Phosphating and chromating

-

Upload

abishek-arumugam -

Category

Science

-

view

406 -

download

4

Transcript of Phosphating and chromating

PHOSPHATING AND

CHROMATING

DONE BY,ABDULLAH

ABISHEK

Whats in it for Me?... Understanding of phosphating,

chromating and its applications. Identifying the process of plating. Study the process.

PHOSPHATING

Phosphate coating-

Its used on steel parts for corrosion resistance, lubricity or as a foundation for subsequent coating or painting.

Its serves as a conversion coating in which dil.Phosphoric acid and phosphate salts is applied via spraying or immersion and chemically reacts with the surface of part being coated to form a layer of insoluble ,crystalline phosphates.

It can also be used on aluminium, zinc, cadmium, silver and tin.

MAIN TYPES OF PHOSPHATE COATING-

A.Manganese.B.Iron.C.Zinc.

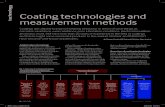

PROCESS OF PHOSPHATING-1. Cleaning the surface.2. Rinsing.3. Surface Activation.4. Phosphating.5. Rinsing.6. Neutralizing Rinse(optional).7. Drying.8. Application of supplemental coating.

Cleaningthe surface

Rinsing

Surface Activation Phosphating

Rinsing

Neutralizing Rinse(option

al)Drying

Applications of

supplemental

coating

End of process

Process-

USES OF PHOSPHATING- Corrosion Resistance. Zinc and Manganese coatings helps

prevent galling. Adhesion and Electric Isolation. Porosity mechanically interlock the

additional materials after dying. Zinc phosphate coatings are used in

conjunction with sodium stearate(soap) to form a lubricating layer in cold and hot forging.

FINISHED PRODUCT OF PHOSPHATING-

CHROMATING

CHROMATE COATING- Its used to passivate steel, aluminium , zinc,

cadmium, copper, silver ,magnesium, and tin alloys.

The chromate conversion coating is named after the chromate found in chromic acid, also known as hexavalent chromium, the chemical most widely used in immersion bath process whereby the coating is applied.

Chromate conversion coatings are commonly applied to everyday items such as hardware and tools they are greenish-yellow colour.

SUBSTRATES-1.Aluminium.2.Magnesium.3.Ferrous.4.Zinc.

1.ALUMINUM SUBSTRATE- Chromate conversion coating on an aluminium

substrate are known by: chemical film, iridite, alodine.

Iridite NCP is non-chromium type of conversion coating for aluminium substrates.

The most commonly referred –to standard for applying chromate conversion coating to aluminium is MIL-DTL-5541.

2.MAGNESIUM SUBSTRATE- Alodine may also refer to chromate-coating magnesium alloys.

3.FERROUS SUBSTRATE(PHOSPHATE COATING)-

Chromate conversion coatings can be applied over phosphate conversion coatings used on ferrous substrates. The process is used to enhance the phosphate coatings.

4.ZINC SUBSTRATE- Chromating is often performed on

galvanized parts to make them more durable.

The chromate coating acts as paint, protecting the zinc from white corrosion.

The protective effect of chromate coatings on zinc is indicated by colour, progression from clear/blue to yellow, gold, olive drab and black.

Darker coating provides more corrosion resistance.

1. CRONAK Process for Zn-cd consists of 5-10 seconds of immersion in room-temp solution of 182 g/l sodium dichromate crystals(Na2Cr2O7.2H2O) and 6ml/l con.sulfuric acid.

2. Iridite 14-2, a chromate conversion coating for aluminium, contains chromium(iv) oxide, barium nitrate, sodium silicofluoride and ferricyanide.

3. Chromate coatings are soft and gelatinous when first applied, but harden and become hydrophobic as the age. Curing can be accelerated by heating up to 70°C, but higher temperatures will gradually damage the coating.

COMPOSITION-

USES OF CHROMATING-

Corrosion Inhibitor. Primer. Decorative Finish. Retain electrical conductivity. Coating Hardware tools….

FINISHED PRODUCT OF CHROMATING-

ZINC PHOSPHATING PROCESS-

THANK YOU…

![[NIIR] the Complete Technology Book on Electroplating, Phosphating Powder Coating and Metal Finishing](https://static.fdocuments.net/doc/165x107/55720683497959fc0b8b9312/niir-the-complete-technology-book-on-electroplating-phosphating-powder-coating-and-metal-finishing.jpg)