Peak Load Sharing at Domestic Level

-

Upload

engr-muhammad-mansoor-ashraf -

Category

Documents

-

view

227 -

download

0

description

Transcript of Peak Load Sharing at Domestic Level

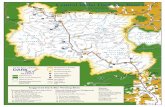

Peak load sharing based on blade pitch control of wind turbine in the presence ofutility supplyMuhammad Mansoor Ashraf, Tahir Nadeem Malik, and Mehroze Iqbal Citation: Journal of Renewable and Sustainable Energy 6, 013110 (2014); doi: 10.1063/1.4862202 View online: http://dx.doi.org/10.1063/1.4862202 View Table of Contents: http://scitation.aip.org/content/aip/journal/jrse/6/1?ver=pdfcov Published by the AIP Publishing This article is copyrighted as indicated in the article. Reuse of AIP content is subject to the terms at: http://scitation.aip.org/termsconditions. Downloaded toIP:111.68.98.148 On: Wed, 15 Jan 2014 03:28:59Peak load sharing based on blade pitch controlof wind turbine in the presence of utility supplyMuhammad Mansoor Ashraf,a)Tahir Nadeem Malik, and Mehroze IqbalElectrical Engineering Department, University of Engineering and Technology,Taxila 47050, Pakistan(Received 22 August 2013; accepted 2 January 2014; published online 14 January 2014)The alternate energy resources are replacing conventional energy sources forelectricityproductionbecauseoftremendouslyincreasingenvironmentalpollutionand cost of fossil fuels. Wind power is one of the potential alternate energyresources and is being deployed actively. Wind power generation system comprisesofwindturbineandelectrical generatorasessential partsinterconnectedthroughgearbox.Theconventionalwindturbinesaredesignedwithadjustablebladepitchto regulate shaft speed of turbineor to withstand against heavy wind blows. In thispaper, atechniquefor peakloadsharinginthepresenceof utilitysupplyusingPitchFrequencyControl(PFC)isproposedforwindturbines. ThistechniquehasbeensimulatedinMATLABenvironment usingSimulink. Thesimulationresultsshowthat PFCndsitsapplicationswithwindenergysystemhavinglowspeedaxial ux synchronous generator as well as with the wind energy system with smallgear ratio. This particular proposedPFCbasedcontrol presents acost effectivetechniquefor efcient peakloadsharingandwindenergysystemfreeof powerelectronic converters. VC2014 AIP Publishing LLC.[http://dx.doi.org/10.1063/1.4862202]I. INTRODUCTIONThe windenergyis gettingimmensepopularityinthe eldof renewable energyresourcesnow-a-days. Thewindenergyrepresentsthesystemconsistingofwindturbineandelectrical gen-eratorcoupledthroughgearbox. Therearethreemajortypesofwindenergysystems(WESs)thatareaddressedinliteratureasdomesticWindTurbine,StandaloneWindTurbine,andConventionalWindTurbine.1Thedomesticwindturbinesaresmall windturbinesthat areemployedforhouseholdapplicationsonthetopofroofsanditsratingislessthan10kW.1Thestandalonewindtur-binesarereferredasintermediatewindturbinesthat arefeedingtoaspecicareasuchashospi-tals, villages, or communitycenters, andtheseareratedbetween10and500 kW.1Theconven-tional windturbinesarerepresentedbylargeratedonshoreandoffshorewindfarmswithratingsbetween500 kWand5 MW.1Thestandaloneandconventionalwindturbinesaremostlygridcon-nectedwindturbines. Thereareanumberoftechniquesaddressedinliteratureforsynchronizationofwindturbinetonationalgrid. Averybriefliteratureisreviewedtoanalyzethedifferenttechni-quesforsynchronizationofwindturbinestonationalgridinthesubsequentparagraph.Most often, there are different types of power electronic based converters employed forAC/DC/AC transformation for grid connected scenario.25A single stage AC-AC converter(MatrixConverter) hasbeendiscussedfor synchronizationof windturbinetonational grid.6ThedifferentPhaseLockedLoopalgorithmsandcodesforgrid-connectedwindturbineshavebeenan-alyzed.7Astar-deltaconverterhasbeenaddressedandHighVoltageDirectCurrent(HVDC)trans-missionlinefor transfer of power fromwindturbines tonational gridhas beenproposed.8ThewindturbinesupplyingHVDCtransmissionlineandvoltagerecoveryafter fault havebeendis-cussed.9Anewtechniquehas beenpresentedtosynchronizethedoublyfedinductiongeneratora)Author to whom correspondence should be addressed. Electronic mail: [email protected]/2014/6(1)/013110/17/$30.00 VC2014 AIP Publishing LLC 6, 013110-1JOURNAL OF RENEWABLE AND SUSTAINABLE ENERGY 6, 013110 (2014) This article is copyrighted as indicated in the article. Reuse of AIP content is subject to the terms at: http://scitation.aip.org/termsconditions. Downloaded toIP:111.68.98.148 On: Wed, 15 Jan 2014 03:28:59alongwithpower electronicbasedconverters usedfor windturbines.10Theinductiongeneratorcoupledwithwindturbinehasbeencontrolledbyasystemcontrollerforswitchingandsynchroni-zationpurpose.11Amulti-poleinductionmachinehasbeenspeciallydesignedfordirectsynchroni-zationof windturbinestoutilitysupply.12Apermanent magnet synchronousgenerator hasbeenproposedwithwindturbinesincoordinationwithpowerelectronicsbasedconvertersforsynchro-nization.13Adesignofbuckboostconverterforpermanentmagnetsynchronousgeneratorcoupledwithwindturbinehasbeenaddressedtointerconnectwindturbineandnationalgridsupply.14Bladepitchmethodismostlyusedforregulationofturbinesshaftspeedagainsthighwindblowsandstorms. Thisbladepitchcontrol(BPC)methodcanbeusedforregulatingtheoutputfrequencyof thegenerator. Thethreebladepitchcontrol techniques: proportional integral dif-ferential (PID) controller, fuzzyPIDcontroller, andfuzzyfeedforwardcombinativecontrollerhavebeenproposedfor windturbines inRef. 15. Aneural networkbasedbladepitchcontroltechniquehasalsobeenpresentedinwhichcontrollerstabilizestheelectrical powersuppliedtonational grid by regulating shaft speed with blade pitch parameter against variable windspeed.16Thesimulationresultsshowthat thecontrol techniquepresentedinthispaper issim-pler andexhibits smoother results thanpresentedinRefs. 15and16. Whileadaptingcontroltechniquepresentedinthispaper, thepercent overshoot (OS) hasbeenreducedto1.5%intheoutputpowercurveofwindenergysystem, whichhasthevalueof43%addressedinRef.15.Fromtheaboveliteraturesurvey, pitchanglecontrol israretechniqueofloadsharinganditalsorequiresanefcientcontroller. ThistechniqueisnamedPitchFrequencyControl(PFC)ofwindturbineforloadsharing.PFCsimpliestheinstrumentationandpowerelectronicbasedcon-verter circuitry for grid synchronization. Moreover, PFCis cheaper technique and it nds itsmajor application with standalone wind turbines as well as with conventional wind turbines,wheregearboxratiois small. Thecompletesystemincludingwindturbine, utilitysupply, andtime varying load (TVL), is modelled in MATLABVRand SimulinkVRusing SimPowerSystemstoolbox.Simulationisperformedandresultsareshownandanalyzed.Inthisresearchpaper,aconventionalwindturbineisaddressedwithsynchronousgeneratorconnectedthroughgearbox. Thiswholewindenergysystemissynchronizedtoutilitysupplytofeedload. Duringpeakload, thewindpowergenerationsystemfeedsthispeakloadbyadjust-ingthebladepitchangleof windturbine. Thesiteof windturbineis consideredwithprede-nedclimaticconditionsbyspecifyingthewindspeedandairdensity.II. WESTheWindenergysystemisbasicallyconsistsof twomaincomponents; windturbineandelectricalgeneratorcoupledthroughgearbox.A. Wind turbineWindturbine represents the intermediate energyconversiondevice, whichextracts energyfromwindandconvertstorotational mechanical energyontheshaft ofwindturbine.1Windtur-binehasdifferentparametersasinputparametersandoutputparameters. Theinputparametersofwindturbineincludewindspeed,bladepitchangle,andmeasurementsofsystemwhereastheout-put parametersincludemechanical power, torque, andshaft speedasinFig. 1. Theoutput me-chanicalpowerofwindturbineisgivenby(1),1Pm 12qaAV3wCpk; b : (1)1. Air densityAccordingtoInternational StandardAtmosphere, at sea level andat 15

Ctemperature,theairdensitycomputedisgivenby17qa 1:225 kg=m3: (2)013110-2 Ashraf, Nadeem Malik, and Iqbal J. Renewable Sustainable Energy 6, 013110 (2014) This article is copyrighted as indicated in the article. Reuse of AIP content is subject to the terms at: http://scitation.aip.org/termsconditions. Downloaded toIP:111.68.98.148 On: Wed, 15 Jan 2014 03:28:592. Swept areaThisisareathatpropellerofwindturbinecoversintheairandfacestheeffectiveair.Sweptarea can be calculated, simply, by computing the area of circle when blade length is known,A pR2: (3)Hereradiuswillrepresentthebladelengthofwindturbine.SweptareaisshowninFig.2.FIG. 1.Wind turbine block.FIG. 2. Swept area.013110-3 Ashraf, Nadeem Malik, and Iqbal J. Renewable Sustainable Energy 6, 013110 (2014) This article is copyrighted as indicated in the article. Reuse of AIP content is subject to the terms at: http://scitation.aip.org/termsconditions. Downloaded toIP:111.68.98.148 On: Wed, 15 Jan 2014 03:28:593. Tip speed ratio (TSR)TSRisdenedastheratioofspeedoftiptospeedofwind. ThevalueofTSRvariesdur-ingtheoperationofwindturbine,17,18k VTVw: (4)Bladetipspeedisgivenby(5).VT 2pR60n: (5)Herenisdenedasshaft speedofwindturbineinrpm. Aftersubstitutionandmanipulation,it isshownby(6) that TSRisfunctionof shaft speedandwindspeedfor aspecicwindtur-bineatconstantbladepitchanglekn; Vw 2pR60n1Vw: (6)4. Blade pitch (b)The topviewof windturbine propeller demonstratingdifferent components is showninFig. 3(a).19Inorder toestablishreasonablelift anddragforcesontheblades, thebladeshavetobeplacedandattachedwithhubatananglewithreferencetodirectionofwind.19Ingeneralpractice, thehorizontal axis of Frameof Reference(FR) (shownbytwoperpendicular dottedlines in Figs. 3(b)3(e)) is parallel to blade chord.1,1921The blade pitch values b 0

andb 90

areshowninFigs. 3(b) and3(c). Inthisresearch, thehorizontal axisof FRhasbeenconsideredparalleltoPlaneofRotation(PR). Thusthebladepitchvalues b 24

and b 104

hasbeendemonstratedinFigs.3(d)and3(e).5. Power coefficient (Cp) and Cp characteristicsThepower coefcient of windturbinedepends onnumber of bladesof turbineandbladepitchangle. For acertainnumber of bladesandbladepitch, thepower coefcient varieswithFIG. 3.(a) Components of propeller, (b) b0

when FR and blade chord are parallel, (c) b90

when FR and blade chordare parallel, (d) b24

when FR and PR are parallel, and (e) b104

when FR and PR are parallel.013110-4 Ashraf, Nadeem Malik, and Iqbal J. Renewable Sustainable Energy 6, 013110 (2014) This article is copyrighted as indicated in the article. Reuse of AIP content is subject to the terms at: http://scitation.aip.org/termsconditions. Downloaded toIP:111.68.98.148 On: Wed, 15 Jan 2014 03:28:59the variation of TSR.22Power coefcient is basically the factor less than 1 that shows theextentofextractedpowerfromwindtoshaftofwindturbine. ThemaximumvalueofCpfactoris 0.59whichis Betzlimit.1Windturbines cannot operateabovethis limit. Cpis functionoftwoparameters:TSRandbladepitchangleCpk; b: (7)Cpcanbemodelledindifferentwaysusingsuitablemathematicalequationwhichdescribesthisparameter.21Cpcanberepresentedbymulti-curvegraphasshowninfollowingFig. 4. Infol-lowinggraph, TSRandCparetakenonx-axisandy-axis, respectively.22,23Bladepitchangleisshownonthecurves.Thisgraphistheultimatemappingofreal physical windturbine, whichismodelledusingLookupTableblockofSimulinkVRandthisisshowninFig.5.6. Shaft speed characteristicsThese are the characteristics of windturbine informof either mathematical equationorgraph, whichshowsrelationbetweenwindspeedandshaft speedat variablebladepitch. Thisis alsoacomplexbehavior tomapfor modellingpurpose. Shaft speedcharacteristics canbesimpliedwhenwindspeedistakenasconstant. Theshaft speedisplottedagainst bladepitchforPFCapplications. TheshaftspeedcharacteristicsareshowninFig.6.7. Gear box modellingUsually, theconventionalwindturbinesoperateatlowshaftspeed.1Gearboxisthedevice,which enhances the shaft speed of wind turbine and electrical generator is coupled at highspeedshaft.1Incaseofidealgearbox,thepowersonbothshaftsareequal,Pt Pg: (8)Poweroneithersideofgearboxisexpressedasproductoftorqueandshaftspeedonthecorre-spondingshaftstxt sgxg: (9)FIG. 4.Cp curves.013110-5 Ashraf, Nadeem Malik, and Iqbal J. Renewable Sustainable Energy 6, 013110 (2014) This article is copyrighted as indicated in the article. Reuse of AIP content is subject to the terms at: http://scitation.aip.org/termsconditions. Downloaded toIP:111.68.98.148 On: Wed, 15 Jan 2014 03:28:59Heresgisrequiredtobecomputedtofeedtothegeneratorshaft. Thengearboxistobemod-elledasgivenby(10),21sg stxtxgPtxg: (10)ThecompleteblockdiagramofwindturbineisshowninFig.7.The information and rated parameters of proposed wind turbine for this case study aregiveninTableI.B. Electrical generatorThewindturbineis connectedtoasynchronous generator, whichis 3-phasesynchronousgenerator blockfoundinSimPowerSystems toolbox. The generator is ratedtosupply2 MWFIG. 6.Shaft speed characteristics.FIG. 5. Cp characteristics (MATLAB).013110-6 Ashraf, Nadeem Malik, and Iqbal J. Renewable Sustainable Energy 6, 013110 (2014) This article is copyrighted as indicated in the article. Reuse of AIP content is subject to the terms at: http://scitation.aip.org/termsconditions. Downloaded toIP:111.68.98.148 On: Wed, 15 Jan 2014 03:28:59loadat 50 Hzsupplyfrequencyand11kVvoltagelevel. Thevoltagecontrol of generator ismodelledbyusingExcitationblockof Simulinktomaintainthevoltageat constant level. Theshaft speed(xg)ofgeneratormodel isregulatedwithpitchcontrol ofwindturbinetomaintain50 Hzsupplyfrequency. Thenthis synchronous generator is synchronizedtoutilitysupplytofeedtheloadinpeakloadtime.III. MODELLING OF UTILITY SUPPLY SYSTEM (USS)TheUSSistheelectrical networktowhichtheproposedwindturbineissynchronizedtofeed the load. The USS specications include 50 Hz supply frequency. The USS is startedfroma132 kVgridstation. A132 kVtransmissionlineof25 kmisfedto132 kV/11 kVsubsta-tion, whichtransforms 132 kVvoltage level to11 kVbymeans of apower transformer withrating 10 MVA. The 11 kVline is represented as distribution line of 5 kmlength, which iscalled Feeder. Ultimately, the feeder and wind turbine bothtake the load of consumer end.The consumer load is modelled as time-varying load. The systemrepresenting the USS isshowninFig. 8.FIG. 7. Wind turbine modelling.TABLE I.Rated parameters of wind turbine and generator.Parameter ValueRated power 2 MWRated shaft speed (n) of wind turbine 33 rpmRated wind speed (Vw) 16 m/sCut-in wind speed 8 m/sPower coefcient (Cp) 0.35Tip speed ratio (k) 56Blade length (R) 27 mRated blade pitch (b) 24 degMaximum blade pitch 104 degRated rotor speed of generator 1500 rpm013110-7 Ashraf, Nadeem Malik, and Iqbal J. Renewable Sustainable Energy 6, 013110 (2014) This article is copyrighted as indicated in the article. Reuse of AIP content is subject to the terms at: http://scitation.aip.org/termsconditions. Downloaded toIP:111.68.98.148 On: Wed, 15 Jan 2014 03:28:59IV. MODELLING OF TVLTheTVLis modelledbytwocomponents as; baseloadandpeakload. Thebaseloadis6 MWandpeakloadis8 MWwhen2 MWloadisaddedinpeaktime. ATimerisprogrammedtoswitchONandOFFthe2 MWloadcomponent inpeaktime. Athreephasecircuit breakerblockisusedfor switchingtheload. Thiscircuit breaker iscontrolledbyaprogrammedtimertomodeltheTVLinspeciedswitchingtimes. LoadCurveisshowninFig.9.TheTVLis, basically, electrical loadconnectedtobothUSSandWESandsuppliedbybothUSSandWESinpeaktimeandbyonlyUSSinoff-peaktime. Thethreephasecircuitbreaker hasbeendeployedonlytomodel theTVL. Inreal practice, thiselectrical loadissup-pliedtoconsumerendandhasultimatelyloadingeffect onutilitysupplysystem. TVLismod-elledinSimulinkasshowninFig.10.V. BPC SYSTEMThe WESis synchronizedtoUSStotake over theextendedloaddemandinpeaktime.TheWESandUSSareinterconnectedthroughacontrol system, whichis calledBPCsystemanditsblockisshowninFig. 11. Sharingof loadinpeaktimefor WESrequiresthesuitableandlogical modelingof BPCsysteminevitably. Thebasicpurposeandtaskof BPCsystemistosuppressthedrasticandundesirabletransientswhileloadingandunloadingtheWESagainstTVLinpeakandoff-peaktime, respectively. ThemodelledBPCsystemhastwoinputs: TotalLoad, Prefand2outputs:Pitch, m_c. Theconventionalcontroltechniquerequiresoneinputandonereferenceinput tocompareandthentochangetheoutput accordingtotheinput changeFIG. 8.Utility supply system.FIG. 9. Load curve.013110-8 Ashraf, Nadeem Malik, and Iqbal J. Renewable Sustainable Energy 6, 013110 (2014) This article is copyrighted as indicated in the article. Reuse of AIP content is subject to the terms at: http://scitation.aip.org/termsconditions. Downloaded toIP:111.68.98.148 On: Wed, 15 Jan 2014 03:28:59avoidingtheabrupt changes. TheBPCsystemchangesthepitchofWESslowlyandsmoothlyagainsttheabruptchangescausedbyTVL.TheschematicandblockdiagramofBPCsystemisshowninFig. 12. TheBPCsystemisfedbyaconstant ReferenceSignal, whichexhibitsthebaseloadofconsumerendinp.u. ThissystemalsomonitorstheCurrent Loadoncommonbusbar, sensestheloadchangeandgener-atestheLoadSignal inp.u. whichiscomparedwithReferenceSignal toproduceErrorSignal.TheLoadGradient CheckblockdiscriminatestheErrorSignal anddenesthepathofErrorSignal either to Loading Controller or Unloading Controller. The Loading Controller andUnloadingControllerarebasicallyPI-controllers. Thepitchpatterniscomplexandapproximatemapping of this pitch pattern is obtained by connecting two PI-controllers. The ControllerSwitchblockselectstherespectivecontrolleroutput decidedbySwitchLogicblocktogen-erateBladePitchSignal. First PI-controller isresponsibleforloadingofWES, wheretheBPCsystemhastodecreasethepitchparameteragainst TVLinpeaktime. ThesecondPI-controllerisusedforunloadingtheWES, whereBPCsystemhastoincreasethepitchparameteragainstTVLinoff-peaktime.TheBladePitchSignalisfedtoWES.TheloadsofWESandUSSareaddedtomaketotalloadtofeedit toBPCsystem. Thereferenceinput isset at 6 MW. Whentotal loadis6 MW,FIG. 10.Modelling of TVL.FIG. 11.BPC system block.013110-9 Ashraf, Nadeem Malik, and Iqbal J. Renewable Sustainable Energy 6, 013110 (2014) This article is copyrighted as indicated in the article. Reuse of AIP content is subject to the terms at: http://scitation.aip.org/termsconditions. Downloaded toIP:111.68.98.148 On: Wed, 15 Jan 2014 03:28:59theUSSsuppliestheloadandWESdoesnot shareload. Whentotal loadis8 MW, BothUSSandWESsupplythe load. Whenloadis increasedinpeaktime, the rst loadingcontrollerloadstheWESwhilewhenloadisdecreasedinoff-peaktime, thesecondunloadingcontrollerunloadstheWES. Theswitchingoftheseloadingandunloadingcontrollersisalsodecisivepa-rameter, whichis modelledinSwitchLogic. Theswitchingoperationis depictedas: WESisloadedbyloadingcontrollerduring6 MW8 MWloadchange, loadingcontrollerisswitchedtounloadingcontroller at instant approximatelyhalf peakof theloadandWESis unloadedbyunloadingcontrollerduring8 MW6 MWloadchange.VI. SIMULATIONThe one-line diagramof the simulation case studyis shown in Fig. 13. The previouslyexplainedmodellingof systems is combinedtomakeacompleteblockdiagramas showninFig. 14. The block diagramincludes the USS, WES, TVL, and BPCsystem. The WES issynchronizedtoUSS. InbetweenofWESandUSS, thereisBPCsystemwhichsuppressestheabrupt changescausedbyTVLtoalevel whichispermissibleforWES. TheUSSsuppliesthebaseloadoncommonbusbar B4all thetimewhileWESsuppliesthepeakloadonthecom-monbusbarB4onlyinthepeaktime. TheBPCsystemgeneratesthebladepitchsignal, whichisfedtoWESagainstloadgradientsignal.The one-line diagramof case study has been implemented in Simulink environment ofMATLAB, whichisshowninFig.14.VII. DISCUSSION ON SIMULATION RESULTSThesimulationmodel isrunfor 1h10min(70 min) timescaleaxis. Thedurationof thepeak load is 30 min. Peak of the load occurs at 20 min, where the WEShas to be loadedFIG. 12.Schematic diagram of BPC system.FIG. 13.One-line diagram of simulation.013110-10 Ashraf, Nadeem Malik, and Iqbal J. Renewable Sustainable Energy 6, 013110 (2014) This article is copyrighted as indicated in the article. Reuse of AIP content is subject to the terms at: http://scitation.aip.org/termsconditions. Downloaded toIP:111.68.98.148 On: Wed, 15 Jan 2014 03:28:59against 2 MWpeak. At time 50 min, peakloadis switchedOFF. The WES, now, has tobeunloaded. PeaksharingforWESisshowninFig. 15. Fromthegraph,itisclearthatWESdoesnot deliver any load in off-peak time, 020 min and 5070 min, rather it feeds the load of2 MWinpeaktimeduring2050 min.Duringpeaktimeaswell asinoff-peaktime, theUSSfeedsthebaseloadof 6 MW. Thebaseloadingof USSisshowninFig. 16. Fromthegraph, it isshownthat USSalwaysfeedsthebaseload. At20 minand50 min, small uctuationscanbeseeninthecurveduetoloadingandunloadingofWES.Thetotal sumof loads deliveredbybothUSSandWESis representedinFig. 17. Fromthegraph, it is shownthat base loadis 6 MWandpeakloadis 8 MWinoff-peakandpeaktimes, respectively.ThepeakloadsharingisbasedonPFCasinthistechnique; thegeneratorsshaft speedisalsotoberegulatedagainst TVL. FromthegraphshowninFig. 18, it isshownthat generatorshaft speedis maintainedat 1500 rpminpeakandoff-peaktimes. Small uctuations canbeseenatinstantsofloadingandunloadingofWES.FIG. 14.Complete block diagram.FIG. 15.Load delivered by WES.013110-11 Ashraf, Nadeem Malik, and Iqbal J. Renewable Sustainable Energy 6, 013110 (2014) This article is copyrighted as indicated in the article. Reuse of AIP content is subject to the terms at: http://scitation.aip.org/termsconditions. Downloaded toIP:111.68.98.148 On: Wed, 15 Jan 2014 03:28:59FIG. 16.Load delivered by USS.FIG. 17.Total load of WES and USS.FIG. 18.Generator shaft speed.013110-12 Ashraf, Nadeem Malik, and Iqbal J. Renewable Sustainable Energy 6, 013110 (2014) This article is copyrighted as indicated in the article. Reuse of AIP content is subject to the terms at: http://scitation.aip.org/termsconditions. Downloaded toIP:111.68.98.148 On: Wed, 15 Jan 2014 03:28:59For this simulation, the BPCsystemis designedbyusingtwoPI controllers. Followinggraph represented in Fig. 19 shows the output blade pitch signal of rst loading controlleragainst occurrenceof peakloadat 20 mintime. First controller isonlyresponsiblefor loadingofWES.DuringpeakloadafterloadingofWES, theBPCsystemswitchesthesecondcontrollertounloadtheWESduringtheoccurrenceof off-peakloadat 50 mintime. ThesecondcontrollerisresponsibleforunloadingofWESanditsoutputisshowninFig.20.Fig. 21showsthecombinedresponseof twocontrollers. Thisshowsthecompletepatternofbladepitch,whichisultimatelyfedtoWEStoloadandunloadWESagainstTVL.Fig. 22representstheerror signal, whichisobtainedafter comparingreferencesignal andinputtoBPCsystem.TheCpcharacteristicsof windturbinewhileat loadingtransitionandunloadingtransitionare showninFig. 23. The maximumreachedvalue of Cpfor proposedwindturbine is 0.35whichcanbeseenfromgraphs.TheTSRcharacteristicsofwindturbinewhileatloadingtransitionandunloadingtransitionareshowninFig. 24. Fromgraphs, it isclear that windturbineoperatesat TSRvalueof 5.8approximately.FIG. 19.Output of loading controller.FIG. 20.Output of unloading controller.013110-13 Ashraf, Nadeem Malik, and Iqbal J. Renewable Sustainable Energy 6, 013110 (2014) This article is copyrighted as indicated in the article. Reuse of AIP content is subject to the terms at: http://scitation.aip.org/termsconditions. Downloaded toIP:111.68.98.148 On: Wed, 15 Jan 2014 03:28:59FIG. 21.Blade pitch pattern from BPC system.FIG. 22.Error signal of BPC system.FIG. 23.Cp characteristics of wind turbine.013110-14 Ashraf, Nadeem Malik, and Iqbal J. Renewable Sustainable Energy 6, 013110 (2014) This article is copyrighted as indicated in the article. Reuse of AIP content is subject to the terms at: http://scitation.aip.org/termsconditions. Downloaded toIP:111.68.98.148 On: Wed, 15 Jan 2014 03:28:59Thetransient portions of bladepitchoutput fromBPCsystemandoutput power of WESareenlargedandshowninFig. 25, whileloadinginpeaktime. Fromtherst diagramofbladepitchsignal, it isshownthat BPCsystemchangesthevalueofbladepitchfrom104

to24

in0.36 min(21.6 s). Thediagramshowingoutput power of WESistheresponseof WESagainstBPCsysteminpeaktimeafterfeedingwithbladepitchcontrolsignal.Fromtheseconddiagramof output power of WES, it isshownthat BPCsystemhassup-pressedthetransientstogreaterextent. Theoutput powercurveofWEShasbeenanalyzedbycomputingtheparameters: percent overshoot (1.5%), risetime[15s (0.25 min)], andsettlingtime[24s (0.40 min)]. Theoutput power curveof WEShas percent overshoot of 43%whileusingPIDcontroller andthisparameter hasbeenimprovedbyusingfuzzyPIDcontroller andfuzzyfeed forwardcombinative controller.15But inthis paper, BPCsystemis composedofverysimple PI controllers employedfor loadingandunloadingof WES. UsingBPCsystem,thepercent overshoot of output power of WEShasbeenreducedto1.5%. ThecomparisonoftheresultisgiveninTableII.FIG. 24.TSR characteristics of wind turbine.FIG. 25.Blade pitch signal of BPC system and output power of WES.013110-15 Ashraf, Nadeem Malik, and Iqbal J. Renewable Sustainable Energy 6, 013110 (2014) This article is copyrighted as indicated in the article. Reuse of AIP content is subject to the terms at: http://scitation.aip.org/termsconditions. Downloaded toIP:111.68.98.148 On: Wed, 15 Jan 2014 03:28:59VIII. CONCLUSIONInthisresearcharticle, thepeakloadissharedbywindturbineusingtheconcept ofbladepitchcontrol.Inthepresentedsimulationcasestudy,thetechniqueofPFCndsitsmajorappli-cationwithstandalonewindturbinefeedingtoaspecicareaandforconventionalwindturbinehavingsmall gearboxratio. TheproposedPFCtechniqueofloadsharingischeaperasit doesnot usepowerelectronicbasedconvertersfordirect loaddriveorforgridconnectedwindtur-bines. However, PFCrequiresanefcient control against anumber ofconstraintslikevariablewindspeed, timevaryingwinddirection, andmanyotherclimaticconditions.NOMENCLATUREPmoutputmechanicalpowerofwindturbine(W)qaairdensity(kg/m3)A sweptareaofwindturbinespropeller(m2)Vwwindspeed(m/s)Cppowercoefcientk tipspeedratiob bladepitch(

)R bladelengthofwindturbine(m)VTbladetipspeed(m/s)n shaftspeedofwindturbine(rpm)PtpoweratwindturbineshaftPgpoweratgeneratorshaftsttorqueatwindturbineshaftsgtorqueatgeneratorshaftxtspeedofwindturbineshaft(rad/s)xgspeedofgeneratorshaft(rad/s)TSR tipspeedratio1O. Anaya-Lara, N. Jenkins, J. Ekanayake, P. Cartwright, andM. Hughes, WindEnergyGenerationModellingandControl (John Wiley & Sons, Ltd., West Sussex, United Kingdom, 2009).2W. Haining, C. Nayar, S. Jianhui, and D. Ming, IEEE Trans. Energy Convers. 26, 428 (2011).3W.Haining,C.Nayar,S.Jianhui,andD.Ming,in AustralasianUniversitiesPower EngineeringConference (AUPEC),2730 September, 2009, pp. 15.4L.WeiandL.Weiguo,in World Non-Grid-ConnectedWind Power and Energy Conference (WNWEC), 57 November,2010, pp. 16.5M. Van Dessel, M. Gay, and G. Deconinck, in IEEE International Symposium on Industrial Electronics (ISIE), 47 July,2010, pp. 14791484.6R.BharanikumarandA.N.Kumar,J.Sci.Ind.Res. 70,379(2011);onlineathttp://nopr.niscair.res.in/handle/123456789/11647.7A. Nagliero, R. A. Mastromauro, M. Liserre, andA. DellAquila, in35thAnnual Conferenceof IEEEonIndustrialElectronics (IECON 09), 35 November, 2009, pp. 46064613.8O. C. Ozerdem, inIEEEInternational ElectricMachines &Drives Conference(IEMDC07), 35May, 2007, pp.442446.9D. Chung Phan and K.-S. Ro, J. Renewable Sustainable Energy 4, 063109 (2012).10N. Joshi and N. Mohan, IEEE Trans. Energy Convers. 24, 504 (2009).11R.Ahshan,M.T.Iqbal,andG.K.I.Mann,inIEEE ElectricalPowerConference(EPC 07),Canada, 2526October,2007, pp. 490495.12R. Saiju, A.Tamzarti, and S. Heier, in 33rd Annual Conference of IEEE on Industrial Electronics Society (IECON 07),58 November, 2007, pp. 11271131.13A. E. Haniotis,K. S. Soutis, A. G. Kladas,andJ. A. Tegopoulos, inIEEEPowerSystemsConferenceandExposition,1013 October, 2004, pp. 759764.TABLE II.Result comparison.Parameter BPC system PID controller15Percent overshoot 1.5% 43%013110-16 Ashraf, Nadeem Malik, and Iqbal J. Renewable Sustainable Energy 6, 013110 (2014) This article is copyrighted as indicated in the article. Reuse of AIP content is subject to the terms at: http://scitation.aip.org/termsconditions. Downloaded toIP:111.68.98.148 On: Wed, 15 Jan 2014 03:28:5914T. Porselvi and R. Muthu, Eur. J. Sci. Res. 83, 397 (2012).15S. Jie, Z. Yaliang, F. Wenxiu, and Z. Xin, in 25th Chinese Control and Decision Conference (CCDC), 2527 May, 2013,pp. 390395.16L. Y. Wang, J. Meng, andT. Zhang, inInternational ConferenceonElectricInformationandControl Engineering(ICEICE), 1517 April, 2011, pp. 29582961.17S. Joshi, A. Patel, P. Patel, and V. Patel, Int. J. Comput. Commun. Inf. Syst. 2, 228 (2010).18See http://www.windynation.com/articles/wind/tip-speed-ratio-how-calculate-and-apply-tsr-blade-selection for TipSpeed Ratio: How to Calculate and Apply TSR to Blade Selection, 2010.19H. Stiesdal, The wind turbine components and operation, Bonus Info, 1999, available at http://users.wpi.edu/~cfurlong/me3320/DProject/BonusEnergy-1998.pdf.20T. Ackermann, Wind Power in Power Systems (Wiley Online Library, 2005).21S. Evren, M.Unel, M. F. Aksit, and I. Tuzla, Math. Comput. Appl. 18, 408 (2013).22S. Lain, B. Quintero, and Y. Lopez, J. Sci. Ind. Res. 69, 142 (2010).23B. Gilev, J. Slavchev, D. Penev, and A. Yonchev, in Proceedings of AIP Conference, 2011, p. 15.013110-17 Ashraf, Nadeem Malik, and Iqbal J. Renewable Sustainable Energy 6, 013110 (2014) This article is copyrighted as indicated in the article. Reuse of AIP content is subject to the terms at: http://scitation.aip.org/termsconditions. Downloaded toIP:111.68.98.148 On: Wed, 15 Jan 2014 03:28:59