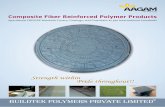

Natural Fiber Glass Fiber Hybrid Bio Composite Building Materials

…performing fiber - holtex.pl · Glass fiber Composite material1 ... 2,0 575 Carbon Composite...

Transcript of …performing fiber - holtex.pl · Glass fiber Composite material1 ... 2,0 575 Carbon Composite...

Volcanic Fiber Quality

High mechanical properties

Alkali and acid resistance

High chemical resistance

High temperature resistance

Low thermal conductivity

No electrical conductivity

No interference with RF signals

Fiber

Footprint

Material Specifications

Fiber

Footprint

Density [g/cm³]

Specific Strenght2

[MPa/(g/cm³)]

Composite material1 Fiber density: 2,6 g/cm³

1,9 750

Steel 7,8 65 - 154

Aluminium 2,7 19 - 185

Glass fiber Composite material1

Fiber density: 2,6 g/cm³2,0 575

Carbon Composite material1

Fiber density: 1,8 g/cm³1,5 1170

1 Composite with 50% fiber volume content with epoxy resin (Density 1,2g/cm³)

2 Tensile strength based on the density of the material

Volcanic Fiber Quality

No corrosion

Perfect for pre-stressing technology

Lightweight material

Ballistic impact properties

High abrasion resistance

Excellent sound insulation

Very good machinability

High environmental compatibility

Ecological recyclability

Fiber

Footprint

Comparative Characteristics

Fiber

Footprint

General Technical Comparison of Filament made from

E-Glass, commercially available Basalt and Silica.

Source: Internet research

CO2 Footprint Comparison

Fiber

Footprint

Industry Overall CO2 – Exposure

FIBER 800 - 1.400 kg CO2/t

Fiberglass 800 – 2.700* kg CO2/t

Carbon fiber ca. 25.000 kg CO2/t

Raw steel 1.850 – 2.500 kg CO2/t

Special steel 3.000 – 5.000 kg CO2/t

Aluminium 4.600 kg CO2/t

� CO2 – Exposure has a huge influence on the life-cycle assessment

� CO2 – Footprint of FIBERS is significantly better than of Carbon fibers or any other

conventional metallic material

*Source: LCA GlassFibreEurope