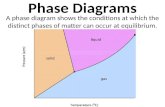

PHASE DIAGRAMS...• Phase equilibrium: for a system which has more than one phase • Phase Diagram...

Transcript of PHASE DIAGRAMS...• Phase equilibrium: for a system which has more than one phase • Phase Diagram...

PHASE DIAGRAMSPhase – a chemically and structurally homogenous region of a material. Region of uniform physical and chemical characteristics. Phase boundaries separate two distinct phases.A single phase system is called homogeneous. A system with two or more phases is called heterogeneous.Phase Diagram – a graphic representation showing the phase or phases present for a given composition, temperature and pressure.Component – the chemical elements which make up the alloy.

Solvent atoms: primary atomic species. Host atoms Solute atoms: the impurities. Normally the minor component

Solubility Limit ‐Maximum concentration of solute atoms that may dissolve in the solvent to form a solid solution. The excessof solute forms another phase of different composition. Example: water‐sugar

Phase Diagrams of Pure Substances• Predicts the stable phase as a function of Ptotal and T. Example:

water can exist in solid, liquid and vapor phases, depending on the conditions of temperature and pressure.

• Characteristic shape punctuated by unique points.

– Phase equilibrium lines

– Triple Point (three different phases of water in equilibrium)

– Critical PointExample:

In the pressure‐temperature (PT) phase diagram of water there exists a triple point at low pressure (4.579 torr) and low temperature (0.0098oC) where solid, liquid and vapor phases of water coexists.

Vaporization Line – Liquid and vapor coexists

Freezing Line – Liquid and solid coexist.

Sublimation Line – Solid and vapor coexist

Phase ‐ Any portion including the whole of a system, which is physically homogeneous within it and bounded by a surface so that it is mechanically separable from any other portions.

Gibbs Phase RuleFrom thermodynamic considerations, J.W. Gibbs (1839‐1903 American physicist – University of Yale) derived the following equation:

P + F = C + 2WhereP = number of phases which coexists in a given systemF = degrees of freedomC = number of components in the system2 = one can vary temperature and pressure

F = 0 zero degrees of freedom. Neither P or T can be change (a point –invariant point)

F = 1 one degree of freedom. One variable (P or T) can be changed independently (a line)

F = 2 two degrees of freedom. Two variables (P or T) can be changed independently (an area).

Schematic unary phase diagram for magnesium, showing the melting and boiling temperatures at one atmosphere pressure.C= 1 for pure magnesiumPoint A:P= 1 for pure liquid phase2+C=F+P2+1=F+1F=2 degrees of freedom – changepressure and temperature in liquidPhase.

Point B: P= 2 for liquid and solid2+C=F+P2+1=F+2F=1 degrees of freedom – change pressure or temperature (and the other variable is dependent – to stay on the line).

Point X:P= 3 (liquid, solid and vapor coexist)2+C=F+P2+1=F+3F=0 degrees of freedom – pressure and temperature are fixed at the the single point called the triple point.

Example

‐ For pure substance where P and T can be changed

P + F = C + 2 = 1 + 2 = 3

Pure substance in a triple point, then C = 1 (one component) and P = 3 (number of phases that coexist)

The value of F is zero (zero degrees of freedom) the three phases coexist in a point.

‐ For pure substance where P and T can be changed

P + F = 1 + 2 = 3

Pure substance in a freezing line, then

C = 1 (one component) and P = 2 (number of phases that coexist)

The value of F is one (one degree of freedom) the two phases (solid and liquid) coexist in a line.

Solubility: The amount of one material that will completely dissolve in a second material without creating a second phase.Unlimited solubility:When the amount of one material that will dissolve in a second material without creating a second phase isunlimited.Limited solubility ‐When only a maximum amount of a solute material can be dissolved in a solvent material.

Solid Solution:

Solid‐solution strengthening ‐ Increasing the strength of a metallic material via the formation of a solid solution.Dispersion strengthening ‐ Strengthening, typically used in metallic materials, by the formation of ultra‐fine dispersions of a second phase.

The effects of several alloyingelements on the yield strength of copper.

Resistance to dislocation motion (loss in ductility)

Microstructure

The structure observed under a microscope

Al Brake – more than one phase

Iron‐chromium alloy – one phase (solid solution)

Phase Equilibria

• Free energy: a function of the internal energy of a system

• Equilibrium: a system is at equilibrium if its free energy is at a minimum

• Phase equilibrium: for a system which has more than one phase

• Phase Diagram is a diagram with T and Composition as axes. They define the stability of the phases that can occur in an alloy system at constant pressure (P). The plots consist of temperature (vertical) axis and compositional (horizontal) axis.

• Constitution: is described by(a) the phases present(b) the composition of each phase(c) the weight fraction of each phase

Binary phase diagram ‐ A phase diagram for a system with two components (C=2).Ternary phase diagram ‐ A phase diagram for a system with three components (C=3).Isomorphous phase diagram ‐ A phase diagram in which components display unlimited solid solubility.Liquidus temperature ‐ The temperature at which the first solid begins to form during solidification.Solidus temperature ‐ The temperature below which all liquid has completely solidified.Freezing range – between the liquidus and solidus.

Isomorphous Phase Diagrams

Binary isomorphous systems• Binary alloy: A mixture of two metals is called a binary alloy and

constitute a two‐component system.

• Each metallic element in an alloy is called a separate component.[Sometimes a compound is considered a component, (e.g., iron carbide)]

• Isomorphous System: In some metallic systems, the two elements are completely soluble in each other in both the liquid and solid states. In these systems only a single type of crystal structureexists for all compositions of the components (alloy) and therefore it is called isomorphous system.

T<1085oC: Cu & Ni are mutually soluble in solid state – complete solubility →• both have the same FCC structures,

• atomic radii and electronegativities are nearly identical

• similar valences

→ isomorphous

Example: Binary Isomorphous System (Cu – Ni)

Interpretation of Phase Diagrams

Constitution: is described by(a) the phases present(b) the composition of each phase(c) the weight fraction of each phase

(a) Phases Present

Point A: at T=1100oC

60wt% Ni – 40wt% Cu

Only α phase is presentPoint B: at T= 1250oC

35wt%Ni – 65wt% Cu

Both α & liquid phases are present at equilibrium

(b) Composition of each phase

Single phase:Point A:

60wt%Ni – 40%Cu alloy at 1100oC

Two‐phase region:Tie line: across the two‐phase region at the temperature of the alloyPoint B: T=1250oCComposition of Liquid phase: CL=31.5wt%Ni – 68.5%CuComposition of α phase:Cα=42.5wt%Ni‐ 57.5wt%Cu

(c) Weight fraction of each phaseSingle phase: 100% Ex: Point A: 100% α phase

Two‐phase region:

Ex: Point B

LEVER RULE (Inverse Lever Rule)

L

Lo

L

oL

L

CCCCW

CCCCW

SRRW

SRSW

−−

=−−

=

+=

+=

αα

α

α

α

Example: Point B:

C0 = 35wt%Ni

Cα = 42.5%, CL = 31.5% 68% or ...

.

32% or ...

.

680531542

35542

320531542

53135

=−−

=−−

=

=−

−=

−−

=

Ls

osL

Ls

Lo

ccccW

ccccWα

Volume fractionFor an alloy consisting of α and β phases, the volume fraction of the α phase is

defined as

ββαα

βββ

ββαα

ααα

βαβα

αα

ρρρ

ρρρ

vvv

Wvv

vW

VVvv

vV

+=

+=

=++

=

;

, 1 Then, the weight fractions are

Where να and νβ are the volumes of α and β

β

β

α

α

α

α

α

ρW

ρW

ρW

V+

=

β

β

α

α

β

β

β

ρW

ρW

ρW

V+

=

Derivation of the lever rule

1) All material must be in one phase or the other:

2) Mass of a component that is present in both phases equal to the mass of the component in one phase + mass of the component in the second phase:

3) Solution of these equations gives us the Lever rule.

L

oL cc

ccW−−

=α

α

L

Lo

ccccW

−−

=α

α

1=+ LWWα

oLL ccWcW =+αα

Equilibrium Cooling ‐ Development of Microstructure in Isomorphous Alloys

Example:

35wt%Cu‐65wt%Ni system – Slow coolingfrom point a to point e

a: 1300oC: complete liquid with 35wt%Cu-65wt%Ni

b: ~1260oC: first solid begin to form

(α-46wt%Ni)

c: ~1250oC: α-43wt%Ni, L-32wt%Ni

d:~1220oC: last liquid to solidify

e: 35wt%Cu – 65wt%Ni solid phase

Nonequilibrium Cooling ‐ Development of Microstructure in Isomorphous Alloys

Fast cooling

Compositional changes require diffusion

•Diffusion in the solid state is very slow. ⇒ The new layers that solidify on top of the existing grains have the equilibrium composition at that temperature ⇒ Formation of layered (cored) grains. Tie‐line method to determine the composition of the solid phase is invalid.

•The tie‐line method works for the liquid phase, where diffusion is fast.

•Solidus line is shifted to the right (higher Ni contents), solidification is complete at lower T, the outer part of the grains are richer in the low‐melting component (Cu).

•Upon heating grain boundaries will melt first. This can lead topremature mechanical failure.

Complete solidification occurs at lower temperature and higher Nickel concentration than equilibrium

Solid can’t freeze fast enough: solidus line effectively shifted to higher Ni concentrations. Shift increases with faster cooling rates, slower diffusion

Mechanical properties of isomorphous alloys

Solid solution strengthening

The mechanical properties of copper‐nickel alloys. Copper is strengthened by up to 60% Ni and nickel is strengthened by up to 40% Cu.

Solidification of a Solid‐Solution AlloySegregation ‐ The presence of composition differences in a material, often caused by insufficient time for diffusion during solidification.

Non‐Equilibrium Solidification and Segregation

Coring ‐ Chemical segregation in cast products, also known as microsegregation or interdendritic segregation.

Homogenization heat treatment ‐ The heat treatment used to reduce the microsegregation caused during nonequilibrium solidification.Macrosegregation ‐ The presence of composition differences in a material over large distances caused by nonequilibrium solidification.

Invariant Points in Binary Systems•Binary alloys – two components at ambient pressure. Gibbs rule states that

P + F = 2 + 1= 3.

•If three phases coexists (P = 3), they coexist at a point (zero degrees of freedom – the invariant point, at a specific temperature and chemical composition

•Types of invariant points:

eutectic, eutectoid, peritectic

peritectoid, monotectic etc.

Five of the Most Important Three Phase Reactions (Invariant Points) in Binary Diagrams

eutectic: Liquid/solid reaction

eutectoid: solid/solid reaction

1150oC: The in‐between point is at 15% B. δ + L are present above the point, γ is present below. The reaction is: δ + L ⇒ γ, a peritectic

920oC: This reaction occurs at 40% B: L1 ⇒ γ + L2 a monotectic

750oC: This reaction occurs at 70% B: L ⇒ γ + β, a eutectic

450oC: This reaction occurs at 20% B: γ ⇒ α + β, a eutectoid

300oC: This reaction occurs at 50% B: α + β ⇒ μ or a peritectoid

Eutectic Systems

• The simplest kind of system with two solid phases is called a eutectic system.

• A eutectic system contains two solid phases at low temperature. These phases may have different crystal structures, or the same crystal structure with different lattice parameters.

• Examples:

– Pb (FCC) and Sn (tetragonal) ‐ solder systems

– Fe (BCC) and C (graphite ‐ hexagonal) ‐ cast irons

– Al (FCC) and Si (diamond cubic) ‐ cast aluminum alloys

– Cu(FCC) and Ag(FCC) – high temperature solder

Cu/Ag Eutectic System• Copper and Silver are both FCC, but their lattice parameters and

atomic radii are very different, so they have limited solubility in the solid state.

• There are two solid stable phases α and β, and at high temperatures there is a eutectic reaction where the solids α, βand the liquid coexist.

)()()( EECooling

Heating

E CCCL βα βα +⎯⎯ →⎯⎯⎯ ⎯←

Hypoeutectic alloy ‐ An alloy composition between that of the left‐hand‐side end of the tie line defining the eutectic reaction and the eutectic composition.Hypereutectic alloys ‐ An alloy composition between that of the right‐hand‐side end of the tie line defining the eutectic reaction and the eutectic composition.

Cu – Ag System

Cu: α phase

Ag: β phase

Eutectic means “easily melted” in Greek

Point E: invariant point (eutectic point)

BG line: isotherm line

AB & FG: Solidus line

BC & GH: Solvus line

AE & EF: Liquidus line

BEG: Solidus line,

isotherm line

TE: eutectic isotherm

Invariant or eutectic point

Eutectic isotherm

Eutectic Reaction:

For copper‐silver system:

Eutectic or invariant point ‐ Liquid and two solid phases co‐exist in equilibrium at the eutectic composition CE and the eutectic temperature TE.

Eutectic isotherm ‐ horizontal solidus line at TE.

( ) ( ) ( )EEE CCCLCooling

Heating

βα βα +⎯⎯⎯ →⎯⎯⎯⎯ ⎯←

( ) ( ) ( )AgwtAgwtAgwtLCooling

Heating %2.91%0.8%9.71 βα +⎯⎯⎯ →⎯⎯⎯⎯ ⎯←

Binary Eutectic SystemEutectic reaction – transition from liquid to mixture of two solid phases, α + β at eutectic concentration CE.

At most two phases can be in equilibrium. Three phases (L, α, β) may be in equilibrium only at a few points along the eutectic isotherm. Single‐phase regions are separated by 2‐phase regions.

Binary Eutectic SystemCompositions and relative amounts of phases are determined from the same tie lines and lever rule, as for isomorphous alloys‐‐demonstrate

• C

• B

• A

Example

For Point C: 40wt%Sn‐60wt%Pb alloy at 150oC

a) What are the phases present?

b) What are the compositions of the phases present?

c) Mass fraction?

d) Volume fraction at 150oC?

Knowing that the densities of Pb and Sn are 11.23 and 7.24g/cm3, respectively

a) At C, α and β phases coexist

b) Draw Tie Line at 150oC:

For α‐phase:Cα = 10%

→10wt%Sn–90wt%Pb

For β‐phase:Cβ = 98%

→98wt%Sn–2wt%Pb

• C

c) Mass fraction:

d) volume fraction:

where

34.010981040

66.010984098

1

1

=−−

=−−

=

=−−

=−−

=

αβ

αβ

αβ

βα

CCCCW

CCCC

W

43.057.011

57.039.7

34.064.10

66.064.10

66.0

=−=−=

=+

=+

=+

=

αβ

β

β

α

α

α

α

βα

αα

ρρ

ρνν

ν

VV

WW

WV

3

33

3

33

.29.7

.23.112

.24.798

100100

.64.10

.23.1190

.24.710

100100

−

−−−−

−

−−−−

=+

=+

=

=+

=+

=

cmg

cmgcmgCC

cmg

cmgcmgCC

Pb

Pb

Sn

Sn

Pb

Pb

Sn

Sn

ρρ

ρ

ρρ

ρ

ββα

ααα

Development of microstructure in eutectic alloys (I)

Several types of microstructure formed in slow cooling an different compositions. Cooling of liquid lead/tin system at different compositions.

In this case of lead-rich alloy (0-2 wt% of tin) solidification proceeds in the same manner as for isomorphous alloys (e.g. Cu-Ni) that we discussed earlier.

L⇓

L+α⇓α

Development of microstructure in eutectic alloys (II)

At compositions between room temperature solubility limit and the maximum solid solubility at the eutectic temperature, β phase nucleates as the α solid solubility is exceeded at solvus line.

L

α +L

α

α +β

No changes above eutectic temperature, TE. At TE liquid transforms to α and β phases (eutectic reaction).

L → α +β

Development of microstructure in eutectic alloys (III)Solidification at the eutectic composition (I)

Development of microstructure in eutectic alloys (IV)Solidification at the eutectic composition (II)

Compositions of α and β phases are very different → eutectic reaction involves redistribution of Pb and Sn atoms by atomic diffusion. Simultaneous formation of α and β phases results in a layered (lamellar) microstructure:called eutectic structure.

Formation of eutectic structure in lead‐tin system.

Dark layers are lead‐

reach α phase.Light layers are the

tin‐reach β phase.

Development of microstructure in eutectic alloys (V) Compositions other than eutectic but

within the range of the eutectic isotherm

Primary α phase is formed in the α + L region, and the eutectic structure that includes layers of α and β phases (called eutectic α and eutectic β phases) is formed upon crossing the eutectic isotherm.

L ⇓

α+L⇓

α+β

Development of microstructure in eutectic alloys (VI)

Microconstituent – element of microstructure having a distinctive structure. For case described on previous page, microstructure consists of two microconstituents, primary αphase and the eutectic structure.

Although the eutectic structure consists of two phases, it is a microconstituent with distinct lamellar structure and fixed ratio of the two phases.

Compositions of α and β phases are very different → eutectic reaction involves redistribution of Pb and Sn atoms by atomic diffusion. Simultaneous formation of α and β phases results in a layered (lamellar) microstructure:called eutectic structure.

Formation of eutectic structure in lead‐tin

system.Dark layers are lead‐

reach α phase.Light layers are the tin‐

reach β phase.

Relative amounts of microconstituents?

Eutectic microconstituent forms from liquid having eutectic composition (61.9 wt% Sn)Treat the eutectic as if it were a separate phase and apply lever rule to find relative fractions of primary α phase (18.3wt% Sn) and eutectic structure (61.9wt% Sn):

( )

( ) primaryQP

QW

eutecticQPPWe

....

....

+=

+=

α

Terminal solid solution: a solid solution that exists over a composition range extending to either composition extremity of a binary phase diagram.

(a) A hypoeutectic lead‐tin alloy. (b) A hypereutectic lead‐tin alloy. The dark constituent is the lead‐rich solid α, the lightconstituent is the tin‐rich solid β, and the fine plate structure is the eutectic (x400).

The effect of the chemical composition and strengthening mechanism on the tensile strength of lead‐tin alloys.

Eutectic colonies and interlamellar spacing

Equilibrium Diagrams Having Intermediate Phases or Compounds

Intermediate solid solution:

α and η: two terminal solid solution

β, γ, δ, & ε are intermediatephasesα

β

γ

δ

ε

Copper-zinc

Intermetallic Compounds

Ex: magnesium‐lead phase diagram:

Intermetalliccompound: Mg2Pb can exist by itself only at the precise composition of 19wt%Mg –81wt%Pb

Eutectoid Reaction (Invariant Point E at 560oC)

Copper‐zinc

δ γ + εcooling

heatingEutectoid reaction

Peritectic Reaction (Invariant Point P at 598oC)Copper‐zinc

δ + L εcooling

heatingPeritectic reaction