94 6 16 26000 117.04

24 24 12 31 1/2 4 16 35000 147.00 6 18 35000 152.1

30 30 17.5 38 4 19 38000 241.64 6 15 38000 248.44

36 36 20.5 44 4 22 41000 355.00 6 16 41000 365.00

42 42 23 1/2 50 4 25 44000 510.00 6 18 44000 525.00

APPLICATION: The Fig. 5220 Shoe is to be clamped to the pipe along the top edge and can also be welded to the base.

CONSTRUCTION: The Pipe Shoe is constructed of two braced vertical flat bars welded on a support flat bar of A-36 steel.

FINISH: The Pipe Shoe can be provided with a black, painted or hot dip galvanized finish.

OPTIONAL FEATURES: The Pipe Shoe can be supplied in different BOP to TOS dimensions as well as different lengths.

ORDERING: See Page 2 for ordering instructions.

EXAMPLE: 3” - Fig.5220 - 4”x12” - S1/GP - T/T - AG

7/27/2019 Pipe Shoe Catalog

http://slidepdf.com/reader/full/pipe-shoe-catalog 25/26

713-849-3366 | www.aaatech.com | [email protected] Page 23

PIPE SHOES

(All possible slot opons pictured for informaon purposes only)

FIG. 5500

SPLIT BEAM PIPE SHOE

Pipe Size R (IN) A (IN) B

C (IN) T (IN) T2 (IN) T3 (IN) WIDE STD.

20 10 20 1/2 20 6 14 3/8 1/2 3/8 ---

22 11 22 20 6 15 3/8 1/2 3/8 ---

24 12 23 1/2 20 6 16 3/8 1/2 3/8 ---

26 13 25 1/2 20 6 17 3/8 1/2 3/8 ---

28 14 27 20 6 18 3/8 1/2 3/8 ---

30 15 29 20 6 19 1/2 5/8 1/2 1/2

32

16

31

20

6

20 1/2

5/8

1/2

1/2 34 17 32 20 6 20 1/2 5/8 1/2 1/2

36 18 34 20 6 22 1/2 5/8 1/2 1/2

38 19 36 20 6 22 1/2 5/8 1/2 1/2

40 20 38 20 6 24 1/2 5/8 1/2 1/2

42 21 40 20 6 26 1/2 5/8 1/2 1/2

48 24 46 20 6 32 1/2 5/8 1/2 1/2

54 27 52 20 6 36 1/2 5/8 1/2 1/2

60 30 58 20 6 40 1/2 5/8 1/2 1/2

APPLICATION: The Fig. 5500 Heavy Duty Pipe Saddle is used to support large diameter pipe.

CONSTRUCTION: The Saddle is constructed of A-36 steel.

FINISH: The Saddle can be provided with a black, painted or hot dip galvanized finish.

OPTIONAL FEATURES: The Saddle can be supplied in different dimensions upon request.

ORDERING: To order specify pipe size and figure number and desired finish.

EXAMPLE: 20”-

Fig.6000-

Plain

7/27/2019 Pipe Shoe Catalog

http://slidepdf.com/reader/full/pipe-shoe-catalog 26/26

AAA TECHNOLOGY & SPECIALTIES CO., INC.

6219 Brimoore Road, Houston, Texas 77041-5114, U.S.A.

Telephone: 713-849-3366; FAX: 713-849-3654

E-mail: [email protected]; Website: hp://www.aaatech.com