Performance Analysis and Optimization of a 5-DOFs Mechanism

-

Upload

tuan-pham-minh -

Category

Documents

-

view

215 -

download

0

Transcript of Performance Analysis and Optimization of a 5-DOFs Mechanism

-

8/20/2019 Performance Analysis and Optimization of a 5-DOFs Mechanism

1/10

Performance analysis and optimization of a ve-degrees-of-freedomcompliant hybrid parallel micromanipulator

Dan Zhangn, Zhen Gao

Faculty of Engineering and Applied Science, University of Ontario Institute of Technology, Oshawa, Ontario, Canada

a r t i c l e i n f o

Article history:

Received 7 August 2014

Received in revised form16 January 2015

Accepted 17 January 2015Available online 7 February 2015

Keywords:

Compliant mechanisms

Optimization

Hybrid mechanisms

Performance index

a b s t r a c t

There are generally two main directions for the investigation and development of parallel manipulators,

namely macro/meso stream and micro/nano stream, in which the former one has been thoroughly in-

vestigated in recent decades, while the latter one still remains many performance related open issuesthat signicantly affect their application potentials in critical situations such as high-precision automated

cell manipulation. Improving the overall performance of parallel manipulators is the bridge to connect

the academia and industry for the great development and real-world application. This research is to

develop a novel methodology called performance decomposition and integration for governing the de-

sign optimization process of complicated micromanipulator. A new ve degrees-of-freedom (DOF)

compliant hybrid parallel micromanipulator which is congured with ve identical PSS limbs and one

constraining UPU limb is proposed as a case study. The performance visualization, nite element ana-

lysis, and dimensional optimization are implemented. The proposed methodology is applicable for the

design improvement of different kinds of compliant/parallel mechanisms.

& 2015 Elsevier Ltd. All rights reserved.

1. Introduction

For the past several decades, parallel mechanisms/manip-

ulators can be found for extensive applications including three-

dimensional printers, machine tools, and vehicle simulators,

picking and placing tools, sensors and robots [1–8]. Although a

major portion of these applications are not fully commercialized

and needs further improvement, it has been commonly recognized

with the continuing effort of several decades, parallel manipulator

has become one of the main branches of the family of mechanisms

and robotic systems due to their natural merits many aspects

[9–14].

Regarding performance parallel mechanisms, the global re-

searchers have conducted huge work on from design, analysis to

control [15–18]. However, due to the limitation of capabilities,

conventional manipulators cannot well adapt to the rapid change

of critical applications where reliability, robustness and resilience

are highly demanded. More ef cient methodologies, especially in

micro/nano applications for parallel manipulators, are highly re-

quired to guide the development of compliant manipulators. In

this scenario, a paradigm called as performance decomposition

and integration (PDI) is proposed. Performance decomposition is

necessary to explore the macroscopic characteristics of a

complicated system in a microscopic method. A system may have

many performance indices. Integration is a universal notion thatranges from component level to system level. For a robotic system,

the methodology of performance integration covers the measures

from integrated design and optimization. To explore the overall

performance of a complex system, it will be rstly divided into

several sub-criterions based on PDI. These sub-criterions are in-

vestigated and managed separately. Then, a united index can be

built to examine the comprehensive performance and conse-

quently improve it with performance integration.

As a case study, a 5-DOFs compliant hybrid parallel micro-

manipulator (CHPMM) is proposed. It is congured with ve

identical PSS limbs and one constraining UPU limb. A multi-layer

amplication mechanism based prismatic joint is designed for

each limb and the piezoelectric actuator will be placed at the

center position of the active prismatic joint. In each limb, two

exures based spherical joints are connected either with the

prismatic joint or with the moving stage, respectively. An em-

beddable passive UPU limb is applied to constrain the mobility of

the proposed manipulator into 5DOF. For the content of this paper,

the analysis of kinematic model and Jacobian matrix is conducted.

Three essential performance indices, i.e. dexterity, manipulability

and workspace, are derived and visualized. The nite element

analysis is performed to observe the mechanism behavior. Finally,

dimensional improvement is implemented based on hybrid opti-

mization algorithm.

Contents lists available at ScienceDirect

journal homepage: www.elsevier.com/locate/rcim

Robotics and Computer-Integrated Manufacturing

http://dx.doi.org/10.1016/j.rcim.2015.01.002

0736-5845/& 2015 Elsevier Ltd. All rights reserved.

n Corresponding author.

E-mail address: [email protected] (D. Zhang).

Robotics and Computer-Integrated Manufacturing 34 (2015) 20–29

http://www.sciencedirect.com/science/journal/07365845http://www.elsevier.com/locate/rcimhttp://dx.doi.org/10.1016/j.rcim.2015.01.002mailto:[email protected]://dx.doi.org/10.1016/j.rcim.2015.01.002http://dx.doi.org/10.1016/j.rcim.2015.01.002http://dx.doi.org/10.1016/j.rcim.2015.01.002http://dx.doi.org/10.1016/j.rcim.2015.01.002mailto:[email protected]://crossmark.crossref.org/dialog/?doi=10.1016/j.rcim.2015.01.002&domain=pdfhttp://crossmark.crossref.org/dialog/?doi=10.1016/j.rcim.2015.01.002&domain=pdfhttp://crossmark.crossref.org/dialog/?doi=10.1016/j.rcim.2015.01.002&domain=pdfhttp://dx.doi.org/10.1016/j.rcim.2015.01.002http://dx.doi.org/10.1016/j.rcim.2015.01.002http://dx.doi.org/10.1016/j.rcim.2015.01.002http://www.elsevier.com/locate/rcimhttp://www.sciencedirect.com/science/journal/07365845

-

8/20/2019 Performance Analysis and Optimization of a 5-DOFs Mechanism

2/10

2. Conceptual design and kinematic modeling

The computer-aided design (CAD) model of the proposed

CHPMM is shown as Fig. 1. It can be observed that this mechanism

has ve identical limbs which are featured as prismatic–spherical–

spherical structure, within which the prismatic joint is a multi-

layer compliant structure. There is a complicated passive con-

straining limb inside of this mechanism, which is connected with

the base and the moving platform with one universal joint re-

spectively. Between the two universal joints of the embedded

limb, a novel passive prismatic joint is proposed. Five electric-

piezos are mounted at the edge of the base platform to actuate the

external identical limbs. The inside embedded limb constrain the

Fig. 1. The proposed 5-DOF CHPMM: (a) the CAD model and (b) the kinematical

structure.

-1

-0.5

0

0.5

1

-1

-0.5

0

0.5

10

2

4

6

8

x 10-4

x (mm)y (mm)

D e x t e r i t y

Fig. 2. The landscapes of dexterity.

-1

-0.5

0

0.5

1

-1

-0.5

0

0.5

10

0.2

0.4

0.6

0.8

1

x (mm)y (mm)

M a n i a b i l i t y

Fig. 3. The landscapes of manipulability.

-0.4 -0.3 -0.2 -0.1 0 0.1

0.2 0.3-0.2

0

0.2

0.95

1

1.05

1.1

1.15

1.2

x (mm)y (mm)

z ( m m )

Fig. 4. The landscapes of workspace.

D. Zhang, Z. Gao / Robotics and Computer-Integrated Manufacturing 34 (2015) 20 – 29 21

-

8/20/2019 Performance Analysis and Optimization of a 5-DOFs Mechanism

3/10

mobility of the end-effector into ve degrees-of-freedom. The

whole mechanism is compact and has the capability to fulll ad-

vanced manipulation in micro-range eld such as cell probing and

cell injection. Since for the commonly used automated cell ma-

nipulation, the electric-piezos are congured in three perpendi-

cular directions to control the motion in each axis separately.

However, it is dif cult to perform complicated manipulation in

higher DOFs, i.e. 5DOFs or 6DOFs. Thus, the proposed structure

provides a solution to achieve this.

The kinematical structure of the proposed 5-DOF CHPMM has

two platforms, namely the xed platform B1B2B3B4B5, and the

moving platform P 1P 2P 3P 4P 5, as shown in Fig. 1(b). There are two

coordinate frames, the xed reference frame which is expressed as

O x y z { , , } is attached to the center of the base platform. Another

reference frame is attached to the center of the mobile platform.

A constraining limb with prismatic–universal–universal joints

and each universal joint is attached to the centers of the xed

platform and the moving platform, respectively. The inverse ki-

nematics of the proposed mechanism means to derive the solution

of the actuated joints when the pose of the end-effector is known.

By observing Fig. 1(b), it has,

p x y z i[ , , ] 1, , 5 (1)i i i i T

= = …

r l l i[ cos , sin , 0] 1, , 5 (2)i e ei e ei T θ θ = = …

p x y z [ , , ] (3)T =

b l l i[ cos , sin , 0] 1, , 5 (4)i b bi b bi T θ θ = = …

where p i is the position vector of point P i expressed in the xed

coordinate frame, r i is the position vector of point P i expressed in

the moving coordinate frame, and p is the position vector of point

P expressed in the xed frame, and

⎡

⎣⎢⎤

⎦⎥

[ , , , , ]

, 2 /5 , 4

5 ,

6

5 ,

8

5 (5)

bi b b b b b T

T

1 2 3 4 5 θ θ θ θ θ θ

β π β π

β π

β π

β

=

= + + + +

⎡⎣⎢

⎤⎦⎥

[ , , , , ]

, 2 /5 , 45

, 65

, 85 (6)

pi p p p p p T

T

1 2 3 4 5 θ θ θ θ θ θ

α π α π α π α π α

=

= + + + +

One can then write

p p Qr i, 1, ... , 5, (7)i i= + =

where Q is the rotation matrix, and α , β are the angles on the

base and on the platform respectively. In this case, since there is

no rotation for the moving platform, Q is an identity matrix. Thus

the inverse kinematics can be easily derived through addressing

the closed loop,

′′ ′′ OB O B P P OO i( 1, ... , 5) (8)i i i i ρ = = − − =

Differentiating Eq. (7), one obtains

Fig. 5. The meshing of the proposed CHPMM.

Fig. 6. The piezo force is applied on one limb with 1 N: (a) total deformation and

(b) elastic strain.

D. Zhang, Z. Gao / Robotics and Computer-Integrated Manufacturing 34 (2015) 20 – 2922

-

8/20/2019 Performance Analysis and Optimization of a 5-DOFs Mechanism

4/10

p p Qr (9)i i= +

Hence, one can write the velocity equation as

At B (10) ρ=

Thus the Jacobian matrix is expressed as

B A J . (11)1= −

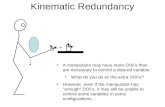

3. Performance decomposition

CHPMM, as a complex system, has the characteristics of non-

linearity, multi-parameters and strong coupling. To explore it

overall performance, one of the initial measures is to decompose it

into several critical sub-criterions and visualize and analysis thesesub-criterions separately. As a case study, the indices of dexterity,

manipulability and workspace are landscaped for the further

integration.

The motion isotropy of the CHPMM is highly related with

dexterity whose value can be derived based on the methods of

condition number, determinant, minimum singular value and joint

range availability. The health condition and robustness of Jacobian

can be investigated through condition number. Thus in this work

the condition number of Jacobian matrix is chosen to express the

dexterity. In this case, the range of dexterity is from zero to one. If

zero, it implies an ill-conditioned matrix and singularity. If one, it

implies the CHPMM has isotropic motion characteristics. The

dexterity is de

ned as follows:

Fig. 7. The piezo forces are applied on two limbs with 1 N: (a) total deformation

and (b) elastic strain.

Fig. 8. The piezo forces are applied on three limbs with 1 N: (a) total deformation

and (b) elastic strain.

D. Zhang, Z. Gao / Robotics and Computer-Integrated Manufacturing 34 (2015) 20 – 29 23

-

8/20/2019 Performance Analysis and Optimization of a 5-DOFs Mechanism

5/10

Dexterity Sing J Sing J ( )/ ( ) (12)min max=

where J Sing ( )min and J Sing ( )max are the minimal and maximal

singular values of J , respectively. Fig. 2 shows the distribution of

the dexterity.

The manipulability of the proposed CHPMM is derived as

LMI J J det( ) (13)T = ⋅

The landscape of the manipulability is illustrated in Fig. 3.

Workspace can be roughly divided into joint workspace and

end-effector workspace. If concerning to the input variables, the

motions of all the actuated joints form a joint space whose di-

mension relies on the number of the actuators [19,20]. In most

cases, the end-effector workspace is investigated, since its shape

and volume which are affected by structure parameters,

constraints and actuation strokes are highly related with the per-

formance of the specic application. A simple solution to generate

the workspace is to take advantage of the inverse kinematics and

the constraints of the mechanism. First of all, the end-effector is

located at the home position. Then it will be moved in the space in

a given step length. The inverse kinematic model is conducted is

check of the input variable exceed the motion stroke or achieve

the constraint. If not, continue to move the end-effector to a fur-

ther post and apply the inverse kinematics again. If yes, stop

moving the end-effector in the previous direction. Fig. 4 illustrates

the shape and envelope of the achieved workspace.

Fig. 9. The piezo forces are applied on four limbs with 1 N: (a) total deformation

and (b) elastic strain.

Fig. 10. The piezo forces are applied on ve limbs with 1 N: (a) total deformation

and (b) elastic strain.

Table 1

Modal.

Mode Frequency [Hz]

1 81.38

2 81.695

3 132.43

4 198.515 198.67

D. Zhang, Z. Gao / Robotics and Computer-Integrated Manufacturing 34 (2015) 20 – 2924

-

8/20/2019 Performance Analysis and Optimization of a 5-DOFs Mechanism

6/10

4. Finite element analysis

The overall features of a CHPMM are greatly affected by the

selected material. In this scenario, stainless steel is chosen after a

critical evaluation of vital design criteria as the mechanical body of

the proposed mechanism. The meshing result of the proposed

CHPMM is provided in Fig. 5. The most sensitive parts in each limb

including the cantilever of the prismatic joint and the specic

joints should be rened using the features of face sizing. In FEA,

the pentagon side length is 150 mm, the peripheral radius of the

mobile stage is 37 mm, the height of the stage is 35 mm, and the

length of each arm is 78 mm.

Fig. 11. The total deformation under different natural frequency: (a) Frequency 1; (b) Frequency 2; (c) Frequency 3; (d) Frequency 4; and (e) Frequency 5.

D. Zhang, Z. Gao / Robotics and Computer-Integrated Manufacturing 34 (2015) 20 – 29 25

-

8/20/2019 Performance Analysis and Optimization of a 5-DOFs Mechanism

7/10

5. Strain and deformation

The strain and deformation results reect the performance of

compliance, sensitivity, linearity and verify the motion of the

proposed CHPMM. A selected piezoelectric linear actuator gen-

erates a representative force of 1 N on a single limb of the me-

chanism in Fig. 6. It can be observed that the cantilever nearest to

the spherical joint is subject to the maximal elastic strain with

1.0819105 mm/mm. Besides, the edge of the moving platform

which is closest to the limb with external force produces the

maximal deformation with 2.9967 μm. The force applied at one

limb only has slight effect on other active joints.

When two piezoelectric actuators are acted on two limbs with

1N force respectively, similarly with the preceding situation, the

total deformation and elastic strain is illustrated in Fig. 7. It can befound that cantilever nearest to the ball joint has the maximal

elastic strain is 1.5044105 mm/mm. The edge of the moving

platform which is near to the apply force is experienced the most

deformation with 4.573 μm. It also can be found that the limb on

the opposite side is subject to larger deformation and elastic strain

than the other two limbs.

If there are three piezoelectric linear actuators generates a re-

presentative force of 1N on three limbs in a row of the mechanism

the proposed CHPMM, in Fig. 8, it can be observed that the can-

tilever nearest to the spherical joint of the middle limb of the three

limbs is subject to the maximal elastic strain with 1.7595105

mm/mm. Furthermore, the edge of the moving platform which is

closest to this middle limb produces the maximal deformation

with 5.2497 μm.

In the fourth scenario, when four piezoelectric actuators are

acted on four limbs with 1 N force respectively, it can be found

that maximal elastic strain is 1.7333105 mm/mm and the

maximal deformation is 4.5035 μm. The ball joints are bent to the

side of the limb where no actuator is applied at (Fig. 9).

Fig. 10 shows the results when all the ve external limbs are

actuated with 1N respectively. It seems that the deformation and

the elastic strain are symmetrical on these active limbs. For the

middle passive limb, the deformation and the elastic strain on

each cantilever is also symmetrically distributed. Each cantilever

nearest to the ball joint has the maximal elastic strain with1.4051105 mm/mm. The moving platform is experienced the

maximal deformation with 3.2607 μm.

6. Modal analysis

The natural frequencies with ve possible modes are given in

Table 1. Fig. 11 characterizes the total deformation under different

cases of natural frequencies.

Fig. 12 describes the frequency response of total deformation

and strain when external force is acted on top of the mobile

platform in the opposite direction of z axis with 1 N.

Fig. 13 reects the results when the external force is applied on

the moving platform only in x axis with 1 N.

Fig.12. Frequency response with applied force on the moving platform – case one:

(a) deformation and (b) strain.

Fig.13. Frequency response with applied force on the moving platform – case two:

(a) deformation and (b) strain.

D. Zhang, Z. Gao / Robotics and Computer-Integrated Manufacturing 34 (2015) 20 – 2926

-

8/20/2019 Performance Analysis and Optimization of a 5-DOFs Mechanism

8/10

The last scenario is the results of frequency response for strain

and total deformation if the external force is implemented on the

mobile platform with 1 N in x-, y- and z - axes, respectively

(Fig. 14).

7. Performance integration

The performance of a CHPMM depends on the overall hy-

bridization, which can be called as system hybridization (SH). SH

stands at the higher viewpoint on a system level to investigate themacro/micro conditions thorough the methods such as mechan-

ism hybridization (MH), actuation hybridization (AH) and opti-

mization hybridization (OH). MH takes the merits of serial/parallel

mechanism to develop new structures with the integrated ad-

vantages of parallel mechanism, compliant mechanism, serial

mechanism and even others. For instance, in a non-structure cir-

cumstance, the integrated tensegrity structure and cable driven

parallel mechanism perform a exible autonomous motion. For

adaptive and robotic manufacturing, the integrated of rigid serial

mechanism and rigid parallel mechanism can implement some

complicated machining as a multi-axis CNC robotic machine tool.

For AH, since different actuation system has various features, the

hybrid actuation mode provide a possibility to improve the overall

performance of a hybrid mechanism. For OH, it is focused onbuilding a comprehensive performance index that can consider a

variety of performance indices in an integrated way. The idea of

OH considers the optimization management involved with multi-

objective hybridization, preformation integration and multi-algo-

rithm hybridization. In this scenario, performance integration is

highly related with OH.

Genetic algorithms as a scholastic method that explores all

regions of state space through the iterative usage of operators

including selection, crossover and mutation to chromosomes in

the population to avoid sticking into local niche [21–27]. In this

scenario, a multi-population genetic algorithm is applied for the

performance integration based optimal design of the proposed

CHPMM. Besides, the objective function ObjFun is dened as the

multiplication of each sub-function, i.e. dexterity, manipulabilityand volume of workspace.

ObjFun ObjFun ObjFun ObjFun1 2 3 (14)= × ×

The boundaries of the decision variables are given as follows:

l

l

l

h

40 mm 80 mm

10 mm 40 mm

50 mm 90 mm

15 mm 36 mm

0 0.436 rad

0.349 rad 0.436 rad (15)

b

e

i

α

β

≤ ≤

≤ ≤

≤ ≤

≤ ≤

≤ ≤

≤ ≤

At the beginning of the iteration, the total population pool is

split into four sub-populations with the numbers of chromosomes

Fig. 14. Frequency response with applied force on the moving platform – case

three: (a) deformation and (b) strain.

Table 2

Iteration process.

Iteration # f -Count ObjFun(104) Time of CPU

1 400 3.4824 00:00:00

3 1116 3.7963 00:00:00

6 2190 4.1758 00:00:01

9 3264 4.2747 00:00:01

12 4338 4.304 00:00:06

15 5412 4.3183 00:00:07

18 6488 4.3183 00:00:07

21 7564 4.3198 00:00:09

24 8638 4.3203 00:00:10

27 9712 4.3203 00:00:10

30 10,786 4.3203 00:00:12

33 11,860 4.3203 00:00:12

36 12,934 4.3204 00:00:13

39 14,008 4.3204 00:00:15

40 14,366 4.3204 00:00:15

Table 3

Size of subpopulations.

Iterat io n # Subpopulations #

1 85 15 95 105

3 85 115 95 105

6 111 159 67 63

9 120 174 41 65

12 126 183 25 66

15 126 183 25 6618 129 190 15 66

21 131 194 9 66

24 194 134 6 66

27 194 134 6 66

30 195 134 5 66

33 195 134 5 66

36 117 134 5 144

39 117 134 5 144

40 71 134 5 190

D. Zhang, Z. Gao / Robotics and Computer-Integrated Manufacturing 34 (2015) 20 – 29 27

-

8/20/2019 Performance Analysis and Optimization of a 5-DOFs Mechanism

9/10

with 85, 115, 95, and 105 respectively. The maximal iterations are

40. Other evolutionary parameters are set as follows:

selection function¼selsus

selection pressure¼1.7

selection gen. gap¼0.9

reinsertion rate¼1

recombination rate¼1

mutation rate¼1mutation range¼0.1, 0.03, 0.01, 0.003

mutation precision¼12

migration rate¼0.1

migration interval¼20

competition rate¼0.4

competition interval¼4

competition subpop minimum¼5

competition div. pressure¼2

The detailed Iteration process and evoluaitonary size of each

subpopulation is given in Tables 2 and 3.

After optimization, the optimal value of objective function is

convergent at 4.3204104 with the optimized dimensional

parameters equal to 54.99 mm, 10 mm, 50 mm, 15 mm,0.0027505 rad, and 0.41112 rad, respectively. The evaluation pro-

cess of the optimal objective function and dimensional parameters

for the proposed CHPMM are obtained in Fig. 15.

8. Conclusions

Performance is a critical topic for the further improvement of

compliant parallel mechanisms. The research attempts to propose

a paradigm called performance decomposition and integration to

manage the overall performance of these mechanisms in a higher

level. A CHPMM is proposed as an example to showcase part of the

principle of PDI in the process of design and optimization. The

proposed method can be well integrated with the methodologyof system hybridization through the specic methods of me-

chanism hybridization, actuation hybridization and optimization

hybridization. For the future work, a physical prototype will

be manufactured to further improve the overall performance in

aspects of manipulation and control under the guidance of the

proposed methods.

Acknowledgments

The authors would like to thank the nancial support from the

Natural Sciences and Engineering Research Council of Canada

(NSERC). The authors gratefully acknowledge the nancial support

from Canada Research Chairs program.

References

[1] M. Agheli, S.S. Nestinger, Comprehensive closed-form solution for the reach-able workspace of 2-RPR planar parallel mechanisms, Mech. Mach. Theory 74(2014) 102–116.

[2] G. Coppola, D. Zhang, K. Liu, Z. Gao, Design of parallel mechanisms for exiblemanufacturing with recongurable dynamics, ASME Trans. J. Mech. Des. 135(2013) 071011-1–071011-10.

[3] S. Refaat, J.M. Herve, S. Nahavandi, , Two-mode overconstrained three-DOFsrotational translational linear motor based parallel-kinematics mechanism formachine tool applications, Robotica 25 (2007) 461–466.

[4] J.A. Palmer, B. Dessent, J.F. Mulling, T. Usher, E. Grant, J.W. Eischen, A.I. Kingon,P.D. Franzon, The design and characterization of a novel piezoelectric trans-ducer-based linear motor, IEEE/ASME Trans. Mechatron. 13 (2004) 441–450.

[5] S.L. Chen, T.H. Chang, Y.C. Lin, Applications of equivalent components concept

Fig. 15. The result of multi-objective optimization: (a) objective function; (b) the

dimensional variables; and (c) size of subpopulations.

D. Zhang, Z. Gao / Robotics and Computer-Integrated Manufacturing 34 (2015) 20 – 2928

http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref1http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref1http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref1http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref1http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref1http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref1http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref2http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref2http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref2http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref2http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref2http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref2http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref2http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref2http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref2http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref2http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref3http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref3http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref3http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref3http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref3http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref3http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref4http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref4http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref4http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref4http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref4http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref4http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref5http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref5http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref4http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref4http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref4http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref4http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref3http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref3http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref3http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref3http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref2http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref2http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref2http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref2http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref1http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref1http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref1http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref1

-

8/20/2019 Performance Analysis and Optimization of a 5-DOFs Mechanism

10/10

on the singularity analysis of TRR –XY hybrid parallel kinematic machine tools,Int. J. Adv. Manuf. Technol. 30 (7–8) (2006) 778–788.

[6] J. Bał chanowski, Topology and analysis of the singularities of a parallel me-chanism with three degrees of freedom, Arch. Civ. Mech. Eng. 14 (1) (2014)80–87.

[7] Z. Gao, D. Zhang, Y.J. Ge, Design optimization of spatial six degree-of-freedomparallel manipulator based on articial intelligence approaches, Robot. Com-put. Integr. Manuf. 26 (2) (2010) 180–189.

[8] G.S. Kima, H.J. Shina, J.W. Yoon, Development of 6-axis force/moment sensorfor a humanoid robot's intelligent foot, Sens. Actuators A: Phys. 141 (2) (2008)276–281.

[9] S. Oh, K. Kong, Y. Hori, Design and analysis of force-sensor-less power-assistcontrol, IEEE Trans. Ind. Electron. 61 (2) (2014) 985–993.

[10] E. Cuan-Urquizo, E. Rodriguez-Leal, Kinematic analysis of the 3-CUP parallelmechanism, Robot. Comput.-Integr. Manuf. 29 (5) (2013) 382–395.

[11] C. Wang, Y. Fang, S. Guo, Y. Chen, Design and kinematical performance analysisof a 3-RUS/RRR redundantly actuated parallel mechanism for ankle re-habilitation, ASME Trans. J. Mech. Robot. 5 (2013) 041003 .

[12] I. Hostens, J. Anthonis, H. Ramon, New design for a 6 dof vibration simulatorwith improved reliability and performance, Mech. Syst. Signal Process. 19 (1)(2005) 105–122.

[13] M. Carricato, Direct geometrico-static problem of underconstrained cable-driven parallel robots with three cables, ASME Trans. J. Mech. Robot. 5 (3)(2013) 031008.

[14] G. Bhutani, T.A. Dwarakanath, Novel design solution to high precision 3 axestranslational parallel mechanism, Mech. Mach. Theory 75 (2014) 118–130.

[15] N. Plitea, D. Lese, D. Pisla, C. Vaida, Structural design and kinematics of a newparallel recongurable robot, Robot. Comput.-Integr. Manuf. 29 (1) (2013)219–235.

[16] J. Guo, L. Zhao, L. Dong, Z. Sheng, The analysis on the processing dexterity of a3-TPT parallel machine tool, Procedia Eng. 15 (2011) 298–302.

[17] J. Zhao, F. Chu, Z. Feng, Symmetrical characteristics of the workspace forspatial parallel mechanisms with symmetric structure, Mech. Mach. Theory 43(2008) 427–444.

[18] U. Schneider, M. Drust, A. Puzik, A. Verl, Compensation of errors in robotmachining with a parallel 3D-piezo compensation mechanism, Procedia CIRP7 (2013) 305–310.

[19] C. Brisan, A. Csiszar, Computation and analysis of the workspace of a re-congurable parallel robotic system, Mech. Mach. Theory 46 (2011)1647–1668.

[20] K. Tsai, J. Lin, Determining the compatible orientation workspace of Stewart –Gough parallel manipulators, Mech. Mach. Theory 41 (2006) 1168–1184.

[21] S.H. Chung, H. Chan, A two-level genetic algorithm to determine productionfrequencies for economic lot-scheduling problem, IEEE Trans. Ind. Electron. 59(1) (2012) 611–619.

[22] C.F.M. Toledo, L. Oliveira, P.M. França, Global optimization using a genetic al-gorithm with hierarchically structured population, J. Comput. Appl. Math. 261(2014) 341–351.

[23] S.M. Elsayed, R.A. Sarker, D.L. Essam, A new genetic algorithm for solvingoptimization problems, Eng. Appl. Artif. Intell. 27 (2014) 57–69.

[24] M. Thakur, S.S. Meghwani, H. Jalota, , A modied real coded genetic algorithmfor constrained optimization, Appl. Math. Comput. 235 (2014) 292–317.

[25] A.S. Ghiduk, Automatic generation of basis test paths using variable lengthgenetic algorithm, Inf. Process. Lett. 114 (6) (2014) 304–316.

[26] M. Dai, D. Tang, A. Giret, M.A. Salido, W.D. Li, Energy-ef cient scheduling for aexible ow shop using an improved genetic-simulated annealing algorithm,Robot. Comput.-Integr. Manuf. 29 (5) (2013) 418–429.

[27] B. Huang, K. Xing, K. Abhary, S. Spuzic, Optimization of oval –round pass designusing genetic algorithm, Robot. Comput.-Integr. Manuf. 28 (4) (2012) 493–499.

D. Zhang, Z. Gao / Robotics and Computer-Integrated Manufacturing 34 (2015) 20– 29 29

http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref5http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref5http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref5http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref5http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref5http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref5http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref5http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref5http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref5http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref6http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref6http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref6http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref6http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref6http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref6http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref6http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref6http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref7http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref7http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref7http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref7http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref7http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref7http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref7http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref7http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref8http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref8http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref8http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref8http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref8http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref8http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref9http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref9http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref9http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref9http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref9http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref10http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref10http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref10http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref10http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref10http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref11http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref11http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref11http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref11http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref12http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref12http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref12http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref12http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref12http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref12http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref13http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref13http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref13http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref13http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref14http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref14http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref14http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref14http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref14http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref15http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref15http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref15http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref15http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref15http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref15http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref15http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref15http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref16http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref16http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref16http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref16http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref16http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref17http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref17http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref17http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref17http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref17http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref17http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref18http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref18http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref18http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref18http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref18http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref18http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref19http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref19http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref19http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref19http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref19http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref19http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref19http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref19http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref20http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref20http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref20http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref20http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref20http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref20http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref21http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref21http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref21http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref21http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref21http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref21http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref22http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref22http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref22http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref22http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref22http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref22http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref23http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref23http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref23http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref23http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref23http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref24http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref24http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref24http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref24http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref24http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref24http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref24http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref25http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref25http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref25http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref25http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref25http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref26http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref26http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref26http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref26http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref26http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref26http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref26http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref26http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref26http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref26http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref26http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref27http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref27http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref27http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref27http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref27http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref27http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref27http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref27http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref27http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref27http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref26http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref26http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref26http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref26http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref25http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref25http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref25http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref24http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref24http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref24http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref23http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref23http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref23http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref22http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref22http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref22http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref22http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref21http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref21http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref21http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref21http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref20http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref20http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref20http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref19http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref19http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref19http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref19http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref18http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref18http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref18http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref18http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref17http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref17http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref17http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref17http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref16http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref16http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref16http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref15http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref15http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref15http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref15http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref14http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref14http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref14http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref13http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref13http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref13http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref12http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref12http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref12http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref12http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref11http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref11http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref11http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref10http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref10http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref10http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref9http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref9http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref9http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref8http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref8http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref8http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref8http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref7http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref7http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref7http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref7http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref6http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref6http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref6http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref6http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref5http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref5http://refhub.elsevier.com/S0736-5845(15)00015-0/sbref5